What are standard offset printing sheet sizes?

Offset Printing Sheet Sizes

Keyword Cluster

Offset printing sheet sizes, Offset printing sheets, Offset print sizes

What are the standard offset printing sheet sizes?

Offset printing, also known as lithography, is a popular printing method that offers flexibility for printing various sizes, from business cards to posters and banners. Understanding the standard offset printing sheet sizes is essential for choosing the right size for your printing project.

The standard offset printing sheet sizes are widely used in the industry and provide consistency and convenience. Here are some of the most common standard offset printing sheet sizes:

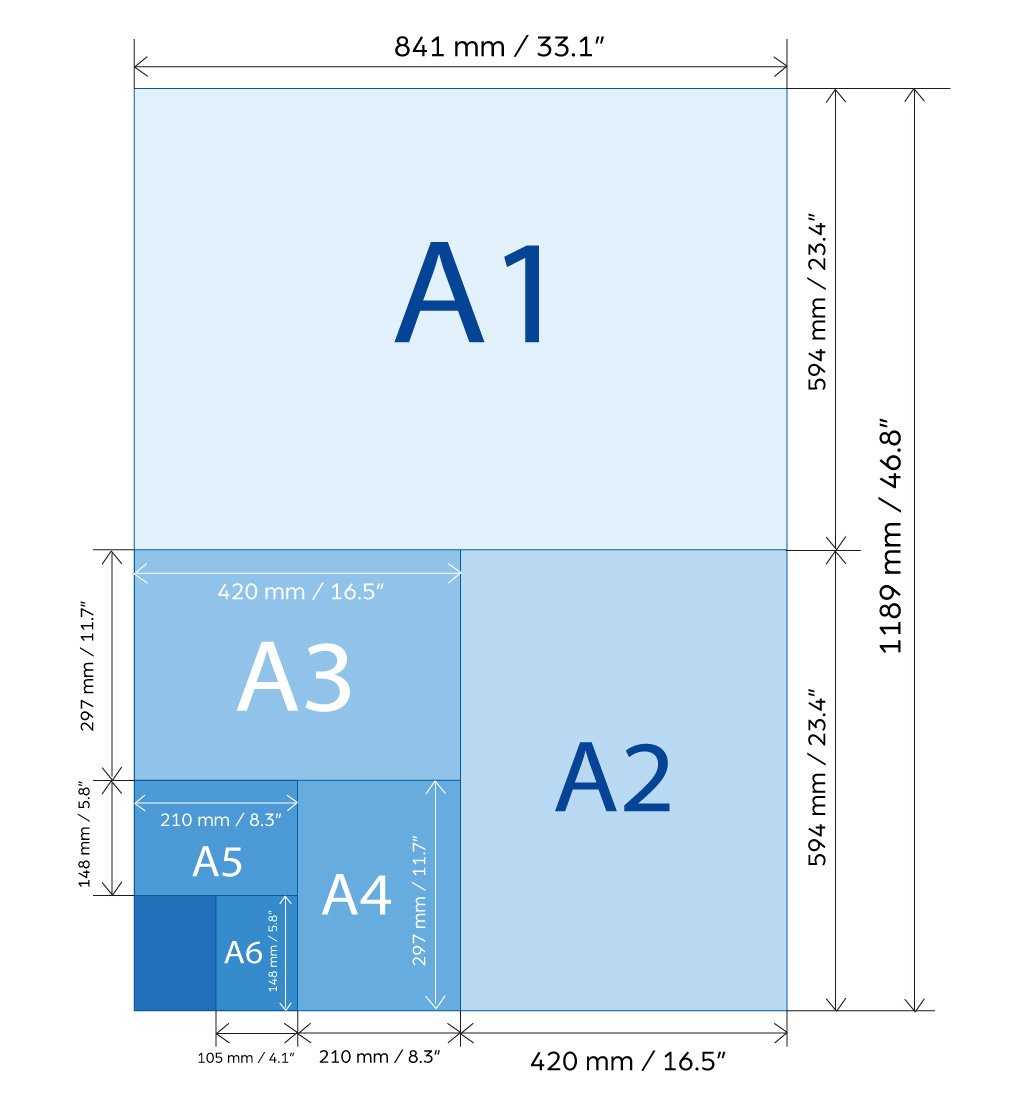

- A4 size: The A4 size measures 8.27 inches by 11.69 inches (210mm x 297mm) and is commonly used for letterheads, brochures, and flyers.

- A5 size: The A5 size measures 5.83 inches by 8.27 inches (148mm x 210mm) and is commonly used for notepads, booklets, and postcards.

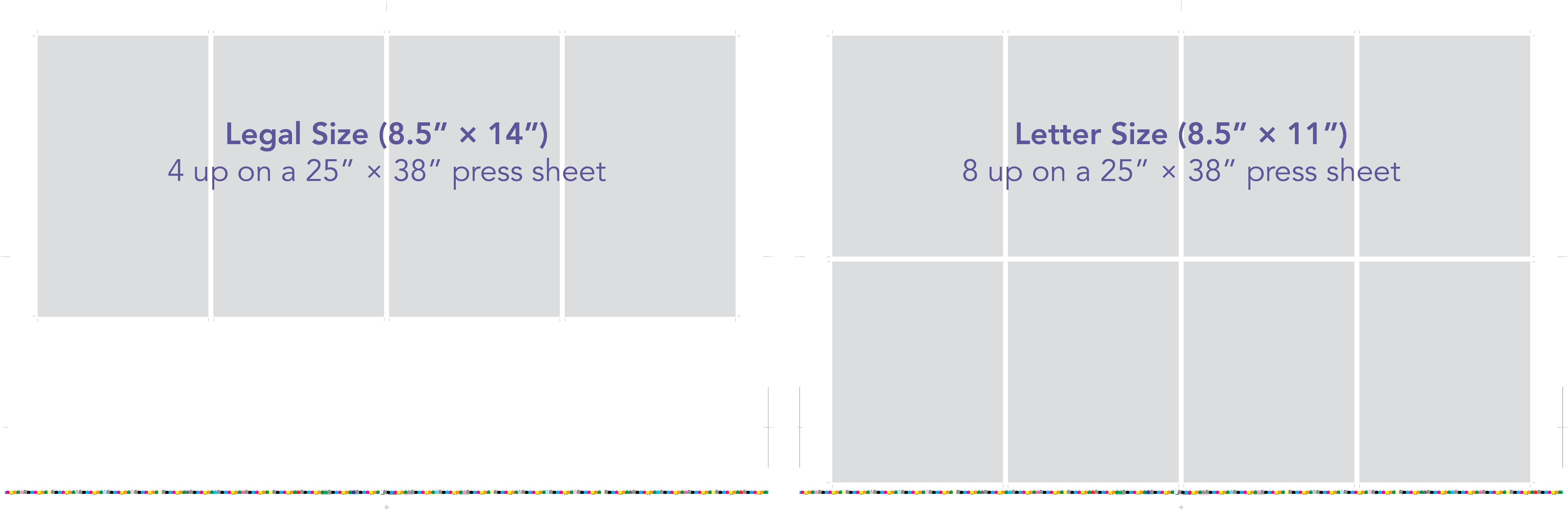

- Letter size: The Letter size measures 8.5 inches by 11 inches (216mm x 279mm) and is widely used in North America for various printing applications.

- Legal size: The Legal size measures 8.5 inches by 14 inches (216mm x 356mm) and is commonly used for legal documents and contracts.

- A3 size: The A3 size measures 11.69 inches by 16.54 inches (297mm x 420mm) and is commonly used for posters, large brochures, and signage.

- Tabloid size: The Tabloid size measures 11 inches by 17 inches (279mm x 432mm) and is commonly used for newspapers, newsletters, and posters.

Differences between sheet sizes in offset printing

While the standard offset printing sheet sizes provide a good starting point, it’s essential to understand the differences between sheet sizes in offset printing. These differences can impact the overall printing process and the final result of your project. Here are some key differences to consider:

- Paper weight: The weight and thickness of the paper can vary depending on the sheet size. Heavier paper stocks are generally used for larger sheet sizes to maintain rigidity and durability.

- Printing press capacity: The size of the printing press can determine the maximum sheet size that can be accommodated. Larger sheet sizes may require specialized equipment or custom printing solutions.

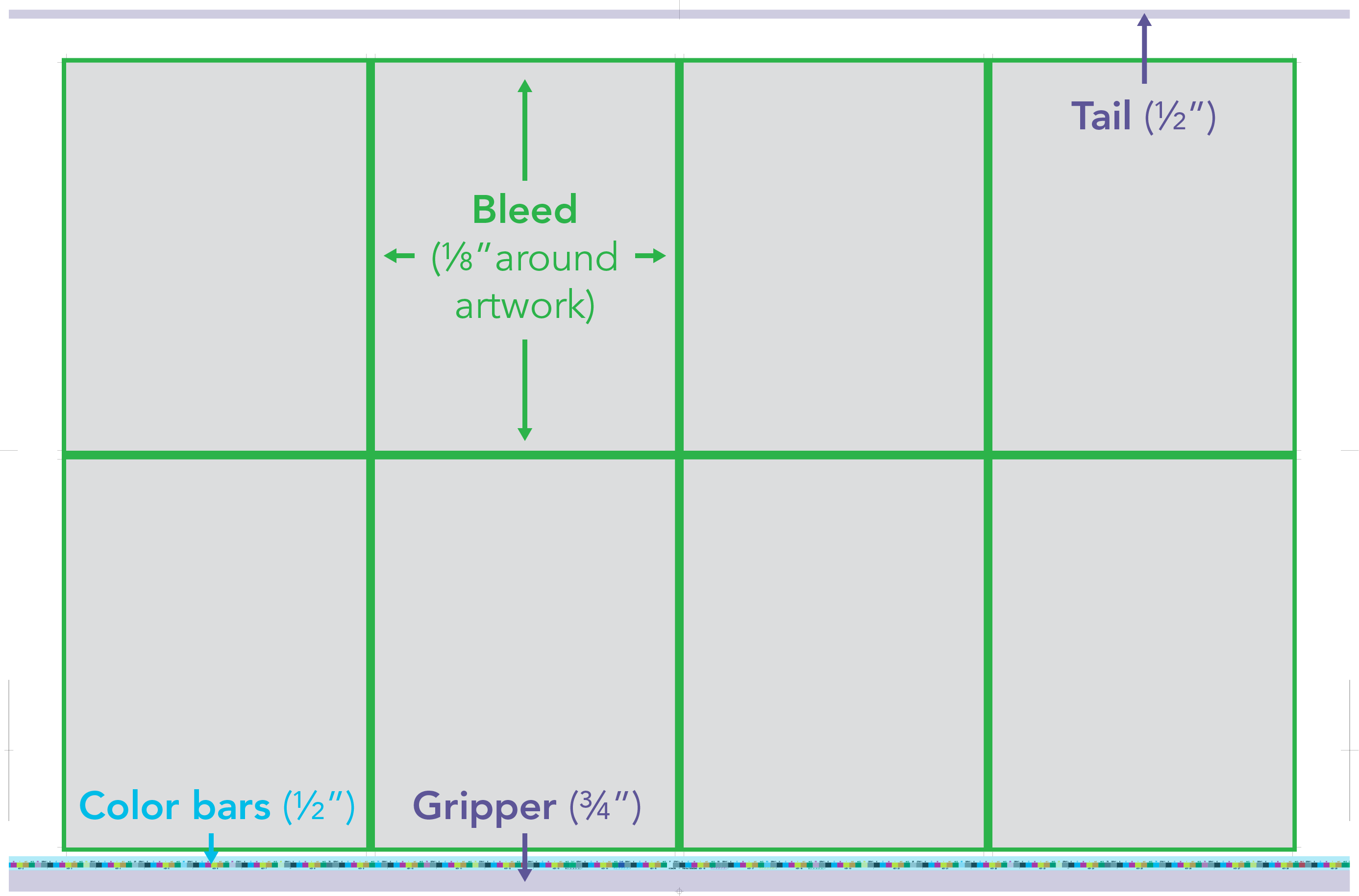

- Sheet cutting and trimming: The sheet size may require cutting and trimming to achieve the desired final product size. Different sheet sizes may have different trim allowances, which can impact the layout and design of your project.

- Cost considerations: Larger sheet sizes may require more materials and production time, resulting in higher costs. It’s important to consider your budget and the cost implications of different sheet sizes for your printing project.

Choosing the right sheet size for your printing project

Choosing the right sheet size for your printing project involves considering various factors, such as the nature of your project, the desired print quality, and the available resources. Here are some tips to help you make the best decision:

- Project requirements: Consider the purpose and specifications of your project. Do you need a small format for business cards or a large format for posters? Understanding the requirements will help you determine the appropriate sheet size.

- Design considerations: Take into account the layout and design elements of your project. Some designs may work better on smaller sheet sizes, while others may require more space and detail, necessitating a larger sheet size.

- Budget constraints: Evaluate your budget and cost limitations. Larger sheet sizes may be more expensive due to increased material and production costs. Ensure that your chosen sheet size aligns with your budget.

- Production capabilities: Assess the capabilities of your printing equipment and resources. If you have access to larger printing presses or specialized equipment, you may have more flexibility in choosing sheet sizes.

- Special requirements: Consider any special requirements or considerations for your project. This could include the need for bleeds, trim allowances, or specific finishing options. Ensure that your chosen sheet size can accommodate these requirements.

In conclusion, understanding the standard offset printing sheet sizes, the differences between sheet sizes, and how to choose the right size for your printing project is crucial for achieving the desired results. By considering factors such as project requirements, design considerations, budget constraints, production capabilities, and special requirements, you can make an informed decision and ensure a successful printing experience.

Common Industry Offset Printing Sheet Sizes

Overview of common offset printing sheet sizes

When it comes to offset printing, knowing the standard sheet sizes used in the industry is crucial for planning and executing successful print projects. Offset printing, also known as lithography, is a popular printing technique that offers flexibility for producing various sizes of printed materials, from business cards to posters and banners.

Commercial offset lithography printing utilizes ink rollers and plates to transfer images onto paper, resulting in high-quality prints with sharp details and vibrant colors. It is widely used for large-scale projects due to its consistent and reliable results throughout the print run. This printing method is also cost-effective for bulk orders, with unit costs decreasing as the quantity increases, making it a preferred choice for larger print jobs.

Standardized sheet sizes play a significant role in offset printing, ensuring efficiency, compatibility, and ease of use. These industry standard sizes facilitate the optimization of printing processes and allow for better planning of layouts, imposition, and finishing options.

Comparison between standard industry sizes

Standard paper sizes such as A4, A5, Letter Size, and Legal Size, along with larger sizes like A3 and tabloid, are commonly used in offset printing. These sizes are widely recognized and accepted in the printing industry, providing consistency and familiarity across different projects and applications.

ISO 216 is the international paper standard for sizes, used throughout most countries except in the USA, Canada, and certain Latin American countries. The A series, including A0, A1, A2, A3, A4, A5, A6, and A7, is a widely accepted range of sizes that are designed to have a consistent aspect ratio when halved or doubled.

In addition to the ISO standard, different countries have developed their own unique standard sizes for printed products such as books and leaflets, often influenced by historical, cultural, and practical reasons. For example, the USA commonly uses Letter Size (8.5″ x 11″) and Legal Size (8.5″ x 14″) for various printing applications.

How different sheet sizes impact printing projects

The choice of sheet size for an offset printing project depends on several factors, including the intended use of the printed materials, the desired layout, the availability of standard sizes, and cost considerations. Here are some key points to consider:

- Design and Layout: Different sheet sizes offer varying design possibilities and layout options. Larger sizes like A3 and tabloid allow for more creative freedom and visual impact, making them ideal for posters, brochures, and other promotional materials. On the other hand, smaller sizes like A5 or letter size are often used for items like flyers or newsletters.

- Paper Waste and Efficiency: The choice of sheet size can significantly affect the efficiency of the printing process and the amount of paper waste generated. By selecting a sheet size that closely matches the final trim size of the printed materials, you can minimize paper wastage and optimize the utilization of each sheet.

- Imposition and Binding: Imposition refers to the arrangement of multiple pages on a single sheet of paper to optimize printing efficiency. Different sheet sizes may require specific imposition schemes to maximize the number of pages per sheet. Additionally, the choice of sheet size can impact the binding options available for the final printed materials.

- Cost Considerations: Larger sheet sizes typically cost more than smaller sizes due to the increased paper and ink usage. When planning a printing project, cost considerations play a crucial role in selecting the appropriate sheet size that aligns with the budget while meeting the desired aesthetic and functional requirements.

Benefits of using industry standard sizes

Opting for industry standard sheet sizes in offset printing offers several advantages for both printers and customers. These benefits include:

- Compatibility: Standard sheet sizes are widely supported by printing equipment and software, ensuring seamless compatibility and reducing the risk of production issues or errors. Printers can optimize their workflows by using standard sizes, streamlining the printing process and minimizing setup time.

- Economies of Scale: Standard sizes are cost-effective for both print shops and customers as they allow for efficient use of paper, reducing waste and maximizing productivity. The availability of standard sizes in large quantities also facilitates bulk purchasing, resulting in lower costs per sheet.

- Storage and Shipping: Standard sizes simplify storage and shipping logistics for both printers and customers. Printers can stock standard-sized paper more efficiently, optimizing warehouse space, while customers can easily store and transport printed materials without the need for custom packaging or special arrangements.

- Client Expectations: Using industry standard sizes helps ensure that printed materials meet client expectations and conform to typical industry norms. Customers often have preconceived ideas of how certain printed items should look and feel, and utilizing standard sizes helps deliver a result that aligns with their expectations.

In conclusion, understanding and utilizing the common industry offset printing sheet sizes are essential for successful print projects. Standard sizes provide compatibility, cost-effectiveness, and ease of use, benefiting both print shops and customers. By considering the layout, paper waste, efficiency, and cost implications, you can choose the right sheet size that best suits your specific printing needs.

Considerations for Paper Weight and Finish in Relation to Sheet Size

In the world of offset printing, there are various factors to consider when it comes to achieving the desired print quality. Two essential considerations are paper weight and paper finish. These elements play a crucial role in determining the overall look and feel of the printed materials.

Importance of Paper Weight in Offset Printing

The paper weight refers to the thickness and sturdiness of the paper used in the printing process. It is measured in grams per square meter (GSM) or pounds (lb.). The choice of paper weight depends on the type of project and the desired outcome.

In offset printing, the paper weight affects the durability of the printed materials. Lighter-weight papers, such as those with a weight of 80gsm, are commonly used for everyday documents like flyers and brochures. On the other hand, heavier-weight papers with weights ranging from 120gsm to 350gsm are preferred for items like business cards, postcards, and invitations.

When selecting the appropriate paper weight for your offset printing project, it is essential to consider factors such as the intended use of the materials, the level of durability required, and the overall aesthetics.

How Paper Finish Affects Print Quality

The paper finish refers to the texture and coating applied to the surface of the paper. The finish has a significant impact on the print quality and the overall appearance of the printed materials. There are three primary types of paper finishes used in offset printing:

- Gloss Finish: This finish offers a high level of shine and reflects light, resulting in vibrant and sharp images. Glossy paper is commonly used for materials such as magazines, catalogs, and promotional brochures.

- Matte Finish: Matte paper has a smooth and non-reflective surface, providing a more subdued and elegant look. It is commonly used for projects that require a sophisticated and professional appearance, such as premium business cards, invitations, and corporate stationery.

- Uncoated Finish: Uncoated paper has a rough and natural texture, similar to regular printer paper. It absorbs ink more than the other finishes, giving a more organic and tactile feel to the printed materials. Uncoated paper is often used for items like letterhead, envelopes, and notepads.

The choice of paper finish depends on the desired aesthetics, the nature of the project, and the ink absorption requirements. Each finish offers a unique look and feel, so it is important to select the one that best aligns with your project goals.

Matching Paper Weight and Finish with Sheet Size for Desired Results

In offset printing, it is crucial to match the paper weight and finish with the sheet size to achieve the desired results. The sheet size refers to the dimensions of the paper used in the printing process. It determines the printable area and affects the overall layout and design.

When selecting the appropriate sheet size for your offset printing project, consider the following:

- Design considerations: The sheet size should accommodate the intended design and layout. It should provide enough space for the content, images, and any additional elements like bleeds or crop marks.

- Production efficiency: Using standard sheet sizes can improve production efficiency and reduce costs. Standard sheet sizes, such as A4, A5, Letter Size, and Legal Size, are readily available and widely used. They simplify the printing process and make it easier to source materials.

- Equipment compatibility: Ensure that the selected sheet size is compatible with your printing equipment. Different printing presses have different capabilities and limitations in terms of sheet size.

- Project requirements: Consider the specific requirements of your project, such as the quantity, type of materials, and intended use. Some projects may require custom sheet sizes to accommodate unique design elements or specifications.

By carefully matching the paper weight, finish, and sheet size, you can achieve optimal results in terms of print quality, durability, and overall aesthetics.

Tips for Selecting the Right Paper Weight and Finish for Your Project

Choosing the right paper weight and finish for your offset printing project can be a daunting task. Here are some tips to help you make informed decisions:

- Understand the project requirements: Consider the nature of your project, the intended use of the printed materials, and the target audience. This will help you determine the level of durability required and the desired visual impact.

- Request paper samples: Many printing companies offer paper sample packs that allow you to see and feel different paper weights and finishes. Request samples to get a better sense of how each option will look and feel.

- Consult with professionals: If you’re unsure about which paper weight and finish to choose, don’t hesitate to seek advice from professionals in the printing industry. They can provide valuable insights and guide you towards the best options for your specific project.

- Consider the budget: Keep in mind that different paper weights and finishes come with varying price points. Set a budget for your project and select materials that offer the best balance between quality and cost-effectiveness.

- Evaluate print quality: Consider the level of detail and color reproduction required for your project. Certain finishes may enhance or diminish the visual impact of the printed materials. Request print samples to evaluate the print quality on different paper weights and finishes.

In conclusion, when it comes to offset printing, considering paper weight and finish in relation to sheet size is crucial for achieving the desired print quality and overall aesthetics. By understanding the importance of these factors and following the tips provided, you can make informed decisions and create standout printed materials for your projects.

Tables

Standard Offset Printing Sheet Sizes

| Size | Dimensions (inches) | Dimensions (mm) |

|---|---|---|

| A4 | 8.27 x 11.69 | 210 x 297 |

| A5 | 5.83 x 8.27 | 148 x 210 |

| Letter | 8.5 x 11 | 216 x 279 |

| Legal | 8.5 x 14 | 216 x 356 |

| A3 | 11.69 x 16.54 | 297 x 420 |

| Tabloid | 11 x 17 | 279 x 432 |

Sheet Sizes and Print Applications

| Sheet Size | Common Print Applications |

|---|---|

| A4 | Letterheads, brochures, flyers |

| A5 | Notepads, booklets, postcards |

| Letter | Various printing applications in North America |

| Legal | Legal documents and contracts |

| A3 | Posters, large brochures, signage |

| Tabloid | Newspapers, newsletters, posters |

Paper Finish Options

| Finish | Description |

|---|---|

| Gloss | High shine, reflects light |

| Matte | Smooth, non-reflective surface |

| Uncoated | Rough, natural texture |

FAQs about Offset Printing Sheet Sizes

What are the standard offset printing sheet sizes?

In the realm of offset printing, knowing the standard sheet sizes is crucial for selecting the right dimensions for your print projects.

Answer: Standard offset printing sheet sizes, like A4, A5, Letter, Legal, A3, and Tabloid, are widely used in the industry to maintain consistency and convenience.

How do differences between sheet sizes impact offset printing?

Understanding the variations in sheet sizes is vital as they can affect the printing process and the final outcome of your project.

Answer: Variations in sheet sizes can impact elements like paper weight, printing press capacity, trimming requirements, and cost considerations during offset printing.

What factors should be considered when choosing a sheet size for an offset printing project?

Selecting the appropriate sheet size for your printing project involves evaluating multiple aspects to ensure the best results.

Answer: Considerations such as project requirements, design elements, budget constraints, production capabilities, and special project needs are crucial when choosing a sheet size for offset printing.

Why opt for industry standard sheet sizes in offset printing?

Using standard sheet sizes in offset printing offers numerous benefits for both printers and customers.

Answer: Industry standard sheet sizes provide compatibility, cost-effectiveness, efficiency, and meet client expectations, making them a preferred choice in the printing industry.

How do paper weight and finish relate to sheet size in offset printing?

When it comes to achieving optimal print quality, factors

In wrapping up, we covered standard offset printing sheet sizes and industry standards. Understanding these sizes is crucial for successful print projects. Remember, selecting the right sheet size, paper weight, and finish is key. By aligning these elements, you can achieve the desired print quality and results. Take note of these considerations to optimize your printing projects effectively.