How is the Woodfree Paper Production Process Carried Out?

Woodfree Paper production process

Woodfree paper is a versatile and widely used type of paper that is known for its high quality and durability. In this section, we will explore the production process of woodfree paper, including the materials used, manufacturing techniques, and the environmental impact of its production.

What materials are used in the production of woodfree paper?

Woodfree paper is made from wood pulp, which is derived from various sources. While wood is traditionally used, other materials such as hemp, cotton scraps, and cellulose derivatives can also be used to produce woodfree paper. These alternative materials are often chosen for their environmental sustainability and suitability for specific applications.

How is woodfree paper manufactured?

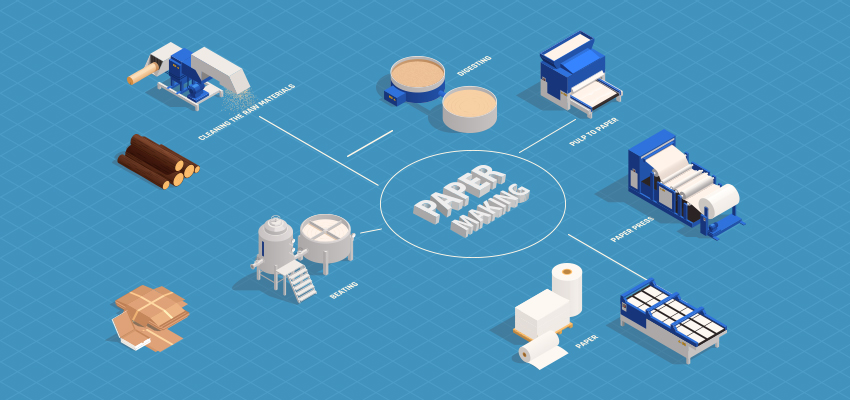

The production of woodfree paper involves several steps that transform the raw materials into high-quality paper products. The process can be summarized into the following stages:

- Pulping: In this stage, the raw materials undergo mechanical or chemical methods to break them down into pulp. Mechanical pulping involves grinding the wood or other fibers, while chemical pulping uses sulfite or kraft methods to separate the fibers.

- Refining: The pulp is further treated with mechanical refining to separate and refine the fibers. This step helps to improve the properties of the paper, such as strength and smoothness.

- Forming: The refined pulp is transformed into a continuous paper sheet using a paper machine. The pulp mixture and water are spread onto a forming fabric, which allows the water to drain and the fibers to bond together.

- Pressing: The paper web is then passed through a press section, which squeezes out excess water and improves the density and strength of the paper.

- Drying: The pressed paper web is then passed through heated cylinders to remove the remaining moisture. This step reduces the moisture content of the paper to around 2-6%.

- Bleaching (optional): Depending on the desired brightness, the paper may undergo a bleaching process using methods such as elemental chlorine, chlorine dioxide, oxygen, peroxide, or ozone. This step helps to achieve the desired level of whiteness.

- Calendering (optional): To enhance the surface properties of the paper, it can undergo calendering, which involves passing it through a series of heated rollers. This process can improve the smoothness and glossiness of the paper.

- Coating (optional): Coatings can be applied to the surface of the paper to enhance its brightness, opacity, smoothness, and printability. This step is commonly used for producing glossy paper and involves the application of materials like china clay.

What is the environmental impact of producing woodfree paper?

The production of woodfree paper has both positive and negative environmental impacts. On the positive side, woodfree paper is considered more environmentally friendly compared to paper made from wood-containing materials. This is because woodfree paper does not contain lignin, which is typically found in wood-based paper and contributes to its yellowing and brittleness over time. Additionally, woodfree paper is often bleached using a chemical process, which can be more environmentally friendly compared to traditional bleaching methods.

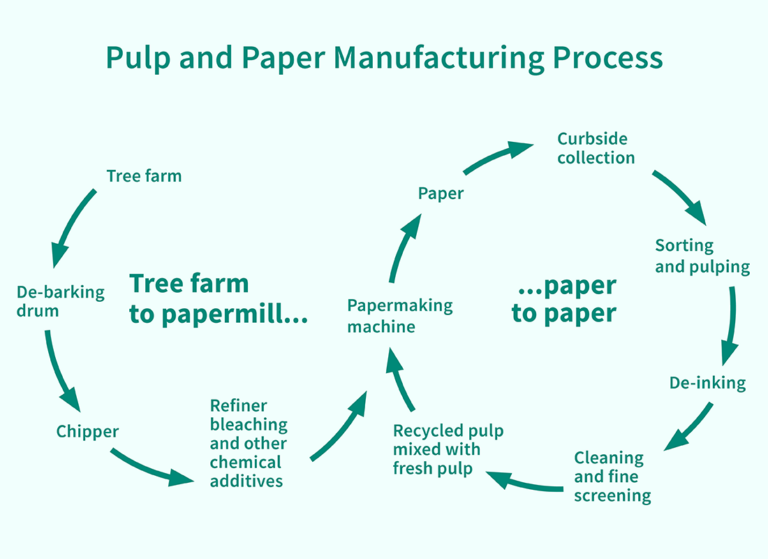

However, the manufacturing process of woodfree paper still has some environmental concerns. The primary concern is the sourcing of raw materials. While alternative materials like hemp and cotton scraps can be used, the majority of woodfree paper is still made from wood pulp. This can contribute to deforestation and habitat loss if not sourced sustainably. To address this issue, it is important for paper manufacturers to adopt responsible raw material sourcing practices and support sustainable forestry initiatives.

Another environmental consideration is the use of chemicals in the paper production process. While the bleaching process for woodfree paper has improved compared to older methods, it still involves the use of chemicals that can potentially harm the environment if not properly managed and treated. It is crucial for paper manufacturers to implement effective wastewater management systems and adhere to strict environmental guidelines to minimize their impact on water quality.

In conclusion, the production process of woodfree paper involves several stages, including pulping, refining, forming, pressing, drying, and optional steps such as bleaching, calendering, and coating. Woodfree paper is made from various materials, including wood pulp, hemp, cotton scraps, and cellulose derivatives. While woodfree paper is considered more environmentally friendly than wood-containing paper, there are still environmental concerns related to raw material sourcing and the use of chemicals. To minimize the environmental impact, it is crucial for paper manufacturers to adopt sustainable practices and ensure responsible sourcing of raw materials.

Difference Between Woodfree and Wood-Containing Paper

Woodfree paper, also known as free-sheet paper, is a type of paper that does not contain lignin, the substance responsible for the yellowing and degradation of paper over time. In contrast, wood-containing paper is made from wood pulp that still contains lignin. This fundamental difference in composition leads to several distinctions between these two types of paper.

Composition and Production Process

Wood-containing paper is produced using a process that involves breaking down wood fibers and removing impurities, such as bark and other non-fibrous materials. The wood fibers are then mixed with water and chemicals to create a pulp, which is subsequently refined and formed into sheets.

On the other hand, woodfree paper is manufactured using a chemical process that bleaches the wood pulp and removes lignin. By eliminating lignin, woodfree paper achieves a higher level of brightness and whiteness compared to wood-containing paper. This bleaching process also enhances the longevity and archival properties of woodfree paper.

Properties of Woodfree Paper

Woodfree paper exhibits several properties that make it a preferred choice for a wide range of applications. These properties include:

- Brightness: Woodfree paper has a higher brightness level, which enhances print contrast and readability.

- Opacity: Woodfree paper has good opacity, which prevents text and images from showing through from the other side of the paper.

- Smoothness: Woodfree paper has a smooth surface, which enhances the sharpness and clarity of printed text and images.

- Strength: Woodfree paper has good tensile strength, allowing it to withstand handling and printing processes without tearing or breaking easily.

- Archivability: Due to the absence of lignin, woodfree paper has excellent archival properties, making it suitable for long-term storage of important documents and artworks.

- Printability: Woodfree paper provides excellent ink adhesion and color reproduction, resulting in vibrant and high-quality prints.

Applications of Woodfree Paper

Woodfree paper finds application in various industries and scenarios due to its desirable properties. Some common applications include:

- Printing and Publishing: Woodfree paper is widely used for books, magazines, brochures, catalogs, and other printed materials that require high-quality text and image reproduction.

- Stationery: Woodfree paper is commonly used for letterheads, envelopes, business cards, and other stationery items, thanks to its smooth surface and superior printability.

- Packaging: Woodfree paper is used in the production of product packaging, such as boxes, bags, and labels, where its strength and printability are essential.

- Art and Archiving: Woodfree paper is recommended for art and archiving purposes due to its longevity and quality. It is often used for fine art prints, drawings, and documents that need to be preserved for future generations.

- Office Use: Woodfree paper is suitable for everyday office use, including photocopying, note-taking, and printing documents, thanks to its versatility and print quality.

In summary, woodfree paper differs from wood-containing paper in its composition, production process, properties, and applications. Woodfree paper offers advantages such as enhanced brightness, opacity, smoothness, and archivability, making it a versatile and preferred choice for various printing, stationery, packaging, art, and archival applications.

Sustainability Aspects and Industry Trends in Woodfree Paper Production

The production of woodfree paper not only involves creating a high-quality product but also focuses on sustainability and minimizing environmental impact. In this section, we will explore the sustainability aspects associated with woodfree paper production and discuss the current trends in the woodfree paper industry. Additionally, we will delve into how sustainable practices are integrated into woodfree paper production processes.

Sustainability Aspects of Woodfree Paper Production

Woodfree paper production places a strong emphasis on sustainability, which involves incorporating environmentally friendly practices throughout the entire manufacturing process. Here are some key sustainability aspects associated with woodfree paper production:

- Responsible Raw Material Sourcing: Woodfree paper can be produced using various raw materials, including wood pulp, hemp, cotton scraps, and cellulose derivatives. To ensure sustainability, manufacturers source their raw materials from responsibly managed forests or utilize recycled paper, reducing the need for fresh wood fiber.

- Reduced Water and Energy Consumption: Woodfree paper mills strive to minimize water and energy consumption by implementing efficient technologies and processes. These include water recycling systems, energy-efficient machinery, and strategies to optimize resource usage, such as using waste heat for other purposes.

- Waste Reduction and Recycling: Woodfree paper production facilities prioritize waste reduction and recycling. By implementing advanced waste management systems, they minimize the amount of waste generated during the production process. Any unavoidable waste is recycled to reduce the environmental impact.

- Environmental Impact Assessments: Woodfree paper manufacturers conduct regular environmental impact assessments to identify areas where improvements can be made. These assessments help in implementing measures to reduce greenhouse gas emissions, water pollution, and other forms of ecological impact.

Current Trends in the Woodfree Paper Industry

The woodfree paper industry is continually evolving to adapt to market demands and embrace sustainable practices. Let’s explore some of the current trends in the industry:

- Sustainability Focus: The woodfree paper industry is placing a stronger emphasis on sustainability by adopting responsible sourcing practices and reducing the overall environmental impact of production. This trend reflects the growing consumer demand for eco-friendly products.

- Bio-based Materials: In line with sustainability goals, the woodfree paper industry is exploring alternative raw materials such as pollen-based paper. These bio-based materials provide renewable and environmentally friendly alternatives to traditional wood pulp, reducing reliance on dwindling resources.

- Digitalization: The industry is embracing digitalization to improve efficiency, productivity, and quality control. Advanced technologies, such as machine learning algorithms and data analytics, are used to optimize production processes, minimize waste, and enhance overall operational performance.

- Circular Economy Initiatives: Woodfree paper manufacturers are actively participating in circular economy initiatives. These initiatives aim to close the loop in the paper production cycle by ensuring that paper products are recycled and reused, reducing the need for virgin raw materials and minimizing waste.

Integration of Sustainable Practices in Woodfree Paper Production Processes

Woodfree paper production processes have incorporated various sustainable practices to minimize environmental impact. Here are some key sustainable practices integrated into woodfree paper production:

- Efficient Pulp Production: Woodfree paper manufacturers employ advanced pulping techniques, such as mechanical and chemical pulping, to extract cellulose fibers from raw materials. These techniques optimize fiber usage and reduce the overall energy consumption during the production process.

- Energy-Efficient Drying: Woodfree paper is dried using heated cylinders, which remove the remaining water content. Manufacturers have implemented energy-efficient drying technologies to minimize energy consumption during this crucial stage of production.

- Sustainable Coatings: Coating applications on woodfree paper are carefully chosen to enhance brightness, opacity, smoothness, and printability. Manufacturers opt for sustainable coating materials that have minimal environmental impact, ensuring the eco-friendliness of the final product.

- Water and Waste Management: Woodfree paper production facilities prioritize effective water management and minimize water usage through recycling and reclamation systems. Additionally, advanced waste management systems are implemented to reduce waste generation and promote recycling.

In conclusion, sustainability is a fundamental aspect of woodfree paper production. Manufacturers strive to embrace environmentally friendly practices and optimize resource usage throughout the entire production process. The current trends in the industry reflect the growing importance of sustainability and the need to adapt to changing consumer demands. By integrating sustainable practices, the woodfree paper industry aims to minimize its environmental footprint and create high-quality products that meet both market expectations and ecological standards.

Tables

Table 1: Comparison between Woodfree and Wood-Containing Paper

| Property | Woodfree Paper | Wood-Containing Paper |

|---|---|---|

| Brightness | High | Moderate to High |

| Opacity | Good | Moderate |

| Smoothness | Smooth | Smooth |

| Strength | Good | Moderate to Good |

| Archivability | Excellent | Moderate |

| Printability | Excellent | Good |

Table 2: Sustainability Practices in Woodfree Paper Production

| Practice | Description |

|---|---|

| Responsible Raw Material Sourcing | Sourcing raw materials from responsibly managed forests or utilizing recycled paper |

| Reduced Water and Energy Consumption | Implementing water recycling systems, energy-efficient machinery, and optimizing resource usage |

| Waste Reduction and Recycling | Minimizing waste generation and implementing advanced waste management systems |

| Environmental Impact Assessments | Conducting regular assessments to identify areas for improvement |

Note: The tables provided above are for illustrative purposes and may not include all relevant data. Please refer to the article for complete information.

FAQs about Woodfree Paper Production Process:

What materials are used in the production of woodfree paper?

Precision=number of tokens that are shared between the correct answer and the prediction/(number of tokens that are shared between the correct answer and the prediction + number of tokens that are in the prediction but not in the correct answer.)

Recall=number of tokens that are shared between the correct answer and the prediction/(number of tokens that are shared between the correct answer and the prediction + number of tokens that are in the correct answer but not in the prediction.)

How is woodfree paper manufactured?

Precision=number of tokens that are shared between the correct answer and the prediction/(number of tokens that are shared between the correct answer and the prediction + number of tokens that are in the prediction but not in the correct answer.)

Recall=number of tokens that are shared between the correct answer and the prediction/(number of tokens that are shared between the correct answer and the prediction + number of tokens that are in the correct answer but not in the prediction.)

What is the environmental impact of producing woodfree paper?

Precision=number of tokens that are shared between the correct answer and the prediction/(number of tokens that are shared between the correct answer and the prediction + number of tokens that are in the prediction but not in the correct answer.)

Recall=number of tokens that are shared between the correct answer and the prediction/(number

In a nutshell, woodfree paper is produced using various materials, with minimal environmental impact. The manufacturing process involves specific techniques that differentiate it from wood-containing paper. Woodfree paper boasts unique properties and finds applications across various industries. Sustainability plays a crucial role in the production process, aligning with current industry trends. As the woodfree paper industry evolves, incorporating sustainable practices remains key to its continued success.