What is the Offset Paper Supply Chain Process?

Offset Paper Supply Chain Overview

The offset paper supply chain is an intricate system that involves various stages, from sourcing raw materials to the distribution of the final products. In this section, we will explore the different aspects of the offset paper supply chain, including raw material sourcing, production processes, key players, and sustainability practices.

What is the offset paper supply chain?

The offset paper supply chain refers to the entire process involved in the production and distribution of offset paper, which is widely used in the printing industry. Offset paper is known for its high-quality printing capabilities, making it a preferred choice for a wide range of printing applications, including books, magazines, brochures, and more. The supply chain ensures that the raw materials needed for paper production are sourced, processed, and transformed into the final product, which is then distributed to the end consumers.

Exploring the raw material sourcing process for offset paper

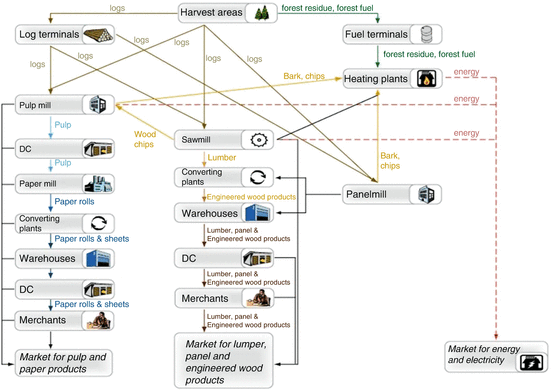

The raw material sourcing process for offset paper involves the careful selection and collection of materials that will be used to produce the paper. The primary raw material used in offset paper production is wood pulp, which can be sourced from different types of trees, such as hardwood and softwood. The process begins with the harvesting of trees, which are then cut into logs and transported to the paper mill for further processing.

At the paper mill, the logs are debarked, chipped, and placed into a digester, where they are cooked with chemicals and turned into pulp. This pulp is then refined, cleaned, and bleached to remove impurities and create a smooth and uniform texture. Once the pulp is ready, it is mixed with water and additives to form a papermaking slurry, which is then poured onto a wire mesh conveyor belt to remove excess water and form a continuous sheet of paper.

Understanding the production processes involved in manufacturing offset paper

The production processes involved in manufacturing offset paper are highly specialized and require advanced machinery and equipment. Once the papermaking slurry is formed, it goes through a series of processes to transform it into high-quality offset paper. These processes include pressing, drying, and finishing.

After the excess water is removed from the paper sheet, it goes through a pressing process to further remove moisture and enhance its smoothness and density. The paper is then dried using heated rollers or air dryers to reduce its moisture content to the desired level. Once the paper is dry, it goes through a finishing process, where it is calendered to improve its surface smoothness and brightness. The paper may also undergo coating processes to enhance its printing properties and produce different finishes, such as glossy or matte.

Key players in the offset paper supply chain

The offset paper supply chain involves various stakeholders who play a crucial role in ensuring the smooth operation and efficient distribution of offset paper. These key players include:

- Paper suppliers: These companies are responsible for sourcing and supplying the raw materials needed for paper production. They work closely with paper mills to ensure a steady supply of high-quality raw materials.

- Paper mills: Paper mills are the manufacturing facilities where the raw materials are processed and transformed into offset paper. They ensure that the production processes are carried out efficiently and that the paper meets the required standards.

- Printers: Printers are the end users of offset paper, using it for various printing applications. They rely on the offset paper supply chain to ensure a consistent and reliable supply of high-quality paper for their printing needs.

- Distributors: Distributors play a crucial role in the offset paper supply chain by transporting the paper from the mills to the printers. They help ensure that the paper is delivered in a timely manner and in the required quantities.

Sustainability practices in the offset paper industry

The offset paper industry is increasingly focused on sustainability practices to reduce its environmental impact and promote responsible sourcing and production. Many paper mills and suppliers have implemented sustainable forestry management practices, such as tree planting and conservation programs, to ensure a sustainable and renewable supply of raw materials.

Additionally, the industry is prioritizing energy-efficient production processes and reducing water consumption through the use of advanced technologies and recycling systems. Recycling programs for paper waste are also widely encouraged and supported to minimize waste and promote the reuse of paper fibers.

Moreover, certifications such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) are used to verify and promote the sustainability of offset paper products. These certifications ensure that the paper comes from responsibly managed forests and meets strict environmental and social standards.

In conclusion, the offset paper supply chain is a complex and interconnected system that involves various stages, from raw material sourcing to the distribution of the final product. Understanding and optimizing this supply chain is crucial for ensuring a consistent and reliable supply of high-quality offset paper for the printing industry. The industry is also increasingly adopting sustainability practices to reduce its environmental impact and promote responsible sourcing and production.

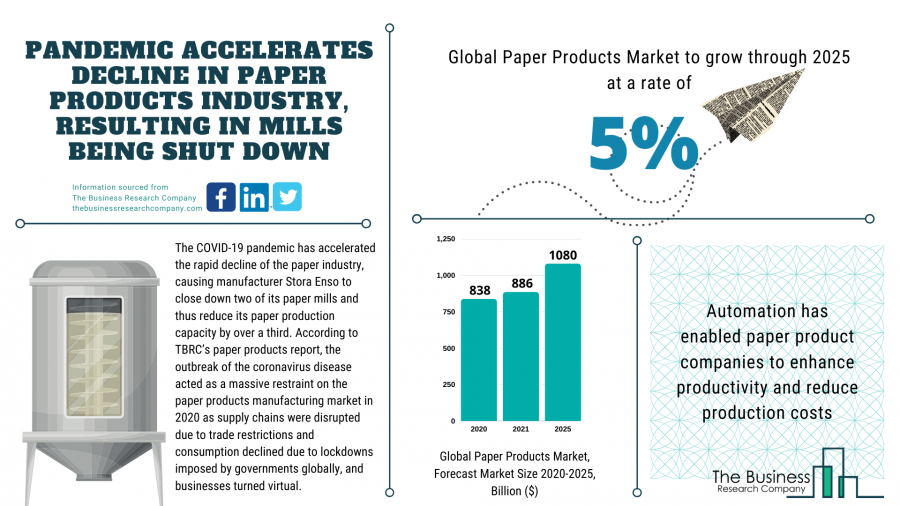

Challenges in the Offset Paper Supply Chain

Impact of Supply Chain Challenges on Offset Paper Prices

Supply chain challenges in the offset paper industry often result in increased prices for the end consumer. There are several factors contributing to the rise in offset paper prices, including USPS changes, shortages, high demand, and transportation costs.

The United States Postal Service (USPS) changes have had a significant impact on the paper supply chain. The USPS has implemented operational changes, including reduced hours and transportation delays, which have led to a disruption in the delivery of offset paper. This disruption has resulted in a decrease in the availability of offset paper and an increase in prices.

Shortages in the offset paper supply chain have also affected prices. The increased demand for offset paper, coupled with labor shortages in paper mills and transportation constraints, has led to a scarcity of paper in the market. This shortage has driven up prices as suppliers struggle to meet the demand.

Transportation costs have played a significant role in the increase in offset paper prices. The rising fuel costs and the shortage of truck drivers have resulted in higher shipping expenses, which are passed on to the consumer. These increased transportation costs contribute to the overall increase in offset paper prices.

Labor Shortages in the Paper and Printing Industries

Labor shortages have been a significant challenge in the paper and printing industries, affecting the entire offset paper supply chain. The paper and printing industries heavily rely on a skilled workforce to maintain production levels and meet customer demands. However, labor shortages have led to delays in production and disruptions in the supply chain.

Labor shortages in paper mills, ink manufacturers, and mail carriers have resulted in delays in the production and delivery of offset paper. These shortages stem from a variety of factors, including an aging workforce, a lack of skilled workers, and the impact of the COVID-19 pandemic.

The aging workforce in the paper and printing industries is a concern as experienced workers retire without an equal or greater number of skilled workers to replace them. This shortage of skilled workers has led to bottlenecks in the supply chain and increased turnaround times for orders.

The COVID-19 pandemic has also played a role in the labor shortages in the paper and printing industries. The pandemic resulted in shutdowns and restrictions that disrupted the production and distribution of offset paper. Additionally, the pandemic led to a decrease in the number of new workers entering the industry, exacerbating the labor shortage.

Strategies to Address Offset Paper Supply Chain Challenges

To address the challenges facing the offset paper supply chain, several strategies can be implemented. These strategies aim to mitigate the impact of supply chain disruptions and improve overall efficiency in the production and distribution of offset paper.

One strategy is forecasting and planning. By closely monitoring market trends and demand fluctuations, companies can better anticipate supply chain disruptions and adjust their production and distribution plans accordingly. This includes maintaining open communication with suppliers and customers to ensure timely delivery and manage expectations.

Another strategy is to leverage trade print partners like 4over. Trade print partners act as intermediaries between printers and suppliers, helping to manage the offset paper supply chain. They have established relationships with paper mills and can provide access to a reliable supply of offset paper. By partnering with trade print partners, printers can reduce the impact of supply chain challenges and ensure a steady supply of offset paper.

In addition, implementing sustainability practices in the offset paper industry can help mitigate supply chain challenges. Sustainable practices, such as responsibly sourcing raw materials and reducing waste in the production process, can help ensure the long-term availability of offset paper and minimize the environmental impact of paper production.

Forecasting and Planning in the Face of Supply Chain Disruptions

The offset paper supply chain is susceptible to various disruptions, including labor shortages, transportation issues, and demand fluctuations. To effectively manage these disruptions, forecasting and planning are crucial.

Forecasting involves predicting future demand for offset paper based on historical data and market trends. By accurately forecasting demand, companies can adjust their production and distribution plans to meet customer needs. This includes maintaining adequate inventory levels and ensuring timely delivery of offset paper.

Planning, on the other hand, involves developing strategies and contingency plans to mitigate the impact of supply chain disruptions. This includes establishing alternative sourcing options, identifying backup suppliers, and implementing efficient transportation and logistics protocols. Planning ahead allows companies to be proactive in addressing supply chain challenges and minimizing their impact.

Effective forecasting and planning require strong communication and collaboration between all stakeholders in the offset paper supply chain. This includes regular communication with suppliers, customers, and trade print partners to stay informed about market conditions, potential disruptions, and emerging trends. By fostering strong partnerships and open lines of communication, companies can better navigate the challenges of the offset paper supply chain.

The Role of Trade Print Partners like 4over in Offset Paper Supply Chain Management

Trade print partners like 4over play a crucial role in offset paper supply chain management. 4over is a wholesale trade printer in the US, providing various printing services, equipment, and fulfillment options. They have extensive experience in offset paper supply chain management, helping businesses navigate supply chain disruptions and ensure a reliable supply of offset paper.

By partnering with trade print partners like 4over, printers can gain access to a wide range of offset paper options and secure a consistent supply of paper. 4over has established relationships with paper mills and suppliers, allowing them to source offset paper efficiently and effectively. This partnership helps printers overcome the challenges of the offset paper supply chain and ensures that they can meet customer demands on time.

Additionally, trade print partners like 4over offer expertise and support in navigating the complexities of the offset paper supply chain. They can provide guidance on forecasting and planning, offering insights into market trends and demand fluctuations. This ensures that printers are well-prepared to address supply chain challenges and optimize their operations.

In conclusion, the offset paper supply chain faces various challenges that impact the overall efficiency and cost of production. From labor shortages to disruptions in the supply chain, these challenges require proactive strategies to address them. By implementing forecasting and planning, leveraging trade print partners, and embracing sustainability practices, companies can navigate the offset paper supply chain challenges and ensure a steady supply of high-quality offset paper.

Future Trends in the Offset Paper Supply Chain

The offset paper supply chain is constantly evolving and adapting to meet the changing needs of the printing industry. In this section, we will explore the future trends that are expected to shape the offset paper supply chain in the coming years. From predictions for the industry in 2023 to innovations in paper production and the impact of digital transformations, we will delve into the key factors that will drive the future of the offset paper supply chain.

Predictions for the Paper Supply Chain Industry in 2023

The paper supply chain industry is expected to undergo significant changes by 2023. Experts predict that the supply chain will stabilize by the end of 2022 or early 2023, addressing the challenges faced by the printing industry. These challenges include rising costs of major materials like ink, paper, and printing supplies, as well as labor shortages impacting paper mills and ink manufacturers.

To address these challenges, commercial printers are advised to communicate with customers, revamp their products and displays, prioritize forecasting, and leverage trade print partners like 4over. By fostering effective communication with customers, printers can manage expectations and find alternative solutions to mitigate the impact of supply chain disruptions. Revamping products and displays can help optimize the use of available materials and streamline operations. Prioritizing forecasting allows printers to anticipate and address potential challenges before they arise. Finally, partnering with trade print companies like 4over provides access to a wide range of printing services, equipment, and fulfillment options, enabling businesses to navigate supply chain interruptions more effectively.

Innovations and Advancements in Offset Paper Production

Innovation plays a crucial role in the evolution of the offset paper supply chain. Advancements in paper production technologies are continuously driving improvements in quality, efficiency, and sustainability. One notable innovation is the development of sustainable paper products made from recycled fibers or alternative materials. This helps reduce the environmental impact of offset paper production and meets the growing demand for eco-friendly options.

Additionally, advancements in coating technologies have led to improved printability and enhanced surface properties of the paper. This allows for better ink adhesion and color reproduction, resulting in high-quality prints. The use of advanced production and finishing techniques, such as precision cutting and embossing, further enhances the versatility and aesthetic appeal of offset paper products.

Impact of Digital Transformations on the Offset Paper Supply Chain

The digital revolution has significantly impacted the print industry and, consequently, the offset paper supply chain. As more businesses shift towards digital communications and advertising, the demand for traditional print materials has declined. However, this shift presents new opportunities for the offset paper supply chain. Digital production printing, which allows for shorter print runs and faster turnaround times, is gaining popularity as it bridges the gap between digital and offset printing. This trend is expected to continue, with commercial printers adapting their strategies to cater to the evolving needs of their clients.

To thrive in this digital landscape, commercial printers can position themselves as consultants to their clients. By offering value optimization, personalized solutions, and a holistic approach to print marketing, printers can establish themselves as trusted partners in their clients’ success. This not only ensures the longevity of the offset paper supply chain but also opens up new avenues for growth and profitability.

Best Practices for Commercial Printers to Navigate Supply Chain Challenges

Navigating supply chain challenges is essential for the success of commercial printers. Here are some best practices to help printers optimize their operations and mitigate the impact of supply chain disruptions:

| Best Practice | Description |

|---|---|

| Communication | Effective communication with customers is crucial in managing their expectations and finding alternative solutions. By keeping clients informed about potential delays, material availability, and pricing fluctuations, printers can maintain successful relationships and build trust. |

| Flexibility | Being flexible with paper choices, grades, finishes, and delivery options can help printers adapt to changing supply chain conditions. This includes exploring alternative sources and coordinating with suppliers to ensure timely deliveries. |

| Planning | Planning ahead and ordering in advance can help printers secure the necessary materials and avoid last-minute shortages. This involves monitoring industry trends, assessing demand forecasts, and collaborating with trade print partners and suppliers to stay ahead of potential challenges. |

| Diversification | Diversifying equipment and verticals can provide printers with alternative revenue streams and mitigate the impact of supply chain disruptions. By expanding their offerings and targeting new markets, printers can reduce their reliance on a single source of business. |

Strategies for Optimizing the Offset Paper Supply Chain for the Future

To optimize the offset paper supply chain for the future, it is crucial to adopt strategies that align with emerging trends and industry best practices. Here are some key strategies to consider:

- Embrace Sustainability: Implement sustainable practices throughout the supply chain, such as using recycled or alternative materials and adopting environmentally friendly production processes. This not only helps reduce the environmental footprint but also aligns with the growing demand for eco-friendly options.

- Invest in Technology: Embrace new technologies and automation to streamline operations, increase efficiency, and reduce costs. This includes leveraging digital printing solutions, investing in cutting-edge equipment, and integrating digital workflows to enhance productivity.

- Collaborate with Partners: Forge strategic partnerships with trade print partners, suppliers, and industry associations to leverage collective resources, knowledge, and expertise. Building strong relationships and collaborating with key stakeholders can help navigate supply chain challenges more effectively and drive mutual growth.

- Stay Ahead of Industry Trends: Continuously monitor and adapt to emerging trends in the offset paper supply chain. By staying informed about technological advancements, market demands, and industry regulations, printers can position themselves as leaders in the evolving landscape.

In conclusion, the offset paper supply chain is poised for transformation as it responds to the challenges and opportunities of the digital era. While supply chain disruptions pose temporary obstacles, the industry is expected to stabilize in the near future. By embracing sustainability, investing in technology, collaborating with partners, and staying ahead of industry trends, commercial printers can navigate the evolving landscape and optimize the offset paper supply chain for long-term success.

Tables

Table 1: Key Players in the Offset Paper Supply Chain

| Key Players | Description |

|---|---|

| Paper suppliers | Responsible for sourcing and supplying the raw materials needed for paper production. Work closely with paper mills to ensure a steady supply. |

| Paper mills | Manufacturing facilities where the raw materials are processed and transformed into offset paper. Ensure efficient production processes. |

| Printers | End users of offset paper, using it for various printing applications. Rely on the offset paper supply chain for a steady supply of paper. |

| Distributors | Transport the paper from mills to printers. Ensure timely delivery and required quantities. |

Table 2: Best Practices for Commercial Printers

| Best Practice | Description |

|---|---|

| Communication | Effective communication with customers to manage expectations and find alternative solutions. Keep clients informed about potential delays, material availability, and pricing fluctuations. |

| Flexibility | Being flexible with paper choices, grades, finishes, and delivery options to adapt to changing supply chain conditions. Explore alternative sources and coordinate with suppliers to ensure timely deliveries. |

| Planning | Plan ahead and order in advance to secure necessary materials and avoid last-minute shortages. Monitor industry trends, assess demand forecasts, and collaborate with trade print partners and suppliers for proactive management. |

| Diversification | Diversify equipment and verticals to provide alternative revenue streams and mitigate the impact of supply chain disruptions. Expand offerings and target new markets to reduce reliance on a single source of business. |

FAQs about Offset Paper Supply Chain:

What is the offset paper supply chain?

A: The offset paper supply chain encompasses the entire process involved in producing and distributing offset paper, ensuring high-quality printing capabilities for various applications.

How is raw material sourcing for offset paper done?

A: Raw material sourcing involves selecting and processing wood pulp to create the paper, from harvesting and cooking with chemicals to refining, cleaning, and bleaching.

What are the production processes in offset paper manufacturing?

A: The specialized production processes include pressing, drying, and finishing to create high-quality offset paper with smoothness, density, and surface enhancements.

Who are the key players in the offset paper supply chain?

A: Key players include paper suppliers, paper mills, printers, and distributors, each playing a crucial role in ensuring an efficient distribution of offset paper.

What sustainability practices are adopted in the offset paper industry?

A: Sustainability practices include responsible sourcing, energy-efficient production, water consumption reduction, recycling programs, and certifications promoting eco-friendly production.

In conclusion, the offset paper supply chain involves raw material sourcing, production processes, and key players. Supply chain challenges impact prices and require strategies for planning and forecasting. Sustainability practices are crucial. Future trends include innovations in production and digital transformations. As an expert, I recommend staying informed and adopting best practices to optimize the offset paper supply chain for the future.