What Are the Top 5 Applications of Aqueous Coated Paper?

Here's the updated blog with images inserted under the corresponding h2 headings:

Top 5 Applications of Aqueous Coated Paper in Industrial Printing

Aqueous coated paper is widely used in the printing industry due to its numerous benefits and versatility. This water-based, eco-friendly coating enhances the appearance and durability of printed materials, making it a popular choice for various applications. In this article, we will explore the top 5 applications of aqueous coated paper in industrial printing and discuss its advantages over other coating options.

1. Packaging

Aqueous coated paper is extensively used in the packaging industry, particularly for food and household products. Its non-toxic nature makes it a safe choice for packaging materials that come into direct contact with food. The coating provides a protective barrier, preventing moisture and contaminants from seeping into the packaging and compromising product quality. Additionally, aqueous coated paper enhances the visual appeal of packaging, making colors appear more vibrant and details more crisp.

2. Brochures, Booklets, and Business Cards

Aqueous coated paper is an ideal option for creating professional-looking brochures, booklets, and business cards. The coating enhances the print quality by improving color saturation and sharpness, resulting in a polished and visually appealing finished product. Moreover, aqueous coatings offer durability, protecting printed materials from fingerprints, smudges, and scuffs. This ensures that marketing materials maintain their high-quality appearance even with frequent handling.

3. Label Printing

Label printing is another area where aqueous coated paper shines. The coating adds a layer of protection to printed labels, extending their lifespan and preserving their readability. Whether used on consumer products or industrial equipment, aqueous coated labels maintain their visual appeal and resist fading, even with exposure to various environmental factors. This enhances product presentation and helps brands leave a lasting impression on consumers.

4. Promotional Materials

Aqueous coated paper is a popular choice for promotional materials due to its ability to make colors "pop" and elevate the overall aesthetic. The coating enhances the vibrancy and richness of colors, giving promotional materials a visually striking appearance. Whether it's brochures, flyers, or posters, aqueous coated paper helps captivate the reader's attention and effectively communicate the intended message. Additionally, the coating provides an extra layer of protection against wear and tear, ensuring that promotional materials remain intact and maintain their impact during long campaigns.

5. High-Quality Printed Materials

In summary, aqueous coated paper offers a range of benefits that make it highly suitable for various industrial printing applications. Its water-based, eco-friendly nature, improved print quality, enhanced durability, and compatibility with different substrates make it a top choice for the packaging, brochures, labels, promotional materials, and high-quality printed materials. By leveraging the advantages of aqueous coated paper, businesses can create visually appealing and long-lasting printed materials that leave a lasting impression on their target audience.

How is aqueous coated paper used in different industrial printing applications?

Aqueous coated paper is a versatile and popular choice in the field of industrial printing. Its unique properties make it suitable for a wide range of applications where durability, visual appeal, and environmental friendliness are essential. Let's explore some of the top uses of aqueous coated paper in industrial printing.

1. Packaging for food and household products

One of the main applications of aqueous coated paper in industrial printing is packaging, particularly for food and household products. Aqueous coatings are non-toxic, making them an ideal choice for packaging materials that come into direct contact with consumables. The coating provides a protective barrier, ensuring the integrity and freshness of the packaged goods. Additionally, aqueous coatings enhance the visual appeal of packaging, making products more enticing on store shelves.

2. Brochures, booklets, and business cards

Aqueous coated paper is widely used in the production of high-quality printed materials such as brochures, booklets, and business cards. The coating adds a professional touch, giving these materials a polished and sophisticated look. Aqueous coatings also offer scuff resistance, protecting these printed materials from fingerprints and smudges, ensuring they maintain their pristine appearance even with frequent handling.

3. Label printing for consumer products

Label printing is another area where aqueous coated paper excels. Labels serve as a critical element in product presentation, conveying important information and attracting consumer attention. Aqueous coatings give labels a vibrant and high-quality finish, making colors pop and enhancing the overall appearance. The coating also provides excellent protection against fading and smudging, ensuring that labels maintain their pristine condition throughout their usage.

4. Promotional materials

Promotional materials play a crucial role in marketing and creating brand awareness. Aqueous coated paper is commonly used in the production of promotional materials, such as flyers, posters, and banners. The coating adds a glossy finish and enhances the colors, making the promotional materials more visually appealing. Additionally, aqueous coatings protect the prints from scratches and scuffs, ensuring the longevity of the promotional materials even in high-traffic areas.

5. Compatibility and limitations

Aqueous coated paper offers compatibility with various substrates, including different types of paper and synthetic materials. This versatility allows for its usage in a wide range of industrial printing applications. However, it is important to note that aqueous coatings may not adhere well to certain substrates, especially those with specialized coatings or treatments. Therefore, it is recommended to conduct tests on sample materials before full-scale production to ensure compatibility and avoid costly errors.

In summary, aqueous coated paper finds its place in various industrial printing applications. Its usage in packaging, brochures, labels, and promotional materials demonstrates its versatility, durability, and visual enhancement capabilities. By providing protection against smudges and scuffs, aqueous coatings ensure that prints maintain their pristine appearance. Additionally, the environmental friendliness of aqueous coatings makes them a popular choice in the industry. When selecting the type of aqueous coating, considering factors like glossiness, substrate compatibility, and drying/curing processes is crucial for achieving the desired results. With proper application techniques and quality control, aqueous coated paper can be effectively utilized to create visually stunning and long-lasting prints in the industrial printing field.

Considerations and Best Practices for Applying Aqueous Coatings in Industrial Printing

Aqueous coating is a popular choice in industrial printing due to its versatility, eco-friendliness, and ability to enhance the visual appeal of printed materials. However, to achieve optimal results, it is essential to consider various factors and follow best practices during the application process.

Selecting the Right Type of Aqueous Coating

When choosing an aqueous coating type, it is crucial to consider the desired finish and the specific requirements of the printed material. Some common types of aqueous coatings include gloss, matte, soft-touch, satin, and high-slip.

- Gloss coatings provide a high-gloss finish and vibrant colors, making them ideal for magazines and promotional materials.

- Matte coatings create a non-reflective and sophisticated look, enhancing the readability of text-heavy materials like brochures and booklets.

- Soft-touch coatings offer a luxurious velvety texture, perfect for high-end packaging and business cards.

- Satin coatings strike a balance between gloss and matte, offering a subtle sheen that adds an elegant touch to packaging.

- High-slip coatings improve material stackability, making them suitable for materials that require easy movement or handling.

Consider the desired aesthetic, the intended purpose of the printed material, and the target audience when selecting the type of aqueous coating to achieve the desired result.

Importance of Testing on Samples

Before applying aqueous coatings to the actual printed materials, it is essential to perform testing on samples. This step helps ensure compatibility between the coating and the substrate, preventing potential issues like adhesion failure or changes in color accuracy.

By testing on samples, you can evaluate the interaction between the coating and the substrate to determine the optimal application process. This testing phase allows you to identify any potential challenges or limitations and make necessary adjustments before moving forward with the full production run.

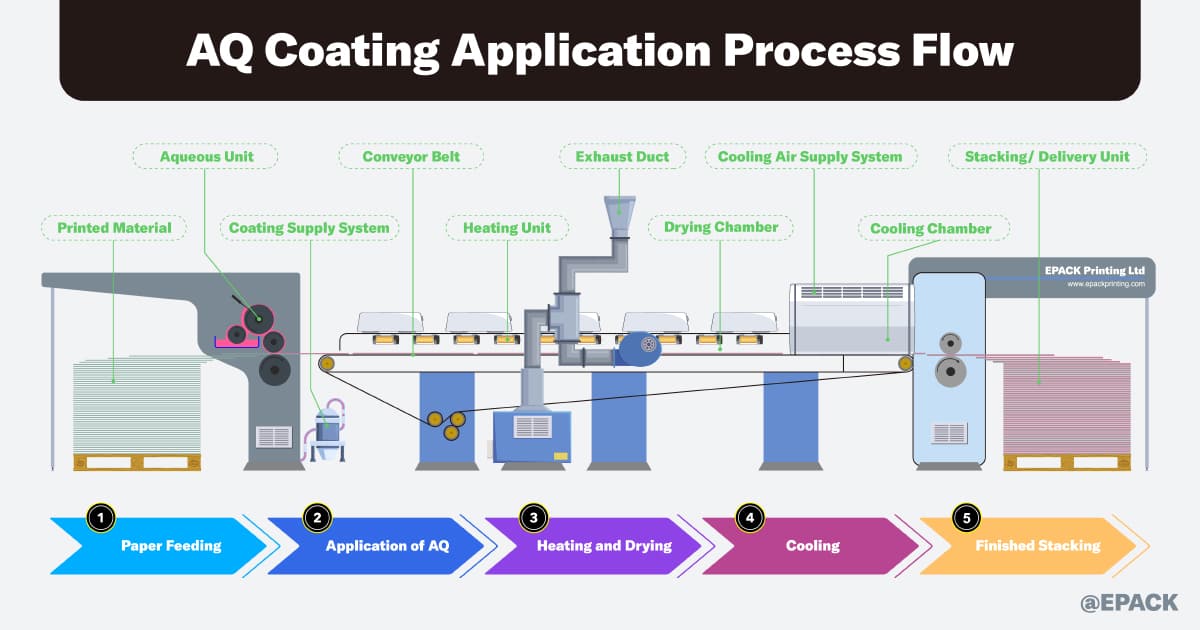

Step-by-Step Application Process

-

Preparation: Before applying the aqueous coating, ensure that the printed material is properly prepared. This may involve cleaning the surface, removing debris or dust, and ensuring the substrate is free from any contaminants that may affect adhesion.

-

Drying: Once the material is prepared, allow sufficient drying time before applying the aqueous coating. This step ensures that the ink is completely dry and minimizes the risk of smudging or color bleed.

-

Application: Apply the aqueous coating evenly using a reliable coating machine or appropriate equipment. Take care to avoid over-application, as this can lead to coating build-up or pooling, resulting in an uneven or suboptimal finish.

-

Curing: After coating application, the material needs to undergo proper drying and curing. Follow the manufacturer's instructions regarding temperature, humidity, and curing time to ensure optimal adhesion and finish quality.

Table 1: Comparison of Different Types of Aqueous Coatings

| Type of Aqueous Coating | Finish | Suitable Applications |

|---|---|---|

| Gloss | High-gloss | Magazines, promotional materials |

| Matte | Non-reflective | Brochures, booklets |

| Soft-touch | Velvety texture | High-end packaging, business cards |

| Satin | Subtle sheen | Packaging |

| High-slip | Improved stackability | Materials requiring easy movement or handling |

Table 2: Factors to Consider when Applying Aqueous Coatings

| Factor | Considerations |

|---|---|

| Substrate compatibility | Ensure the coating adheres well to the substrate, and conduct compatibility tests if needed. |

| Desired finish | Consider the desired appearance (glossy, matte, etc.) and select the appropriate coating type. |

| Drying and curing conditions | Follow the manufacturer's guidelines for temperature, humidity, and curing time to achieve optimal results. |

| Quality control | Regularly inspect the coated materials for imperfections and address any issues to maintain consistency in the final output. |

By using the right equipment and following the manufacturer's guidelines, you can ensure consistent and high-quality results in your aqueous coating applications.

Case Studies and Examples

To further illustrate the applications and benefits of aqueous coated paper in industrial printing, consider including case studies or examples of successful applications. These real-life examples can help readers understand how aqueous coating has been utilized effectively in various industries and offer inspiration for their own printing projects.

In conclusion, when applying aqueous coatings in industrial printing, it is essential to consider the type of coating, perform testing on samples, follow a step-by-step application process, maintain high-quality finish standards, and use appropriate equipment. By adhering to these best practices, you can achieve optimal results and unlock the full potential of aqueous coated paper in industrial printing applications.

FAQs about Top 5 Applications of Aqueous Coated Paper in Industrial Printing

How is aqueous coated paper used in packaging?

Aqueous coated paper is extensively used in packaging, particularly for food and household products, due to its non-toxic nature which makes it a safe choice for materials coming into direct contact with consumables, while also providing protection against moisture and enhancing visual appeal.

What are the benefits of using aqueous coated paper for brochures and business cards?

Aqueous coated paper is an ideal option for brochures and business cards as it improves color saturation and sharpness, resulting in a professional look, and offers durability by protecting against fingerprints, smudges, and scuffs.

How does aqueous coated paper benefit label printing?

In label printing, aqueous coated paper provides a protective layer that extends labels' lifespan and preserves readability, making colors more vibrant and ensuring labels resist fading, even when exposed to environmental factors.

Why is aqueous coated paper preferred for promotional materials?

Aqueous coated paper is favored for promotional materials due to its ability to enhance vibrancy and richness of colors, capture attention, and provide protection against wear, ensuring materials remain intact during campaigns.

What are the advantages of using aqueous coated paper for high-quality printed materials?

Aqueous coated paper is widely used for high-quality printed materials, such as art prints and catalogs, because it adds depth and richness to colors, gives a sophisticated finish, and protects against fingerprints and smudges.

Aqueous coated paper offers clear benefits for industrial printing. It provides vibrant colors, improved durability, and is eco-friendly due to its water-based nature, lacking harmful VOCs. This coating is cost-effective and perfect for packaging and high-end materials. In industrial settings, it's versatile, enhancing packaging, brochures, and promotional items with ease. Choosing the right coating and applying it correctly ensures quality results. In the end, aqueous coatings are a smart choice for businesses looking to merge quality with sustainability in their printed products.