Offset Paper Product Development: How is it Done?

Offset Paper Product Development

The Process of Developing Offset Paper Products

In this section, we will explore the key steps involved in developing offset paper products, including how plant fibers are treated to prepare materials for offset paper production, and the different manufacturing techniques used in offset paper product development.

What are the key steps involved in developing offset paper products?

Developing offset paper products involves several key steps, including material preparation, pulp cooking, pulp screening, pulp washing, papermaking, and offset printing. Let’s dive deeper into each step:

- Material Preparation: To prepare materials for offset paper production, plant fibers need to be treated. This process involves removing bark, knots, and other impurities from the fibers. The fibers are then cut into specific sizes to meet production requirements. Clean chips should be 3-8mm thick, 10-15mm wide, and 25mm long for efficient pulp cooking and high-quality paper.

- Pulp Cooking: The pulp cooking process is crucial in offset paper product development. Controlling the cooking temperature is essential, especially for softwood with 30% lignin. Additionally, the ash content should be between 0.3% to 0.5%. The selection of pulp digester equipment is also important. Vertical pulp digester offers high capacity, productivity, and occupies less area compared to a rotary digester. The process involves steam blowing and heat recovery using a heat exchanger to improve pulp strength and reduce steam consumption.

- Pulp Screening: After the pulp cooking process, the fibers are screened to remove impurities. Roughing and preliminary screening equipment are used based on factors like bore diameter, pulp concentration, and pressure difference. The screening process helps to achieve a consistent quality pulp.

- Pulp Washing: After screening, the pulp goes through a washing process to remove any remaining impurities. Different types of pulp washing equipment are used, such as dilution dehydration, displacement washing, and combined functions, to improve washing efficiency.

- Papermaking: Once the pulp is prepared, the papermaking process begins. Offset paper is woodfree and is typically made from softwood and hardwood wood pulp after removing lignin. It has ISO brightness over 80%, grammage ranging from 40-300 gsm, and high sizing for moisture resistance. Offset paper is available in coated (for durability and brightness) and uncoated (for easier ink absorption) varieties.

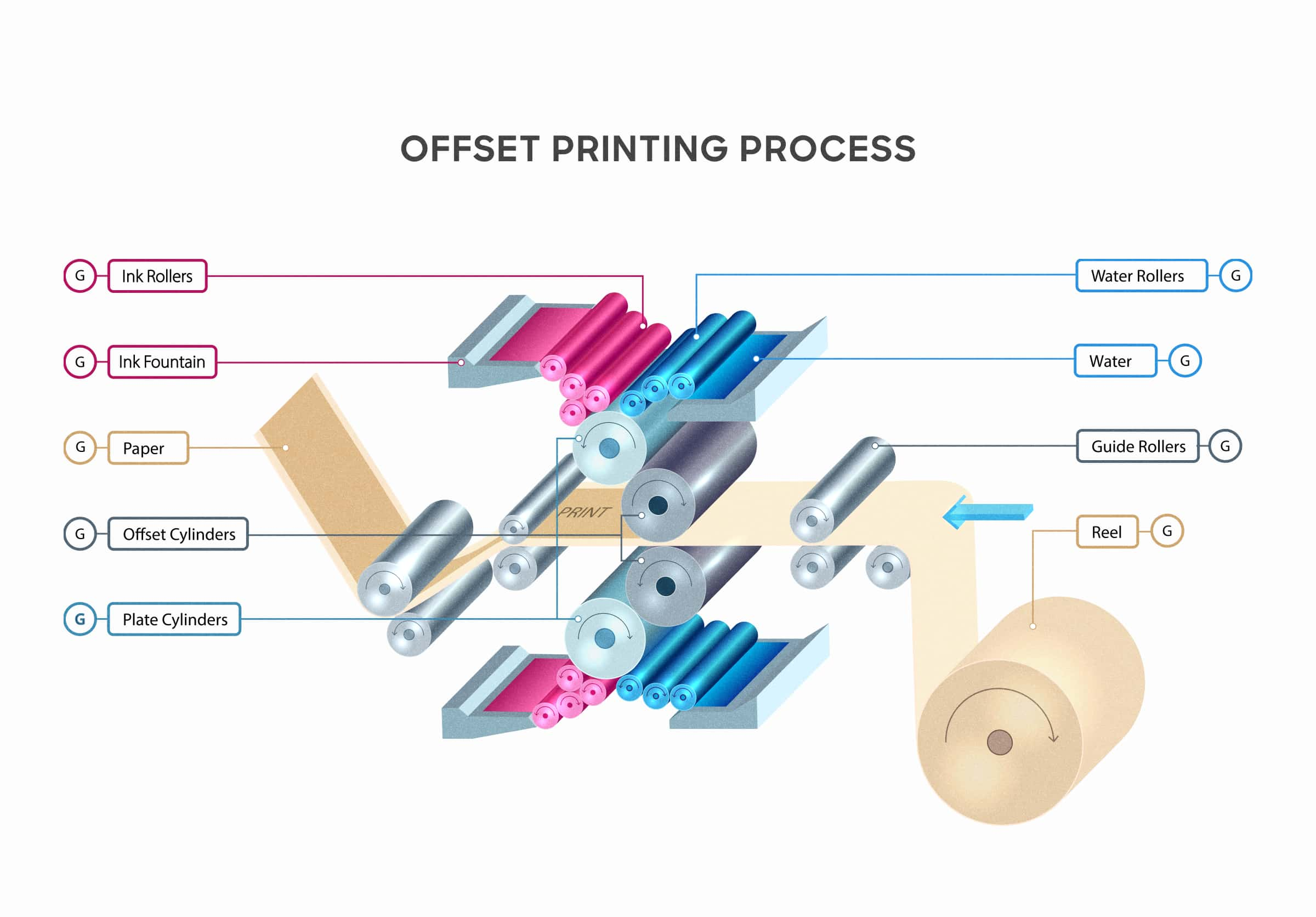

- Offset Printing: After the papermaking process, the offset paper is ready for printing. Offset printing is a widely used technique that transfers ink from a plate to paper via a rubber cylinder. It produces high-quality results suitable for various surfaces. Offset printing uses metal plates with real inks for image transfer onto a rubber roller and then onto the paper. It is efficient and cost-effective for mass production with high-quality results.

How are plant fibers treated to prepare materials for offset paper production?

To prepare plant fibers for offset paper production, they undergo a series of treatments to remove impurities and achieve the desired quality. The process includes the following steps:

- Removal of Bark and Knots: Plant fibers, such as wood chips, are subjected to a debarking process to remove the outer layer of bark. This helps to eliminate impurities and improve the quality of the final product. Knots, which are areas where branches once grew, are also removed to ensure uniformity in the fibers.

- Cutting and Chipping: After debarking, the plant fibers are cut and chipped into specific sizes to meet the requirements of offset paper production. The chips should have a certain thickness, width, and length for efficient pulp cooking and high-quality paper.

- Cleaning and Screening: The plant fibers are then cleaned to remove any remaining impurities, such as dirt and foreign materials. This is typically done through a screening process that separates the clean fibers from the unwanted particles.

- Chemical Treatment (Optional): Depending on the desired properties of the offset paper, such as brightness and durability, the fibers may undergo chemical treatments. These treatments can include bleaching or adding additives to enhance specific characteristics of the paper.

What are the different manufacturing techniques used in offset paper product development?

Offset paper product development involves various manufacturing techniques to achieve the desired quality and characteristics of the final product. Here are some of the commonly used techniques:

- Pulp Cooking: Pulp cooking is a crucial step in offset paper product development. The process involves cooking the plant fibers, usually wood chips, using heat and chemicals to break down the lignin and separate the cellulose fibers. The cooking temperature and the choice of cooking chemicals vary depending on the type of wood and the desired properties of the paper.

- Pulp Screening: After the pulp cooking process, the fibers are screened to remove any remaining impurities. Screening equipment is used to separate the fibers from the larger particles, ensuring a consistent pulp quality.

- Pulp Washing: The screened pulp goes through a washing process to remove the chemicals and impurities. This helps to improve the purity and cleanliness of the pulp, resulting in higher-quality offset paper.

- Papermaking: Once the pulp is prepared, it is mixed with water and additives to form a slurry. The slurry is then spread onto a wire mesh conveyor belt, where the water is drained and the fibers begin to bond together. The paper is then dried, pressed, and rolled onto large rolls for further processing.

- Coating (Optional): In some cases, offset paper may undergo a coating process to enhance its surface characteristics, such as gloss, smoothness, and ink absorption. Coating materials, such as clay or latex, are applied to the surface of the paper to achieve the desired properties.

By following these manufacturing techniques, offset paper manufacturers can produce high-quality products that meet the specific requirements of the printing industry.

In the next section, we will explore the current market trends and innovations in offset paper product development. Stay tuned!

Market Trends and Innovations in Offset Paper Product Development

The offset paper product industry is constantly evolving to meet the changing needs of consumers and adapt to emerging trends. In this section, we will explore the current market trends in offset paper product development, the influence of sustainable practices, and potential future innovations in offset paper production.

Current Market Trends

- Digital Transformation: With the rise of digital media, the demand for traditional printed materials has declined. However, offset printing still holds a significant market share due to its high-quality results and cost-effectiveness for large volume production.

- Customization and Personalization: As consumers seek unique and personalized products, there is a growing trend in the offset paper product industry towards customization. This includes personalized packaging, stationery, and promotional materials.

- Eco-Friendly Materials and Practices: In response to increasing environmental concerns, there is a rising demand for eco-friendly offset paper products. This includes the use of recycled paper, sustainable sourcing of raw materials, and implementing environmentally-friendly production processes.

- High-Quality Finishes: Customers are looking for offset paper products with visually appealing finishes, such as matte, gloss, or satin coatings. These finishes enhance the aesthetics and durability of printed materials, making them more attractive to customers.

- Digital Integration: Offset paper product manufacturers are incorporating digital technology into their processes to streamline workflows and improve efficiency. This includes the use of digital printing equipment, online ordering systems, and digital asset management platforms.

Sustainable Practices in Offset Paper Product Development

The offset paper product industry is increasingly focused on adopting sustainable practices to reduce its impact on the environment. Here are some ways in which sustainable practices are influencing offset paper product development:

1. Sustainable Sourcing: Paper manufacturers are sourcing raw materials from responsibly managed forests, ensuring a sustainable supply chain. This helps protect biodiversity, conserve water resources, and reduce deforestation.

2. Recycled Paper: Many offset paper products are now made from recycled paper, reducing the demand for virgin fibers and minimizing waste. Using recycled paper in offset printing can save up to 50% of water compared to traditional pulp paper production methods.

3. Water and Energy Conservation: Paper mills are adopting technologies and processes that minimize water and energy consumption. For example, the Asia Symbol paper mill utilizes 100% recycled water in its production processes, reducing water consumption by 30%. Sustainable paper production significantly reduces carbon dioxide emissions, with the Asia Symbol mill achieving a 35% decrease.

4. Forest Stewardship Council (FSC) Certification: FSC certification ensures that paper products come from responsibly managed forests, promoting environmental conservation. Offset paper products with FSC certification are preferred by environmentally conscious consumers.

5. Waste Reduction and Recycling: Offset paper product manufacturers are implementing waste reduction and recycling initiatives. This includes recycling paper trimmings, using eco-friendly inks and coatings, and promoting the responsible disposal of printed materials.

Future Innovations in Offset Paper Production

The offset paper product industry is continuously exploring new innovations to improve efficiency, sustainability, and product quality. Here are some potential future innovations we can expect:

- Advanced Coating Technologies: Research and development efforts are focused on developing new coating technologies that enhance the performance and appearance of offset paper products. This includes anti-static coatings, antimicrobial coatings, and coatings that improve ink absorbency.

- Digital Integration with Offset Printing: The integration of digital technology with offset printing is a growing trend in the industry. Digital printing presses are being combined with offset presses to offer hybrid printing solutions that combine the cost-effectiveness and quality of offset printing with the personalization and variable data capabilities of digital printing.

- Automation and Robotics: The adoption of automation and robotics in the offset paper product industry can streamline production processes and improve efficiency. Automated paper handling, robotic stacking, and computerized quality control systems are some examples of how automation is being implemented.

- Smart Packaging: The development of smart packaging solutions is an area of innovation in the offset paper product industry. This includes incorporating NFC (Near Field Communication) technology, QR codes, or RFID (Radio Frequency Identification) tags into packaging to enable interactive experiences, product tracking, and authentication.

- Digital Workflow Optimization: The optimization of digital workflows is an ongoing area of innovation in offset paper product development. This includes the integration of digital prepress systems, cloud-based collaboration platforms, and automated color management solutions to streamline the production process and improve efficiency.

In conclusion, the offset paper product industry is adapting to changing market trends, incorporating sustainable practices, and embracing new innovations. As consumer preferences evolve, manufacturers are focusing on customization, eco-friendly materials, and high-quality finishes. The adoption of sustainable practices is driving the development of offset paper products that have a reduced impact on the environment. Looking ahead, we can expect further innovations in coating technologies, digital integration, automation, smart packaging, and workflow optimization in the offset paper product industry.

Challenges and Opportunities in Offset Paper Product Development

Offset paper product development comes with its own set of challenges and opportunities. In this section, we will explore the challenges faced in offset paper product development, discuss ways companies can overcome environmental challenges in offset paper production, and highlight the opportunities that exist for growth and advancement in the offset paper product industry.

1. Challenges Faced in Offset Paper Product Development

Developing offset paper products involves several challenges that need to be addressed to ensure high-quality and sustainable production. Some of the main challenges include:

1.1. Raw Material Preparation:

- Treating plant fibers: Offset paper production requires the careful treatment of plant fibers, including the removal of bark, knots, and other impurities. This process ensures the fibers are clean and suitable for papermaking.

- Fiber size requirements: Clean chips used for offset paper pulp making should have specific dimensions, such as being 3-8mm thick, 10-15mm wide, and 25mm long. Adhering to these dimensions ensures efficient pulp cooking and high-quality paper production.

1.2. Pulp Cooking Process:

- Cooking temperature control: Properly controlling the cooking temperature is crucial, especially for softwood with a high lignin content. Maintaining the right temperature range helps achieve the desired pulp quality and reduces the ash content.

- Selection of pulp digester equipment: The choice of pulp digester equipment plays a significant role in offset paper production. Opting for the right equipment, such as a vertical pulp digester, ensures high capacity, productivity, and efficient space utilization.

1.3. Kraft Pulp Processing:

- Specific processing factors: Kraft pulp processing for offset papermaking involves considering various factors, such as sizes, alkaline consumption, sulfidity, liquor ratio, and temperature. Accommodating these factors ensures the production of high-quality offset paper.

1.4. Pulp Screening and Washing:

- Pulp screening equipment: Roughing and preliminary screening equipment are essential for the pulp screening process. The choice of equipment should be based on factors like bore diameter, pulp concentration, and pressure difference.

- Pulp washing efficiency: Efficient washing of the pulp is crucial for offset paper production. Various washing technologies, including dilution dehydration, displacement washing, and combined functions, can be employed to achieve optimum washing efficiency.

1.5. Paper Quality:

- Offset paper specifications: Offset paper is wood-free and used in offset lithography for various printing needs. It typically has ISO brightness over 80%, a grammage range of 40-300 gsm, and high sizing for moisture resistance.

- Coated and uncoated varieties: Offset paper is available in both coated and uncoated varieties. Coated paper offers durability and high brightness, while uncoated paper provides better ink absorption.

2. Overcoming Environmental Challenges in Offset Paper Production

In recent years, there has been a growing emphasis on sustainable practices in the paper industry. To overcome environmental challenges in offset paper production, companies need to adopt environmentally friendly methods and technologies. Here are some ways to address these challenges:

2.1. Sustainable Forest Management:

- Using responsibly sourced materials: Companies can ensure that the wood used in offset paper production comes from responsibly managed forests. Forest Stewardship Council (FSC) certification is one way to ensure sustainable sourcing practices.

- Protecting endangered species: Sustainable forest management practices help protect endangered species by preserving their habitats. For example, the Sumatran tiger population benefits from sustainable practices in forest management.

2.2. Water Conservation:

- Recycled water usage: Paper mills can reduce water consumption by utilizing recycled water in their production processes. For instance, the Asia Symbol paper mill has achieved a 30% reduction in water consumption by utilizing 100% recycled water.

- Environmental impact reduction: Recycling paper significantly reduces water consumption compared to traditional pulp paper production methods. Adopting such practices can help offset paper production reduce its environmental impact.

2.3. Carbon Footprint Reduction:

- Decreasing carbon dioxide emissions: Sustainable paper production practices can significantly reduce carbon dioxide emissions. For example, the Asia Symbol mill has achieved a 35% decrease in carbon dioxide emissions.

- Energy-efficient technologies: Adopting energy-efficient technologies and optimizing production processes can contribute to a reduced carbon footprint in offset paper production.

3. Opportunities for Growth and Advancement in the Offset Paper Product Industry

Despite the challenges, several opportunities exist for companies involved in offset paper product development. These opportunities can lead to growth and advancement in the industry. Some of the key opportunities include:

3.1. Research and Collaboration:

- Leveraging industry expertise: Companies can invest in experienced product development and research staff with industry experience. Their expertise can drive innovation and help overcome challenges.

- Collaboration with research institutions: Partnering with research and educational institutions opens doors for valuable collaborations, which can lead to breakthroughs in offset paper product development.

3.2. Technological Advancements:

- Access to advanced facilities: Having access to advanced analytical facilities enables companies to conduct in-depth research and development, fostering technological advancements.

- Improved coating capabilities: On-machine coating technologies, such as blade, rod, and metering coating, and off-machine coating capabilities, allow for enhanced product quality and customization.

3.3. Printing Advancements:

- Offset printing advancements: Advancements in offset printing technology continue to drive growth in the offset paper product industry. This traditional printing technique offers high-quality results and is suitable for various printing surfaces.

- Diverse printing applications: Offset paper finds applications in books, magazines, brochures, and catalogs. The versatility of offset paper opens up opportunities for companies to cater to different printing needs.

3.4. Sustainable Demand:

- Growing demand for sustainable materials: There is an increasing demand for sustainable products across various industries. Offset paper, with its eco-friendly properties, is well-positioned to meet this demand.

- Consumer preference for eco-friendly options: Consumers are becoming more conscious of their environmental impact. Offering offset paper products can help companies align with consumer preferences and increase market share.

In conclusion, offset paper product development comes with its own set of challenges and opportunities. Overcoming environmental challenges, adopting sustainable practices, and leveraging technological advancements are key factors that can drive growth and advancement in the offset paper product industry. By addressing these challenges and capitalizing on the opportunities, companies can position themselves for success in this dynamic market.

FAQs about Offset Paper Product Development:

How are plant fibers treated to prepare materials for offset paper production?

To prepare plant fibers for offset paper production, they undergo treatments like the removal of bark and knots, cutting into specific sizes, cleaning, and sometimes chemical treatments to enhance desired characteristics.

What are the key steps involved in developing offset paper products?

Developing offset paper products entails material preparation, pulp cooking, pulp screening, pulp washing, papermaking, and offset printing, each step contributing to the quality and characteristics of the final product.

What are the different manufacturing techniques used in offset paper product development?

Manufacturing techniques include pulp cooking, screening, washing, and papermaking processes, followed by optional coating for enhanced properties like gloss and smoothness, all aimed at crafting high-quality offset paper products.

How can companies overcome environmental challenges in offset paper production?

Companies can adopt sustainable practices like responsibly sourced materials, water conservation through recycled water usage, carbon footprint reduction, and FSC certification to address environmental challenges in offset paper production.

In conclusion, we explored the process, market trends, and challenges of offset paper products. Sustainable practices are shaping the industry, while innovation holds promise for the future. Overcoming environmental challenges and seizing growth opportunities are key for success in this field. Offset paper product development entails crucial steps and diverse manufacturing techniques. Keeping pace with market trends and embracing innovation will drive the industry forward. Embracing change and focusing on sustainability will be vital for navigating the evolving landscape of offset paper product development.