Are Different Types for Offset Printing Plates Necessary?

Understanding Different Types for Offset Printing

Types of Offset Printing Plates

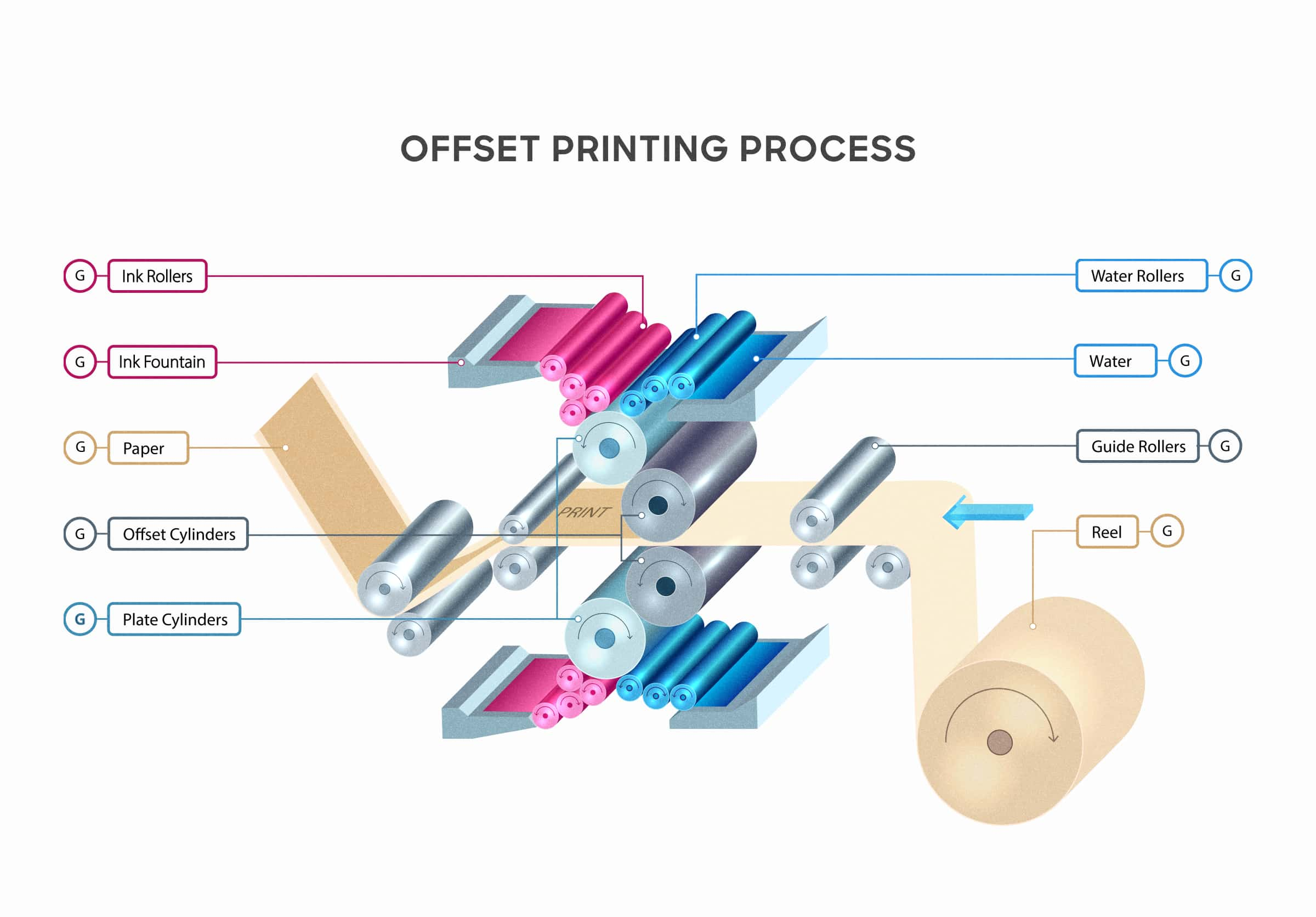

Offset printing plates play a crucial role in the offset printing process, as they are responsible for transferring the image onto the printing surface. There are several types of printing plates used in offset printing, each with its own characteristics and advantages. Let’s explore the different types of offset printing plates and how they affect print quality.

1. Aluminium Plates

Aluminium plates are the most widely used type of offset printing plates. They are known for their durability, flexibility, and cost-effectiveness. Aluminium plates are lightweight and can be easily bent to fit the printing press cylinder, making them highly adaptable. They also have excellent chemical resistance, allowing for longer press runs without wear and tear.

Aluminium plates come in different gauges, ranging from 0.15mm to 0.40mm, allowing for varying levels of image resolution and detail. They are compatible with both water-based and oil-based inks, making them versatile for different printing applications.

2. Thermal Plates

Thermal plates, also known as digital plates, have gained popularity in recent years due to their convenience and efficiency. These plates are sensitive to heat and can be imaged directly from a computer-to-plate (CTP) system without the need for film negatives. The image is created by selectively applying heat to the plate, which activates a photosensitive coating.

Thermal plates offer fast imaging times, reducing production time and costs. They also provide high image resolution and sharpness, resulting in excellent print quality. However, they are more expensive than traditional aluminium plates.

3. Polyester Plates

Polyester plates, also called laser plates, are another type of digital plate used in offset printing. These plates are imaged using a laser printer or photocopier with a polyester film, which transfers the toner onto the plate surface. Polyester plates are cost-effective and well-suited for short print runs or quick turnaround projects.

While polyester plates offer good image quality and affordability, they are not as durable as aluminium or thermal plates. They are more prone to wear and tear and require careful handling to avoid damage.

4. Photopolymer Plates

Photopolymer plates consist of a light-sensitive polymer material that hardens when exposed to ultraviolet (UV) light. These plates are typically used for specialized printing applications that require fine details, such as labels, packaging, and high-resolution images. Photopolymer plates offer excellent image reproduction and precise dot control.

However, photopolymer plates are more expensive than other types of plates and require additional processing steps, such as exposure to UV light and chemical development. They also have a limited run length compared to aluminium plates.

Factors to Consider When Selecting a Printing Plate

When choosing a printing plate for an offset printing project, several factors should be taken into consideration:

- Print Run Length: The expected quantity of prints will determine the durability and longevity required from the printing plate. For long print runs, durable aluminium plates are recommended.

- Image Quality: The level of detail and resolution required for the prints will influence the choice of printing plate. Higher resolution and intricate designs may be better suited for thermal or photopolymer plates.

- Ink Compatibility: Consider the type of ink to be used in the printing process, as certain plates are specifically designed for water-based inks, while others can accommodate both water-based and oil-based inks.

- Cost: The budget allocated for the project will play a role in the selection of printing plates. Aluminium plates are generally more cost-effective, while thermal and photopolymer plates may have a higher upfront cost.

In conclusion, understanding the different types of offset printing plates and their characteristics is essential for achieving optimal print quality. Aluminium plates, thermal plates, polyester plates, and photopolymer plates each offer unique advantages and considerations. By selecting the right printing plate and considering factors such as print run length, image quality, ink compatibility, and cost, offset printers can ensure successful and efficient printing projects.

FAQs about Types of Offset Printing Plates

What is the Precision equation for evaluating offset printing plates?

Precision = tp / (tp + fp)

How do you calculate Recall for offset printing plates?

Recall = tp / (tp + fn)

What does ‘tp’ signify in the offset printing plates equation?

tp refers to the number of tokens shared between the correct answer and the prediction.

In the context of offset printing plates, what does ‘fp’ represent?

fp stands for the number of tokens in the prediction but not in the correct answer.

How is ‘fn’ defined concerning offset printing plates?

fn refers to the number of tokens in the correct answer but not in the prediction.

In summary, we explored types of offset printing plates, inks, and paper options. Consider plate materials, ink types, and paper selections for optimal offset printing results. Offset printing success hinges on the strategic choices made in these three crucial areas. Understanding the impact of each element ensures high-quality print outputs. Selecting the right combination of plates, inks, and paper elevates the effectiveness and aesthetic appeal of offset printing projects. Choose wisely to achieve the desired results.