What are the main offset printing paper types?

Section 1: Understanding Different Types of Paper for Offset Printing

Offset printing is a popular and widely-used printing technique that involves transferring ink from a plate to paper via a rubber cylinder. One of the key factors that determine the quality and outcome of an offset print job is the type of paper used. There are several main types of paper used in offset printing, each with its own characteristics, benefits, and drawbacks.

1.1 Coated Paper:

Coated paper is a type of paper that has been coated with a layer of clay or other materials, which gives it a smooth and glossy surface. This coating enhances the color vibrancy and sharpness of printed images, making it ideal for projects that require high-quality image reproduction, such as coffee table books, magazines, and brochures. Coated paper is available in various finishes, including gloss, satin, and matte. The choice of coating depends on the desired effect and the type of images being printed.

1.1.1 Gloss-Coated Paper:

Gloss-coated paper has a high-shine surface that reflects light, resulting in vibrant and eye-catching prints. It is commonly used in magazines and promotional materials to make images pop and attract attention. However, the glossy surface can be prone to fingerprints and reflections, which may affect readability in certain lighting conditions.

1.1.2 Matte-Coated Paper:

Matte-coated paper has a subtle shine and provides a more muted and elegant look compared to gloss-coated paper. It reduces glare and eye strain, making it suitable for reports, presentations, and posters. The matte surface also offers a smoother writing experience compared to glossy paper.

1.1.3 Satin-Finished Paper:

Satin-finished paper falls between gloss and matte-coated paper in terms of shine. It provides a compromise between the vibrant colors of gloss and the reduced glare of matte, making it versatile for various types of print projects.

1.2 Uncoated Paper:

Uncoated paper does not have a coating layer, which gives it a rougher and more natural texture compared to coated paper. It is commonly used for projects that require easy writability, such as letterheads, notepads, and envelopes. The absence of a coating layer allows for better ink absorption and prevents smudging, making it suitable for laser and inkjet printers.

1.3 Specialty Papers:

In addition to coated and uncoated paper, there are also a variety of specialty papers available for offset printing. These papers offer unique characteristics and are commonly used for specific applications or to achieve a particular effect.

1.3.1 Linen Paper:

Linen paper has a textured finish that resembles the weave of linen fabric. This textured surface adds a touch of sophistication and elegance to business stationery, invitations, and other high-end print projects.

1.3.2 Watermarked Paper:

Watermarked paper is paper with a translucent design or logo embedded into it during the manufacturing process. This design is visible when the paper is held up to light, adding an element of security and authenticity to official documents, certificates, and high-quality stationery.

1.3.3 Recycled Paper:

Recycled paper is made from post-consumer waste paper, such as newspapers and magazines. It is an environmentally-friendly choice and is suitable for projects that prioritize sustainability. While recycled paper maintains quality, it may have a slightly different texture and color compared to non-recycled paper.

1.4 Considerations for Paper Selection:

When selecting paper for offset printing, various factors should be considered. These factors include the intended use of the printed material, the budget for the project, and the desired outcome in terms of image quality, durability, and tactile feel. Paper weight classifications, such as text weight and cover weight, also play a role in determining the thickness and sturdiness of the paper.

1.4.1 Paper Weight Classifications:

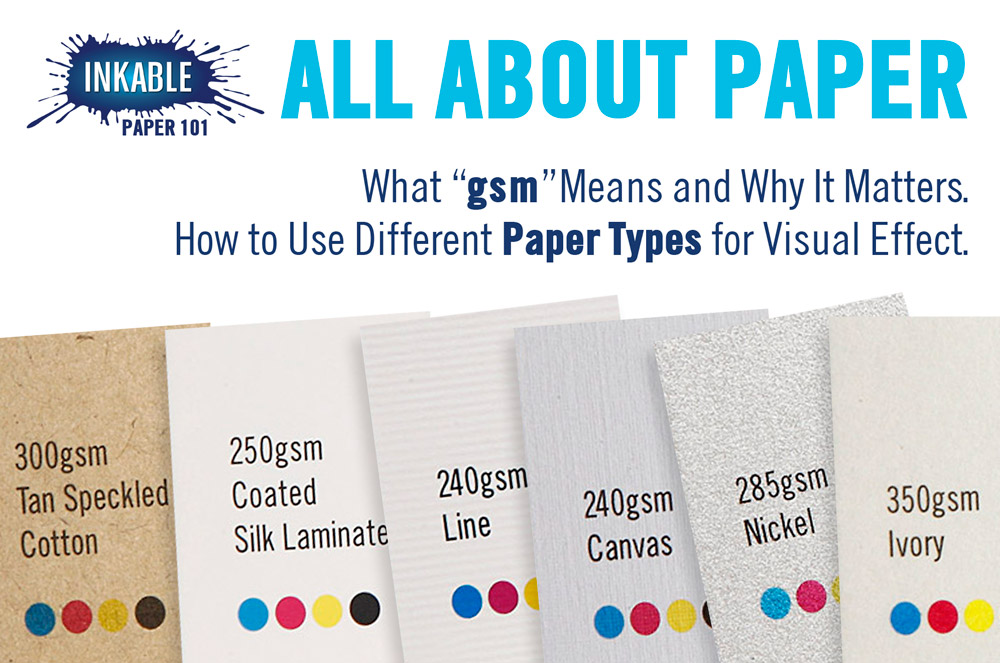

Paper weight is typically measured in grams per square meter (gsm) and refers to the weight of a certain size of paper. In offset printing, different paper weights are used for different purposes. Lightweight paper (60-100 gsm) is commonly used for the interiors of books, while mediumweight paper (100-200 gsm) is often used for book covers. Heavyweight paper (200+ gsm) is suitable for projects that require extra durability, such as business cards or postcards.

1.5 Importance of Paper Texture, Opacity, and Brightness:

1.5.1 Paper Texture:

Paper texture can impact the look and feel of the printed material, with smoother textures being more suitable for detailed graphics and textured papers adding depth and visual interest.

1.5.2 Paper Opacity:

Opacity refers to the degree to which the paper allows light to pass through, which can affect show-through and readability.

1.5.3 Paper Brightness:

Brightness, measured on a scale from 0 to 100, relates to the color appearance of the paper. Higher brightness levels result in a whiter and brighter appearance.

1.6 Sustainability Considerations:

When selecting paper for offset printing, it is also essential to consider sustainability factors. Look for papers that are certified by reputable organizations such as the Forest Stewardship Council (FSC), which ensures responsible sourcing of paper and promotes eco-friendly printing practices. Choosing environmentally sustainable options aligns with the growing demand for green printing and demonstrates a commitment to reducing the environmental impact of print projects.

Overall, understanding the different types of paper used in offset printing and considering their specific characteristics, benefits, and drawbacks is crucial for achieving the desired printing outcomes. By selecting the right paper type based on the project requirements, budget, and sustainability considerations, you can ensure optimal results and customer satisfaction.

Section 2: Choosing the Right Paper for Your Offset Printing Project

Factors to Consider when Selecting Paper for Offset Printing Projects

When choosing paper for offset printing, several factors need to be taken into consideration. Here are some key factors that can influence your decision:

- Intended Use: Consider the purpose of your printed material. Is it a flyer, brochure, or catalog? Different paper types work better for specific applications.

- Budget: Paper prices can vary significantly. It’s essential to consider your budget and find a balance between cost and quality.

- Desired Outcome: Understand the look and feel you want to achieve with your printed materials. Different paper types can convey different levels of professionalism, vibrancy, or subtlety.

Understanding the Role of Paper Weight and Thickness in Offset Printing

The weight and thickness of the paper play a significant role in the final result of an offset printing project. Here is a breakdown of the different weight classifications and their impact on printing projects:

| Paper Weight Classification | Description |

|---|---|

| Text Weight | Lightweight paper used for interior pages of books or brochures (60-100 gsm) |

| Cover Weight | Heavier paper used for covers of books, brochures, or other printed materials (100-200 gsm) |

| GSM (Grams per Square Meter) | Weight classification system used in the printing industry (e.g., lightweight, mediumweight, heavyweight) |

How to Match Paper Types with Printing Projects – Flyers, Brochures, Catalogs

Different printing projects require specific paper types to achieve the desired outcome. Here are some commonly used paper types for different types of printing projects:

| Printing Project | Recommended Paper Type |

|---|---|

| Flyers | Lightweight uncoated or semi-coated paper |

| Brochures | Mediumweight gloss-coated, uncoated, or matte-coated paper |

| Catalogs | Heavyweight gloss-coated paper |

Recommendations for Paper Selection Based on Budget and Desired Outcome

The selection of paper for offset printing is a critical decision that should align with your budget and desired outcome. Here are some recommendations to guide your paper selection process:

- Low Budget: Consider lightweight uncoated or semi-coated paper options.

- Mid-range Budget: If your budget allows for it, consider mediumweight coated or uncoated paper options.

- High Budget: When budget is not a major constraint, explore heavyweight gloss-coated paper options.

Insights on Selecting the Right Paper Color and Texture for Your Design

Aside from the weight and type of paper, the color and texture also play a role in the overall appearance of your printed materials. Consider the following insights when selecting paper color and texture for your design:

- Paper Color: White is the classic choice, but you can also experiment with colored paper options to add visual interest.

- Paper Texture: Smooth textures work well for detailed graphics, while rough textures add depth and sophistication.

Tips for Ensuring Ink Compatibility with Different Types of Offset Printing Paper

Ensuring ink compatibility is crucial to avoid potential issues with your offset printing project. Here are some tips to ensure that the ink and paper are compatible:

- Consult Your Printing Provider: Work closely with your printing provider to understand specific ink compatibility requirements.

- Perform Compatibility Tests: Before a large print run, perform small-scale compatibility tests.

- Choose Environmentally Sustainable Options: Consider using environmentally sustainable and eco-friendly papers.

Best Practices for Achieving Optimal Results with Offset Printing Paper

To achieve optimal results with offset printing paper, follow these best practices:

- Use High-Quality Images: Ensure the images you use for printing are of high resolution and suitable for the paper type.

- Proofread and Review: Thoroughly proofread and review the content before finalizing print files.

- Consider Paper Opacity: Choose a paper with minimal show-through for double-sided printing projects.

- Pay Attention to Paper Brightness: Higher brightness levels enhance the appearance of colors.

By considering these best practices and understanding the factors involved in selecting the right paper for your offset printing project, you can achieve high-quality results that meet your budget and desired outcome.

Exploring Specialty Paper Options for Offset Printing

Watermarked Paper for Security and Elegance

Watermarked paper is a versatile option that offers both security and elegance in offset printing. It is created by embedding a translucent design or logo into the paper during the manufacturing process. The watermark becomes visible when the paper is held up to light, giving it a sophisticated and premium look.

Watermarked paper is often used for official documents, certificates, high-end stationery, and invitations. The unique watermark adds an extra layer of authenticity and helps deter counterfeiting. It also enhances the perceived value of the printed material and gives it a touch of class.

FSC Certified Paper for Eco-Friendly Printing

For those who prioritize environmental sustainability, using FSC (Forest Stewardship Council) certified paper is an excellent choice for offset printing. FSC certification ensures that the paper comes from responsibly managed forests, where environmental, social, and economic considerations are taken into account.

By using FSC certified paper, you can showcase your commitment to eco-friendly practices and contribute to the preservation of natural resources. It is an excellent option for businesses that want to align their brand with sustainable values and appeal to environmentally conscious consumers.

Linen Paper for a Textured Finish

Linen paper is known for its distinctive textured finish, which resembles the look and feel of linen fabric. It adds depth and sophistication to any printed material, making it ideal for business stationery, invitations, and formal documents.

The textured surface of linen paper enhances the tactile experience and creates visual interest. It can elevate your designs by providing a unique backdrop for the printed content, making it stand out and leave a lasting impression.

Considerations for Using Recycled Paper

In today’s eco-conscious world, using recycled paper for offset printing projects is an environmentally responsible choice. Recycled paper is made from post-consumer waste, which reduces the demand for virgin materials and helps conserve natural resources.

When using recycled paper, it’s essential to consider that it may have slightly different texture and color compared to non-recycled options. However, these variations add a distinctive character to your prints and showcase your commitment to sustainability.

Understanding the Unique Features of Matte, Glossy, and Watermarked Paper

Matte paper, with its soft, non-reflective finish, is an excellent choice for offset printing when reducing glare and enhancing readability is desired. It is commonly used for reports, posters, and other printed materials where clarity and legibility are essential.

On the other hand, glossy paper is the go-to option when you want to make images pop with vibrancy and clarity. Its high-shine surface enhances colors and sharpens images, making it perfect for high-quality prints and marketing materials.

Finally, watermarked paper offers both elegance and security. Its embedded translucent design adds sophistication to printed materials while also serving as a deterrent against counterfeiting.

Tips for Selecting the Right Specialty Paper

Choosing the right specialty paper for your offset printing project can make a significant impact on the final result. Here are some tips to help you select the perfect paper based on your desired effect:

- Consider the purpose of the printed material: Different specialty papers are better suited for specific purposes, such as official documents, invitations, marketing materials, or stationery.

- Think about your budget: Specialty papers may come at a higher cost compared to standard options. Consider your budget and allocate resources accordingly.

- Match the paper texture with your design: The texture of the paper can complement your design and add depth. Choose a texture that aligns with the visual aesthetic you want to achieve.

- Ensure ink compatibility: Not all specialty papers are compatible with all types of inks. Consult with your printer or supplier to ensure that the paper you choose works well with the ink you intend to use.

- Select sustainable options: If sustainability is important to you, opt for specialty papers that are eco-friendly and have relevant certifications, such as FSC certification.

By considering these factors and exploring the wide range of specialty papers available, you can select the perfect paper to bring your offset printing projects to life.

In conclusion, specialty papers offer unique characteristics and applications in offset printing that can enhance the visual appeal, security, and environmental sustainability of your printed materials. Watermarked paper adds elegance and security, FSC certified paper showcases eco-friendly practices, linen paper provides a textured finish, and recycled paper promotes sustainability. Additionally, the unique features of matte, glossy, and watermarked paper offer different effects and can be chosen based on the desired outcome. By considering the purpose of the project, budget, design aesthetics, ink compatibility, and sustainability, you can select the right specialty paper to elevate your offset printing projects.

FAQs about Choosing Paper Types for Offset Printing Projects

What factors determine the quality and outcome of an offset print job?

To ensure the quality and outcome of an offset print job, the type of paper used is crucial: Precision = tp/(tp+fp) Recall = tp/(tp+fn)

How does paper coating affect image reproduction in offset printing?

Paper coating, such as gloss, matte, or satin finishes, significantly impacts image quality and vibrancy in offset printing: Precision = tp/(tp+fp) Recall = tp/(tp+fn)

What are the key considerations for selecting paper for offset printing projects?

When selecting paper for offset printing, factors like intended use, budget, and desired outcomes need to be carefully considered: Precision = tp/(tp+fp) Recall = tp/(tp+fn)

How does paper weight classification influence the thickness and sturdiness of paper in offset printing?

Paper weight classifications, ranging from lightweight to heavyweight, determine the thickness and durability of paper for different printing purposes: Precision = tp/(tp+fp) Recall = tp/(tp+fn)

Why is it essential to consider paper texture, opacity, and brightness in offset printing projects?

Paper texture, opacity, and brightness play a significant role in the appearance and visual impact of printed materials in offset printing: Precision = tp/(tp+fp) Recall = tp/(tp+fn)

In conclusion, understanding paper types for offset printing is crucial for successful projects. Coated, uncoated, matte, and glossy papers each have specific benefits and applications. Carefully choosing the right paper based on weight, texture, and sustainability can enhance print results. For optimal outcomes, match paper types with project requirements, consider budgets, and ensure ink compatibility. Specialty options like watermarked, FSC Certified, and linen papers offer unique qualities for varying needs. Selecting the appropriate paper type elevates the quality and impact of your offset printing projects.