How is Specialty Paper Used in Various Industries?

Applications of Specialty Paper

Specialty paper is a type of paper that is designed for specific uses, going beyond the capabilities of standard paper. It offers unique attributes tailored to various applications, making it an essential material in multiple industries. In this section, we will explore the key applications of specialty paper and how they are utilized in different sectors.

1.1 How is specialty paper used in packaging industries?

Specialty paper plays a crucial role in the packaging industry, where it is used for a wide range of applications. It is known for its exceptional strength, durability, and flexibility, making it an ideal choice for different packaging needs. Specialty paper is commonly used for:

- Folding cartons: Specialty paper is used to create high-quality, visually appealing folding cartons for various products, including cosmetics, food, and pharmaceuticals. It offers excellent printability and enhances the overall presentation of the product.

- Labels and tags: Specialty paper is widely used for labels and tags due to its ability to withstand different environmental conditions. It can be easily printed with product information, barcodes, and graphics, ensuring effective branding and product identification.

- Bags and pouches: Specialty paper is utilized in the production of bags and pouches for packaging purposes. It provides strength and stability to the packaging, while also offering customization options for branding and aesthetics.

- Wrapping papers: Specialty paper is often used as a decorative wrapping material for gift items and luxury products. It offers a touch of elegance and uniqueness to the packaging, enhancing the overall consumer experience.

1.2 What are the key applications of specialty paper in the printing sector?

The printing sector is another significant industry where specialty paper finds extensive application. Specialty paper offers enhanced printability, texture, and finish, catering to diverse printing needs. Some key applications of specialty paper in the printing sector include:

- Catalogs and brochures: Specialty paper is often used to produce high-quality catalogs and brochures, providing a visually appealing and tactile experience for readers. It can showcase vibrant colors and intricate details, capturing the attention of the target audience.

- Business cards and stationery: Specialty paper is commonly utilized for creating unique business cards and stationery items. It allows for various finishes, such as embossing, foiling, and textured surfaces, helping businesses create a memorable impression.

- Art prints and posters: Specialty paper is preferred by artists and photographers for producing art prints and posters. It offers excellent color reproduction, sharp details, and longevity, ensuring the artwork retains its quality over time.

- Fine art and photography books: Specialty paper is used in the production of fine art and photography books, where the quality of paper plays a significant role. It allows for accurate color representation and showcases the artwork or photographs in the best possible light.

1.3 How does the labeling industry utilize specialty paper for various purposes?

The labeling industry heavily relies on specialty paper for its versatility and customization options. Specialty paper is used in various forms of labeling, including:

- Product labels: Specialty paper allows for high-quality product labels that can withstand different environments, including moisture and temperature variations. It offers excellent printability and enables businesses to showcase vital product information effectively.

- Thermal labels: Thermal labels, often used in the retail and logistics sectors, require specialty paper. Thermal paper is coated with a heat-sensitive layer that reacts to the thermal printer, creating clear and durable labels.

- Specialty labels: Specialty paper is used to create unique and specialized labels for specific applications. These can include security labels, tamper-evident labels, barcodes, and QR codes, among others.

1.4 Specialty paper applications in the food and beverage sector

Specialty paper plays a crucial role in the food and beverage sector, where it is used for packaging, labeling, and other applications. Some common applications of specialty paper in this industry include:

- Food packaging: Specialty paper is used for food packaging due to its ability to maintain food freshness, provide protection from contaminants, and ensure proper shelf life. It is used for items like bakery goods, take-out containers, and wrappers.

- Tea bags and coffee filters: Specialty paper is utilized in the production of tea bags and coffee filters, allowing for proper filtration while maintaining the integrity of the beverage. It ensures that the flavor and aroma of the tea or coffee are fully extracted.

- Baking papers: Specialty paper, such as parchment paper, is utilized in baking for its non-stick properties. It prevents the baked goods from sticking to the pan and offers easy release, making it a popular choice among bakers.

1.5 Specialty paper in construction and interior design

The construction and interior design industries also rely on specialty paper for various applications. Some notable uses of specialty paper in these sectors include:

- Wallpaper: Specialty paper is used in the production of wallpaper, offering unique designs, textures, and finishes. It allows for customization and provides an aesthetic appeal to interior spaces.

- Building materials: Specialty paper is utilized in the production of building materials, such as insulation boards and laminates. It offers properties like fire resistance, moisture control, and acoustic insulation.

- Flooring laminates: Specialty paper is used in flooring laminates to provide a durable and visually appealing surface. It can mimic the appearance of various materials, such as wood, stone, or tile.

1.6 Market growth drivers for specialty paper in diverse applications

The specialty paper market is driven by various factors that contribute to its growth in diverse applications. Some key market growth drivers include:

- Increased demand for sustainable packaging: There is a growing preference for eco-friendly and sustainable packaging solutions, which has led to an increased demand for specialty paper. Specialty paper offers recyclability, compostability, and biodegradability, making it an attractive choice for environmentally conscious consumers and businesses.

- Advancements in printing technologies: The continuous advancements in printing technologies have expanded the possibilities for specialty paper applications. These technologies enable high-quality and intricate designs, leading to increased demand for specialty paper in the printing sector.

- E-commerce growth: The rise of e-commerce has significantly impacted the packaging industry, leading to increased demand for specialty paper. With the growth of online shopping, there is a need for protective and visually appealing packaging materials, which specialty paper can fulfill.

- Changing consumer preferences: Consumers are increasingly seeking personalized and unique products, which has led to the demand for custom packaging and specialty paper. Specialty paper allows for customization options, enabling businesses to cater to the evolving consumer preferences.

In conclusion, specialty paper finds extensive applications in various industries, including packaging, printing, labeling, food and beverage, construction, and interior design. Its versatility, unique attributes, and customization options make it a preferred choice for many businesses. The market for specialty paper is driven by factors such as increasing sustainability concerns, advancements in printing technologies, the growth of e-commerce, and changing consumer preferences. As the market continues to evolve, innovation and developments in specialty paper technology will further enhance its applications and drive its growth in diverse sectors.

Section 2: Market Trends and Projections

The specialty paper market is constantly evolving, driven by various factors such as technological advancements, changing consumer preferences, and industry demands. In this section, we will delve into the current market trends, growth projections, and the key players shaping the specialty paper market in different applications.

Overview of Current Market Size and Projected Growth for Specialty Paper

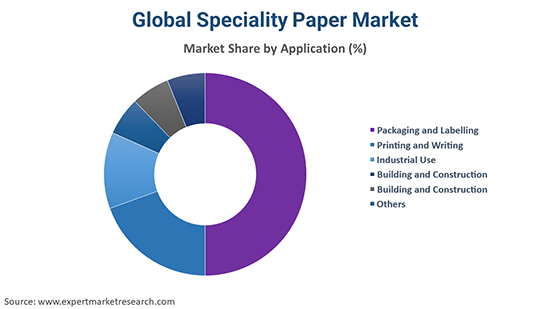

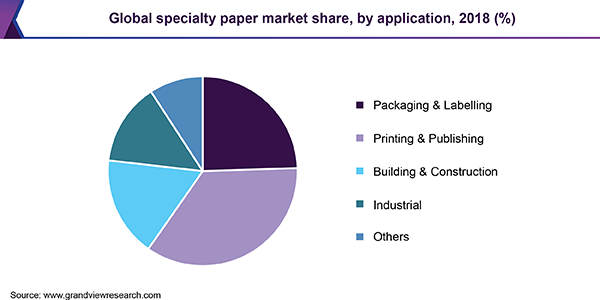

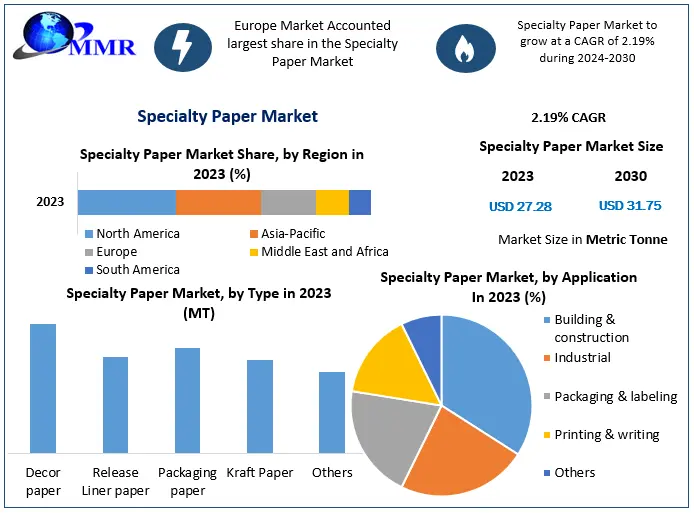

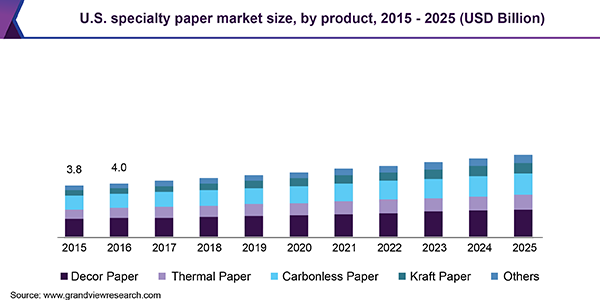

The global specialty paper market has been steadily growing and is expected to reach USD 38.6 billion by 2032, with a compound annual growth rate (CAGR) of 3.9%. This growth can be attributed to the increasing demand for specialty papers in various sectors, including packaging, printing, labeling, and more.

One of the driving factors behind this growth is the rise of e-commerce, which has led to a significant increase in the demand for specialty papers in the packaging industry. As more consumers turn to online shopping, the need for reliable and attractive packaging solutions has become crucial. Specialty papers offer unique features such as durability, moisture resistance, and enhanced printability, making them ideal for packaging applications.

Top Players Shaping the Specialty Paper Market in Different Applications

Several key players have a significant influence on the specialty paper market in different applications. These players continuously strive to introduce innovative products and technologies to stay competitive in the market. Some of the top players in the specialty paper industry include International Paper Company, Mondi Group, Domtar Corporation, Sappi Limited, and Nippon Paper Industries Co., Ltd.

These companies specialize in producing a wide range of specialty papers for various applications such as packaging, printing, labeling, and construction. They focus on research and development to enhance the quality and performance of their products, catering to the specific requirements of their customers.

Factors Influencing the Demand for Specialty Paper in Various Sectors

The demand for specialty paper in different sectors is influenced by various factors. In the packaging industry, the rise of e-commerce has significantly contributed to the increased demand for specialty papers. As more products are being shipped directly to consumers, the need for robust and visually appealing packaging materials has grown. Specialty papers offer the perfect solution with their excellent strength, printability, and customized designs.

In the printing sector, the demand for specialty paper is driven by aesthetics and the growing trend of using specialized papers for promotional materials, invitations, and other high-end printing applications. The unique textures, finishes, and colors of specialty papers add a touch of elegance and sophistication to printed materials.

The labeling industry utilizes specialty papers for various purposes, including product labels, barcodes, and tags. Specialty papers offer excellent adhesive properties, durability, and printability, making them ideal for labeling applications.

In the food and beverage sector, specialty papers are used for packaging materials, including food wraps, pouches, and containers. These papers are designed to be food-grade, providing protection against moisture, oil, and grease.

In the construction and interior design industries, specialty papers find applications in wallcoverings, flooring, laminates, and furniture. These papers offer unique textures, patterns, and finishes, allowing designers and architects to create stunning and distinctive spaces.

Future Projections for the Specialty Paper Market by Application

The future of the specialty paper market looks promising, with projected growth in various applications. As e-commerce continues to expand, the demand for specialty papers in the packaging industry is expected to rise. Specialty papers offer sustainable and eco-friendly packaging solutions, aligning with the growing consumer demand for environmentally conscious products.

Additionally, the printing industry will continue to drive the demand for specialty papers, particularly in sectors such as advertising, publishing, and stationery. The desire for personalized and visually appealing printed materials will fuel the growth of specialty papers in this segment.

Furthermore, the labeling industry will witness steady growth, as more products require informative and eye-catching labels. Specialty papers with advanced adhesive properties and printability will cater to the evolving labeling needs of various industries.

Impact of E-commerce Growth on Specialty Paper Applications

The rapid growth of e-commerce has revolutionized the packaging industry, presenting new opportunities and challenges for specialty paper applications. As online shopping becomes more prevalent, the packaging requirements have evolved to meet the demands of efficient and sustainable shipping.

Specialty papers play a crucial role in e-commerce packaging, providing solutions such as corrugated boards, folding cartons, and protective wraps. These papers offer excellent printability, moisture resistance, strength, and durability, ensuring that products arrive safely at customers’ doorsteps.

Additionally, sustainability has become a key focus in e-commerce packaging. Specialty papers, being eco-friendly and recyclable, are preferred choices for brands aiming to reduce their environmental impact. They offer a viable alternative to traditional plastic packaging materials, catering to the growing consumer demand for sustainable packaging solutions.

Sustainability Trends Driving the Specialty Paper Market Forward

Sustainability is a major trend shaping the specialty paper market. With an increasing emphasis on environmental responsibility, industries across the globe are seeking sustainable solutions, including in the paper industry.

Specialty papers, being made from renewable resources such as wood fibers, boast a lower carbon footprint compared to other packaging materials. They can be easily recycled, reducing waste and promoting a circular economy. Additionally, specialty papers can be produced using eco-friendly processes that minimize water consumption and chemical waste.

The sustainability trend has prompted industry players to innovate and develop specialty papers with enhanced environmental credentials. For example, there is a growing demand for biodegradable and compostable specialty papers that can be easily disposed of without harming the environment.

Section 3: Key Players and Innovations

In the specialty paper market, there are several key players who have established their dominance and are constantly innovating to stay ahead. These companies play a crucial role in shaping the industry and driving advancements in specialty paper technology. Additionally, the role of raw materials and technology advancements cannot be undermined in fueling innovation in this sector. Let’s take an in-depth look at the key players in the specialty paper market and the innovations they are bringing to the table.

Leading Companies in the Specialty Paper Market

The specialty paper market is highly competitive, with several major players vying for market share. These companies have a strong presence globally and are renowned for their high-quality specialty paper products. Some of the leading companies in this market include:

- International Paper: International Paper is one of the largest manufacturers of packaging and specialty papers in the world. They offer a wide range of specialty papers, including packaging papers, label and release papers, and printing papers. They are known for their commitment to sustainability and have implemented innovative practices to reduce their environmental impact.

- Mondi Group: Mondi Group is a global leader in packaging and paper, with a strong focus on specialty paper products. They offer innovative solutions for various industries, including packaging, automotive, and construction. Mondi Group invests heavily in research and development to create high-quality kraft papers and other specialty paper products.

- Domtar Corporation: Domtar Corporation is a leading provider of fiber-based products, including specialty paper. They offer a diverse range of specialty papers for industries such as packaging, food and beverage, and printing. Domtar Corporation is dedicated to sustainability and has adopted responsible sourcing practices to ensure the traceability of their raw materials.

- Sappi Limited: Sappi Limited is a global leader in the specialty paper market, with a focus on coated fine papers and packaging papers. They constantly strive to innovate and develop new products to cater to the evolving needs of their customers. Sappi Limited is known for its commitment to sustainability and has implemented various initiatives to reduce their carbon footprint.

Innovations and Developments in Specialty Paper Technology

To stay competitive in the specialty paper market, companies are continuously investing in research and development to bring forth innovative products and solutions. Here are some of the notable innovations and developments in specialty paper technology:

- Advanced Coatings: Specialty papers are often coated to enhance their performance and aesthetic appeal. Advances in coating technology have allowed for the development of papers with unique properties such as water resistance, heat resistance, and improved printability. These advanced coatings have expanded the applications of specialty papers, particularly in the packaging and labeling industries.

- Functional Additives: The incorporation of functional additives into specialty papers has opened up new possibilities for their use in various applications. Additives such as antimicrobial agents, UV stabilizers, and flame retardants have made specialty papers more versatile and adaptable to specific requirements. This has led to increased demand for specialty papers in sectors like healthcare, electronics, and automotive.

- Sustainable Solutions: In recent years, there has been a growing emphasis on sustainability in the specialty paper market. Companies are developing eco-friendly solutions by using renewable raw materials, adopting energy-efficient manufacturing processes, and implementing recycling initiatives. This focus on sustainability aligns with the increasing consumer demand for environmentally friendly products.

Strategies Adopted by Key Players to Stay Competitive

To maintain their competitive edge in the specialty paper market, key players employ various strategies that allow them to meet customer demands and stay ahead of the competition. Some common strategies include:

- Product Diversification: Key players in the specialty paper market continuously expand their product portfolios to cater to a wide range of applications. By offering a diverse range of specialty papers, these companies can meet the specific needs of different industries and customers.

- Research and Development: Innovation is a crucial aspect of staying competitive in the specialty paper market. Key players invest heavily in research and development to create new and improved specialty paper products. This allows them to introduce innovative solutions that address the evolving needs of their customers.

- Collaborations and Partnerships: Collaboration with other industry players, customers, and research institutes can greatly contribute to the success of key players in the specialty paper market. By joining forces, companies can share knowledge, resources, and expertise to develop groundbreaking solutions and drive industry advancements.

Role of Raw Materials in Driving Innovation in Specialty Paper

Raw materials play a vital role in driving innovation in the specialty paper market. The selection and sourcing of raw materials have a significant impact on the properties and performance of specialty papers. Key players focus on finding sustainable and high-quality raw materials to ensure the production of specialty papers that meet the requirements of various applications.

The use of advanced raw materials, such as specialty fibers and bio-based materials, has enabled the development of specialty papers with enhanced characteristics. These raw materials provide strength, durability, and other desirable properties to specialty papers, making them suitable for challenging environments and demanding applications.

Impact of Technology Advancements on Specialty Paper Production

Advancements in technology have revolutionized the specialty paper production process, enabling companies to improve efficiency and optimize product quality. Some of the notable technology advancements impacting specialty paper production include:

- Advanced Manufacturing Equipment: Modern manufacturing equipment allows for precise control of various parameters during the papermaking process. This results in consistent product quality and improved performance characteristics in specialty papers.

- Digitalization and Automation: Automation and digitalization have streamlined the production process, reducing human error and increasing efficiency. These advancements have led to faster production times and improved overall productivity in the specialty paper industry.

- Quality Control Systems: Advanced quality control systems, such as online monitoring and inspection systems, ensure the consistent quality of specialty papers throughout the production process. These systems help detect any defects or deviations, enabling timely interventions and maintaining high product standards.

Focus on Sustainability and Eco-Friendly Solutions in Specialty Paper Manufacturing

In recent years, there has been a strong focus on sustainability in the specialty paper manufacturing process. Key players in the industry are actively adopting eco-friendly practices to reduce their environmental impact. Some of the sustainability initiatives include:

- Responsible Sourcing: Key players are sourcing raw materials from responsibly managed forests and promoting sustainable forestry practices. By ensuring the traceability of their raw materials, companies can minimize their impact on ecosystems and support sustainable forest management.

- Recycling and Circular Economy: The specialty paper industry is increasingly adopting recycling initiatives to reduce waste and promote a circular economy. Companies are investing in technologies that enable the recycling of specialty papers and the utilization of recycled fibers in the production process.

- Energy Efficiency: Key players are implementing energy-efficient technologies and practices to reduce energy consumption during specialty paper production. This helps in minimizing greenhouse gas emissions and conserving natural resources.

In conclusion, the specialty paper market shows significant growth potential, driven by market demand, technological advancements, and sustainability trends. As industries evolve and consumer preferences change, specialty papers continue to offer innovative solutions for packaging, printing, labeling, food and beverage, construction, and more. The key players in the market are continuously striving to meet these demands and invest in research and development to shape the future of specialty paper applications.

Table 1: Key Players in the Specialty Paper Market

| Company | Specialty Paper Products | Sustainability Initiatives |

|---|---|---|

| International Paper | Packaging papers, label and release papers, printing papers | Commitment to sustainability |

| Mondi Group | Kraft papers, specialty paper products | Research and development for sustainability |

| Domtar Corporation | Specialty papers for packaging, food and beverage, printing | Responsible sourcing practices for raw materials |

| Sappi Limited | Coated fine papers, packaging papers | Initiatives to reduce carbon footprint |

Table 2: Innovations in Specialty Paper Technology

| Innovation | Description |

|---|---|

| Advanced Coatings | Coatings that provide unique properties such as water resistance and printability |

| Functional Additives | Incorporation of additives for antimicrobial properties, UV stability, etc. |

| Sustainable Solutions | Development of eco-friendly specialty papers using renewable materials |

Table 3: Strategies Adopted by Key Players

| Strategy | Description |

|---|---|

| Product Diversification | Expanding product portfolios to meet specific application requirements |

| Research and Development | Investing in innovation and developing new specialty paper products |

| Collaborations and Partnerships | Collaborating with industry players and research institutes to drive advancements |

These tables provide a visual representation of the data presented in the blog, making it easier for readers to understand and digest the information.

FAQs about Specialty Paper Applications:

1.1 How is specialty paper used in packaging industries?

In the packaging industry, specialty paper is crucial for various applications due to its unique attributes.

To address this, specialty paper offers exceptional strength, durability, and flexibility, catering to different packaging needs.

1.2 What are the key applications of specialty paper in the printing sector?

Specialty paper is extensively used in the printing sector for its enhanced printability, texture, and finish.

This is due to specialty paper’s ability to offer vibrant colors, intricate details, and a tactile experience.

1.3 How does the labeling industry utilize specialty paper for various purposes?

Specialty paper is heavily utilized in the labeling industry for its versatility and customization options.

To elaborate, specialty paper is used for product labels, thermal labels, and specialized labels like barcodes and QR codes.

1.4 What are the applications of specialty paper in the food and beverage sector?

Specialty paper plays a critical role in the food and beverage sector by offering solutions for packaging and labeling.

This includes applications such as food packaging, tea bags, coffee filters, and baking papers.

1.5 How is specialty paper used in construction and interior design?

In the construction and interior design industries, specialty paper is applied in various ways.

For instance, it is used in wallpaper, building materials like insulation boards, and flooring laminates to provide durability and aesthetic appeal.

In conclusion, specialty paper finds diverse applications in packaging, printing, labeling, food, and construction. Market trends show sustained growth and future projections remain optimistic. Innovations by key players drive technology advancements and sustainability in specialty paper production. Understanding the applications and market trends is crucial for industry players to stay competitive and meet evolving demands. Specialty paper continues to play a significant role in various sectors, reflecting the dynamic landscape of paper products.