What are the Different Types of Paper Board Used in Packaging?

Types of Paper Board: A Comprehensive Guide

Understanding Different Types of Paper Board

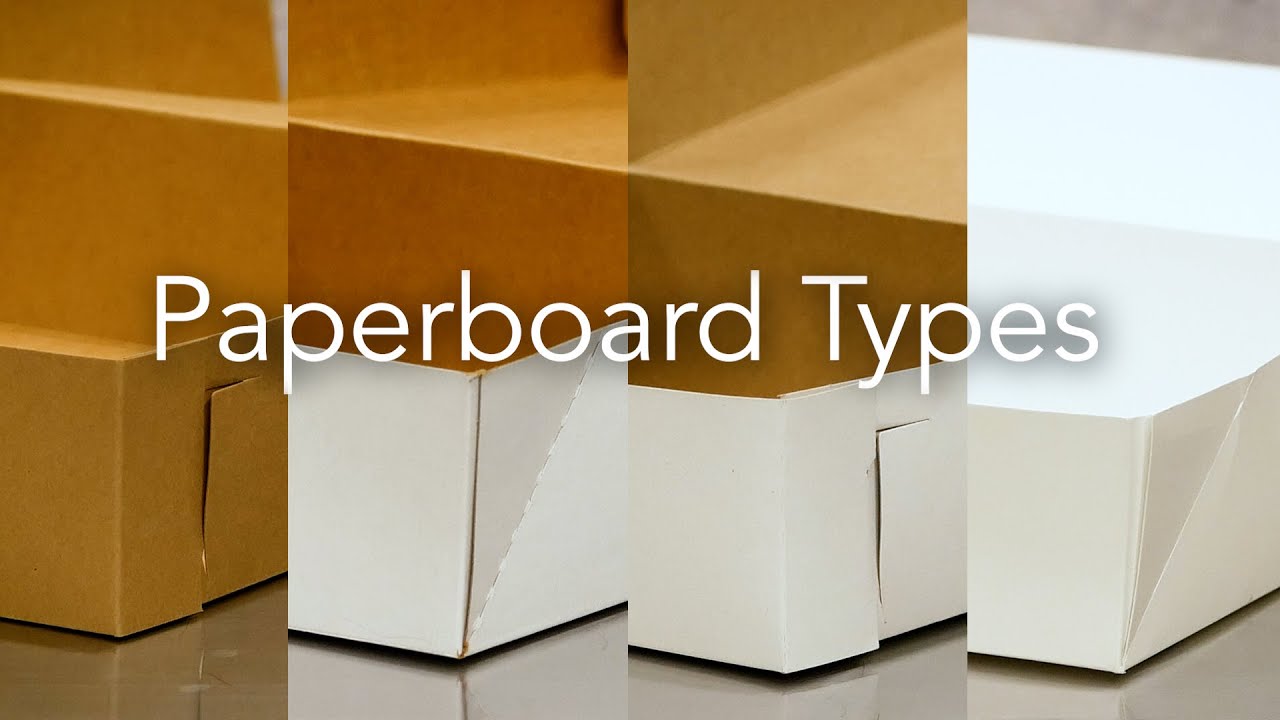

When it comes to packaging materials, paper board is a versatile and widely used option. It is known for its durability, customization options, and eco-friendliness. In this section, we will explore the different types of paper board and their applications in various industries.

What are the main differences between paper board and cardboard?

Paper board and cardboard are often used interchangeably, but there are some key differences between the two. Cardboard is typically thicker and more rigid than paper board. It is made from heavy-duty paper fibers and is commonly used for shipping boxes and packaging that requires sturdiness. On the other hand, paper board is thinner and more flexible. It is made from layers of compressed and glued paper fibers, giving it a smooth and sturdy texture. Paper board is often used in the production of folding cartons, set-up boxes, and other packaging materials.

Exploring the various types of paper board used in packaging

- Solid Bleached Sulfate (SBS): SBS is a premium grade white paper board that is commonly used for food packaging and high-end retail products such as dairy items. It has a smooth and bright surface, providing an excellent canvas for printing and graphic designs. SBS is known for its strength, rigidity, and ability to withstand moisture.

- Coated Unbleached Kraft (CUK): CUK is made from unbleached virgin kraft fiber, making it a strong and eco-friendly option. It is commonly used for beverage containers, hardware packaging, and laundry detergents. CUK provides excellent protection for the products it houses while also maintaining its structural integrity.

- Coated Recycled Paperboard: As the name suggests, coated recycled paperboard is made from recycled fibers. It is often used in the packaging of laundry detergents, bakery products, and paper products such as facial tissues. Coated recycled paperboard is an environmentally friendly option that offers good printability and moderate moisture resistance.

- Non-Bending Chipboard: Non-Bending Chipboard is made from recycled newsprint and is known for its strength and aesthetics. It is commonly used for rigid boxes in industries such as cosmetics, confections, electronics, and jewelry. Non-Bending Chipboard provides excellent protection for delicate and valuable products.

Comparing the properties of different types paper board materials

Each type of paper board has its unique properties that make it suitable for specific packaging needs.

- SBS: SBS is a high-quality paper board that offers excellent printability, moisture resistance, and durability. It is often used in industries that require premium packaging, such as medical, cosmetics, and food packaging.

- CUK: Coated Unbleached Kraft is known for its strength, making it suitable for packaging products that require extra protection and rigidity. It offers good printability and resistance to moisture and grease. CUK is often used in industries such as organic food, natural cosmetics, and eco-friendly packaging.

- Coated recycled paperboard: This type of paper board is an environmentally friendly option made from recycled fibers. It provides good printability and moderate moisture resistance. It is commonly used in the packaging of detergents, cleaners, and tissues.

- Non-Bending Chipboard: Non-Bending Chipboard is valued for its strength and aesthetics. It is often used in the packaging of luxury goods that require a rigid structure and thick protection, such as cosmetics, confections, electronics, and jewelry.

Understanding the different types of paper board materials and their properties is crucial when selecting the most suitable one for your packaging needs. Each type offers unique advantages depending on the industry and product requirements.

In conclusion, paper board is a versatile and eco-friendly packaging material that comes in various types to suit different needs. Whether you require high printability, moisture resistance, or strength, there is a type of paper board that can meet your requirements. Understanding these different types of paper board materials allows you to make informed decisions when it comes to packaging your products.

Applications and Advantages of different types Paper Board

Paper board is a versatile material that finds applications in various industries, including food, cosmetics, and electronics. Its unique properties and characteristics make it a preferred choice for packaging solutions. In this section, we will explore the different applications of paper board in these industries, examine real-world examples of paper board packaging solutions, and discuss the advantages it offers over other packaging materials.

How is paper board used in different industries such as food, cosmetics, and electronics?

Types of Paper board in the food industry

Paper board is widely used in the food industry due to its durability, versatility, and ability to protect and preserve the quality of food products. It is commonly used for packaging bakery items, frozen foods, dry goods, confectionery, and juice and dairy products.

For example, in the bakery industry, paper board is used to package cookies, cakes, donuts, and other baked goods. Its sturdiness and ability to withstand moisture make it ideal for keeping the products fresh. Similarly, in the dairy industry, paper board cartons are used to package milk, yogurt, and other dairy products, providing protection against light and contamination.

Types of Paper board in the cosmetics industry

In the cosmetics industry, paper board is used for packaging products like perfumes, makeup, skincare, and hair care items. The primary reason for its use is its ability to provide an attractive and visually appealing presentation for these products.

Paper board is customizable and can be printed on, allowing for intricate designs, vibrant colors, and branding elements to be incorporated. It also offers options for various finishes, such as matte or glossy, embossing, foil stamping, and spot UV coating, further enhancing the overall aesthetic appeal of cosmetic packaging.

Types of Paper board in the electronics industry

The electronics industry also leverages the properties of paper board for packaging purposes. Paper board packaging solutions for electronics include boxes, displays, and protective packaging for various electronic devices like smartphones, tablets, and cameras.

Paper board offers a balance between protection and aesthetics when it comes to packaging electronic products. It provides cushioning and shock absorption to protect delicate electronic components during transit while offering space for branding and product information.

Examining real-world examples of paper board packaging solutions

Example 1: Packaging for a food product

Take, for instance, the packaging for a chocolate bar. The outer packaging is typically made of paper board. It not only protects the chocolate from external factors but also serves as an excellent medium for branding and product information. The paper board can be printed with appealing designs, logos, and nutritional information, making it visually appealing to consumers.

Inside the outer packaging, the chocolate bar is further protected by a paper board sleeve or tray. This inner packaging ensures that the chocolate remains intact and offers an additional layer of protection during transportation and storage.

Example 2: Luxury cosmetic packaging

Luxury cosmetic brands often use paper board packaging to create a premium and upscale look for their products. The packaging may include paper board boxes, containers, and inserts that showcase the brand’s identity and evoke a sense of luxury and elegance.

For instance, high-end perfume bottles are often presented in luxurious paper board boxes that exude sophistication. The boxes may feature embossed or foil-stamped designs, velvet or silk linings, and magnetic closures, enhancing the overall perceived value of the product.

Example 3: Electronics packaging

When it comes to electronics packaging, paper board is used to create sturdy boxes and protective inserts. These boxes protect the electronic devices during shipping and storage, ensuring they reach the consumer in perfect condition.

Additionally, paper board packaging for electronics often features foam or molded inserts that securely hold the devices in place, preventing any movement or damage. This level of protection is vital, especially for delicate electronic components that can be easily damaged during transportation.

What are the advantages of using paper board over other packaging materials?

| Advantages of Paper Board |

|---|

| Sustainability and eco-friendliness |

| Versatility and customization |

| Durability and protection |

| Visual appeal |

Sustainability and eco-friendliness

One of the key advantages of paper board is its sustainability and eco-friendliness. It is made from renewable and recyclable materials, such as wood pulp and recycled fibers. Paper board packaging can be recycled, reducing waste and environmental impact. Additionally, the production of paper board requires less energy compared to other packaging materials like plastic.

Versatility and customization

Paper board is a versatile material that can be easily customized for different packaging needs. It can be cut, folded, and shaped into various forms, making it suitable for different product sizes and shapes. Additionally, it can be printed on, allowing for branding, product information, and attractive designs to be incorporated into the packaging.

Durability and protection

Paper board offers a good balance of durability and protection. It provides sufficient strength and rigidity to protect products during transportation and storage. It can withstand mild impacts and provides cushioning for fragile items. The thickness of paper board can be varied to meet specific packaging requirements, ensuring proper protection for different products.

Visual appeal

Paper board packaging can be visually appealing, making it attractive to consumers. The ability to print on paper board allows for vibrant colors, eye-catching designs, and high-quality graphics. This helps in capturing the attention of consumers and creating a positive brand image.

In summary, paper board finds applications in various industries such as food, cosmetics, and electronics. It offers advantages like sustainability, versatility, durability, and visual appeal. By understanding the different types of paper board and their applications, businesses can make informed decisions when it comes to packaging their products.

Sustainability and Eco-Friendliness of Paper Board

Paper board is not only a versatile and durable packaging material, but it also offers several sustainable and eco-friendly advantages. In this section, we will delve into the recyclability of paper board, its eco-friendly aspects, and how it contributes to sustainable packaging practices.

Is Paper Board a Recyclable Material?

One of the key sustainable features of paper board is its recyclability. Recycling paper board helps reduce waste, conserve resources, and minimize environmental impact. The majority of paper board products can be recycled, including those used for packaging.

When paper board is recycled, it goes through a process where it is broken down into fibers and then used to create new paper products. This helps reduce the demand for raw materials, as recycled fibers can replace virgin fibers in the production process.

It is important to note that not all paper board products are equally recyclable. Some paper board materials, such as Coated Unbleached Kraft (CUK) and Solid Bleached Sulfate (SBS) with certain coatings or finishes, may have lower recyclability compared to other types of paper board. It is recommended to check with local recycling facilities or consult with packaging specialists to determine the recyclability of specific paper board materials.

Exploring the Eco-Friendly Aspects of Paper Board Packaging

Paper board packaging offers several eco-friendly features that make it a preferred choice for sustainable packaging solutions. Here are some key aspects to consider:

- Renewable and Sustainable Material: Paper board is made from a renewable resource – trees. Sustainable forest management practices ensure that trees are responsibly harvested and replanted, contributing to the long-term sustainability of the industry.

- Reduced Carbon Footprint: Paper board has a lower carbon footprint compared to materials like plastic. The production of paper board requires less energy and produces fewer greenhouse gas emissions.

- Biodegradability: Unlike plastics, paper board is biodegradable. It naturally breaks down over time and decomposes without leaving harmful residues in the environment.

- Use of Recycled Content: Many paper board products, particularly those made from recycled fibers, contain a percentage of post-consumer waste. This minimizes the need for virgin materials and reduces the overall environmental impact.

- Energy Efficiency: The manufacturing process of paper board is energy-efficient, using less energy compared to other packaging materials.

- Reduced Water Usage: Paper board production requires less water compared to materials like plastic.

By choosing paper board packaging, businesses can contribute to a more sustainable and environmentally friendly future.

How Does Paper Board Contribute to Sustainable Packaging Practices?

Paper board plays a significant role in promoting sustainable packaging practices. Here’s how:

- Lightweight and Space-Efficient: Paper board packaging is lightweight, which means less energy is required for transportation. Additionally, its compact design allows for efficient use of storage space, reducing the carbon footprint associated with logistics.

- Customizable and Recyclable: Paper board packaging can be easily customized to suit specific product requirements. This eliminates the need for excessive materials and waste. Furthermore, paper board packaging is recyclable, ensuring that it can be reused and repurposed after use.

- Renewable Resources: The use of paper board encourages the sustainable management of forests. Sustainable forest practices ensure the continual supply of raw materials without depleting natural resources.

- Consumer-Friendly: Eco-conscious consumers are increasingly seeking products packaged in sustainable materials. By using paper board packaging, businesses can meet consumer demands for environmentally friendly packaging options.

In conclusion, paper board is not only a versatile and durable packaging material, but it also offers several sustainability advantages. Its recyclability, eco-friendly aspects, and contribution to sustainable packaging practices make it a preferred choice for businesses and consumers alike. By choosing paper board packaging, businesses can reduce their environmental impact, meet consumer demands for sustainable options, and contribute to a more sustainable future.

Tables

Comparison of Paper Board Types

| Type | Key Features | Applications |

|---|---|---|

| Solid Bleached Sulfate | Premium grade white paper board | Food packaging, high-end retail products |

| Coated Unbleached Kraft | Strong and eco-friendly option | Beverage containers, hardware packaging, laundry detergents |

| Coated recycled paperboard | Made from recycled fibers | Packaging of laundry detergents, bakery products, paper products |

| Non-Bending Chipboard | Made from recycled newsprint | Rigid boxes in cosmetics, confections, electronics, jewelry |

Eco-Friendly Aspects of Paper Board Packaging

| Eco-Friendly Aspects of Paper Board Packaging |

|---|

| Renewable and Sustainable Material |

| Reduced Carbon Footprint |

| Biodegradability |

| Use of Recycled Content |

| Energy Efficiency |

| Reduced Water Usage |

FAQs about Types of Paper Board

What are the main differences between paper board and cardboard?

To distinguish between paper board and cardboard, consider their thickness and rigidity levels.

How can the various types of paper board be used in packaging?

Explore the applications of Solid Bleached Sulfate (SBS), Coated Unbleached Kraft (CUK), Coated Recycled Paperboard, and Non-Bending Chipboard.

What are the unique properties of different paper board materials?

Compare the qualities of SBS, CUK, Coated recycled paperboard, and Non-Bending Chipboard.

How is paper board utilized in the food, cosmetics, and electronics industries?

Discover the versatile applications of paper board in various sectors like food, cosmetics, and electronics.

What are the advantages of using paper board over other packaging materials?

Examine the sustainability, versatility, durability, and visual appeal benefits of choosing paper board for packaging needs.

In conclusion, understanding paper board vs cardboard is essential for packaging choices. Exploring paperboard varieties reveals unique properties. Paperboard finds use in food, cosmetics, and electronics due to its versatility. Its eco-friendly nature makes it a sustainable packaging choice. Making informed decisions about paperboard packaging benefits both businesses and the environment.