PLA Coated Paper Cost Analysis: What You Need to Know?

How Much Does PLA Coated Paper Cost?

[Keyword Cluster]: PLA coated paper cost analysis, PLA paper pricing, PLA coated paper cost comparison

In the world of sustainable packaging, PLA (Polylactic Acid) coated paper has gained significant attention for its eco-friendly properties. As businesses strive to reduce their environmental impact, understanding the cost analysis of PLA coated paper becomes crucial. In this section, we will delve into the various factors that contribute to the overall cost of PLA coated paper, including raw material costs, production and manufacturing expenses, and a comparison with alternative materials.

Raw Material Costs of PLA Coated Paper

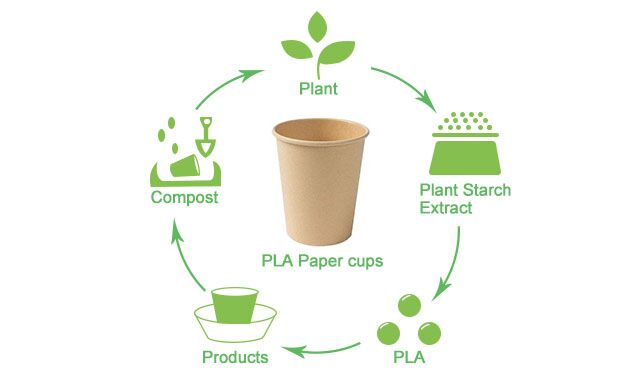

To understand the cost analysis of PLA coated paper, we must first examine the raw materials used in its production. PLA coated paper is made by applying a thin layer of polylactic acid, a bioplastic derived from renewable resources like corn starch or sugarcane, onto paper. The cost of raw materials plays a significant role in determining the overall cost of the PLA coated paper.

When comparing raw material costs for PLA coated paper with other coatings like PE (Polyethylene) or wax, it is important to consider factors such as availability, production processes, and environmental impact. PLA coated paper may have slightly higher raw material costs compared to traditional coatings due to the production process and the limited availability of renewable resources. However, as the demand for sustainable packaging increases and production scales up, economies of scale may lead to a decrease in raw material costs for PLA coated paper.

Production and Manufacturing Costs

The production and manufacturing costs of PLA coated paper are another important aspect of its overall cost analysis. The production process typically involves applying the PLA coating onto the paper substrate using specialized equipment and technology, which can contribute to the overall cost. The cost of machinery, labor, and energy consumption are factors that influence the production costs of PLA coated paper.

Additionally, advancements in technology and manufacturing processes may lead to cost savings in the production of PLA coated paper. As technology improves and becomes more efficient, the cost of manufacturing can decrease, making PLA coated paper more affordable in the long run.

Comparison with Alternatives

To fully understand the cost analysis of PLA coated paper, it is essential to compare its costs with alternative materials such as PE coated paper and other traditional packaging options. PE coated paper, which is paper coated with polyethylene, is widely used in the industry due to its water-resistant properties and cost-effectiveness. However, it is important to consider the long-term costs and environmental implications of using PE coated paper.

In terms of long-term cost analysis, PLA coated paper may offer advantages over traditional alternatives. While the initial cost of PLA coated paper may be higher, its biodegradability and compostability can lead to potential cost savings in waste disposal and recycling. As regulations and incentives promoting sustainable packaging continue to evolve, businesses that switch to PLA coated paper may benefit from financial incentives and reduced environmental costs.

In conclusion, the cost analysis of PLA coated paper involves evaluating the raw material costs, production and manufacturing expenses, and a comparison with alternative materials. While PLA coated paper may have slightly higher raw material costs and initial investment requirements, its long-term benefits and positive environmental impact make it an attractive option for businesses looking to reduce their carbon footprint and meet sustainability goals. As the demand for eco-friendly packaging grows and technology advances, we can expect the cost of PLA coated paper to become more competitive with traditional alternatives.

Is PLA Coated Paper Cost-Effective Compared to Other Materials?

PLA coated paper has gained significant attention in recent years due to its eco-friendly and biodegradable nature. However, one important aspect that businesses and consumers consider is its cost-effectiveness compared to other materials. In this section, we will analyze the cost aspects of PLA coated paper, including environmental and disposal costs, economic benefits and savings, and market pricing trends. By understanding these factors, we can gain insights into whether PLA coated paper is a cost-effective choice for various applications.

Environmental and Disposal Costs

One of the key advantages of PLA coated paper is its biodegradability and compostability. PLA (Polylactic Acid) is derived from renewable resources such as corn starch or sugarcane, making it a more sustainable alternative to petroleum-based plastics like PE (Polyethylene). When disposed of in the proper conditions, PLA coated paper can break down into natural materials, reducing environmental impact.

Analysis of Composting and Biodegradability Costs

Composting is the process by which organic materials, such as food waste and certain paper products, decompose into nutrient-rich soil. PLA coated paper is suitable for industrial composting facilities that maintain high temperatures of around 60°C or higher. Under these conditions, PLA coated paper can decompose within a month, contributing to the circular economy.

Composting costs can vary depending on the region and the availability of composting facilities. Industrial composting may require additional infrastructure and resources compared to other waste disposal methods. However, the environmental benefits of composting PLA coated paper outweigh the costs in terms of reducing landfill waste and promoting sustainability.

Costs Associated with Waste Disposal and Recycling for PLA versus PE and Other Materials

While PLA coated paper offers biodegradability benefits, it’s important to consider the costs associated with waste disposal and recycling. PE coated paper, which is made with a layer of polyethylene plastic, is non-biodegradable and poses challenges for recycling. PE coated paper cups, for example, often end up in landfills due to the difficulty of separating the plastic coating from the paper.

On the other hand, PLA coated paper cups are easier to recycle within existing paper recycling streams. The PLA coating can be separated from the paper, allowing for more efficient recycling. However, it’s worth noting that not all recycling facilities have the necessary infrastructure to recycle PLA coated paper, which may result in additional transportation costs to reach specialized recycling centers.

Considering the costs of waste disposal and recycling, PLA coated paper provides a more sustainable option compared to PE coated paper. The ability to recycle PLA coated paper contributes to the circular economy and reduces reliance on virgin materials.

Economic Benefits and Savings

While the environmental benefits of PLA coated paper are evident, it’s important to consider the economic benefits and potential cost savings associated with its usage. Businesses and consumers alike may find several advantages when opting for PLA coated paper.

Potential for Cost Savings through Environmental Incentives and Regulations

In many regions, governments and regulatory bodies have implemented environmental incentives and regulations to promote the use of sustainable and biodegradable materials. This includes measures such as plastic reduction targets, recycling incentives, and subsidies for eco-friendly alternatives.

By switching to PLA coated paper, businesses can take advantage of these environmental incentives and regulations, which can lead to cost savings. For example, reduced landfill fees for compostable materials or tax breaks for using sustainable packaging can contribute to overall cost savings.

Case Studies: Businesses Saving Costs by Using PLA Coated Paper

Several businesses have already recognized the long-term economic benefits of using PLA coated paper. Case studies have shown that companies in various industries, such as food and beverage, have experienced cost savings by adopting PLA coated paper packaging.

For instance, a restaurant chain that switched to PLA coated paper cups reported cost savings due to reduced waste management expenses. The ability to compost the cups instead of sending them to landfills resulted in significant cost reductions and aligned with the company’s sustainability goals.

These case studies highlight the potential for cost savings and economic advantages that can be achieved by incorporating PLA coated paper into business practices.

Market Pricing Trends

Understanding the current pricing trends of PLA coated paper is crucial for businesses and consumers who are considering its adoption. Market dynamics, supply and demand, and other factors can influence the overall cost of PLA coated paper.

Current Pricing Trends for PLA Coated Paper in Various Markets

The price of PLA coated paper can vary depending on the market and region. Factors such as availability of raw materials, production costs, and market demand can influence the pricing.

Currently, the demand for eco-friendly and sustainable packaging materials is on the rise, driving the market for PLA coated paper. As more businesses and consumers prioritize sustainability, the demand for PLA coated paper is expected to continue increasing. This increase in demand may have an impact on the pricing of PLA coated paper in the future.

Impact of Supply and Demand on PLA Coated Paper Prices

Supply and demand dynamics can have a direct impact on the pricing of PLA coated paper. As the demand for PLA coated paper increases, manufacturers may need to increase production capacity to meet the market needs. This expansion of production capacity can lead to economies of scale and potentially lower costs.

On the other hand, limited supply or disruptions in the supply chain can increase the prices of PLA coated paper. Factors such as availability of raw materials, transportation costs, and production capacity can affect the overall supply and, subsequently, the pricing.

It’s important for businesses and consumers to stay informed about the market pricing trends for PLA coated paper to make informed decisions and understand the potential cost implications.

In conclusion, when considering the cost-effectiveness of PLA coated paper compared to other materials, it’s essential to evaluate both the environmental and disposal costs as well as the economic benefits and savings. While PLA coated paper may have a higher upfront cost compared to traditional alternatives, the potential for cost savings in waste disposal, recycling incentives, and long-term environmental benefits can outweigh the initial investment. Furthermore, the market pricing trends and growing demand for sustainable packaging materials indicate a promising future for PLA coated paper in terms of cost-effectiveness. By considering both the financial and environmental aspects, businesses and consumers can make informed decisions about adopting PLA coated paper for their packaging needs.

Financial Implications of Switching to PLA Coated Paper

Switching to PLA coated paper can have various financial implications for businesses. In this section, we will explore the initial investment and transition costs, long-term financial benefits, and expert opinions on the cost implications of using PLA coated paper.

Initial Investment and Transition Costs

When transitioning to PLA coated paper from other materials, businesses may need to incur certain costs. Some of these costs include:

- Material Costs: PLA coated paper typically comes at a higher cost compared to traditional materials such as polyethylene (PE) coated paper or wax-coated paper. The cost of raw materials for producing PLA coated paper is generally higher.

- Production Machinery: To produce PLA coated paper in-house, businesses may need to invest in specialized machinery. This initial investment can be substantial, considering the cost of purchasing or leasing the equipment.

- Training and Workforce: Switching to PLA coated paper may require training employees to operate the new machinery and understand the production process. Training costs and potential productivity disruptions during the transition period should be taken into account.

- Supply Chain Adjustments: Businesses may need to make adjustments to their supply chain to accommodate the use of PLA coated paper. This can involve finding new suppliers or negotiating contracts with existing suppliers for the procurement of PLA-coated paper.

While there are upfront costs involved in the transition to PLA coated paper, businesses may also benefit from long-term financial advantages.

Long-term Financial Benefits

- Reduced Packaging Costs: PLA coated paper can help businesses reduce packaging costs in the long run. This is because PLA coating is made from renewable resources like corn starch or sugarcane, which are generally more sustainable and readily available compared to fossil fuel-derived materials. By switching to PLA coated paper, businesses can potentially lower their dependence on non-renewable resources, leading to cost savings in the long term.

- Environmental Incentives and Subsidies: Many countries and regions offer incentives and subsidies for businesses that adopt environmentally-friendly practices. Switching to PLA coated paper, which is biodegradable and compostable, can make businesses eligible for such incentives, which can provide significant cost savings.

- Positive Brand Image and Customer Appeal: In recent years, consumer awareness and demand for eco-friendly and sustainable products have been on the rise. By using PLA coated paper, businesses can position themselves as environmentally conscious, which can resonate well with consumers and potentially lead to increased brand loyalty and sales.

Expert Opinions and Industry Insights

Industry experts and real-world examples can provide valuable insights into the cost implications of using PLA coated paper. Here are some perspectives on the financial implications of the switch:

- Industry Experts: Experts in the packaging industry generally agree that the initial investment in transitioning to PLA coated paper may be higher compared to traditional materials. However, they emphasize the long-term benefits of cost savings, environmental advantages, and potential incentives that can outweigh the initial costs.

- Case Studies: Numerous companies have successfully made the switch to PLA coated paper and have witnessed financial benefits. For example, a food packaging company reported cost savings in the form of reduced waste disposal fees and lower production costs after transitioning to PLA coated paper.

In conclusion, switching to PLA coated paper involves initial investment and transition costs. However, businesses can benefit from long-term financial advantages, such as reduced packaging costs, potential incentives and subsidies, and enhanced brand image. It is important for businesses to consider these financial implications and conduct a comprehensive cost-benefit analysis before making the switch to PLA coated paper.

Table 1: Raw Material Comparison

| Coating Type | Raw Material | Cost | Availability | Production Process |

|---|---|---|---|---|

| PLA Coated Paper | Polylactic Acid | Slightly higher | Limited (renewable resources) | Apply PLA coating onto paper substrate |

| PE Coated Paper | Polyethylene | Lower | Widely available | Apply PE coating onto paper substrate |

| Wax Coated Paper | Wax | Lower | Widely available | Apply wax coating onto paper substrate |

Table 2: Cost Implications Comparison

| Aspect | PLA Coated Paper | PE Coated Paper |

|---|---|---|

| Raw Material Cost | Slightly higher | Lower |

| Production Cost | Varies | Lower |

| Disposal Cost | Varies | Higher |

| Recycling Cost | Varies | Higher |

| Long-term Savings | Yes | No |

The above tables provide a visual representation of the comparison between PLA coated paper and alternative materials in terms of raw material costs, production costs, and cost implications. While PLA coated paper may have slightly higher raw material costs compared to PE coated paper or wax-coated paper, it offers long-term savings in terms of disposal and recycling costs. This highlights the cost-effectiveness of PLA coated paper in the context of sustainability and environmental impact.

FAQs about PLA Coated Paper Cost Analysis

How much does PLA coated paper typically cost?

When analyzing the cost of PLA coated paper, it is important to consider the higher initial raw material costs due to the use of renewable resources such as corn starch or sugarcane.

What are the main factors influencing the cost of PLA coated paper?

The primary factors influencing the cost of PLA coated paper include raw material costs, production and manufacturing expenses, and the comparison with traditional materials like PE coating and wax.

How does the production process affect the cost of PLA coated paper?

The production process for PLA coated paper involves specialized equipment and technology, contributing to the overall costs, although advancements in technology can lead to future cost reductions.

How does PLA coated paper compare with PE coated paper in terms of cost?

When comparing PLA coated paper with PE coated paper, it is essential to consider long-term costs and environmental implications, with PLA potentially offering savings in waste disposal and recycling.

What are the economic benefits of using PLA coated paper?

Economic benefits of using PLA coated paper include potential cost savings through environmental incentives, reduced waste management expenses, and alignment with sustainability goals, which can attract eco-conscious consumers.

Switching to PLA coated paper involves understanding raw material, production, and comparison costs. Though initial investments can be high, long-term benefits often justify the switch. Environmental and disposal savings add to its appeal. Market trends show growing interest, and expert insights highlight its potential. Choosing PLA coated paper is not just a financial decision; it’s a step towards sustainable business practices.