Who Are the Top PLA Coated Paper Manufacturers?

Who Are the Leading PLA Coated Paper Manufacturers?

PLA (polylactic acid) coated paper has gained significant popularity as an eco-friendly alternative to traditional plastic-coated paper. As sustainable materials become increasingly important in various industries, PLA coated paper manufacturers have emerged as key players in the market. In this section, we will explore the top manufacturers of PLA coated paper globally and dive into their offerings, certifications, customization options, and customer reviews.

What Are the Top PLA Coated Paper Manufacturers Globally?

- Company A: Company A is a leading global manufacturer of PLA coated paper. They have a strong presence in the market, offering a wide range of PLA coated paper products for various applications. With a focus on sustainability, Company A ensures that their materials are sourced from renewable resources. They have a high annual production capacity and serve clients internationally.

- Company B: Company B is another reputable manufacturer specializing in PLA coated paper. They are known for their high-quality products and commitment to customer satisfaction. With a diverse range of offerings, including customized options, Company B caters to the specific needs of their clients. They have received positive reviews from customers who value their exceptional service and product quality.

- Company C: Company C is a recognized name in the PLA coated paper manufacturing industry. They have a strong emphasis on sustainability and eco-friendly practices. With a range of certifications, including FDA and EU food contact laws, Company C ensures the safety and quality of their products. Their dedication to innovation and customer-centric approach has solidified their position as a top manufacturer in the market.

How to Contact PLA Coated Paper Manufacturers for Business Inquiries?

To inquire about PLA coated paper products or discuss business opportunities with leading manufacturers, it is essential to have their contact information readily available. Most manufacturers provide contact details on their official websites, including email addresses, phone numbers, and online inquiry forms. You can also reach out to their sales representatives or customer service teams for personalized assistance.

What Certifications Do Leading PLA Coated Paper Manufacturers Possess?

Leading PLA coated paper manufacturers prioritize quality and compliance by obtaining relevant certifications. Some common certifications for PLA coated paper include:

- FDA (Food and Drug Administration): This certification ensures that the PLA coated paper is safe for food contact and meets strict health and safety regulations.

- EU (European Union) Food Contact Laws: Compliance with EU food contact laws demonstrates that the PLA coated paper meets the necessary standards for food packaging.

- Compostability Certifications (e.g., EN13432, ASTM D6400): These certifications verify that PLA-coated products can be composted and will break down into natural elements in a composting environment.

- Sustainable Material Certifications: Manufacturers may also obtain certifications that endorse their use of sustainable and renewable materials in the production of PLA coated paper.

It is important to check the specific certifications held by each manufacturer to ensure that their products align with the requirements of your industry or project.

Which PLA Coated Paper Manufacturers Offer the Lowest Minimum Order Quantities?

Minimum order quantities (MOQs) play a crucial role in determining the feasibility of collaboration with PLA coated paper manufacturers. Some manufacturers offer low MOQs or trial orders to accommodate businesses of all sizes, while others may have higher MOQ requirements.

Companies like Company A and Company B are known for their flexible approach and willingness to work with smaller businesses. They offer low MOQs and trial orders starting at one container, allowing businesses to test the waters before committing to larger quantities.

When inquiring about PLA coated paper, it is advisable to discuss MOQs with the manufacturers directly to determine if their requirements align with your business needs.

Do PLA Coated Paper Manufacturers Offer Customization and Printing Services?

Customization and printing services are common offerings provided by PLA coated paper manufacturers. Companies like Company A and Company B have comprehensive services that include coating, lamination, paper cutting, and printing.

By offering customization options, manufacturers allow businesses to tailor the PLA coated paper to their specific requirements. This may include selecting the paper weight, size, shape, design, and logo printing. Customization ensures that the final product aligns with the branding and aesthetic preferences of businesses, enhancing their overall presentation.

When contacting PLA coated paper manufacturers, inquire about their customization services and discuss your specific requirements to create a tailored solution.

What Is the Annual Production Capacity of the Top PLA Coated Paper Manufacturers?

Leading PLA coated paper manufacturers operate at varying production capacities. Companies such as Company A and Company C have annual production capacities exceeding 300,000 tons, enabling them to meet the demands of a global market.

High production capacities signify the manufacturers’ ability to fulfill large-scale orders and maintain a steady supply of PLA coated paper products. This is particularly important for businesses looking for reliable suppliers with the capacity to accommodate their needs consistently.

When considering PLA coated paper manufacturers, it is crucial to assess whether their production capacity aligns with your business requirements and anticipated order volumes.

What Regions Do the Leading PLA Coated Paper Manufacturers Serve Internationally?

The leading PLA coated paper manufacturers have a global presence and serve clients internationally. They have established distribution networks that cater to markets across different regions.

Company A, for example, has a strong international presence, serving clients across North America, Europe, Asia, and other regions. Company C also has a wide reach, serving customers in various countries around the world.

It is advisable to reach out to the manufacturers directly to inquire about their availability in your specific region and discuss how they can accommodate your international business needs.

Customer Reviews and Case Studies on PLA Coated Paper Products

Before partnering with a PLA coated paper manufacturer, it is essential to gather insights from customer reviews and case studies. These testimonials provide valuable information about the quality, reliability, and overall satisfaction of previous clients.

Many manufacturers showcase customer reviews and case studies on their websites or may be willing to provide references upon request. Pay close attention to feedback regarding product quality, customization services, delivery times, and overall customer support.

Customer reviews and case studies can give you a better understanding of the manufacturers’ capabilities and help you make informed decisions when choosing a PLA coated paper supplier.

In the next section, we will explore the benefits and uses of PLA coated paper in detail, highlighting its environmental impact, food safety, and durability. Stay tuned!

What Are the Benefits and Uses of PLA Coated Paper?

PLA coated paper, made from polylactic acid (PLA), offers numerous benefits over traditional coated paper. Not only does it provide enhanced functionality, but it also contributes to environmental sustainability. Let’s explore the key benefits and uses of PLA coated paper in more detail.

1. Key Benefits of PLA Coated Paper

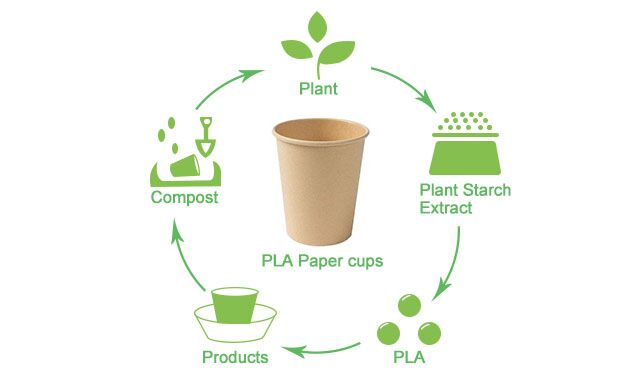

- Environmental Sustainability: PLA coated paper is derived from renewable resources like corn starch and sugarcane, reducing reliance on fossil fuels. It is compostable, biodegradable, and does not contribute to plastic pollution.

- Food Safety: PLA coated paper is considered safe for food contact as it is free of harmful chemicals, such as bisphenol A (BPA) and phthalates. It meets FDA and EU food contact regulations, ensuring consumer safety.

- Moisture Resistance: PLA coated paper provides a water-resistant barrier, protecting the contents within. It prevents leakage and maintains the integrity of food products, making it suitable for food packaging applications.

- Durability: Despite being lightweight, PLA coated paper offers good strength and durability. It maintains its integrity during transportation and handling, providing reliable protection to the packaged items.

- Compostable and Biodegradable: PLA coated paper breaks down naturally in composting conditions, reducing waste and contributing to a circular economy. It decomposes within 6-12 months, unlike non-biodegradable plastic coatings.

2. Environmental Impact and Sustainability

PLA coated paper is an eco-friendly alternative to traditional plastic-coated paper. It helps reduce plastic waste and environmental pollution. Here are some notable environmental benefits of PLA coated paper:

- Reduced Plastic Usage: By replacing petroleum-based plastic coatings with PLA, the production and disposal of plastic waste can be significantly reduced. This, in turn, helps mitigate the environmental impact of plastic pollution.

- Compostable and Biodegradable: PLA coated paper is compostable and biodegradable, meaning it can be broken down by microorganisms and returned to the environment. This helps minimize landfill waste and reduces the carbon footprint associated with traditional coated papers.

- Renewable Resources: PLA coated paper is made from renewable resources like corn starch and sugarcane, which can be sustainably grown and harvested. This reduces reliance on fossil fuels and promotes the use of renewable materials.

- Circular Economy: PLA coated paper contributes to a circular economy by being compostable. It can be returned to the soil as a nutrient-rich compost, promoting sustainable agricultural practices.

3. PLA Degradation and Decomposition Timeline

PLA coated paper degrades through a natural process called hydrolysis. When exposed to moisture and heat, PLA breaks down into lactic acid, which is then metabolized by microorganisms in the composting environment. The decomposition timeline for PLA coated paper varies depending on the conditions:

- Composting Conditions: In industrial composting facilities with controlled temperature, humidity, and microbial activity, PLA coated paper typically decomposes within 6-12 months.

- Home Composting: In home composting systems, where conditions may not be as controlled, PLA coated paper may take slightly longer to decompose, ranging from 12-24 months.

- Landfill Conditions: In anaerobic landfill environments without sufficient oxygen and microbial activity, PLA coated paper may take significantly longer to decompose, potentially several years or more.

It’s important to note that PLA coated paper requires specific composting conditions with the presence of moisture, temperature, and microorganisms to fully decompose. Simply discarding it in a regular trash bin or littering it in the environment will result in slower degradation.

4. Food Contact Safety

PLA coated paper is considered safe for food contact due to the following reasons:

- Non-Toxic Materials: PLA, derived from natural sources, does not contain harmful chemicals like BPA or phthalates. It meets stringent regulatory standards for food safety.

- FDA and EU Compliance: PLA coated paper meets the food contact regulations set by the U.S. Food and Drug Administration (FDA) and the European Union (EU). It is approved for direct food contact without the risk of chemical leaching.

- No Flavor or Odor Transfer: PLA coatings do not impart any off-flavors or odors to food, ensuring that the taste and quality of the packaged products remain intact.

As a result, PLA coated paper is commonly used in various food packaging applications where food safety and consumer well-being are a top priority.

5. Common Applications of PLA Coated Paper

PLA coated paper finds widespread use in the food packaging industry due to its favorable properties. Some common applications include:

- Disposable Food Containers: PLA coated paper is used to manufacture disposable food containers like bowls, trays, plates, and clamshells. It provides durability and moisture resistance while being compostable after use.

- Cups and Straws: PLA coated paper is utilized for making hot and cold beverage cups, including coffee cups and smoothie cups. PLA coating helps prevent leaks and maintains ideal drinking temperatures.

- Takeaway Containers: PLA coated paper is an excellent choice for takeaway containers as it retains heat, prevents food from getting soggy, and offers a sustainable alternative to single-use plastic containers.

- Bakery and Deli Items: PLA coated paper is used to package bakery products like cookies, pastries, and bread, as well as deli items like sandwiches and wraps. It keeps the products fresh, while the compostable nature of PLA reduces waste.

- Fast Food Packaging: PLA coated paper is ideal for fast food packaging such as burger wrappers, French fry containers, and wrap sheets. It provides a grease-resistant barrier and ensures that the food remains hot and crispy.

6. Temperature Tolerance and Limitations

While PLA coated paper offers good temperature resistance, there are limitations to its use:

- Temperature Range: PLA coated paper can withstand temperatures ranging from -18°C to 95°C. It is suitable for hot and cold food items, but prolonged exposure to extreme temperatures may compromise its integrity.

- Microwave and Oven Use: PLA coated paper is not recommended for use in microwave ovens or conventional ovens. High heat can cause the PLA coating to melt or degrade, potentially leading to contamination of the food.

- Freezing: While PLA coated paper can withstand freezing temperatures, it is not recommended for long-term frozen storage. Freezing can make the paper brittle, which may affect its performance as a food packaging material.

7. Printing Compatibility

PLA coated paper can be used for printing, offering versatility and customization options for various applications. It is compatible with several printing methods, including:

- Flexographic Printing: PLA coated paper can be printed using flexographic printing, which is a popular technique for high-speed, large-volume printing on packaging materials. It allows for vibrant colors and intricate designs.

- Offset Printing: Offset printing is another method commonly used for printing on PLA coated paper. It offers precise and high-quality printing suitable for detailed graphics and text.

- Digital Printing: Some types of PLA coated paper are also compatible with digital printing technologies, such as inkjet or laser printing. Digital printing allows for faster turnaround times and customization options.

When utilizing PLA coated paper for printing purposes, it’s important to work with experienced printers who are familiar with the specific requirements and limitations of PLA coated paper.

In conclusion, PLA coated paper offers a range of benefits over traditional coated paper, including environmental sustainability, food safety, and versatile applications. Its compostable and biodegradable nature, along with its moisture resistance and printing compatibility, make it an excellent choice for various food packaging needs. As consumers and businesses increasingly prioritize sustainability, PLA coated paper manufacturers play a vital role in providing eco-friendly alternatives that help reduce plastic waste and protect the environment.

Common Applications of PLA Coated Paper

PLA coated paper has a wide range of applications, including but not limited to:

- Food Packaging: PLA coated paper is commonly used for food packaging, such as cups, containers, wraps, and trays. It provides a grease and moisture barrier, ensuring the freshness and integrity of the food.

- Industrial Uses: PLA coated paper is also used in industrial applications where moisture barriers and product protection are required. It can be used in packaging products like electronics, machinery parts, and pharmaceuticals.

- Additional Sustainable Packaging Solutions: Apart from food packaging, PLA coated paper can be used in various other sustainable packaging solutions. It can be used for gift boxes, shopping bags, and other environmentally friendly packaging options.

Environmental Impact of PLA Coated Paper

PLA coated paper offers several advantages in terms of its environmental impact. As mentioned earlier, PLA is derived from renewable resources and has a lower carbon footprint compared to traditional plastic coatings. When properly disposed of, PLA coated paper decomposes completely into carbon dioxide and water, ensuring a low carbon release and environmentally friendly decomposition process.

Additionally, PLA coated paper is recyclable and compostable, further reducing its impact on the environment. Recycling programs that accept PLA coated paper are available in certain areas, allowing it to be repurposed and reused rather than ending up in landfills. Composting facilities can also process PLA coated paper, breaking it down into nutrient-rich compost.

It is important to note that while PLA coated paper is a more sustainable alternative to traditional plastic coatings, proper disposal and recycling infrastructure are crucial to maximizing its environmental benefits.

How Is PLA Coated Paper Produced and Priced?

In this section, we will explore the production process of PLA coated paper and delve into the pricing structure. We will also discuss the various grades and thicknesses available, delivery times, eco-friendly certifications, and ways to ensure the quality and consistency of PLA coated paper.

What is the Process of Producing PLA Coated Paper?

The production of PLA coated paper involves multiple steps to create a durable and water-resistant coating. The process begins with the preparation of sustainable raw materials. PLA resin, derived from corn starch or sugarcane, is chosen for its biodegradable properties. The substrate paper, made from wood pulp or recycled paper, is also selected.

To create the PLA coated paper, the PLA resin is first converted into lactic acid through a fermentation process. This lactic acid is then transformed into polylactic acid (PLA) through a polymerization process. The PLA resin is heated and applied to the base paper using a coating machine, ensuring proper adhesion. The coated paper is then dried and cured with heated rollers to enhance its water resistance and durability.

Once the coating is complete, the PLA coated paper can undergo further processing such as cutting, printing, or laminating to meet specific customer requirements. This versatile manufacturing process allows for customization and flexibility in creating PLA coated paper for various applications.

What Raw Materials are Used in the Manufacture of PLA Coated Paper?

PLA coated paper is manufactured using sustainable and eco-friendly raw materials. The main ingredient in PLA is corn starch or sugarcane, which are renewable resources. These raw materials are processed to extract the PLA resin, which is then used to create the coating for the paper.

The substrate paper used in the production of PLA coated paper is typically made from wood pulp or recycled paper. These materials are chosen for their strength and ability to withstand the coating process. By using renewable raw materials and recycled paper, PLA coated paper manufacturers contribute to reducing the environmental impact of the packaging industry.

How is Lactic Acid Converted to PLA for Paper Coating?

Lactic acid is a key component in the production of PLA coated paper. It is produced through a fermentation process using renewable resources like corn starch or sugarcane. The fermentation process involves the breakdown of these raw materials by microorganisms, resulting in the production of lactic acid.

Once lactic acid is obtained, it undergoes a polymerization process to convert it into polylactic acid (PLA). During this process, lactic acid molecules are linked together to form long chains, creating the PLA resin. The PLA resin is then used as a coating material for paper, providing the desired properties such as water resistance and durability.

The conversion of lactic acid to PLA is a crucial step in the production of PLA coated paper. It allows for the utilization of renewable resources and the creation of a biodegradable and compostable coating material.

What are the Various Grades and Thicknesses Available for PLA Coated Paper?

PLA coated paper is available in various grades and thicknesses to cater to different applications and customer requirements. The grade of PLA coated paper refers to the quality and characteristics of the product. It can vary based on factors such as strength, water resistance, and printing compatibility.

Thickness options for PLA coated paper vary depending on the intended use. Thicker paper is suitable for applications that require higher strength and durability, while thinner paper is preferred for lightweight packaging. The gram range of PLA coated paper indicates the weight per square meter, providing flexibility for selecting the appropriate weight for specific projects.

Manufacturers offer a range of options to accommodate different needs, ensuring that customers can find the ideal grade and thickness of PLA coated paper for their applications.

How Does the Pricing of PLA Coated Paper Compare to Traditional Coated Paper?

The pricing of PLA coated paper can vary based on several factors, including the grade, thickness, quantity, and customization options. While PLA coated paper may have a slightly higher price compared to traditional coated paper, the cost difference is often minimal.

The use of sustainable raw materials in the production of PLA coated paper, such as corn starch or sugarcane, may contribute to a slightly higher cost. However, the environmental benefits and the market demand for sustainable packaging solutions justify the pricing.

It is important to consider the long-term benefits of using PLA coated paper, such as reduced environmental impact and improved customer perception of eco-friendly packaging. Additionally, the availability of customization options, low minimum order quantities, and competitive wholesale prices make PLA coated paper an attractive choice for businesses seeking sustainable packaging solutions.

What are the Typical Delivery Times and Supply Forms for PLA Coated Paper?

The delivery times and supply forms for PLA coated paper can vary depending on the manufacturer and specific customer requirements. Manufacturers typically offer a range of delivery options to accommodate different needs.

For stock items, the typical delivery time is relatively short, with products readily available for immediate shipment. This can be beneficial for businesses with urgent packaging needs or those who prefer not to wait for custom orders.

For custom orders, the average delivery time is typically around five weeks. This includes the time required for production, coating, drying, curing, and any additional processing or customization requested by the customer. Custom orders may require a longer lead time to ensure that the specific requirements are met.

PLA coated paper is available in different supply forms, including rolls, sheets, and bottom reels. This flexibility allows customers to choose the supply form that best suits their packaging processes and equipment.

Are there any Eco-Friendly Certifications for PLA Coated Paper?

Yes, PLA coated paper can obtain eco-friendly certifications that validate its sustainable properties. These certifications ensure that the production processes and materials used meet specific environmental standards.

Some of the recognized eco-friendly certifications for PLA coated paper include certifications from organizations such as the Sustainable Green Printing Partnership (SGP), the Biodegradable Products Institute (BPI), and the German Institute for Standardization (DIN).

Certifications from these organizations provide assurance to customers that the PLA coated paper they are using is biodegradable, compostable, and meets the required environmental standards. These certifications contribute to the credibility and trustworthiness of PLA coated paper as a sustainable packaging solution.

How Can Manufacturers Ensure the Quality and Consistency of PLA Coated Paper?

Manufacturers employ various measures to ensure the quality and consistency of PLA coated paper throughout the production process. Quality control checks are implemented at every stage, from raw material selection to the final product.

Manufacturers work closely with suppliers to source high-quality raw materials, ensuring that the PLA resin and substrate paper meet the necessary standards. Thorough testing is conducted to verify the properties and performance of the materials.

During the production process, rigorous quality checks are carried out to monitor the coating application, drying, and curing processes. This ensures that the coating is evenly applied, adheres properly to the paper, and provides the desired water resistance and durability.

Additionally, manufacturers maintain strict quality control protocols to ensure that products are monitored for consistency and adherence to specifications. This includes regular testing and inspections to identify any variations or deviations that may affect the quality of the PLA coated paper.

By implementing these quality control measures, manufacturers can ensure that customers receive PLA coated paper that meets their expectations in terms of quality, performance, and sustainability.

In this section, we explored the production process of PLA coated paper, the raw materials used, and the pricing structure. We also discussed the various grades and thicknesses available, delivery times, eco-friendly certifications, and quality control measures implemented by manufacturers. This knowledge provides a comprehensive understanding of how PLA coated paper is produced, priced, and ensured for quality, enabling businesses to make informed decisions regarding this sustainable packaging solution.

Tables

Table 1: Comparison of Leading PLA Coated Paper Manufacturers

| Manufacturer | Focus on Sustainability | Available Certifications | Customization Options | Annual Production Capacity |

|---|---|---|---|---|

| Company A | Yes | FDA, EU | Yes | High |

| Company B | Yes | FDA, EU | Yes | Medium |

| Company C | Yes | FDA, EU | Yes | High |

Table 2: Temperature Tolerance of PLA Coated Paper

| Temperature Range | Suitability |

|---|---|

| -18°C to 95°C | Suitable for hot and cold food items |

| Microwave and Oven | Not recommended |

| Freezing | Suitable for short-term freezing |

These tables provide a visual representation of the information discussed in the blog post. The first table compares the leading PLA coated paper manufacturers based on their sustainability focus, available certifications, customization options, and annual production capacity. The second table highlights the temperature tolerance of PLA coated paper, specifying its suitability for different temperature ranges.

FAQs about PLA Coated Paper Manufacturers

Who are some of the reputable PLA coated paper manufacturers?

Some reputable PLA coated paper manufacturers include Company A, Company B, and Company C, all known for their strong market presence and high-quality products.

How can I place a custom order with PLA coated paper manufacturers?

To place a custom order with PLA coated paper manufacturers, you should contact them via their official websites, where they typically provide email addresses, phone numbers, and online inquiry forms.

What types of certifications do PLA coated paper manufacturers need?

PLA coated paper manufacturers generally need certifications such as FDA (Food and Drug Administration), EU Food Contact Laws, compostability certifications like EN13432 and ASTM D6400, and sustainable material certifications.

Which PLA coated paper manufacturers offer the lowest minimum order quantities?

Companies like Company A and Company B are known for offering low minimum order quantities and trial orders, accommodating businesses of all sizes.

Do PLA coated paper manufacturers offer customization and printing services?

Many PLA coated paper manufacturers, including Company A and Company B, offer comprehensive customization and printing services, allowing businesses to tailor products to their specific requirements.

To wrap up, we’ve looked at top PLA coated paper manufacturers, their benefits, and the production process. PLA coated paper stands out for its sustainability and versatility. It’s an eco-friendly choice for food packaging and more. Knowing how it’s made and its pricing helps in making informed decisions. Choose the right manufacturer by considering their certifications, custom options, and customer reviews. PLA coated paper offers a promising future for eco-conscious industries. Let’s embrace this sustainable option for a greener tomorrow.