How is the Paper Cup Manufacturing Process Executed?

Raw Materials and Preparation

Paper cups are a common sight in our daily lives, especially in coffee shops, fast food chains, and events. But have you ever wondered about the process behind manufacturing these convenient and disposable cups? In this comprehensive guide, we will take you through the step-by-step process of paper cup manufacturing, starting with the raw materials and preparation.

Key Raw Materials Used in Paper Cup Manufacturing

The production of paper cups requires several key raw materials, including paperboard, wood pulp, cotton linters, and recycled paper. Paperboard is derived from wood pulp and is the primary material used for making paper cups. It is a food-grade material that is sourced from sustainable forests. This ensures that the paper cups are safe for food and beverage consumption.

Wood pulp is the main ingredient in paperboard, and it is obtained from trees. The wood pulp is processed and refined to remove impurities and create a material that is suitable for making paper cups. Cotton linters, on the other hand, are short fibers that are derived from the cotton plant. These fibers are added to the wood pulp mixture to improve the strength and durability of the paper cups.

Recycled paper is another important raw material in paper cup manufacturing. It is obtained from used paper products, such as newspapers, magazines, and cardboard boxes. Recycling paper reduces the demand for fresh wood pulp and helps conserve natural resources. Additionally, recycled paper cups have a lower environmental impact compared to those made from virgin materials.

The Preparation Process for Paper Cup Production

The preparation process for paper cup production starts with the transformation of paperboard into pulp. The paperboard is first cleaned to remove any impurities and contaminants. It is then transformed into a slurry by mixing it with water. This slurry is cooked in an open-air vat, which breaks down the fibers and allows them to be easily separated.

Once the cooking process is complete, the slurry is filtered to remove any remaining impurities. It is then bleached to achieve the desired whiteness and cleanliness. After bleaching, the pulp is dried in rotating drums to remove any excess moisture. This prepares the pulp for the next stage of the paper cup manufacturing process.

Importance of Sustainable Sourcing in Raw Materials for Paper Cup Manufacturing

Sustainable sourcing of raw materials is of great importance in the paper cup manufacturing industry. It ensures that the raw materials used are obtained from responsibly managed forests, minimizing the impact on the environment. Sourcing paperboard from sustainable forests helps preserve biodiversity, conserve water resources, and protect the livelihoods of local communities.

In addition to sustainable sourcing, the use of recycled paper in manufacturing paper cups further reduces the environmental impact. By diverting used paper products from landfills and repurposing them for paper cup production, we can significantly reduce the consumption of virgin materials and the associated energy and water required for their production.

By choosing eco-friendly paper cups made from sustainably sourced or recycled materials, we can contribute to a more sustainable future. These choices not only reduce our carbon footprint but also send a message to manufacturers and policymakers about the importance of environmental stewardship.

In conclusion, understanding the raw materials and preparation process involved in paper cup manufacturing gives us insight into the environmental considerations and sustainability efforts in the industry. By opting for eco-friendly paper cups and supporting manufacturers committed to sustainable practices, we can make a positive impact on the environment while enjoying the convenience of disposable paper cups.

Paper Cup Formation Techniques

In the process of manufacturing paper cups, the shaping of cup blanks into the final product is a crucial step. There are various techniques used to achieve this, each with its own advantages and considerations. Additionally, the inclusion of a polyethene (PE) lining is essential in traditional paper cup manufacturing to ensure leak-proof properties and maintain the integrity of the cup. In this section, we will delve into the different techniques used to shape paper cup blanks and explore the significance of the PE lining.

What are the different techniques used to shape paper cup blanks?

Technique 1: Folding and Seam Sealing

One of the most common techniques used to shape paper cup blanks is the folding and seam sealing method. In this technique, the cup blanks are initially scored and cut into the desired shape and size. Special precision machinery is used to fold the blanks along the scored lines, creating the characteristic cylindrical shape of the cup. The folded edges are then sealed with heat or adhesive to ensure the cup remains intact during use.

This technique offers several advantages. It is highly efficient, allowing for the mass production of paper cups at a rapid pace. It also produces cups with clean and seamless edges, providing a superior drinking experience. Additionally, this technique enables customization, as cup blanks can be easily printed with logos, designs, or branding messages before folding and sealing.

Technique 2: Forming Using Molds

Another technique used to shape paper cup blanks is through the use of molds. In this method, cup blanks are placed in specially designed molds that conform to the desired cup shape. Heat and pressure are then applied to the blanks, causing them to mold to the shape of the mold. The molded cup blanks are subsequently cooled to retain their shape.

This technique offers greater flexibility in terms of cup shapes and sizes. Different molds can be used to create cups with unique designs, such as those with fluted or ripple patterns. Additionally, this method allows for the production of cups with complex shapes or features, such as handles or grip textures. However, it is important to note that this technique may require more time and precision to ensure the cups are formed accurately.

Why is a polyethene (PE) lining essential in traditional paper cup manufacturing?

The inclusion of a polyethene (PE) lining is crucial in traditional paper cup manufacturing for several reasons. The PE lining serves as a barrier between the cup and the contents it holds, preventing any leakage or seepage. This is particularly important when it comes to hot or cold beverages, as the lining helps retain the temperature while offering protection to the paperboard material.

Moreover, the PE lining enhances the durability and strength of the cup. It provides a layer of structural support, making the cups resistant to bending or collapsing under the weight of the liquid. Additionally, the lining acts as a moisture barrier, preventing the absorption of liquid and maintaining the integrity of the cup.

From an environmental perspective, it is worth noting that the use of a PE lining in traditional paper cup manufacturing presents challenges in terms of disposal and recycling. The combination of paper and plastic materials makes it difficult to separate and recycle these cups. Consequently, efforts are underway to explore alternative eco-friendly coatings or linings that are more easily recyclable or biodegradable while still maintaining necessary functionality.

Exploring the process of shaping cup blanks into paper cups

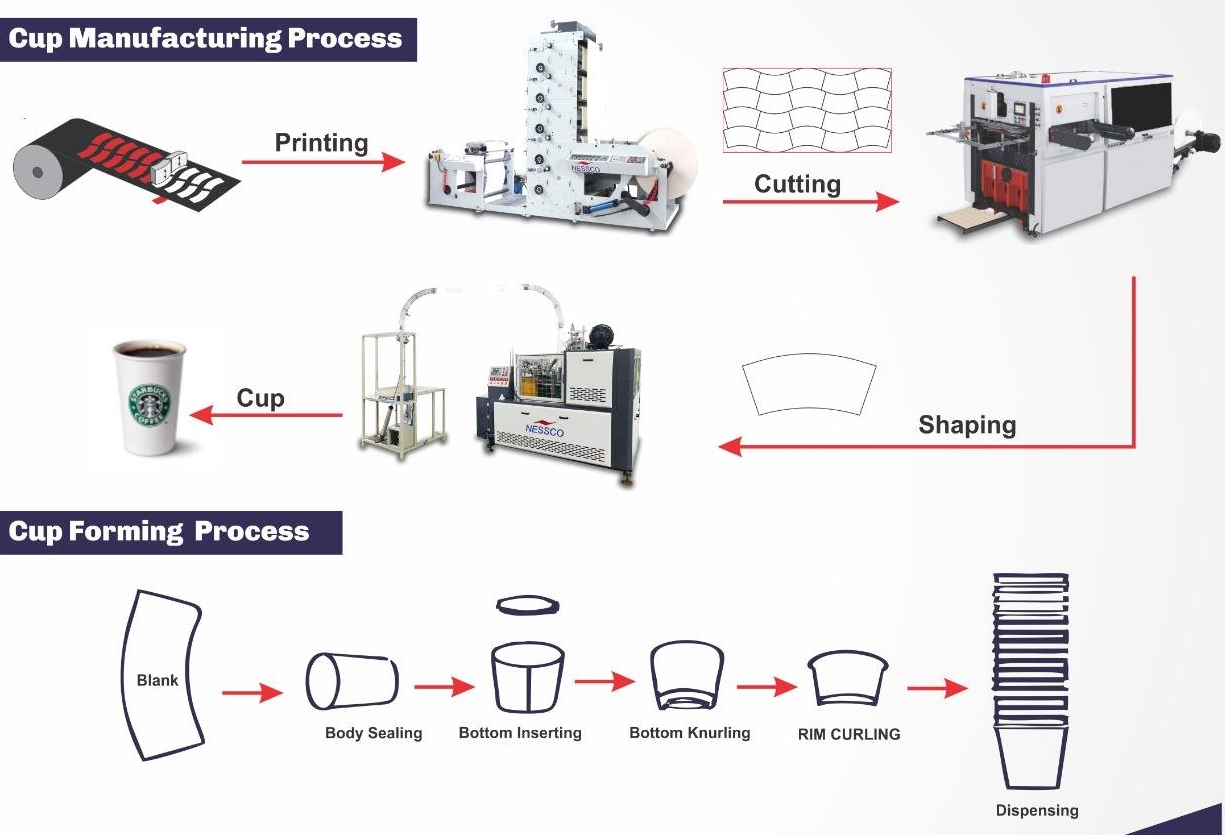

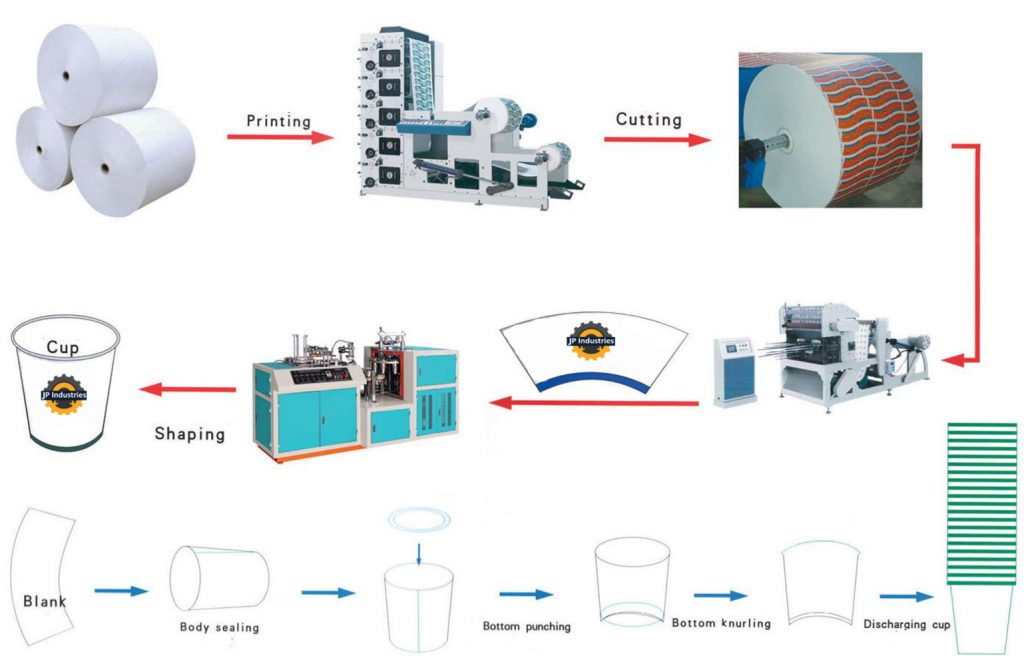

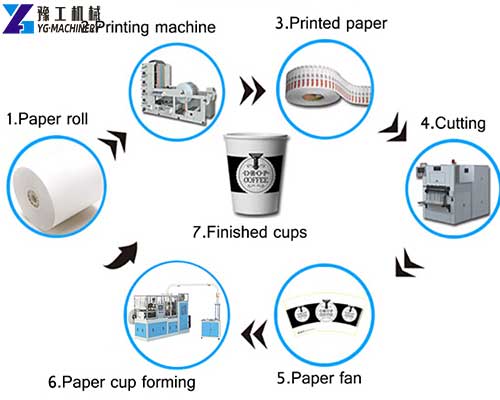

The process of shaping cup blanks into paper cups involves multiple steps that require precision and specialized machinery. Here is a simplified overview of the process:

- Cup Blank Cutting: The prepared paperboard is cut into individual cup blanks of the desired size and shape. The blanks are typically circular with fluted sides to enhance rigidity.

- Folding and Seam Sealing: The cup blanks are folded along pre-scored lines and the edges are sealed together using heat or adhesive to ensure a seamless and sturdy cup structure.

- Polyethene (PE) Lining: The cups are coated with a layer of polyethene (PE) on the inside to provide a leak-proof barrier. This lining is essential in preventing liquid absorption and maintaining the integrity of the cup.

- Printing and Customization: Cup blanks can be customized through various printing techniques like flexographic or offset printing. Logos, designs, or branding messages can be added to enhance visual appeal and brand recognition.

- Cutting and Rim Rolling: The cups are cut to the desired height, and the upper rim is rolled to create a smooth and comfortable drinking edge.

- Quality Control: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the cups meet industry standards for structural integrity, leak-proof properties, and overall quality.

- Packaging: Once the cups pass quality control checks, they are packaged and prepared for distribution and shipment to various businesses such as coffee shops, fast-food chains, or convenience stores.

In conclusion, the shaping of cup blanks into paper cups involves specific techniques such as folding and seam sealing or forming with molds. Additionally, the inclusion of a polyethene (PE) lining is vital for traditional paper cup manufacturing to provide leak-proof properties and enhance cup strength. It is important to balance functionality and environmental considerations in the production of paper cups, exploring alternative coating materials that are more eco-friendly and easily recyclable.

Quality Control Measures and Environmental Considerations

How are quality control measures implemented in paper cup manufacturing?

Quality control is an essential aspect of paper cup manufacturing to ensure that the cups are safe, durable, and meet hygiene standards. The process begins with sourcing high-quality raw materials, such as wood pulp, cotton linters, and recycled paper. These materials undergo cleaning, transforming them into pulp, and bleaching. The cup blanks are then cut from the prepared paperboard and sized for the desired volume.

Once the cup blanks are ready, they go through shaping processes using folding and sealing techniques. Traditional paper cups used to have a polyethene (PE) lining for leak-proofing. However, the industry has evolved, and today, cups receive a PE coating that not only provides leak-proofing but also ensures they can hold hot and cold beverages.

Quality control measures are implemented at various stages of the manufacturing process. After printing, which involves flexographic or offset techniques for customization, the cups go through cutting, rim rolling, and quality control stages. These checks and inspections ensure that the cups meet the necessary standards before they are packaged and shipped.

What are the environmental considerations in paper cup production?

As the world becomes more environmentally conscious, the paper cup industry has been making efforts to address its environmental impact. It is crucial to understand the environmental considerations involved in paper cup production to make informed decisions and encourage sustainable practices.

Paper cups are primarily made from paperboard sourced from sustainable forests. However, it is important to note that the production of paper cups, especially those made from wood pulp, does have an environmental impact. The process requires significant energy and water resources, and the cups take up space in landfills.

To reduce the environmental impact, there has been a shift towards using eco-friendly materials and promoting recycling in the paper cup industry. Manufacturers are exploring plant-based or biodegradable materials for the coating layer of the cups, replacing traditional plastic linings. This shift towards eco-friendly materials aims to reduce the overall environmental impact of paper cup production.

Additionally, recycling plays a crucial role in mitigating the environmental impact of paper cups. While paper cups can be easily recycled, it is important to promote proper recycling practices to maximize their potential. This includes educating consumers about separating the cups from other waste and ensuring that recycling facilities are equipped to handle paper cup recycling effectively.

Exploring the shift towards eco-friendly materials and recycling in the paper cup industry

The demand for eco-friendly alternatives in the paper cup industry has led to a significant shift towards using more sustainable materials and promoting recycling. Manufacturers are actively exploring and implementing innovative solutions to reduce the environmental impact of their products.

One notable example is Yoon, a leading player in the paper cup manufacturing industry. Yoon focuses on material selection, sourcing high-grade recycled or sustainably sourced raw materials, and using alternative coatings to reduce the environmental impact of their cups. They strive to strike a balance between quality and sustainability.

In addition to material considerations, manufacturers are also adopting recycling initiatives to promote a circular economy. Recycling paper cups not only reduces waste but also helps conserve resources. By effectively recycling paper cups, the industry can reduce its environmental footprint and contribute to a more sustainable future.

The future of paper cup manufacturing lies in innovation and continued efforts to improve sustainability. Manufacturers are exploring bio-plastics and more efficient machinery to further minimize the environmental impact of production while meeting the growing demand for paper cups.

In conclusion, quality control measures are an essential part of the paper cup manufacturing process to ensure product safety and hygiene. Environmental considerations have also become a significant focus in the industry, driving the shift towards eco-friendly materials and promoting recycling. By implementing sustainable practices, the paper cup industry can minimize its environmental impact and contribute to a more sustainable future.

Key Raw Materials Used in Paper Cup Manufacturing

| Raw Material | Description |

|---|---|

| Paperboard | Derived from wood pulp, primary material for making cups |

| Wood pulp | Main ingredient in paperboard, obtained from trees |

| Cotton linters | Short fibers derived from cotton plant, added for strength |

| Recycled paper | Obtained from used paper products, reduces environmental impact |

Environmental Considerations in Paper Cup Production

| Environmental Consideration | Actions Taken |

|---|---|

| Sustainable sourcing of raw materials | Sourcing from responsibly managed forests, promoting recycling |

| Use of eco-friendly coating materials | Exploring plant-based or biodegradable coatings |

| Recycling paper cups | Educating consumers, improving recycling facilities |

| Innovation in materials and machinery for sustainability | Exploring bio-plastics, efficient production processes |

| Striving for a circular economy | Adopting recycling initiatives to conserve resources |

Techniques for Shaping Paper Cup Blanks

| Technique | Description |

|---|---|

| Folding and Seam Sealing | Cup blanks are folded and sealed along scored lines, producing clean, seamless cups |

| Forming Using Molds | Cup blanks are molded using specialized molds, allowing for unique designs and features |

| Polyethene (PE) Lining Application | Cups receive a polyethene (PE) lining for leak-proofing and enhancing cup strength |

| Printing and Customization | Cup blanks can be customized with logos, designs, or branding messages before shaping |

| Cutting and Rim Rolling | Cups are cut to size and the upper rim is rolled to create a smooth and comfortable edge |

| Quality Control and Packaging | Rigorous quality control measures ensure cups meet industry standards before packaging |

These tables provide a visual representation of the data discussed in the article, making it easier to understand and reference key information.

FAQs about Paper Cup Manufacturing Process:

Q: What are the key raw materials used in paper cup manufacturing?

A: The key raw materials used in paper cup manufacturing include paperboard, wood pulp, cotton linters, and recycled paper.

Q: How is the preparation process for paper cup production described?

A: The preparation process for paper cup production involves transforming paperboard into pulp through cleaning, slurry creation, cooking, filtering, bleaching, and drying.

Q: Why is sustainable sourcing of raw materials important in paper cup manufacturing?

A: Sustainable sourcing of raw materials in paper cup manufacturing helps preserve biodiversity, conserve water resources, and protect the environment.

Q: What techniques are used to shape paper cup blanks into the final product?

A: Techniques used to shape paper cup blanks include folding and seam sealing, and forming with molds to create the desired cup shape.

Q: How are quality control measures implemented in paper cup manufacturing?

A: Quality control measures in paper cup manufacturing are implemented through the sourcing of high-quality raw materials, shaping processes, printing, cutting, rim rolling, and rigorous inspections before packaging and shipment.

In this guide, we covered the raw materials like wood pulp and cotton linters. Sourcing sustainably is crucial. Forming techniques and PE lining are vital for cup quality. Quality control and eco-friendly practices are key in production. Transition to eco-friendly materials is progressive. Choose wisely for quality and sustainability in paper cup manufacturing.