Why is Paper Offset Grammage Essential in Printing?

Understanding Paper Offset Grammage

Paper offset grammage plays a crucial role in the printing industry. It determines the weight and thickness of the paper used for various printing purposes. In this section, we will explore what paper offset grammage is, why it is important, how it is measured, the importance of gram weight in offset printing, standard ranges of grammage used in offset paper, differences between various paper weights and thicknesses, and tips for choosing the right paper grammage for printing needs.

What is paper offset grammage?

Paper offset grammage refers to the weight and thickness of offset paper used in printing. It is measured in grams per square meter (gsm) and determines the quality and durability of the paper. The higher the grammage, the thicker and heavier the paper.

Why is paper offset grammage important in the printing industry?

Paper offset grammage is important in the printing industry for several reasons. Firstly, it affects the overall quality of the printed material. Thicker and heavier paper provides a more professional and durable finish to printed products like brochures, magazines, and books. It also influences how colors and images appear on the paper, ensuring a better replication of the original design.

Secondly, paper offset grammage affects the printing process itself. The thickness and weight of the paper determine the type of printing technique that can be used. Thicker paper may require specialized printing equipment and processes, while lighter paper can be used with standard printing methods.

Lastly, paper offset grammage affects the cost of printing. Heavier paper typically costs more, which should be taken into consideration when planning a printing project.

How is paper offset grammage measured?

Paper offset grammage is measured using a scale known as grams per square meter (gsm). It represents the weight of the paper per one square meter. A higher gsm indicates a thicker and heavier paper, while a lower gsm indicates a lighter paper.

Importance of gram weight in offset printing

Gram weight is a crucial factor in offset printing. It determines the quality, appearance, and durability of the printed material. Choosing the right gram weight ensures that the printed product meets the desired specifications, whether it’s a brochure, magazine, or book. It affects how the ink adheres to the paper, how the colors appear, and how the paper feels to the touch. Additionally, gram weight affects the overall cost of printing, as heavier paper tends to be more expensive.

Standard ranges of grammage used in offset paper

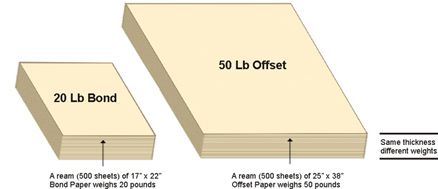

Standard ranges of grammage used in offset paper vary depending on the specific requirements of the printing project. However, some commonly used ranges include:

- 60-80 gsm: Lightweight paper suitable for documents, flyers, and leaflets.

- 80-100 gsm: Standard-weight paper commonly used for letterheads, catalogs, and brochures.

- 100-120 gsm: Medium-weight paper suitable for high-quality brochures, magazines, and booklets.

- 120-160 gsm: Heavyweight paper used for covers, postcards, and high-end marketing materials.

These ranges can vary based on the printer and the desired visual impact and durability of the printed material.

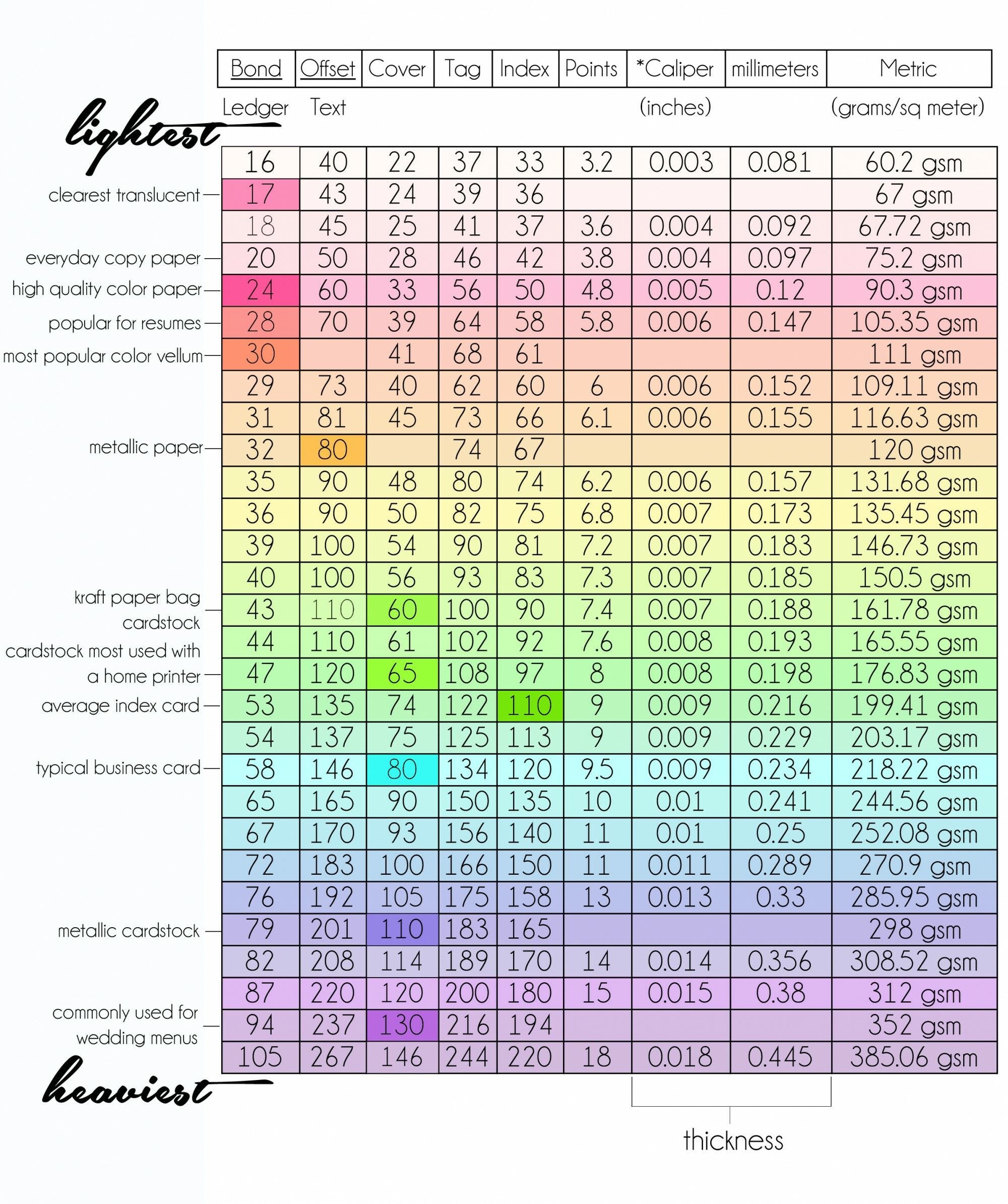

Differences between various paper weights and thicknesses

Different paper weights and thicknesses serve specific purposes. Bond paper, for example, typically has a weight of 20 pounds per 17 x 22 basis size, while offset paper weighs 50 pounds per 25 x 38 basis size. It’s important to understand that these measurements refer to the weight of 500 sheets of paper in the paper’s basis size (ream).

Cover stocks, on the other hand, come in various weights like 60 lb, 65 lb, 80 lb, and 100 lb, with higher weights like 111 lb and 130 lb available as well. The thickness of the paper is often specified in points, where 10-point stock is equal to 100 lb coated cover and 80 lb uncoated cover.

Tips for choosing the right paper grammage for printing needs

When choosing the right paper grammage for printing needs, consider the following tips:

- Consider the type of project: Different projects require different paper thicknesses. For example, a brochure might require a heavier stock than a simple document.

- Determine the desired durability: If the printed material needs to withstand wear and tear, opt for a heavier paper grammage.

- Consider the printing budget: Heavier paper comes with a higher cost. Determine your budget and choose a grammage that fits within your constraints.

- Consult with a professional printer: If you’re unsure about the appropriate paper grammage for your project, consult with a professional printer who can provide guidance based on your specific requirements.

In conclusion, understanding paper offset grammage is crucial when selecting the right paper for printing projects. The weight and thickness of the paper have a significant impact on the quality, appearance, and cost of the final product. By considering the specific project requirements and following these tips, you can choose the perfect paper grammage for your printing needs.

Calculating and Converting Paper Grammage

Methods for Calculating Paper Grammage from Weight

When it comes to paper, one important aspect that needs to be understood is the concept of paper grammage, also known as basis weight or paper weight. Paper grammage refers to the weight of paper per unit area, commonly expressed as grams per square meter (gsm) or pounds per ream (lb). Understanding paper grammage is vital in the printing industry as it helps determine the thickness and quality of paper used in various printing projects.

Calculating paper grammage from weight can be done using simple formulas. For instance, to convert pounds (lb) to grams per square meter (gsm), you can use the formula:

Grams per square meter (gsm) = Pounds (lb) * 453.59237 / Area

Where the area represents the size of the paper in square inches. Similarly, to convert grams per square meter (gsm) to pounds (lb), you can use the formula:

Pounds (lb) = Grams per square meter (gsm) * Area / 453.59237

By using these formulas, you can easily calculate and convert the paper grammage based on weight.

Importance of Understanding Paper Weight Conversion

Understanding paper weight conversion is crucial in the printing industry for several reasons. Firstly, it helps in selecting the right type of paper for a particular printing project. Different types of printing materials, such as books, brochures, or business cards, require different paper weights to achieve the desired results. By understanding paper weight conversion, printers can choose the appropriate grammage to ensure optimal print quality, durability, and functionality.

Secondly, understanding paper weight conversion allows printers to estimate the cost of printing projects accurately. Paper is often one of the significant expenses in printing, and knowing the weight of the paper helps in determining the quantity and cost required for a specific job. By calculating the paper grammage accurately, printers can avoid overordering or underordering paper, thereby optimizing their printing operations and reducing costs.

Using Paper Weight Conversion Calculators for Precision

To simplify the process of calculating and converting paper grammage, there are various online tools and paper weight conversion calculators available. These calculators allow printers and designers to input the desired weight or grammage and convert it into the appropriate unit of measurement. These calculators can provide precise conversions, taking into account the specific area of the paper.

Using paper weight conversion calculators ensures accuracy and saves time, especially when dealing with large quantities and multiple printing projects. It eliminates the need for manual calculations and provides instant results, making it easier to make informed decisions regarding paper selection and ordering.

Standard Basis Weight Conversions for Different Paper Types

Different types of paper have their own standard basis weights, which are widely used in the printing industry. These standard basis weights help establish uniformity and consistency in the selection and use of paper for printing projects. Here are some common standard basis weight conversions for different paper types:

- Bond Paper: The standard basis weight for bond paper is 20 lb (25 x 38 basis size), which is equivalent to approximately 50 gsm.

- Offset Paper: Offset paper typically has a standard basis weight of 50 lb (25 x 38 basis size), which equates to around 120 gsm.

- Cover Stock: Cover stocks come in various weights, including 80 lb, 100 lb, and higher. The basis size for cover stock is usually 20 x 26 inches.

It’s important to note that these standard basis weights may vary depending on the paper manufacturer and specific paper grade. It’s always advisable to consult the paper manufacturer’s specifications for accurate basis weight conversions.

In conclusion, calculating and converting paper grammage is essential in the printing industry for selecting the right paper, estimating costs, and ensuring optimal print quality. By understanding the methods for calculating paper grammage, converting between pounds and grams, and using paper weight conversion calculators, printers and designers can make informed decisions and achieve the desired results in their printing projects. Familiarizing oneself with the standard basis weight conversions for different paper types further enhances the ability to choose the appropriate grammage for specific printing needs.

Practical Applications of Paper Offset Grammage in Printing

Offset printing is a widely used technique in the printing industry, known for its cost-effective and efficient production of high-quality printed materials. One key factor that plays a crucial role in offset printing is the paper offset grammage. In this section, we will explore the practical applications of paper offset grammage in printing, including its characteristics, advantages, common uses, differences between coated and uncoated paper, best practices, and troubleshooting tips.

Characteristics of Offset Paper in Printing

Offset paper is specifically designed for offset lithography, the printing method primarily used for books, magazines, and brochures. This type of paper is woodfree and undergoes a chemical process to remove lignin, resulting in a strong and durable material suitable for printing purposes. Some of the key characteristics of offset paper include:

- ISO Brightness: Offset paper typically has an ISO brightness of over 80%, ensuring vibrant and clear printed images.

- Moisture Resistance: Sizing agents are added to offset paper during manufacturing to enhance its resistance to moisture, preventing unwanted warping or curling.

- Internal Bonding: Offset paper is known for its strong internal bonding, which helps to maintain the integrity of the paper during the printing process, reducing issues like tearing or wrinkling.

- Surface Strength: Offset paper has a high surface strength, allowing for sharp and crisp printing results without smudging or fading.

- Low Linting: Offset paper is designed to have minimal linting, reducing the risk of unwanted debris or particles during printing.

Advantages of Using Offset Paper in Printing Processes

Using offset paper in printing processes offers several advantages that make it a popular choice among printers. Some of the key advantages include:

- Cost-Effective: Offset printing is an efficient and cost-effective method for mass production. Offset paper is often more affordable compared to other specialized papers, making it a practical choice for many printing projects.

- Versatility: Offset paper can be used for a wide range of printed materials, including books, magazines, brochures, flyers, and more. Its versatility makes it suitable for various industries and applications.

- High-Quality Images: Offset printing provides high-quality, detailed images with vibrant colors and sharp text. The use of offset paper enhances the clarity and resolution of the printed images, resulting in professional-looking end products.

- Plate Longevity: Offset printing plates have a longer lifespan compared to other printing methods, allowing for more prints without the need for frequent plate changes. This not only saves time but also reduces printing costs.

Common Uses of Offset Paper in the Printing Industry

Offset paper finds extensive use in the printing industry due to its versatility and high-quality printing capabilities. Some of the common uses of offset paper include:

- Books and Magazines: Offset paper is widely used for book printing, including novels, textbooks, and reference books. It is also the preferred choice for magazine printing, ensuring crisp images and text.

- Brochures and Flyers: Offset paper is commonly used for creating brochures and flyers that require high-quality graphics and vibrant colors to attract readers’ attention.

- Business Forms and Stationery: Offset paper is ideal for printing business forms, letterheads, envelopes, and other stationery items. It provides a professional look and feel, making a lasting impression on recipients.

- Posters and Banners: Offset paper with a heavier grammage is suitable for large-format printing, making it an excellent choice for posters, banners, and signage.

The Difference Between Coated and Uncoated Offset Paper

Offset paper is available in both coated and uncoated variations, each with its own unique properties and applications.

- Coated Offset Paper: Coated offset paper is treated with a coating layer, typically made of clay or other minerals, to improve durability and brightness. This type of paper is commonly used for items like book covers, brochures, and high-end promotional materials. The coating provides a smooth and reflective surface, enhancing the overall appearance of the printed product.

- Uncoated Offset Paper: Uncoated offset paper does not have a coating layer, resulting in a more coarse and rough texture. It is highly absorbent and suitable for applications that require clear printing and writing, such as letterheads, envelopes, and business forms. The ink is absorbed by the paper, providing a natural and tactile feel.

Best Practices for Utilizing Offset Paper in Printing Projects

To ensure optimal results when using offset paper, it is important to follow some best practices:

- Choose the Right Grammage: Select the appropriate grammage of offset paper based on the specific printing project and desired outcome. Consider factors like paper thickness, opacity, and the type of printing method used.

- Consider Coating Options: Determine if a coated or uncoated offset paper is more suitable for the desired application. Coated paper provides enhanced durability and vibrant colors, while uncoated paper offers a natural and tactile finish.

- Test Print Samples: Before proceeding with a large-scale printing project, it is advisable to obtain test print samples to evaluate the final result. This allows for adjustments and fine-tuning if necessary.

- Verify Printer Compatibility: Ensure that the offset paper chosen is compatible with the printing equipment being used. Different printers may have specific requirements in terms of paper weight and thickness.

Common Issues and Troubleshooting with Paper Grammage in Offset Printing

While offset printing with offset paper offers numerous benefits, it is important to be aware of potential issues and troubleshooting techniques. Some common issues related to paper grammage in offset printing include:

- Peel-Offs: In some cases, the ink may not properly adhere to the offset paper, resulting in peel-offs or flaking. This issue can be addressed by adjusting the ink formulation or selecting a paper with more suitable characteristics.

- Blistering: Excessive heat during the printing process can cause blistering or bubbling on the paper surface. Proper temperature control and paper selection can help prevent this issue.

- Paper Thickness: Choosing the wrong paper thickness for a specific printing project can lead to issues with the proper alignment and registration of the printed images. It is important to select the appropriate weight and thickness based on the desired outcome.

- Opacity: Insufficient opacity of the offset paper can result in a lack of color vibrancy or show-through from the reverse side. Consider selecting a more opaque paper option to achieve the desired results.

Understanding the practical applications of paper offset grammage in printing is essential for achieving high-quality, professional results. By considering the characteristics, advantages, common uses, coated versus uncoated options, best practices, and troubleshooting tips, printers can optimize their use of offset paper and deliver exceptional printed materials to their clients.

FAQs about Paper Offset Grammage

What is paper offset grammage?

To understand paper offset grammage, one must recognize that it refers to the weight and thickness of offset paper used in printing, measured in grams per square meter (gsm), impacting the quality and durability of the paper.

Why is paper offset grammage important in the printing industry?

Paper offset grammage is crucial in printing for its influence on overall quality, printing process requirements, color and image replication, and cost considerations.

How is paper offset grammage measured?

Measuring paper offset grammage involves using grams per square meter (gsm), representing the weight of the paper per one square meter, with higher gsm indicating thicker and heavier paper.

What is the importance of gram weight in offset printing?

Gram weight is essential in offset printing, affecting quality, appearance, durability, ink adherence, color rendition, cost considerations, and overall suitability for various printing projects.

What are the standard ranges of grammage used in offset paper?

Commonly used ranges include:

- 60-80 gsm for lightweight paper.

- 80-100 gsm for standard-weight paper.

- 100-120 gsm for medium-weight paper.

- 120-160 gsm for heavyweight paper, varying based on visual impact and material durability.

In conclusion, we delved into paper offset grammage basics, conversions, and practical applications. Understanding gram weight is crucial for precise printing results. Calculating and converting paper weight ensures accuracy in projects. Utilize offset paper’s benefits effectively for optimal printing outcomes. Remember to consider paper thickness variations when selecting the right option. Experimenting with different paper grammages can enhance your printing projects. Mastering the nuances of paper offset grammage will elevate your printing endeavors.