Offset Paper Product Lifecycle: How is it Analyzed?

Offset Paper Product Lifecycle Overview

What is offset paper?

Offset paper is a type of paper commonly used in the printing industry for offset lithography, a popular printing method. It is especially suitable for high-volume printing projects such as books, magazines, posters, and envelopes. Offset paper is known for its high-quality printing results and versatility.

How is offset paper manufactured?

The manufacturing process of offset paper involves several steps. It begins with the preparation of materials, which includes removing bark, knot, and sheath from wood fibers and cutting them into the required sizes. Chipped wood logs are then used in the cooking process. Cooked wood pulp is processed through screening and washing to produce high-quality offset paper.

What are the common uses of offset paper?

Offset paper is widely used in the printing industry for various applications. It is commonly used in book printing, magazine printing, brochure printing, and stationery production. The properties of offset paper, such as its ability to absorb ink, make it suitable for printing with ballpoint pens and stamps.

What makes offset paper different from other types of paper?

Offset paper has distinct characteristics that set it apart from other types of paper. It typically has an ISO brightness of over 80% and a grammage ranging from 40 to 300 grams per square meter (gsm). Offset paper comes in coated and uncoated varieties, with coated paper being more durable and brighter, but challenging to print on. Uncoated offset paper, on the other hand, is ideal for absorbing inks.

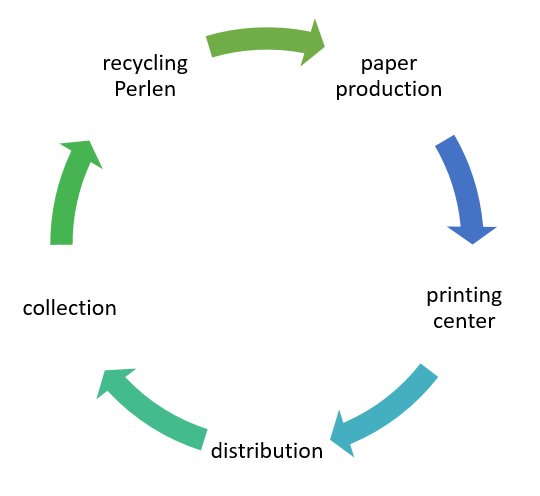

How is the lifecycle of offset paper products typically analyzed?

The lifecycle of offset paper products refers to the assessment of the environmental impact of offset paper from its production to its disposal. This analysis takes into account various stages, including raw material extraction, manufacturing, transportation, use, and end-of-life. By analyzing the lifecycle of offset paper products, we can identify areas where improvements can be made to reduce its environmental footprint.

What are the environmental considerations in the lifecycle of offset paper products?

Several environmental considerations come into play when analyzing the lifecycle of offset paper products. These include the sustainability of raw material sourcing, the energy and water consumption during manufacturing, the carbon emissions associated with transportation, and the waste management and recycling practices at the end of the product’s life. By addressing these considerations, the offset paper industry can work towards more sustainable practices.

In the next section, we will delve deeper into the topic of sustainability in offset paper manufacturing and explore the environmental impact of paper manufacturing processes.

Sustainability in Offset Paper Manufacturing

In today’s world, where sustainability is a top priority, it is crucial to understand the environmental impact of various industries, including paper manufacturing. Offset paper, commonly used in offset lithography for printing purposes, is no exception. This section will explore how the offset paper manufacturing process impacts the environment and discuss sustainable practices that can be implemented to mitigate these impacts.

Environmental Impact of Offset Paper Manufacturing

The offset paper manufacturing process involves several stages, from materials preparation to the actual production of paper. Each stage has its own environmental implications. Let’s take a closer look at some of these stages:

1. Materials Preparation: Before the papermaking process begins, the raw materials, mostly wood logs, need to be prepared. This preparation involves removing bark, knots, sheaths, and cutting the fibers to the required sizes. Chipped wood logs, about 3-8mm thick, 10-15mm wide, and 25mm long, are often used to save chemicals in the cooking process, ensuring the quality of the pulp. Clean wood logs with around 40% moisture can directly enter the pulp production process. Cleaning the wood logs with pressure water reduces the pulp washing load and sand. Using a peeling machine and log splitter can also reduce the silicon content before chipping, leading to better quality pulp.

2. Pulp Cooking: The pulp cooking process is a crucial step in offset paper manufacturing, as it determines the quality of the pulp. Softwood lignin content is of particular importance, as it affects the strength of the final product. The cooking temperature also plays a significant role in the process. Additionally, the ash content in wood, typically ranging from 0.3% to 0.5%, needs to be considered during pulp cooking. Vertical pulp digesters are commonly used for this process due to their high capacity and productivity.

3. Pulp Processing: After cooking, the pulp goes through various processing stages, including screening and washing. Pulp screening involves using a roughing screener to remove impurities and adjust the pulp consistency. Factors such as bore diameter, pulp concentration, and water pressure need to be considered during this stage. Pulp washing, on the other hand, aims to remove chemicals, residuals, and other impurities from the pulp. Different types of pulp washing equipment, such as vacuum drum washers and pressure washers, are commonly used for this purpose.

4. Paper Manufacturing: Once the pulp is processed, it is ready for paper production. The manufacturing process involves forming a paper web, pressing it to remove excess water, and then drying it. Finally, the paper is rolled onto large spools or cut into sheets, depending on its intended use.

Sustainable Practices in Offset Paper Manufacturing

To reduce the environmental impact of offset paper manufacturing, several sustainable practices can be implemented throughout the process. Here are some key practices to consider:

1. Responsible Wood Sourcing: Opt for sustainably managed forests and responsible wood sourcing. This ensures that the raw materials used in paper production come from well-managed and renewable sources. Forest certification programs such as the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) provide assurance that the wood used in paper production comes from responsibly managed forests.

2. Energy Efficiency: Improve energy efficiency in the manufacturing process by implementing energy-saving technologies and equipment. This includes using energy-efficient machinery, optimizing production processes, and investing in renewable energy sources like solar and wind power.

3. Water Conservation: Implement water-saving measures and advanced wastewater treatment systems to minimize water usage and ensure that effluents are properly treated before being discharged back into the environment. This includes recycling and reusing water within the manufacturing proceso and implementing closed-loop water systems.

4. Waste Reduction and Recycling: Implement waste reduction strategies, such as minimizing trim waste and optimizing paper cutting processes. Additionally, establish proper recycling programs within the manufacturing facility to recycle paper waste and other recyclable materials.

5. Chemical Management: Opt for environmentally friendly chemicals and dyes in the manufacturing process to minimize the release of harmful substances into the environment. Implement proper chemical management practices, including safe handling, storage, and disposal of chemicals.

6. Lifecycle Assessment: Conduct a lifecycle assessment (LCA) to analyze the environmental impact of offset paper manufacturing and identify areas for improvement. This assessment considers the entire lifecycle of the product, from raw material extraction to disposal, and provides valuable insights into the environmental hotspots within the process.

Key Factors for Environmentally-Friendly Offset Paper Production

When aiming for environmentally-friendly offset paper production, several key factors need to be considered. These factors include:

1. Raw Material Selection: Choose raw materials that have a lower environmental impact, such as certified sustainably sourced wood pulp. Consider using alternative fibers like agricultural residues or recycled paper where feasible.

2. Chemical Usage and Disposal: Opt for environmentally friendly chemicals and dyes during the manufacturing process. Ensure proper handling, storage, and disposal of chemicals to prevent pollution.

3. Energy Efficiency: Invest in energy-efficient machinery and production processes to minimize energy consumption. Integrate renewable energy sources to reduce reliance on non-renewable energy.

4. Water Management: Implement water-saving measures and advanced wastewater treatment systems to minimize water usage and ensure proper treatment of effluents before discharge.

5. Emissions Reduction: Implement measures to reduce greenhouse gas emissions and other air pollutants, such as installing emission controls and energy recovery systems.

6. Waste Management and Recycling: Properly manage and segregate waste within the manufacturing facility. Implement recycling programs for paper waste and other recyclable materials.

Challenges in Achieving Sustainability in Offset Paper Manufacturing

While there are several sustainable practices that can be implemented in offset paper manufacturing, there are also challenges that need to be addressed. Some of these challenges include:

1. Cost: Implementing sustainable practices often requires upfront investments in new technologies and equipment. This can be a barrier for some manufacturers, especially smaller ones, who may struggle to allocate the necessary financial resources.

2. Market Demand and Perception: The market demand for sustainable offset paper products may not always align with the additional costs associated with sustainable manufacturing practices. Manufacturers need to educate customers about the importance of sustainability and the value of environmentally-friendly products.

3. Regulatory Compliance: Adhering to environmental regulations and certifications can be complex and time-consuming. Companies must stay updated with environmental regulations and invest in compliance measures.

4. Supply Chain Collaboration: Achieving sustainability goals in offset paper manufacturing requires collaboration throughout the supply chain. It is essential to work closely with suppliers and customers to ensure the sustainability and traceability of raw materials.

5. Technological Limitations: Some sustainable technologies and practices are still under development or not yet commercially viable. Manufacturers need to stay informed about the latest innovations and engage in research and development efforts to overcome technological limitations.

Reducing Carbon Footprint in Offset Paper Manufacturing

One of the key focus areas when it comes to sustainability in offset paper manufacturing is reducing the carbon footprint. Here are some strategies that offset paper manufacturers can adopt to achieve this:

1. Energy Efficiency: Implement energy-efficient technologies and practices throughout the manufacturing process. This includes using energy-efficient machinery, optimizing production processes, and investing in renewable energy sources like solar and wind power.

2. Carbon Offsetting: Offset the unavoidable carbon emissions through carbon offsetting programs. This involves investing in projects that reduce or remove greenhouse gas emissions, such as reforestation or renewable energy projects.

3. Supply Chain Collaboration: Work closely with suppliers and customers to identify opportunities for carbon footprint reduction. Collaborate on initiatives such as transportation optimization, waste reduction, and energy efficiency improvement.

4. Life Cycle Assessment: Conduct a comprehensive life cycle assessment (LCA) to identify carbon hotspots within the offset paper manufacturing process. This assessment will help identify areas for improvement and guide carbon footprint reduction efforts.

5. Renewable Energy Integration: Transition to renewable energy sources for power generation. This includes investing in on-site renewable energy systems and sourcing renewable energy from the grid.

6. Efficient Transportation: Optimize transportation logistics to reduce the carbon footprint associated with the transportation of raw materials and finished products. This can include using more fuel-efficient vehicles, optimizing routes, and exploring alternative transportation modes like rail or water transport.

Certifications and Regulations in Promoting Sustainability in Paper Production

Certifications and regulations play a crucial role in promoting sustainability in paper production, including offset paper manufacturing. Here are some key certifications and regulations to be aware of:

1. Forest Stewardship Council (FSC): The FSC certification ensures that the wood used in paper production comes from responsibly managed forests. It provides assurance that the forests are not being overexploited, and biodiversity and local communities are protected.

2. Programme for the Endorsement of Forest Certification (PEFC): Similar to FSC, PEFC is a certification system that promotes responsible forest management. It ensures that the wood used in paper production comes from legally harvested and sustainable sources.

3. Environmental Management Systems (EMS): ISO 14001 is an international standard for environmental management systems. Implementing an EMS helps offset paper manufacturers identify and control their environmental impact, improve environmental performance, and comply with regulatory requirements.

4. Emission Standards and Regulations: Governments around the world have implemented emission standards and regulations to limit the impact of industrial activities on the environment. Compliance with these regulations is essential for offset paper manufacturers to minimize their environmental impact.

5. Carbon Offset Standards: Carbon offset standards, such as the Verified Carbon Standard (VCS) or Gold Standard, provide guidelines for offsetting carbon emissions. These standards ensure that offset projects meet specific criteria and contribute to the reduction of greenhouse gas emissions.

By adhering to certifications and regulations, offset paper manufacturers can demonstrate their commitment to sustainability and provide assurance to customers about the environmental impact of their products.

In conclusion, sustainability in offset paper manufacturing is crucial for reducing the environmental impact of the industry. By implementing sustainable practices, considering key factors, reducing carbon footprints, and adhering to certifications and regulations, offset paper manufacturers can contribute to a more sustainable future.

Offset Paper Recycling and Disposal

Offset paper is widely used in the printing industry for various purposes such as books, magazines, posters, and envelopes. As a sustainable and environmentally friendly option, offset paper has gained popularity. However, like any paper product, there is a need to address its end-of-life phase through recycling and proper disposal methods. In this section, we will explore the options for recycling offset paper products, the benefits of offset paper recycling, common methods for disposing of offset paper, and the impact of proper disposal on the environment.

Recycling Offset Paper Products

When it comes to recycling offset paper products, there are several options available. One common method is to collect and sort used offset paper, which is then sent to specialized recycling facilities. At these facilities, the paper is processed and transformed into new paper products through a series of steps, including pulping, deinking, and refining. The recycled offset paper can then be used to produce new offset paper or other paper products.

Offset paper recycling is an important step towards achieving sustainability. By recycling used offset paper, valuable resources such as wood fibers, water, and energy can be conserved. Additionally, recycling offset paper helps to reduce the amount of waste sent to landfills, thereby minimizing the environmental impact of paper disposal.

Table 1: Comparison of Offset Paper Recycling vs. Landfill Disposal

| Recycling Offset Paper | Landfill Disposal |

|---|---|

| Conserves resources such as wood fibers, water, and energy | Wastes valuable resources |

| Reduces the amount of waste sent to landfills | Contributes to landfill waste |

| Helps to minimize the environmental impact of paper disposal | Contributes to methane emissions from landfills |

| Promotes sustainability and a circular economy | Results in linear consumption and waste |

Benefits of Offset Paper Recycling

Offset paper recycling plays a significant role in promoting sustainability. Recycling offset paper not only reduces the demand for virgin fibers but also saves energy and reduces greenhouse gas emissions. According to research, recycling one ton of paper can save around 17 trees, 7,000 gallons of water, and 4,100 kilowatt-hours of electricity.

Furthermore, offset paper recycling contributes to the circular economy by closing the loop in the paper production process. By recycling and reintegrating used offset paper into the production cycle, the need for raw materials is reduced, leading to a more sustainable and resource-efficient industry.

Table 2: Environmental Benefits of Offset Paper Recycling

| Environmental Benefit | Description |

|---|---|

| Conservation of Resources | Recycling offset paper helps conserve valuable resources such as wood fibers, water, and energy. |

| Energy and Emissions Reduction | Recycling one ton of paper can save significant amounts of energy and reduce greenhouse gas emissions compared to virgin paper production. |

| Waste Reduction | Offset paper recycling helps to reduce the amount of waste sent to landfills, minimizing the environmental impact of paper disposal. |

| Promotion of Circular Economy | By closing the loop and reintegrating used offset paper into the production cycle, offset paper recycling contributes to a more sustainable and resource-efficient industry. |

Challenges in Recycling Offset Paper

While offset paper recycling offers numerous environmental benefits, it is not without its challenges. One of the main challenges is the presence of contaminants in used offset paper, such as inks, coatings, and adhesive residues. These contaminants can affect the quality of the recycled paper and the efficiency of the recycling process.

To address this challenge, it is crucial to implement proper sorting and deinking techniques during the recycling process. Advanced technologies, such as flotation deinking and enzymatic treatments, have been developed to remove contaminants effectively and improve the quality of the recycled offset paper.

Common Methods for Disposing of Offset Paper

Aside from recycling, there are other methods for disposing of offset paper products. One common method is landfilling, where the paper is disposed of in designated landfill sites. However, landfilling is not an ideal solution due to the long decomposition time of paper and its potential to contribute to methane emissions, a potent greenhouse gas.

Another method is incineration, where the offset paper is burned to generate energy. Incineration can be a viable option for waste-to-energy generation, especially when combined with advanced technologies that minimize emissions. However, it is important to ensure that proper air pollution control measures are in place to mitigate the environmental impact of incineration.

Consumer Contributions to Offset Paper Recycling Efforts

Consumers play a vital role in offset paper recycling efforts. By actively participating in recycling programs and properly disposing of used offset paper products, consumers can contribute to the sustainability of the industry. Here are some ways consumers can make a difference:

- Separate and sort: Separate used offset paper from other waste and sort it accordingly for recycling purposes.

- Use recycling bins: Make use of designated recycling bins or containers provided by local authorities or recycling organizations.

- Educate and raise awareness: Spread the word about the importance of offset paper recycling and encourage others to participate in recycling efforts.

- Choose recycled offset paper products: Support the use of recycled offset paper by purchasing products made from recycled materials.

Table 3: Consumer Contributions to Offset Paper Recycling

| Consumer Action | Description |

|---|---|

| Separate and sort | Properly separating and sorting used offset paper from other waste is an essential step in facilitating recycling efforts. |

| Use recycling bins | Utilizing designated recycling bins or containers provided by local authorities or recycling organizations ensures that used offset paper is properly disposed of for recycling. |

| Educate and raise awareness | By educating others about the importance of offset paper recycling, consumers can spread awareness and encourage participation in recycling efforts. |

| Choose recycled offset paper products | Supporting the use of recycled offset paper products by purchasing items made from recycled materials helps create demand for recycled paper and supports a circular economy. |

Initiatives and Technologies for Improved Offset Paper Recycling Rates

The recycling industry is continuously striving to improve offset paper recycling rates through various initiatives and technologies. Some of these include:

- Innovative recycling technologies: Advanced sorting and deinking technologies are being developed to enhance the efficiency and quality of the recycling process.

- Collaboration between stakeholders: Collaboration between paper manufacturers, recycling facilities, and government agencies is essential to create a more integrated and efficient recycling system.

- Extended producer responsibility (EPR) programs: EPR programs shift the responsibility for managing and recycling paper products to the manufacturers, encouraging them to implement recycling-friendly designs and support recycling initiatives.

- Public awareness campaigns: Education and awareness programs are crucial in promoting offset paper recycling among the general public, raising awareness about the environmental benefits and encouraging participation.

Environmental Impact of Proper Offset Paper Disposal

Proper disposal of offset paper products has a significant impact on the environment. When offset paper is disposed of in landfills, it contributes to the generation of methane, a potent greenhouse gas. Methane emissions significantly contribute to climate change and global warming.

By recycling offset paper instead of sending it to landfills, methane emissions can be reduced. Additionally, recycling offset paper saves natural resources, reduces energy consumption, and minimizes water usage. These environmental benefits make proper offset paper disposal an essential component of sustainable waste management practices.

In conclusion, offset paper recycling and proper disposal methods are crucial for achieving sustainability in the paper industry. By choosing to recycle offset paper products, consumers can contribute to resource conservation and waste reduction. Initiatives and technologies aimed at improving recycling rates are being developed, further promoting the circularity of offset paper. Ultimately, the proper disposal of offset paper products has a significant positive impact on the environment and helps build a more sustainable future.

FAQs about Offset Paper Product Lifecycle:

What is offset paper?

In the context of the offset paper product lifecycle, offset paper refers to a type of paper commonly used in the printing industry for high-volume printing projects, known for its high-quality printing results and versatility.

A: Offset paper is a type of paper commonly used in the printing industry for offset lithography, known for its high-quality printing results and versatility.

How is offset paper manufactured?

The manufacturing process of offset paper involves preparing materials, cooking wood pulp, screening, and washing to produce high-quality offset paper.

A: Offset paper is manufactured by preparing materials, cooking wood pulp, and processing it through screening and washing to ensure high quality.

What are the common uses of offset paper?

Offset paper is widely used in book printing, magazine printing, brochure printing, and stationery production due to its ability to absorb ink, making it suitable for printing with ballpoint pens and stamps.

A: Offset paper is commonly used in book printing, magazine printing, and stationery production due to its ink-absorbing properties, making it suitable for various applications.

What makes offset paper different from other types of paper?

Offset paper stands out with an ISO brightness of over 80%, a grammage ranging from 40 to 300 gsm, and comes in coated and uncoated varieties suitable for different printing needs.

***A: Offset paper stands out with

In conclusion, offset paper is crucial for sustainable practices in paper manufacturing. Understanding its lifecycle, environmental impact, recycling options, and disposal methods is essential. By implementing sustainable practices and promoting recycling efforts, offset paper manufacturers can reduce their carbon footprint. Consumers play a vital role in supporting these initiatives. Ultimately, prioritizing sustainability in offset paper production is key to minimizing environmental impact and promoting a greener future.