Is PE Coating Safe and Effective in Industrial Applications?

What is PE Coating and Its Applications?

PE coating, also known as polyethylene coating, is a protective layer made from polyethylene polymer that is applied to various surfaces to provide added durability, moisture resistance, and other beneficial properties. It is widely used in industries such as automotive, construction, and packaging due to its versatility and effectiveness.

What is PE Coating and how does it work?

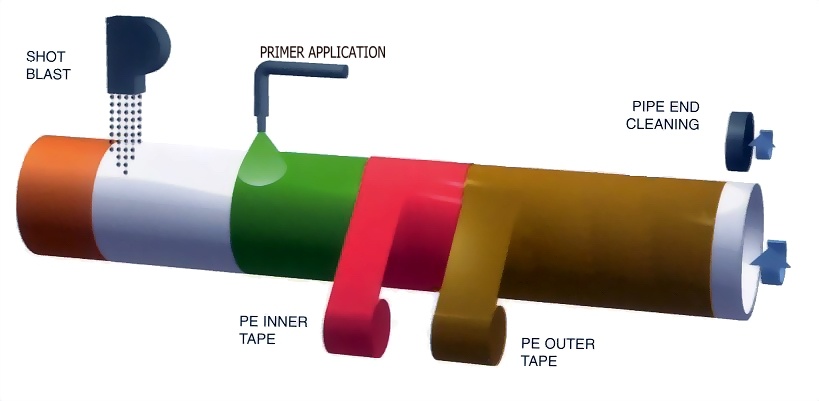

PE coating is a process in which a layer of polyethylene is applied to a surface to provide protection against various environmental factors. The coating can be applied using different techniques such as extrusion coating, lamination, or hot melt coating.

During the extrusion coating process, molten polyethylene is extruded through a die onto a substrate, which can be metal, plastic, or paper. The molten polyethylene then solidifies and forms a seamless and uniform coating. This coating provides a barrier against moisture, chemicals, corrosion, and other external elements.

The lamination process involves bonding a layer of polyethylene film onto a surface using heat and pressure. This method is commonly used for paper and cardboard packaging materials to enhance their water resistance and durability.

Hot melt coating is another technique where a molten layer of polyethylene is applied onto a surface using a heated roller. This method is typically used for coating fabrics, wires, and cables to provide insulation and protection.

PE coating works by forming a protective barrier that prevents the underlying surface from being exposed to moisture, chemicals, and other damaging elements. It improves the lifespan and performance of the coated material, making it suitable for a wide range of applications.

Is PE Coating safe for various applications?

PE coating is generally considered safe for various applications due to its non-toxic nature and resistance to chemical reactions. It is commonly used in industries where safety and durability are critical factors, such as food packaging, medical devices, and automotive components.

PE coatings used for food packaging comply with strict regulations and standards to ensure they do not pose any health risks to consumers. The coating acts as a protective barrier against contaminants, moisture, and grease, ensuring the integrity and safety of the packaged food.

PE coatings are used in the medical industry for sterile packaging and medical devices. These coatings are designed to provide a high level of moisture resistance and protect the integrity of medical products.

When used in automotive applications, such as coating metal parts, PE coatings offer excellent corrosion resistance and durability. This helps protect the components from damage caused by environmental factors and extends their lifespan.

Overall, PE coating is considered safe for various applications as long as it is used in accordance with industry regulations and guidelines.

How is PE coating used in different industries like automotive and construction?

PE coating finds extensive use in different industries due to its versatile properties. Here are some examples of how PE coating is used in automotive and construction:

Automotive Industry:

- PE coatings are applied to metal parts, such as car body panels, to provide corrosion protection. The coating acts as a barrier against moisture, salt, and other corrosive substances, preventing rust and prolonging the lifespan of the components.

- Plastic parts in automobiles, such as bumpers and interior trim, can also be coated with PE to improve their resistance to abrasion, chemicals, and UV radiation.

- Additionally, PE coatings can be used on automotive wiring and cables to provide insulation and protect against moisture and temperature fluctuations.

Construction Industry:

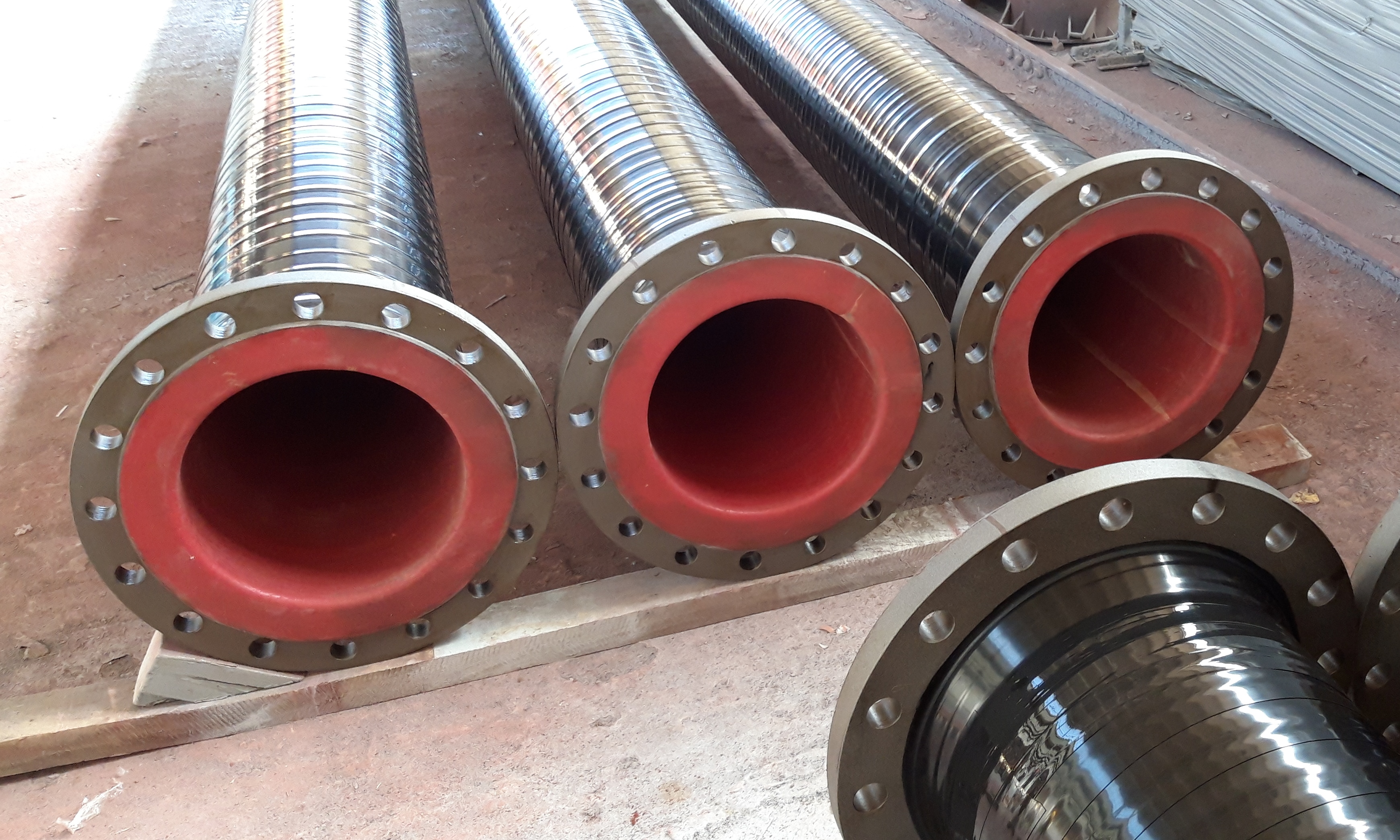

- PE coatings are widely used in the construction industry for various applications. For example, they are applied to metal pipes to prevent corrosion and increase their longevity.

- PE coatings also find use in waterproofing systems for roofs and foundations. The coating acts as a protective barrier against water infiltration, ensuring the structural integrity of buildings.

- In the field of insulation, PE coatings are used in the production of insulating materials, such as foam boards and reflective films. These coatings enhance the energy efficiency and thermal performance of the insulation products.

The versatility and effectiveness of PE coatings make them a valuable solution in many industries, offering protection, durability, and performance enhancements.

Advantages of PE coating on metal surfaces

PE coating offers several advantages when applied to metal surfaces:

- Corrosion Resistance: PE coatings act as a barrier against moisture, chemicals, and corrosive substances, protecting the underlying metal from rust and degradation. This enhances the lifespan and durability of metal components, reducing the need for frequent maintenance and replacement.

- Chemical Resistance: PE coatings have excellent resistance to various chemicals and solvents, making them suitable for applications where exposure to corrosive substances is a concern. The coating helps maintain the integrity and functionality of the metal surface in environments with chemical exposure.

- Impact Resistance: PE coatings provide added protection against impacts and abrasions, minimizing damage to the underlying metal surface. This is particularly beneficial in industries where durability and impact resistance are crucial, such as automotive and construction.

- Moisture Resistance: PE coatings offer high moisture resistance, preventing water penetration and minimizing the risk of corrosion and structural damage. This is especially important in applications where exposure to moisture is common, such as outdoor structures and metal pipes.

- Temperature Resistance: PE coatings can withstand a wide range of temperatures, making them suitable for both hot and cold environments. They offer thermal insulation properties, protecting the underlying metal from heat transfer and temperature fluctuations.

- Ease of Application: PE coatings can be applied using various methods, such as extrusion, lamination, or hot melt coating. These application techniques ensure a seamless and uniform coating, providing consistent protection across the entire metal surface.

The advantages of PE coatings on metal surfaces make them a popular choice in industries where protection, durability, and performance are crucial factors.

FAQs about PE Coating:

What is PE Coating and how does it work?

To understand PE coating, it's essential to know that it involves applying a layer of polyethylene to a surface using techniques like extrusion coating, lamination, or hot melt coating.

Is PE Coating safe for various applications?

PE coating is considered safe due to its non-toxic nature and resistance to chemical reactions, making it suitable for industries like food packaging, medical devices, and automotive components.

How is PE coating used in different industries like automotive and construction?

PE coating is used in the automotive industry for corrosion protection on metal parts and in the construction industry for waterproofing roofs and foundations, among other applications.

What are the advantages of PE coating on metal surfaces?

PE coating offers advantages such as corrosion resistance, impact resistance, moisture resistance, and temperature resistance when applied to metal surfaces.

In conclusion, PE coating offers safety, durability, and corrosion resistance. It's used in various industries such as automotive and construction. Consider factors like quality, pricing, and future trends when choosing a supplier. PE coating on metal and plastic surfaces provides numerous benefits. Stay updated on innovations in technology for optimal coating results.