How are sustainability practices transforming pulp and paper technology?

Pulp and Paper Technology Innovations

The pulp and paper industry has come a long way since its inception, and with advancements in technology, it continues to evolve. In this section, we will explore the latest innovations in pulp and paper technology, the role of automation and data analytics in transforming the industry, as well as the importance of sustainability practices.

Latest Advancements in Pulp and Paper Technology

The pulp and paper industry is experiencing significant advancements in technology, which are revolutionizing the production process. One such advancement is the integration of artificial intelligence (AI) and machine learning algorithms into various aspects of pulp and paper manufacturing. These technologies help optimize production parameters, improve product quality, and increase overall process efficiency.

One notable advancement is the use of AI-powered predictive maintenance systems. These systems analyze data collected from various sensors installed in machines to predict and prevent equipment failures. By detecting potential issues in advance, maintenance activities can be scheduled proactively, reducing downtime and production losses.

Another significant advancement is the development of digital twins. A digital twin is a virtual replica of a physical machine or process that allows for real-time monitoring, analysis, and optimization. By creating a digital twin of a paper machine, for example, operators can simulate different operating conditions and identify the most efficient settings for maximum productivity and energy efficiency.

Automation and Data Analytics in the Pulp and Paper Industry

Automation and data analytics play a crucial role in transforming the pulp and paper industry. Automation enables manufacturers to streamline processes, increase productivity, and reduce labor costs. Automated systems can perform repetitive tasks with precision and accuracy, minimizing the risk of human error. Additionally, automation improves workplace safety by eliminating the need for workers to engage in potentially hazardous activities.

Data analytics, on the other hand, allows manufacturers to gain valuable insights from the vast amount of data generated during the production process. By analyzing this data, companies can identify trends, patterns, and anomalies, leading to process optimization and improved product quality. For example, data analytics can help identify the root causes of quality issues, allowing manufacturers to take corrective actions promptly.

Furthermore, data analytics can aid in supply chain management, inventory optimization, and demand forecasting. By analyzing historical data and customer preferences, manufacturers can make informed decisions about production volumes, inventory levels, and product specifications.

Sustainability Practices in Modern Pulp and Paper Technology

Sustainability is a critical consideration in modern pulp and paper technology. The industry is focusing on optimizing waste management practices and reducing its environmental impact. One approach is to implement circular economy principles, which aim to minimize waste generation and maximize resource use.

To optimize waste management, companies are investing in advanced technologies for recycling and repurposing waste materials. By implementing efficient de-inking processes and magazine upcycling services, the industry aims to reduce paper waste and maximize the utilization of valuable resources.

Another sustainable practice in the pulp and paper industry is the use of alternative fibers. Traditional paper production relies heavily on wood pulp, which contributes to deforestation. However, by using alternative fibers like bamboo and hemp, manufacturers can reduce their reliance on wood pulp and promote more sustainable practices. These fibers are known for their fast growth rates, high yield, and low environmental impact.

The industry is also exploring innovative production processes that minimize water consumption, energy usage, and emissions. Technologies like smart sensors, advanced control systems, and energy-efficient equipment are being implemented to achieve greater resource efficiency.

In conclusion, the pulp and paper industry is continuously evolving with the help of technological advancements. Automation and data analytics are transforming the way paper is produced, leading to increased efficiency and productivity. Moreover, sustainability practices are becoming a top priority, with a focus on waste management optimization and the use of alternative fibers. By embracing these innovations and practices, the pulp and paper industry is poised to create a more sustainable and environmentally friendly future.

Sustainable Practices in Pulp and Paper Industry

Sustainable practices in the pulp and paper industry are increasingly becoming a priority as companies recognize the need to minimize their environmental impact and contribute to a greener future. In this section, we will explore the steps being taken to optimize waste management in the industry, the role of alternative fibers like bamboo and hemp in sustainability, and the latest developments in eco-friendly paper manufacturing processes.

Optimizing Waste Management in the Pulp and Paper Industry

The pulp and paper industry traditionally produces a significant amount of waste during its manufacturing processes. However, companies are now implementing various strategies to optimize waste management and minimize their ecological footprint.

One of the key efforts in waste management is the implementation of the circular economy approach. This approach focuses on reducing waste generation by reusing and recycling materials within the production process. By adopting this approach, companies can minimize the amount of waste sent to landfills and significantly reduce their environmental impact.

Additionally, many companies in the pulp and paper industry are investing in advanced technologies to enhance waste management practices. For instance, innovative de-inking processes have been developed to improve the recycling of paper products. These processes involve removing ink and contaminants from used paper, allowing it to be reprocessed into new paper products.

Furthermore, magazine upcycling services have emerged as a sustainable solution in waste management. These services collect and process discarded magazines, transforming them into high-quality recycled paper products. By promoting the recycling and upcycling of waste materials, companies in the pulp and paper industry are taking significant steps towards achieving a more sustainable future.

The Role of Alternative Fibers in Sustainability

Alternative fibers, such as bamboo and hemp, have gained significant attention in the pulp and paper industry due to their sustainability benefits. These fibers offer several advantages over traditional wood pulp, making them an attractive choice for eco-friendly paper production.

Bamboo, for example, is a fast-growing plant that requires minimal water and pesticides to cultivate. Its rapid growth rate allows for more frequent harvesting, making it an abundant and renewable resource. Bamboo fibers also have excellent strength properties, contributing to the production of high-quality paper products.

Hemp, on the other hand, is known for its versatility and sustainability. Hemp fibers are derived from the stalk of the hemp plant, which can be cultivated without the need for herbicides and pesticides. Hemp paper is known for its superior durability and longevity, making it an ideal choice for a variety of applications.

By incorporating alternative fibers like bamboo and hemp into paper production, companies can reduce their reliance on traditional wood pulp and promote more sustainable practices. These fibers offer a viable alternative that meets the growing demand for eco-friendly and responsibly sourced paper products.

Latest Developments in Eco-Friendly Paper Manufacturing Processes

In recent years, significant advancements have been made in eco-friendly paper manufacturing processes. Companies are constantly developing and implementing new technologies to reduce energy consumption, minimize water usage, and decrease emissions.

One such development is the use of advanced sensors and data analytics in paper manufacturing. These technologies allow for real-time monitoring and optimization of production processes, resulting in increased efficiency and reduced waste. By analyzing data, companies can identify areas for improvement and implement targeted strategies to enhance sustainability.

Another emerging trend in eco-friendly paper manufacturing is the use of non-fiber materials like polypropylene. These materials enhance the durability and moisture resistance of paper products, reducing the need for additional chemical treatments. This not only contributes to sustainability but also improves the longevity and performance of paper.

Furthermore, there is a growing focus on renewable energy sources in the paper manufacturing process. Companies are increasingly investing in technologies like biomass boilers and solar panels to generate clean, renewable energy for their operations. By reducing reliance on fossil fuels, these technologies contribute to a more sustainable and environmentally friendly production process.

In conclusion, the pulp and paper industry is actively embracing sustainable practices through optimized waste management, the use of alternative fibers, and the implementation of eco-friendly manufacturing processes. By prioritizing sustainability, companies in this industry are not only reducing their environmental impact but also meeting the growing demand for eco-friendly paper products. Through ongoing research and development, we can expect to see further advancements in the future, leading to a more sustainable and responsible pulp and paper industry.

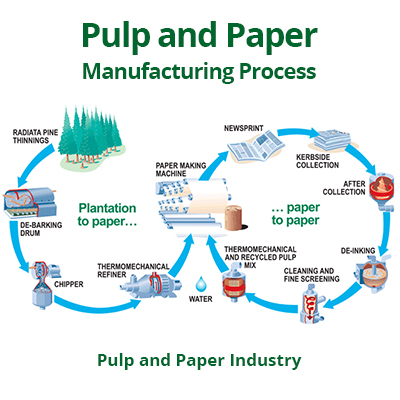

Pulp and Paper Machinery and Manufacturing Process

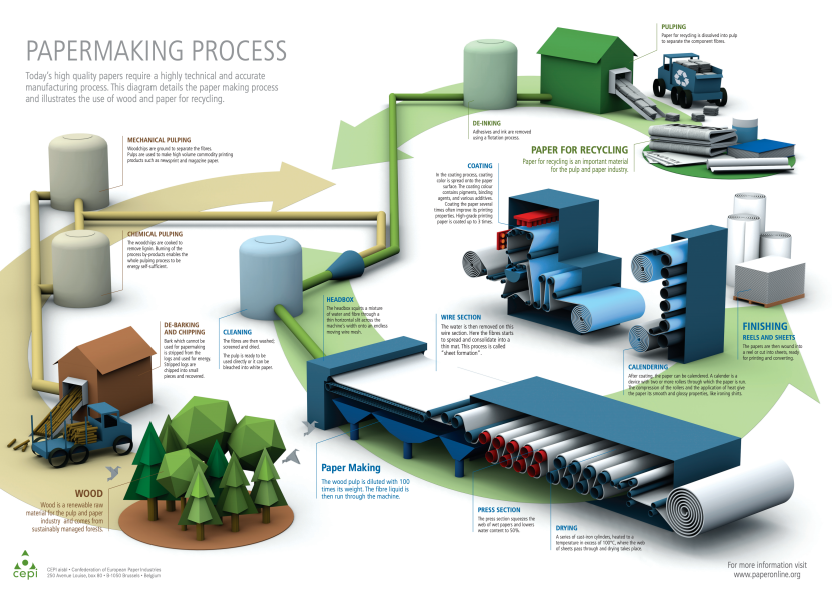

In the pulp and paper industry, the design and manufacturing process of machinery play a crucial role in producing high-quality paper products. From designing a paper mill to understanding the intricacies of the paper machine process, various technologies and techniques are utilized to ensure efficient and reliable production. In this section, we will delve into the process involved in designing a paper mill for unique paper products, explore how the paper machine process works from the headbox to calendering and winding, and understand the role of technologies like vacuum foils and drying cylinders in producing coated paper products.

Designing a Paper Mill for Unique Paper Products

Designing a paper mill for unique paper products involves a meticulous process that focuses on meeting the specific requirements of the desired paper quality and characteristics. Several considerations come into play, such as the type of raw materials to be used, the desired production capacity, and the sustainability goals of the paper mill.

The process begins with the selection of appropriate machinery and equipment that can handle the chosen raw materials efficiently. Factors such as the type of pulping process, bleaching method, and refining techniques need to be determined based on the desired paper quality.

Additionally, the design should incorporate advanced technologies that allow for flexibility and customization. This enables the production of unique paper products that cater to the specific needs of customers. By designing a paper mill with flexibility in mind, manufacturers can easily adapt to market demands and stay ahead in the competitive paper industry.

The Paper Machine Process

The paper machine process is a complex sequence of steps that transforms pulp into paper. It involves several stages, each contributing to the formation and enhancement of the final paper product. Let’s explore the paper machine process from the headbox to calendering and winding.

- Headbox: The process starts with the headbox, where a slurry of fibers, water, and additives is evenly distributed onto a moving wire mesh. The headbox ensures uniform fibers deposition and controls the basis weight of the paper.

- Wire Section: In the wire section, water drains through the wire mesh, leaving fiber mat formation. This section also aids in fiber orientation, which determines the strength and formation of the paper.

- Press Section: The press section removes excess water and consolidates the paper web by passing it through a series of press rolls. The pressure applied squeezes out water and improves paper density.

- Dryer Section: In the dryer section, the paper travels through a series of steam-heated drying cylinders. The heat evaporates the remaining moisture, resulting in a dry and strong paper web.

- Calendering: Calendering is the process of smoothening the paper surface to improve its appearance, glossiness, and printability. This is achieved by passing the paper web through a series of rolls under controlled pressure.

- Winding: The final step in the paper machine process involves winding the paper onto a reel, known as the parent reel. It is important to ensure precise tension control during winding to avoid defects in the final product.

Role of Technologies in Producing Coated Paper Products

Coated paper products, such as glossy magazines and brochures, require additional processing to achieve the desired surface characteristics. Technologies like vacuum foils and drying cylinders play a crucial role in producing high-quality coated paper products.

Vacuum Foils: Vacuum foils are used in the drying section of the paper machine to improve the drying efficiency and quality of the paper. They enhance the evaporation of moisture by creating a pressure difference, effectively pulling out water from the paper web. This technology ensures faster drying times and reduces energy consumption, resulting in cost-effective production.

Drying Cylinders: Drying cylinders are another essential component of the paper machine process for producing coated paper products. They provide additional heat and thermal stability to the drying section, enabling better control over the drying process. The precise temperature control helps in achieving the desired smoothness and surface properties of the coated paper.

Sizing Solution and Calendering: Alongside vacuum foils and drying cylinders, the use of sizing solution and calendering play vital roles in producing coated paper with glossiness. Sizing solution is applied during the papermaking process to improve the paper’s surface strength and reduce ink absorption. Calendering further enhances the surface smoothness and glossiness of the paper by pressing the paper web between heated rolls.

By incorporating these technologies into the paper machine process, manufacturers can produce coated paper products that meet the high standards of the printing and publishing industries.

Tables

Table 1: Advancements in Pulp and Paper Technology

| Technology | Advancement |

|---|---|

| Artificial Intelligence | Integration of AI and machine learning algorithms for optimization and efficiency |

| Predictive Maintenance | AI-powered systems for predicting and preventing equipment failures |

| Digital Twins | Virtual replicas for real-time monitoring, analysis, and optimization |

| Automation | Streamlining processes, increasing productivity, and reducing labor costs |

| Data Analytics | Extracting insights from data for process optimization and improved quality |

| Alternative Fibers | Using bamboo and hemp fibers for sustainable paper production |

Table 2: Eco-Friendly Paper Manufacturing Technologies

| Technology | Description |

|---|---|

| Advanced Sensors | Real-time monitoring and optimization of production processes |

| Non-Fiber Materials | Polypropylene and other materials that enhance paper durability and reduce chemical treatments |

| Biomass Boilers | Renewable energy source for paper manufacturing |

| Solar Panels | Clean, renewable energy generation for paper production |

| Vacuum Foils | Enhancing drying efficiency and quality of paper |

| Drying Cylinders | Provides additional heat and thermal stability for the drying process |

| Sizing Solution | Improving paper surface strength and reducing ink absorption |

| Calendering | Smoothening paper surface for improved glossiness |

FAQs about Pulp and Paper Technology Innovations

How do artificial intelligence (AI) and machine learning algorithms benefit the pulp and paper industry?

To understand how AI and machine learning algorithms benefit the pulp and paper industry, we need to consider their impact on optimizing production parameters, product quality improvement, and overall process efficiency.

Why are predictive maintenance systems important in pulp and paper manufacturing?

The significance of predictive maintenance systems in pulp and paper manufacturing can be determined by analyzing how they predict and prevent equipment failures through data analysis and sensor monitoring.

How does the concept of digital twins contribute to enhancing the efficiency of paper machines?

Exploring how digital twins, as virtual replicas of physical machines, facilitate real-time monitoring, analysis, and optimization to improve operating conditions and identify efficient settings for maximum productivity and energy efficiency.

What role do automation and data analytics play in transforming the pulp and paper industry?

In unlocking the transformation potential of automation and data analytics, it is essential to understand how they streamline processes, increase productivity, and provide valuable insights for process optimization and improved product quality.

Why is sustainability a critical consideration in modern pulp and paper technology?

Emphasizing sustainability as a critical consideration in modern pulp and paper technology encompasses optimizing waste management practices, implementing circular economy principles, utilizing alternative fibers, and exploring innovative production processes to minimize environmental impact and promote resource efficiency.

In the world of pulp and paper technology, advancements abound. Automation drives industry evolution. Sustainability practices shape innovation. Waste optimization and eco-friendly production lead. Alternative fibers improve sustainability. Latest machinery enhances product quality. Technology drives efficiency in manufacturing. Sustainable practices cement the future. In conclusion, pulp and paper technology thrives on innovation and sustainability for a brighter future.