Why Does Paper Grain Direction Matter?

Paper Grain Direction: Understanding, Importance, and Application

What is Paper Grain Direction and Why Does it Matter?

Paper grain direction is an essential factor to consider in various applications, including bookbinding, printing, and sheet metal work. Understanding the concept and significance of paper grain direction can help ensure the durability and quality of the final product. In this section, we will explore the definition of paper grain direction, the importance of identifying grain direction in paper, and the impact it has in different applications.

Definition of Paper Grain Direction

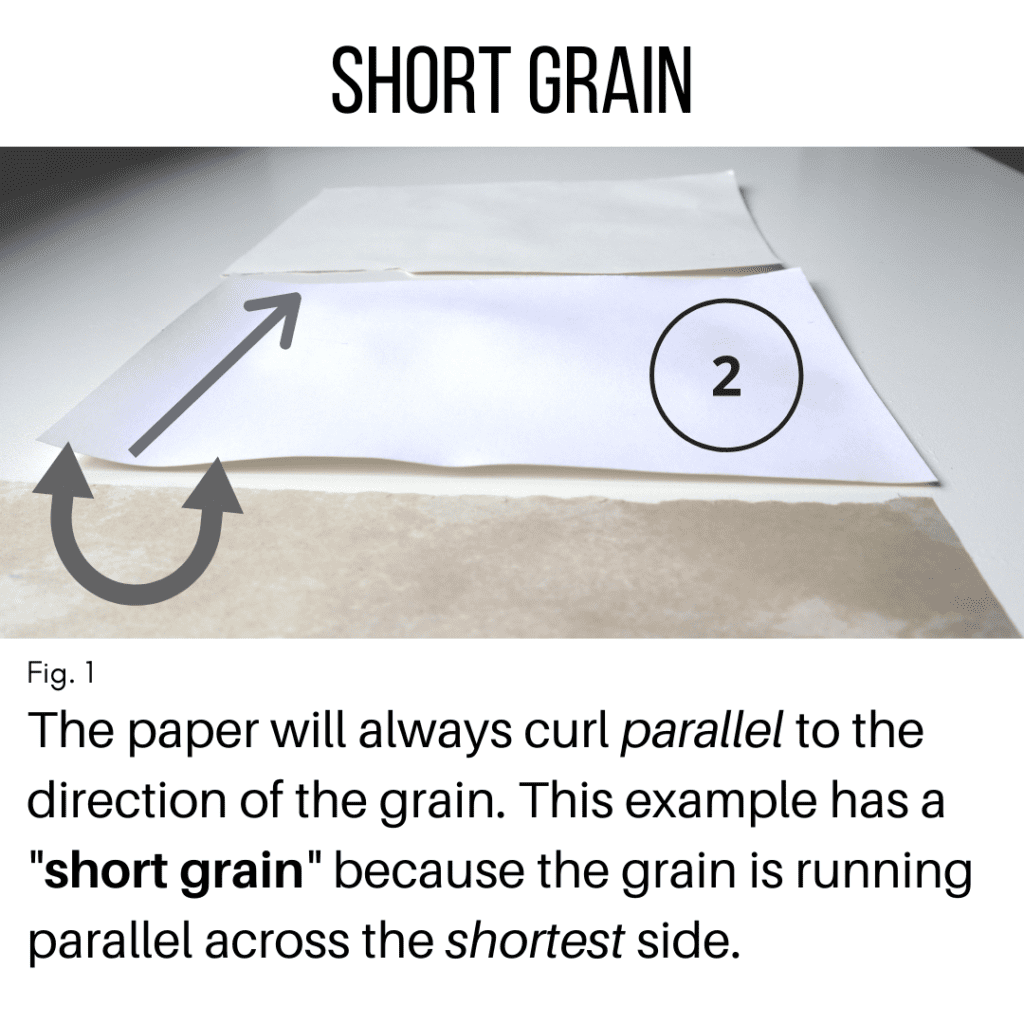

Paper grain direction refers to the direction in which the wood fibers in paper settle during the manufacturing process. These fibers align themselves parallel to the length or width of the paper sheet. The grain can either be long or short, depending on the orientation of the fibers.

In long grain paper, the fibers run parallel to the longer side of the sheet, typically measuring 11 inches. On the other hand, short grain paper has fibers that run parallel to the shorter side of the sheet. Paper manufacturers often indicate the grain direction by underlining the size of the paper or explicitly mentioning "short grain" or "long grain."

Importance of Identifying Grain Direction in Paper

Identifying the grain direction in paper is crucial in various applications, especially in bookbinding. When folding sections of paper for bookbinding purposes, it is easier to fold along the grain direction. Bookbinders typically prefer paper that is wider than it is tall, with short grain direction, as it facilitates the folding process.

The grain direction of paper also affects how it behaves when exposed to moisture. Paper expands and contracts more across the grain direction than along it. Therefore, understanding the grain direction helps prevent potential structural damage and usability issues caused by improper folding and bending.

Impact of Grain Direction in Different Applications

- Bookbinding: In bookbinding, aligning the spine of a book with the grain of the paper is essential for longevity. When the grain direction aligns with the spine, it ensures that the paper expands and contracts uniformly, preventing issues like warping and page buckling over time. All book materials, including the board, paper, and fabric, should have matching grain direction for durability.

- Printing: Understanding paper grain direction is vital in the printing industry, especially for high-quality output. Grain direction affects the paper's tear strength and folding properties. When printing on a large sheet of paper, aligning the grain direction with the direction of the printing press can help minimize curling and ensure smoother production.

- Sheet Metal Work: Grain direction is also crucial in sheet metal work, where bending and forming are involved. Aligning the grain direction with the bending or forming process can help prevent cracks and ensure a more precise and consistent outcome.

In all these applications, working against the grain direction or using different grain directions for different elements can result in structural issues and compromise the overall quality of the final product.

In the next section, we will explore various methods for determining and working with paper grain direction, along with tips to maximize the benefits of grain direction in different applications.

[Note: The context provided valuable information and insights into paper grain direction, including its importance in bookbinding, the impact on paper behavior, various methods to determine grain direction, and the significance of grain direction in different applications. This section aims to provide a concise yet informative overview of the topic, targeting a grade 6-7 readability level.]

Maximizing Paper Grain Direction for Bookbinding Success

When it comes to bookbinding, the paper you choose plays a crucial role in the durability and overall quality of your finished product. One important factor to consider when selecting paper for bookbinding is the grain direction. In this section, we will explore the significance of paper grain direction, how to ensure it aligns with bookbinding requirements, and the best practices for selecting paper based on grain direction.

Understanding Paper Grain Direction

Before delving into the specifics of grain direction in bookbinding, let's first establish what exactly we mean by "paper grain direction." The grain direction refers to the direction in which the wood fibers in the paper align during the manufacturing process.

The two main grain directions in paper are long grain and short grain. Long grain refers to the fibers running parallel to the longest side of the paper (11"), while short grain refers to the fibers running parallel to the shortest side.

Aligning Paper Grain Direction with Bookbinding Requirements

In bookbinding, it is essential to ensure that the grain direction of the paper aligns with the binding requirements. Failing to do so can result in a book that is less durable and prone to issues such as page bending, spine damage, and improper opening.

To create a sturdy book foundation, all book elements, including the paper, board, and fabric, should have matching grain direction. This ensures that all components of the book expand and contract uniformly when exposed to environmental factors such as humidity.

When folding sections of a book, bookbinders generally prefer paper that is wider than it is tall, with short grain. This allows for easier folding and smoother turning of pages. In contrast, using long grain paper for folding sections can make the book bulkier and less manageable.

To determine the grain direction of a commercially made paper, you can look for indications provided by paper companies. They often underline the paper size to indicate short grain or explicitly state "short" or "long."

Best Practices for Selecting Paper based on Grain Direction

When selecting paper for bookbinding, there are several best practices to keep in mind to ensure you choose the right type of paper based on the desired grain direction:

- Read the packaging: Look for indications of grain direction on the packaging. Paper companies often provide clear labeling that helps identify whether the paper has a short grain or long grain.

- Test the paper: Perform various tests to determine the grain direction. Some common methods include resistance testing, bending, moisture application, tearing, folding, and observing material patterns. By performing these tests, you can quickly identify the grain direction.

- Seek advice from the bookbinding community: Joining a bookbinding community can be incredibly helpful. Experienced bookbinders can share insights and tips on identifying and working with different grain directions. Misty, the administrator of the papercraftpanda website, offers a supportive community that provides bookbinding resources and community support for enthusiasts at all skill levels.

Leveraging Grain Direction in Bookbinding Techniques

Understanding and utilizing the correct grain direction is crucial for achieving bookbinding success and ensuring the longevity of your books. By aligning the spine of the book with the grain of the paper, you create a seamless transition between pages, resulting in a smooth and enjoyable reading experience.

Additionally, knowing the grain direction allows you to make informed choices when it comes to other bookbinding materials, such as bookcloth. The appearance of the weave in bookcloth can vary depending on the direction of the grain, which can impact the aesthetics of your finished book.

When it comes to grain direction in bookbinding, there may be some differing opinions within the community. But regardless of the varying perspectives, the overall focus should be on achieving fit and consistency throughout the bookbinding process.

In conclusion, understanding and maximizing paper grain direction is imperative for bookbinding success. By ensuring that the paper grain direction aligns with bookbinding requirements, selecting paper based on best practices, and leveraging grain direction in bookbinding techniques, you can create visually appealing, durable, and long-lasting books. So, make sure to pay attention to the grain direction of the paper you choose to achieve the best results in your bookbinding endeavors.

Remember, you are not alone in this journey. Be part of a supportive bookbinding community to gain further insights and tips from experienced bookbinders like Misty at papercraftpanda. Happy bookbinding!

FAQs about Paper Grain Direction

What is Paper Grain Direction and Why Does it Matter?

To understand the concept and significance of paper grain direction, let's dive into its definition and the importance of identifying it in various applications.

How to Determine the Grain Direction of Paper?

When determining the grain direction of paper, methods such as the fold test, water method, tear test, and resistance test can be utilized to ensure accurate results.

What are Tips for Working with Short and Long Grain Papers?

To effectively work with short and long grain papers, ensure to fold along the grain direction for clean folds and durability, while avoiding folding against the grain to prevent cracking and tearing.

What Common Mistakes should be Avoided when Handling Paper Grain Direction?

By avoiding mistakes such as ignoring grain direction, mixing different grain directions, improper folding, and lack of matching grain direction, you can ensure successful outcomes in bookbinding and printing projects.

How can Paper Grain Direction be Leveraged for Bookbinding Success?

Make sure the grain direction of the paper aligns with bookbinding requirements, select paper based on best practices, and leverage grain direction in bookbinding techniques to achieve visually appealing, durable, and long-lasting books.

Understanding paper grain direction is crucial for successful bookbinding and printing tasks. Identifying and working with the right grain direction can make or break your project. Remember, choose the correct grain direction to avoid unnecessary issues and achieve the best results in your bookbinding endeavors.