Is Carbon Paper or Carbonless Paper Better for Forms Printing?

Carbonless Copy Paper vs. Carbon Paper

Carbon paper and carbonless paper are both used for making duplicate copies of handwritten or impact-printed documents, but they differ in terms of their technology and application.

Carbon paper is a thin paper coated with a waxy dark carbon film. When placed between two sheets of paper, the pressure from writing or typing causes the carbon film to transfer the image onto the underlying sheets, creating a copy. It is a simple and inexpensive method for creating duplicate copies, but it has some drawbacks. The carbon film can be messy, easily smudged, and potentially harmful if it comes into contact with the skin or eyes. Additionally, since the carbon film is only one-sided, the copies can only be made on one side of the paper.

On the other hand, carbonless paper, also known as NCR (No Carbon Required) paper, eliminates the need for carbon paper by using a chemical reaction to create copies. Carbonless paper is coated with microencapsulated dye, reactive resins, and clay. When pressure is applied to the top sheet, the microencapsulated dye is released and reacts with the reactive resins on the clay-coated bottom sheet, creating a copy. This chemical process allows for multiple copies without the mess and limitations of carbon paper.

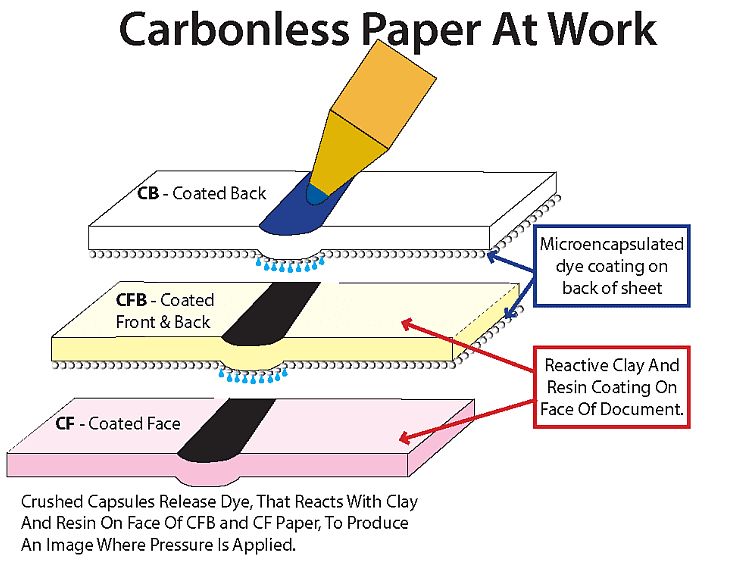

How Does Carbonless Copy Paper Work?

Carbonless copy paper works through a chemical process that utilizes microencapsulated dye, reactive resins, and clay coatings. Here is a breakdown of the steps involved:

- Coating: The top sheet of carbonless paper is coated with microencapsulated dye, reactive resins, and clay, while the bottom sheet is coated with clay only.

- Pressure: When pressure is applied to the top sheet, such as through handwriting or impact printing, the microcapsules containing the dye burst, releasing the dye onto the reactive resins.

- Chemical Reaction: The dye reacts with the reactive resins on the bottom sheet, resulting in a color change. The clay coating helps to spread and stabilize the dye, ensuring a clear and legible copy.

- Copy Formation: The chemical reaction creates a copy on the underlying sheets of carbonless paper, producing multiple copies simultaneously without the need for carbon paper.

Carbonless copy paper comes in different types, including two-part (carbonless back and carbonless front), three-part (white, canary, and pink sheets), and four-part (additional colors such as goldenrod). These variations allow for different color combinations and organization options when creating duplicate copies.

Carbonless copy paper is not suitable for inkjet printers, as the ink does not have the required pressure to initiate the chemical reaction. However, it is compatible with various printing methods like letterpress, offset, and flexographic printing.

Uses and Applications of Carbonless Paper

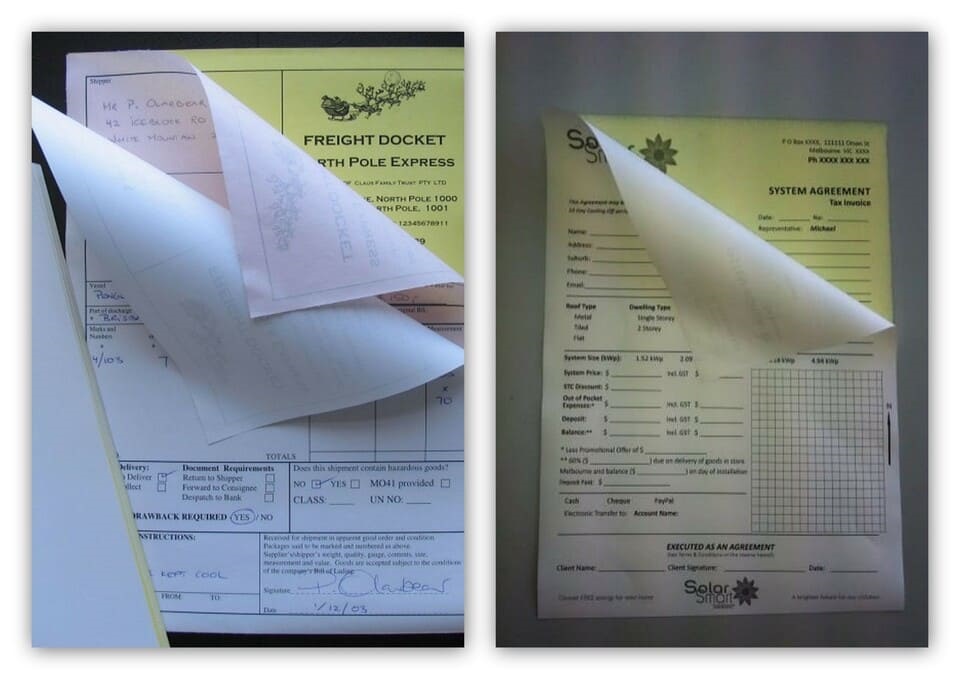

Carbonless paper has a wide range of uses and applications across various industries. Here are some common applications:

- Invoices and Receipts: Carbonless paper is commonly used for creating invoices and receipts, allowing businesses to generate duplicate copies for their records and their customers. The copies can be easily separated and handed out as needed.

- Business Forms: Carbonless paper is widely used for creating various business forms such as sales orders, purchase orders, delivery receipts, and time sheets. The ability to produce multiple copies saves time and improves efficiency in record-keeping and documentation.

- Custom Forms: Carbonless paper can be customized with company logos, branding, and specific form layouts. This customization option allows businesses to create professional-looking forms that align with their corporate identity.

- Medical Records: Medical facilities often utilize carbonless paper to create duplicate copies of important documents such as patient records, insurance claim forms, and lab requisitions. This ensures an accurate and organized system for maintaining medical records.

- Checks: Carbonless paper can also be used for carbonless copy checks, providing a convenient way to produce duplicate copies of checks for record-keeping purposes.

The versatility of carbonless paper extends to its customization options. It is available in various colors, allowing for color-coding and organization within documents. Additionally, carbonless paper can be cut to different sizes according to specific requirements.

In summary, carbonless paper offers a cleaner and more efficient alternative to traditional carbon paper. It utilizes a chemical process to create duplicate copies without the mess and limitations of carbon paper. With its versatility and wide range of applications, carbonless paper is a preferred choice for businesses looking to streamline their document duplication process and improve efficiency in record-keeping.

Tables:

Table 1: Comparison between Carbon Paper and Carbonless Paper

| Carbon Paper | Carbonless Paper | |

|---|---|---|

| Technology | Transfer of carbon film | Chemical reaction |

| Messiness | Can be messy and smudged | Clean and smudge-free |

| Application | One-sided copies | Multiple copies |

| Compatibility with printers | Works with most printers | Not suitable for inkjet printers |

Table 2: Common Applications of Carbonless Paper

| Application | Description |

|---|---|

| Invoices and Receipts | Create duplicate copies for business and customers |

| Business Forms | Sales orders, purchase orders, delivery receipts, time sheets |

| Custom Forms | Customize forms with logos and branding |

| Medical Records | Duplicate copies of patient records, insurance claim forms |

| Checks | Produce duplicate copies of checks for record-keeping |

Table 3: Types of Carbonless Paper

| Number of Parts | Description |

|---|---|

| Two-part | Carbonless back and carbonless front |

| Three-part | White, canary, and pink sheets |

| Four-part | Additional colors such as goldenrod |

FAQs about Carbon vs. Carbonless Paper

How does carbonless copy paper work?

To understand how carbonless copy paper works, it’s important to know that it involves a chemical process using microencapsulated dye, reactive resins, and clay coatings.

What are the benefits of using carbonless paper over carbon paper?

When comparing carbonless paper to carbon paper, the former eliminates the messiness and limitations of the latter, offering a cleaner and more efficient way to create duplicate copies.

What are the different types of carbonless copy paper available?

Carbonless copy paper is available in various types, including two-part, three-part, and four-part, each offering different color combinations and organization options for creating duplicate copies.

In what applications is carbonless paper commonly used?

Carbonless paper finds common applications in creating invoices, business forms, custom forms, medical records, and checks, offering businesses a convenient way to generate duplicate copies for various documentation needs.

Is carbonless paper compatible with all printing methods?

While carbonless paper is not suitable for inkjet printers due to the lack of required pressure, it is compatible with printing methods such as letterpress, offset, and flexographic printing, providing flexibility in printing options.

In this guide on carbon vs. carbonless paper, we explored their differences and applications. Carbonless paper offers versatility and efficiency in business document generation. Understanding the chemical process and types of carbonless paper can enhance your knowledge. Consider the advantages and disadvantages of each paper type for your specific needs. Implementing carbonless paper can streamline your document creation process and improve overall efficiency in various industries.