What is PLA Coated Paper – An In-Depth Look

What is PLA Coated Paper?

In today's world, where sustainability and eco-friendliness are becoming increasingly important, innovative solutions are being created to replace traditional materials with more environmentally-friendly alternatives. One such solution is PLA coated paper. In this article, we will explore what PLA coated paper is, how it is made, and the benefits it offers.

What is PLA Coated Paper?

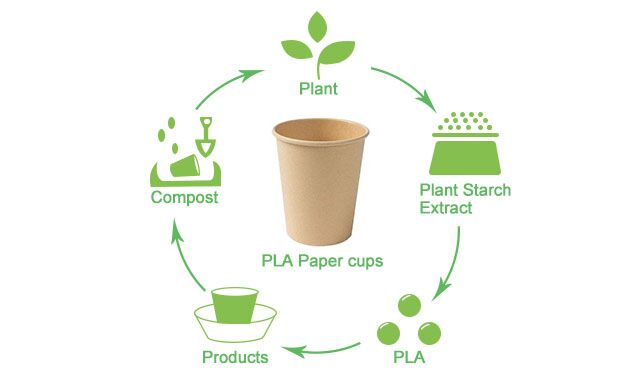

PLA coated paper, also known as polylactic acid coated paper, is a type of food-grade paper that is coated with a PLA film layer. This coating provides the paper with water resistance, making it a viable alternative to plastic food packaging. PLA coating is made from cornstarch and sugarcane, which are renewable resources. It is 100% biodegradable and compostable within 6-12 months under specific composting conditions.

The PLA coating used on the paper complies with Bio-standards and FDA regulations, ensuring that it is safe for food contact. This makes PLA coated paper an ideal choice for various food packaging applications.

How is PLA Coated Paper Made?

The process of making PLA coated paper involves coating a base paper with a thin layer of PLA. The base paper can be different types, such as kraft paper, white paper, or bamboo paper, depending on the specific requirements of the application.

To create the coating, the PLA film is melted and then applied to the base paper using a laminating process. The paper is then cooled, resulting in a thin layer of PLA on the surface. This coating provides the paper with water resistance, ensuring that it remains durable and functional in various food packaging applications.

Benefits of PLA Coated Paper

PLA coated paper offers several advantages over traditional coated papers, making it a popular choice for eco-conscious businesses and consumers. Here are some of its key benefits:

- Eco-Friendly: PLA coated paper is made from renewable resources, such as cornstarch and sugarcane. Unlike traditional plastic coatings, PLA is 100% biodegradable and compostable, reducing reliance on non-renewable resources and contributing to a more sustainable future.

- Food-Grade and Safe: PLA coated paper is safe for food contact and complies with Bio-standards and FDA regulations. This ensures that it does not release any harmful chemicals into the food it comes into contact with, making it a reliable choice for food packaging.

- Water Resistance: The PLA coating provides the paper with water resistance, ensuring that it remains durable and functional even when exposed to liquids. This makes PLA coated paper suitable for applications like paper cups, bowls, food boxes, and bags for take-out food, where water resistance is crucial.

- Lower Carbon Footprint: Compared to traditional PE (polyethylene) coatings, PLA has a lower carbon footprint. It requires less energy to produce and emits fewer greenhouse gases during the manufacturing process. Additionally, PLA coated paper can be biodegraded and recycled in industrial conditions, further reducing waste.

- Versatility: PLA coated paper can be used in a wide range of applications. It can be easily adapted to different shapes and sizes, making it suitable for various food packaging needs. Whether it's cups, bowls, or food containers, PLA coated paper offers versatility and functionality.

While PLA coated paper offers numerous benefits, there are still some challenges and opportunities in the market. Awareness and demand for PLA coated paper need to be increased to encourage its adoption. However, the superior water resistance and sturdiness of PLA coated paper compared to PE-coated products present opportunities for its growth and popularity.

In conclusion, PLA coated paper is an eco-friendly alternative to traditional coated papers, offering water resistance and food-grade safety. Its biodegradability, lower carbon footprint, and versatility make it a compelling choice for businesses and consumers alike. By choosing PLA coated paper, we can contribute to a more sustainable future, reducing our reliance on non-renewable resources and minimizing our environmental impact.

Properties and Uses of PLA Coated Paper

PLA coated paper, also known as biodegradable paper, has gained popularity in recent years as a sustainable alternative to traditional coated papers. This environmentally friendly paper is commonly used in food packaging due to its unique properties and benefits.

Characteristics of PLA Coated Paper

PLA coated paper is made by applying a thin layer of PLA (polylactic acid) film onto the surface of the paper. PLA is a biodegradable and compostable polymer derived from renewable resources such as corn starch or sugarcane. The coating provides water resistance and durability to the paper, making it suitable for food packaging applications.

Here are some key characteristics of PLA coated paper:

- Biodegradability: PLA coated paper is 100% biodegradable within 6-12 months under specific composting conditions. It breaks down into natural materials, such as carbon dioxide and water, without leaving harmful residues.

- Compliance with regulations: PLA coated paper complies with bio-standards and FDA regulations, making it safe for food contact. It does not contaminate the food with any toxic substances.

- Versatility: PLA coating can be applied to various types of paper, including kraft paper, white paper, and bamboo paper. This allows for flexibility in choosing the paper material based on specific requirements such as strength, aesthetics, and sustainability.

- Water resistance: The PLA film layer provides excellent water resistance, ensuring that the paper remains intact and the contents of the packaging are protected from moisture. This makes it suitable for applications such as hot beverage cups and take-out food containers.

- Environmental footprint: PLA coated paper has a lower carbon footprint compared to traditional coatings like polyethylene (PE). PLA is made from renewable resources, reduces greenhouse gas emissions during production, and can be composted instead of ending up in landfills.

Applications of PLA Coated Paper

PLA coated paper offers a wide range of applications in the food packaging industry. Its unique properties make it suitable for various products, ensuring stability, freshness, and eco-friendliness. Some common applications include:

- Paper cups: PLA coated paper is widely used in the production of disposable paper cups for both hot and cold beverages. The water-resistant coating prevents leaks and ensures the cup remains sturdy.

- Food boxes and containers: Take-out food boxes and containers made from PLA coated paper are a sustainable alternative to plastic packaging. These containers provide excellent insulation and can withstand a wide range of temperatures.

- Bags and wrappers: PLA coated paper can be used to make bags and wrappers for a variety of food products, providing both protection and an eco-friendly packaging solution.

- Labels and tags: The durability and water resistance of PLA coated paper make it suitable for labels and tags that need to withstand various handling and storage conditions.

Advantages of Using PLA Coated Paper over Traditional Coatings

Using PLA coated paper offers several advantages over traditional coatings like polyethylene (PE). Here are some notable benefits:

- Environmental friendliness: PLA coated paper is made from renewable resources and is fully biodegradable. It does not contribute to plastic pollution and reduces the reliance on fossil fuels.

- Safety for food contact: PLA coated paper complies with bio-standards and FDA regulations, ensuring its safety for direct contact with food. Consumers can be confident that the packaging material is free from harmful substances.

- Reduced carbon footprint: The production of PLA coated paper generates fewer greenhouse gas emissions compared to traditional coatings. This contributes to a more sustainable and eco-friendly packaging solution.

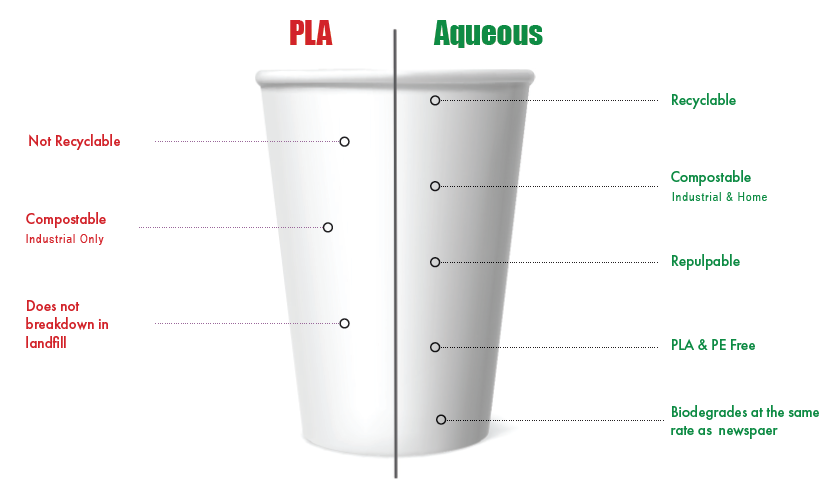

- Improved recyclability: While PLA coated paper cannot be recycled in traditional recycling facilities, it can be composted in industrial composting facilities. This allows the paper to break down into natural materials and become a valuable resource for soil fertility.

- Consumer perception: PLA coated paper is perceived as a sustainable alternative to plastic packaging, which can enhance a company's brand image. Consumers are becoming increasingly conscious of their environmental impact and are more likely to choose products packaged in eco-friendly materials.

In summary, PLA coated paper offers a sustainable alternative to traditional coated papers for food packaging applications. Its biodegradability, water resistance, and compliance with food safety regulations make it a preferred choice for environmentally conscious businesses and consumers. By using PLA coated paper, companies can reduce their carbon footprint and contribute to a greener future.

Comparing PLA Coated Paper to Other Coated Papers

When it comes to coated papers, PLA coated paper stands out as a sustainable and eco-friendly option. In this section, we will compare PLA coated paper to other commonly used coated papers, such as PE coated paper, and explore the environmental impact of these coatings. We will also discuss the future trends in eco-friendly paper coatings.

Differences between PLA and PE coatings

PLA (polylactic acid) and PE (polyethylene) are two commonly used coatings for paper. While both coatings provide water resistance and improved durability, there are significant differences between them.

- Raw Materials: PLA coating is made from cornstarch and sugarcane, which are renewable resources. On the other hand, PE coating is made from petroleum-based materials.

- Biodegradability: PLA coated paper is 100% biodegradable within 6-12 months under specific composting conditions. It can break down into water, carbon dioxide, and organic matter. PE coating, on the other hand, is not readily biodegradable and can persist in the environment for hundreds of years.

- Recyclability: PLA coated paper is not recyclable due to the challenges in separating the PLA film from the paper. However, it can be composted in commercial composting facilities. PE coated paper can be recycled, but due to the specialized facilities required, many PE coated products end up in landfills.

- Environmental Impact: PLA coating has a lower carbon footprint compared to PE coating. PLA is made from renewable resources and requires less energy to manufacture, resulting in fewer greenhouse gas emissions. PE, being derived from petroleum, has a higher carbon footprint and contributes to the depletion of fossil fuels.

Environmental Impact of PLA vs PE coatings

When it comes to sustainability in paper products, the choice of coating plays a crucial role. PLA coated paper offers several environmental advantages compared to PE coated paper.

- Reduced Waste: PLA coated paper is biodegradable and breaks down into environmentally friendly byproducts. This reduces the amount of waste that ends up in landfills, contributing to a cleaner environment.

- Renewable Resources: PLA coating is made from renewable resources like cornstarch and sugarcane, while PE coating is derived from petroleum, a non-renewable resource. By using PLA coated paper, we can reduce our dependence on fossil fuels.

- Water Pollution: PLA coated paper poses a lower risk of water pollution compared to PE coated paper. PLA is derived from plant-based sources and does not release harmful substances during degradation, unlike petroleum-based coatings.

- Emissions: The production of PLA coating results in fewer greenhouse gas emissions compared to PE coating. This makes PLA coated paper a more eco-friendly choice, contributing to the reduction of carbon footprints.

Future Trends in Eco-friendly Paper Coatings

The demand for eco-friendly alternatives is on the rise, including in the paper industry. As consumers become more conscious of environmental issues, the market for sustainable paper coatings is expected to grow. Here are some future trends in eco-friendly paper coatings:

- Innovation in Biodegradable Coatings: Researchers are constantly exploring new materials and technologies to develop biodegradable coatings for paper. This includes coatings made from plant-based polymers, such as PLA, as well as coatings made from other renewable resources.

- Advancements in Water Resistance: One challenge in using eco-friendly coatings is achieving the same level of water resistance as traditional coatings. Future developments may focus on improving the water resistance properties of biodegradable coatings, making them more suitable for various applications.

- Increased Awareness and Adoption: As awareness about the environmental impact of traditional coatings grows, more businesses and consumers are likely to switch to eco-friendly alternatives. This increased demand will drive further innovation and advancements in eco-friendly paper coatings.

- Regulatory Support: Governments and regulatory bodies around the world are taking steps to encourage the use of eco-friendly products. This includes incentivizing the adoption of sustainable coatings and imposing regulations on the use of harmful coatings.

In conclusion, PLA coated paper offers a more sustainable and eco-friendly option compared to traditional coatings like PE. With its biodegradability, use of renewable resources, and lower environmental impact, PLA coated paper is paving the way for a greener future in the paper industry. As the demand for eco-friendly alternatives continues to rise, we can expect to see further developments and advancements in the field of eco-friendly paper coatings.

Properties and Uses of PLA Coated Paper

PLA coated paper, also known as biodegradable paper, has gained popularity in recent years as a sustainable alternative to traditional coated papers. This environmentally friendly paper is commonly used in food packaging due to its unique properties and benefits.

Characteristics of PLA Coated Paper

PLA coated paper is made by applying a thin layer of PLA (polylactic acid) film onto the surface of the paper. PLA is a biodegradable and compostable polymer derived from renewable resources such as corn starch or sugarcane. The coating provides water resistance and durability to the paper, making it suitable for food packaging applications.

Here are some key characteristics of PLA coated paper:

- Biodegradability: PLA coated paper is 100% biodegradable within 6-12 months under specific composting conditions. It breaks down into natural materials, such as carbon dioxide and water, without leaving harmful residues.

- Compliance with regulations: PLA coated paper complies with bio-standards and FDA regulations, making it safe for food contact. It does not contaminate the food with any toxic substances.

- Versatility: PLA coating can be applied to various types of paper, including kraft paper, white paper, and bamboo paper. This allows for flexibility in choosing the paper material based on specific requirements such as strength, aesthetics, and sustainability.

- Water resistance: The PLA film layer provides excellent water resistance, ensuring that the paper remains intact and the contents of the packaging are protected from moisture. This makes it suitable for applications such as hot beverage cups and take-out food containers.

- Environmental footprint: PLA coated paper has a lower carbon footprint compared to traditional coatings like polyethylene (PE). PLA is made from renewable resources, reduces greenhouse gas emissions during production, and can be composted instead of ending up in landfills.

Applications of PLA Coated Paper

PLA coated paper offers a wide range of applications in the food packaging industry. Its unique properties make it suitable for various products, ensuring stability, freshness, and eco-friendliness. Some common applications include:

- Paper cups: PLA coated paper is widely used in the production of disposable paper cups for both hot and cold beverages. The water-resistant coating prevents leaks and ensures the cup remains sturdy.

- Food boxes and containers: Take-out food boxes and containers made from PLA coated paper are a sustainable alternative to plastic packaging. These containers provide excellent insulation and can withstand a wide range of temperatures.

- Bags and wrappers: PLA coated paper can be used to make bags and wrappers for a variety of food products, providing both protection and an eco-friendly packaging solution.

- Labels and tags: The durability and water resistance of PLA coated paper make it suitable for labels and tags that need to withstand various handling and storage conditions.

Advantages of Using PLA Coated Paper over Traditional Coatings

Using PLA coated paper offers several advantages over traditional coatings like polyethylene (PE). Here are some notable benefits:

- Environmental friendliness: PLA coated paper is made from renewable resources and is fully biodegradable. It does not contribute to plastic pollution and reduces the reliance on fossil fuels.

- Safety for food contact: PLA coated paper complies with bio-standards and FDA regulations, ensuring its safety for direct contact with food. Consumers can be confident that the packaging material is free from harmful substances.

- Reduced carbon footprint: The production of PLA coated paper generates fewer greenhouse gas emissions compared to traditional coatings. This contributes to a more sustainable and eco-friendly packaging solution.

- Improved recyclability: While PLA coated paper cannot be recycled in traditional recycling facilities, it can be composted in industrial composting facilities. This allows the paper to break down into natural materials and become a valuable resource for soil fertility.

- Consumer perception: PLA coated paper is perceived as a sustainable alternative to plastic packaging, which can enhance a company's brand image. Consumers are becoming increasingly conscious of their environmental impact and are more likely to choose products packaged in eco-friendly materials.

In summary, PLA coated paper offers a sustainable alternative to traditional coated papers for food packaging applications. Its biodegradability, water resistance, and compliance with food safety regulations make it a preferred choice for environmentally conscious businesses and consumers. By using PLA coated paper, companies can reduce their carbon footprint and contribute to a greener future.

FAQs about PLA Coated Paper

What is PLA Coated Paper?

To explain what PLA coated paper is, it is a type of food-grade paper coated with a PLA film layer made from cornstarch and sugarcane, providing water resistance and biodegradability.

How is PLA Coated Paper Made?

To discuss how PLA coated paper is made, it involves coating a base paper with a thin layer of melted PLA film using a laminating process, resulting in water resistance for various food packaging applications.

What are the Benefits of PLA Coated Paper?

To highlight the benefits of PLA coated paper, it is eco-friendly, safe for food contact, water-resistant, has a lower carbon footprint than traditional coatings, and offers versatility for food packaging needs.

What are the Properties and Uses of PLA Coated Paper?

To elaborate on the properties and uses of PLA coated paper, it is biodegradable, complies with regulations, provides water resistance, and can be used for applications like paper cups, food boxes, bags, labels, and tags.

In conclusion, PLA coated paper is a sustainable choice for food packaging. Made from biodegradable material, it offers advantages over traditional coatings. Eco-conscious consumers can opt for PLA over PE coatings to reduce environmental impact. As the demand for eco-friendly options grows, PLA coated paper presents a promising future trend in paper products.