Is Paper Cup Manufacturing Sustainable?

The Ultimate Guide to the Manufacturing of Paper Cups

Section 1: Understanding the Basics of Paper Cup Manufacturing

In this section, we will explore the key materials used in paper cup manufacturing and the process through which paper cups are made.

What are the key materials used in paper cup manufacturing?

Paper cups are made from a combination of materials, including paper, coating, and additives. The main materials used in paper cup manufacturing are:

- Paperboard: Paper cups are typically made from food-grade paperboard sourced from sustainable forests. The paperboard provides structure and strength to the cups.

- SBS Pulp: SBS (Solid Bleached Sulfate) pulp is a key material used in the paper layer of paper cups. SBS pulp is sourced from responsibly managed forests and is sustainable and food-grade.

- Coating: The coating on the inside of the paper cups is typically made of plastic, such as polyethylene (PE) or polylactic acid (PLA). The coating prevents liquid seepage and makes the cups suitable for holding hot and cold beverages.

- Additives: Additives like dyes and chemicals are used to enhance the properties of the paper and coating materials. These additives ensure the cups are hygienic, durable, and resistant to heat.

How is the paper cup manufacturing process initiated?

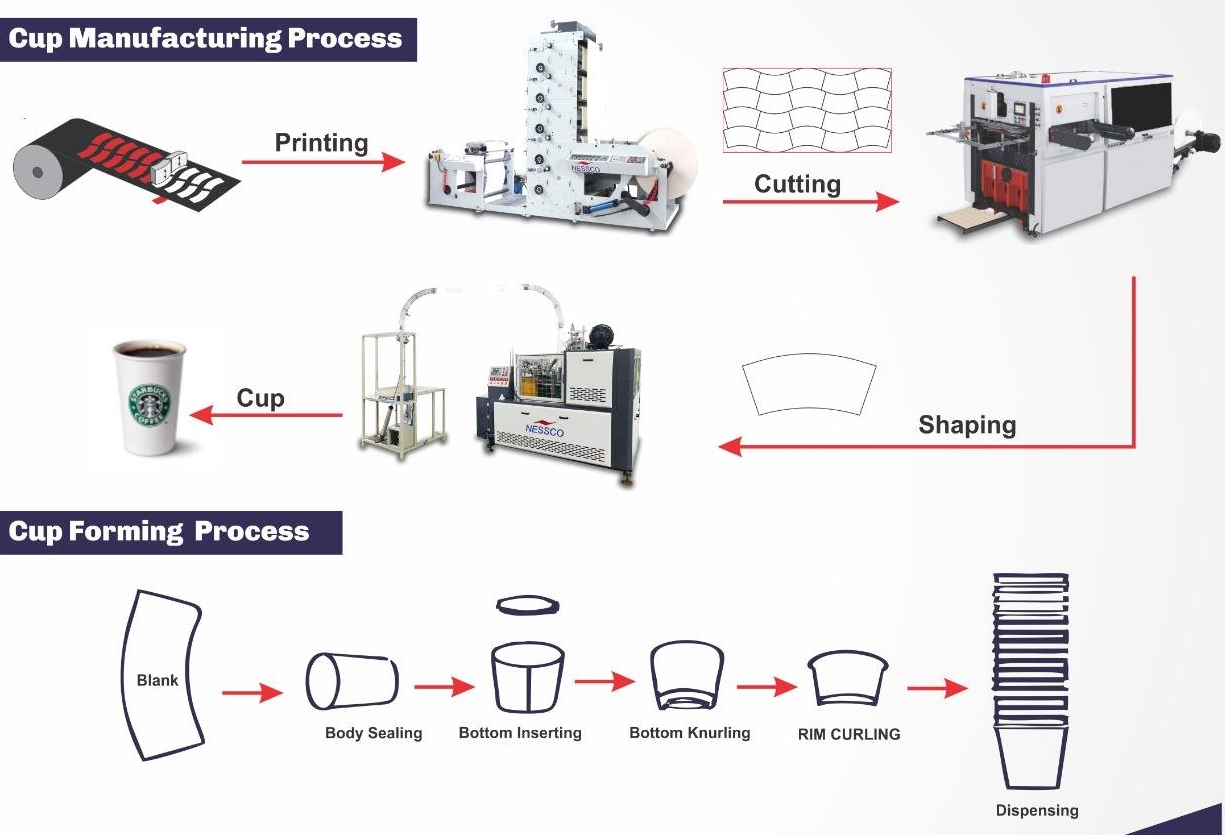

The paper cup manufacturing process involves several steps, from preparing the pulp to forming the cups. Here’s an overview of the process:

The Role of SBS Pulp in Paper Cup Production

SBS pulp plays a crucial role in the paper cup production process. The unique properties of SBS pulp, such as its strength and ability to hold shape, make it an ideal material for the paper layer of the cup. SBS pulp is bleached to achieve the desired brightness and purity before being used in cup production.

Pulping and Bleaching: From Pulp to Cup Blanks

The paper cup manufacturing process begins with pulping and bleaching the SBS pulp. The pulp is mixed with water to create a slurry, which is then cooked in an open-air vat to break down the fibers and remove impurities. The resulting pulp is filtered, washed, and bleached to achieve the desired color and cleanliness.

Once the pulp is ready, it is transformed into cup blanks. Cup blanks are large sheets of paperboard that will later be cut, shaped, and formed into cups. The pulp is spread evenly onto a wire mesh conveyor belt, and excess water is drained away. The pulp is then pressed and dried to achieve the desired thickness and moisture content.

Cup Forming Techniques: Folding and Sealing Methods

After the cup blanks are prepared, they go through cup forming techniques to shape them into the final cup design. Cup forming involves intricate folding and sealing processes. The cup blanks are fed into a paper cup forming machine, which wraps the paperboard around a mandrel to create the signature cylindrical shape of the cup. The machine then seals the paperboard with glue to keep the cup in its final shape.

Various sizes of paper cups can be manufactured by adjusting the height and diameter of the mandrel in the forming machine. Once the cups are formed, they undergo a cutting process to remove any excess paperboard and give them a smooth rim. Quality control checks are performed to ensure the cups meet the required standards for leakage prevention and overall quality.

In conclusion, the manufacturing of paper cups involves the use of key materials like SBS pulp, paperboard, and plastic coatings. The process includes pulping, bleaching, cup forming, and quality control checks. Understanding the basics of paper cup manufacturing helps us appreciate the craftsmanship and sustainability practices behind this essential everyday item.

Next in the series: Section 2: Sustainability Practices in Paper Cup Manufacturing.

Section 2: Sustainability Practices in Paper Cup Manufacturing

Why is sustainable manufacturing crucial in the production of paper cups?

Incorporating tables to visualize data from this blog post

FAQs about Paper Cup Manufacturing

What are the key materials used in paper cup manufacturing?

A: To understand the key materials used in paper cup manufacturing, we consider paperboard, SBS pulp, coating, and additives.

How is the paper cup manufacturing process initiated?

A: The paper cup manufacturing process usually begins by preparing the pulp, forming cup blanks, and utilizing cup forming techniques.

Why is sustainable manufacturing crucial in the production of paper cups?

A: Sustainable manufacturing is vital to minimize environmental impact and promote eco-friendly practices during paper cup production.

What are the future trends in eco-friendly paper cup production?

A: Exploring responsibly sourced materials, sustainable manufacturing practices, biodegradable coatings, and stringent quality control checks are key trends in eco-friendly paper cup production.

What factors influence the cost of manufacturing paper cups?

A: Understanding the raw materials, energy consumption, labor costs, production volume, and quality control are essential in analyzing the cost factors affecting paper cup production.

In conclusion, we explored the manufacturing process of paper cups, from materials to sustainability. Sustainable practices and cost factors play vital roles in the industry’s future. Implementing eco-friendly strategies and staying updated on market trends are key. Remember, choosing responsibly sourced materials and adopting innovative techniques can shape a more sustainable paper cup industry. Stay informed, stay ahead!