What Are Offset Paper Weights and How Do They Impact Printing?

Mastering Offset Paper Weights: Everything You Need to Know

Section 1: Demystifying Offset Paper Weights

In the world of offset printing, understanding the significance of paper weight is essential for producing high-quality print materials. Paper weight refers to the thickness and density of the paper, indicating its durability and suitability for different printing projects. Let’s demystify offset paper weights and explore everything you need to know.

What is the significance of paper weight in offset printing?

Paper weight plays a crucial role in determining the overall quality and perception of the final printed product. It affects various aspects such as durability, stiffness, and the overall feel of the print materials. Thicker paper generally gives a more premium and substantial impression, while lighter-weight paper can feel more lightweight and delicate.

How are paper weights measured in the printing industry?

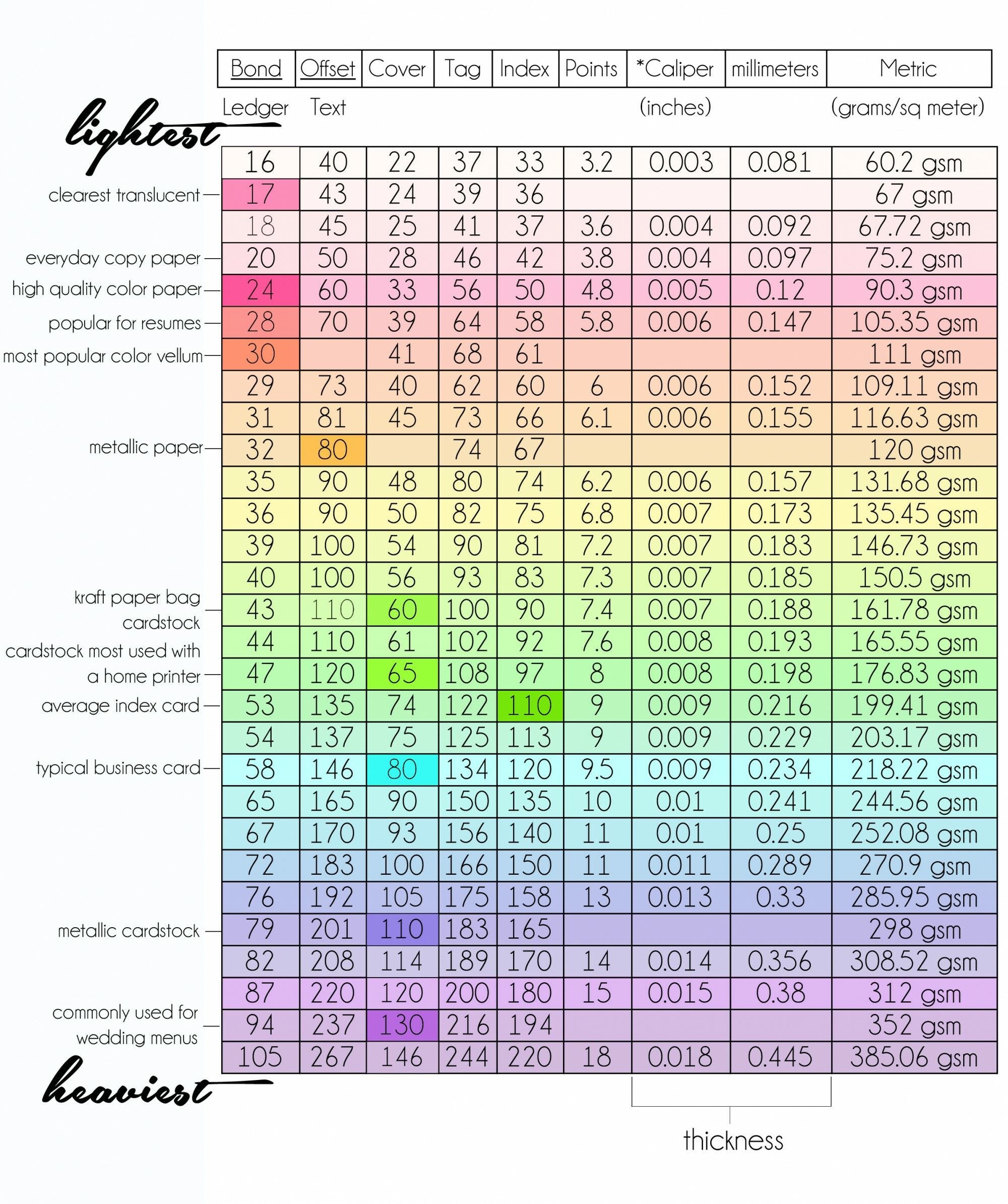

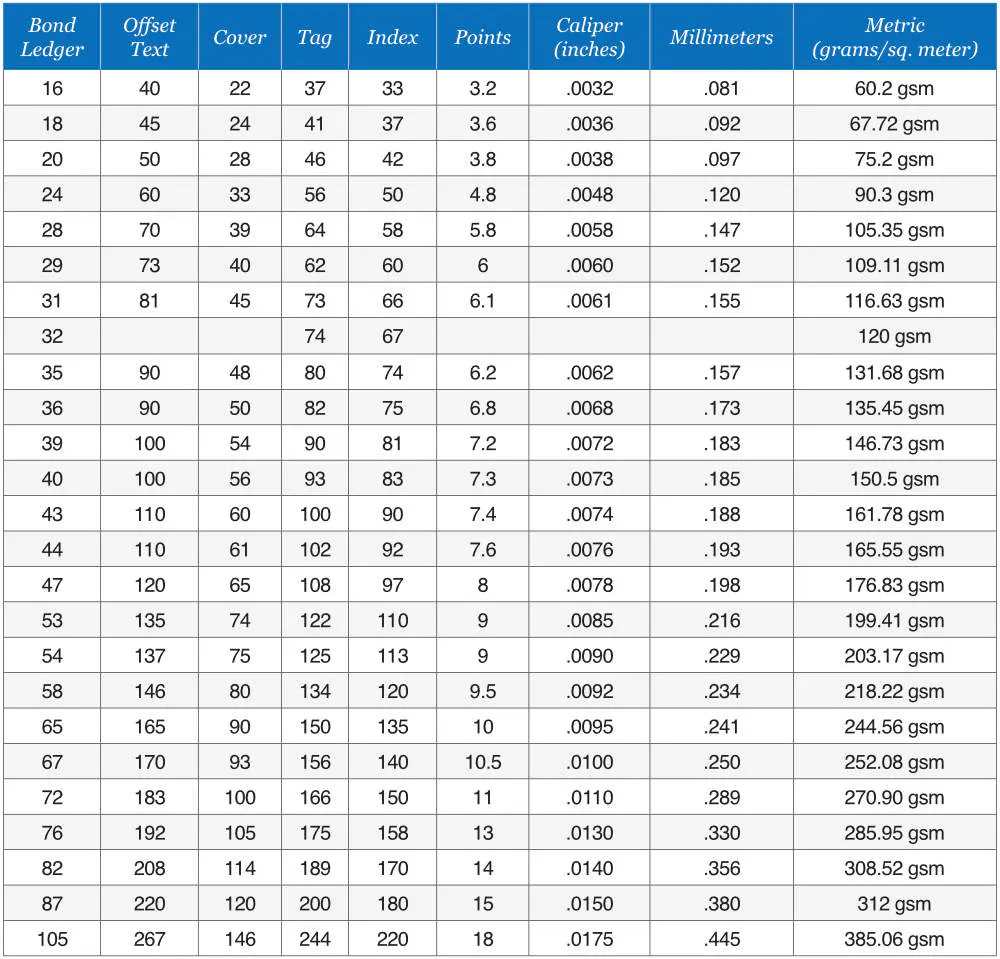

Paper weights in the printing industry are measured using different systems. One common method is pounds (lbs), which refers to the weight of 500 sheets of paper in its basis size. Another widely used system is grams per square meter (GSM), which measures the weight of the paper per square meter. Understanding both systems and their respective conversions can help in selecting the right paper weight for your printing needs.

Differentiating between 50lbs, 60lbs, 70lbs, and 80lbs paper options

When it comes to offset paper weights, there are various options available, including 50lbs, 60lbs, 70lbs, and 80lbs. These numbers represent the weight of 500 sheets of paper in their respective basis sizes. It’s important to note that higher poundage does not necessarily mean thicker paper. The basis size, GSM, and other factors influence the thickness and weight of the paper.

Understanding the impact of paper weight on printing quality

The choice of paper weight can significantly impact the overall print quality. Heavier paper weights are more durable and resist tearing or wrinkling, making them suitable for items that need to withstand heavy handling, such as business cards or brochures. Lighter-weight paper, on the other hand, is more suitable for high-volume printing or documents that don’t require additional durability or stiffness.

Benefits of using varying paper weights in different print projects

Using varying paper weights in different print projects can offer several advantages. Thicker paper can give a more premium feel to printed materials, making it ideal for business cards or invitations. On the other hand, lighter-weight paper may be more flexible, making it suitable for items like flyers or newsletters. By carefully considering the paper weight for each print project, you can enhance the overall aesthetic and durability of the final product.

Choosing the right paper weight for specific printing needs

When choosing the right paper weight for specific printing needs, it’s essential to consider factors such as the type of project, printing technique, printer compatibility, and budget. For example, if you’re printing a document that requires frequent handling, opting for a higher paper weight can ensure that it lasts longer. Consulting with your printer or print professional can provide valuable insights into the most suitable paper weight for your specific requirements.

Common misconceptions about paper thickness and weight

There are some common misconceptions when it comes to paper thickness and weight. One of the most prevalent errors is assuming that higher poundage means thicker paper. As previously mentioned, other factors such as basis size and GSM contribute to the overall thickness and weight of the paper. Understanding these differences can help in making more informed decisions when selecting paper for printing projects.

Importance of understanding GSM and basis size in paper weight measurements

GSM (grams per square meter) is a consistent number that indicates the weight of the paper per square meter, regardless of the paper’s basis size. Basis size refers to the standard sheet size used to weigh the paper. Understanding GSM and basis size can help in comparing paper weights across different types and sizes. It is essential to familiarize yourself with these measurements to make accurate and informed choices when selecting paper for offset printing.

In the next section, we will explore the different types of paper weight categories and their specific characteristics.

Continue reading: Section 2: Navigating Through Paper Weight Varieties

Section 2: Navigating Through Paper Weight Varieties

In the world of printing, there are various paper weight options available, each with its unique characteristics and uses. Understanding the differences between these paper weight varieties is crucial for selecting the right paper for your printing projects. In this section, we will explore the distinctions between text weight and cover weight papers, delve into the implications of paper finish and coating on perceived thickness and weight, and discuss the relationship between paper weight and printer specifications. Additionally, we will provide an overview of common bond paper weights and their equivalents in offset printing. Let’s dive in!

Exploring the Differences between Text Weight and Cover Weight Papers

When you dive into the world of paper weight, you may come across terms like text weight and cover weight. Understanding the differences between these two categories is essential for selecting the appropriate paper for your printing needs.

- Text Weight: Text weight papers are commonly used for copying, laser/ink printing, and letterheads. They are slightly heavier than standard letterhead paper. Text weight papers are ideal for projects that require flexibility, such as brochures, flyers, or lightweight packaging.

- Cover Weight: On the other hand, cover weight papers are lighter than text weight papers and are often used for postcards, business cards, greeting cards, door hangers, and other similar applications. Cover weight papers provide a balance between durability and flexibility.

It’s important to choose the right weight category based on the requirements of your printing project. The right weight will ensure that your printed materials are sturdy enough to withstand handling while also meeting your desired visual appeal.

How Does Paper Thickness Differ from Paper Weight?

While paper weight refers to the density of the paper material, paper thickness measures the actual thickness of the paper. It’s important to note that paper thickness is not directly proportional to paper weight.

Paper thickness is usually measured in thousandths of an inch or millimeters. Thicker paper will have a higher caliper measurement, indicating a greater thickness. However, the weight of the paper is determined by the density of the paper fibers.

When selecting paper for your printing projects, it’s important to consider both paper weight and thickness. The right combination will ensure that your printed materials meet the desired aesthetic appeal and functionality.

Considering Different Paper Types and Their Weight Characteristics

In addition to text weight and cover weight papers, there are various other paper types available, each with its specific weight characteristics. Here are some common paper types and their typical weight ranges:

| Paper Type | Typical Weight Range |

|---|---|

| Bond Paper | 20lbs, 24lbs, 28lbs, 32lbs |

| Offset Paper | 50lbs, 60lbs |

| Coated Book Paper | 80lbs, 100lbs |

Understanding the weight characteristics of different paper types will help you make informed decisions when selecting paper for your printing projects. Consider the specific requirements of your project and choose the appropriate paper weight accordingly.

Implications of Paper Finish and Coating on Perceived Thickness and Weight

The finish and coating of a paper can also impact the perceived thickness and weight of the paper. When a paper has a glossy or coated finish, it may appear thicker and heavier to the eye. On the other hand, uncoated papers may appear thinner and lighter.

Paper coatings can also affect the tactile feel of the paper. For example, a high-gloss coated paper will have a smooth and shiny surface, while an uncoated paper will have a more natural, textured feel.

When selecting paper for your printing projects, consider the impact that the finish and coating may have on the desired look and feel of the final product. Additionally, factor in the printing process, as certain coatings may affect ink absorption and print quality.

Relationship between Paper Weight and Printer Specifications

When choosing paper for your printing projects, it’s important to consider the specifications and recommendations of your printer. Different printers have specific paper weight limitations, and using papers that exceed these specifications may lead to issues such as paper jams or poor print quality.

Check the printer’s manual or consult with a printing professional to determine the recommended paper weight range for your specific printer. Following these guidelines will ensure optimal printing results and minimize the risk of printing complications.

Common Bond Paper Weights and Offset Paper Weight Equivalents

Bond paper is one of the most common types of paper used in various printing applications. It is important to understand the weight terminology used for bond paper to make informed decisions while selecting paper for your projects.

The most common bond paper weights are 20lbs, 24lbs, 28lbs, and 32lbs. These weights indicate the weight of 500 sheets of paper in the standard basis size of 17 x 22 inches. The bond paper weight system is different from the offset paper weight system.

Offset paper is commonly used in offset printing, and its weight is measured based on a different basis size of 25 x 38 inches. The most common offset paper weights are 50lbs and 60lbs. To give you a basis for comparison, a 60lbs offset paper is equivalent to a 24lbs bond paper in terms of thickness.

Understanding the different weight systems and equivalences between bond paper weights and offset paper weights will help you select the right paper for your printing projects.

Overview of Different Paper Grades and Their Typical Uses

In addition to different paper weights, there are various paper grades available, each with its typical uses. Here’s an overview of some common paper grades and their applications:

- Bond (Copier & Digital): Bond paper is commonly used for everyday printing needs such as documents, reports, and letterheads. It is often used in copiers and digital printers.

- Coated Book: Coated book papers are known for their high-quality finish and are commonly used for magazines, catalogs, brochures, and other visually appealing printed materials.

- Bristol: Bristol papers are heavier and sturdier than standard paper. They are commonly used for products like postcards, business cards, and covers for books or manuals.

- Index: Index papers are thick, stiff, and durable. They are commonly used for index cards, dividers, and file folders.

- Cover: Cover papers are sturdy and thick, making them ideal for products like greeting cards, invitations, and book covers.

Understanding the typical uses of different paper grades will help you select the appropriate paper for your printing projects based on their specific requirements.

Decoding Confusing Paper Weight Terminology and Categories

The world of paper weight can be confusing, with various categories and terminology to decipher. Here are some commonly used terms and categories in the paper weight industry:

- Basis Weight: Basis weight refers to the weight of 500 sheets of paper in the standard basis size before being cut. Common examples include 20 lb Bond and 65 lb Cover papers.

- Standard Printer Paper: Standard printer paper typically weighs between 20-28 lbs and is commonly used for everyday printing needs such as letterheads and forms.

- Cardstock/Cover Paper: Cardstock or cover paper is thicker than standard paper and is commonly used for products like business cards, book covers, and invitations. It comes in various textures and colors to suit different design preferences.

- Vellum Bristol: Vellum Bristol is an uncoated and translucent paper with a high ink absorbency. It is commonly used for media kits, promotional materials, and catalogs.

- Kraft Paper: Kraft paper is a durable and strong type of paper, often used for shipping and packaging purposes. It is 100% recyclable and provides an eco-friendly packaging solution.

Navigating through the various terminology and categories of paper weight can be challenging. However, once you understand these terms, you will be better equipped to make informed decisions when selecting paper for your printing projects.

Section 3: Applications and Considerations of Paper Weight

When it comes to choosing the right paper for your printing projects, understanding paper weight is essential. Paper weight plays a significant role in determining the durability, texture, and overall quality of the final product. In this section, we will explore the various applications and considerations of different paper weights, including cardstock, Vellum Bristol, and Kraft paper. We will also discuss how paper weight can impact printer compatibility and provide tips for selecting the optimal paper weight for your printing needs.

Utilizing Cardstock/Cover Paper for Business Cards, Book Covers, etc.

Cardstock, also known as Cover paper, is a heavyweight paper that is ideal for projects that require sturdiness and durability. It is thicker than standard printing paper and provides a premium feel to printed materials. Cardstock is commonly used for business cards, book covers, postcards, greeting cards, and invitations. Due to its thickness, it can withstand heavy use and handling, making it perfect for products that need to leave a lasting impression.

Characteristics and Uses of Vellum Bristol Paper in Print Projects

Vellum Bristol paper is a unique type of paper that is uncoated and translucent. It has high ink absorbency, which makes it great for printing media, promotional materials, and catalogs. The transparency of Vellum Bristol paper adds a subtle elegance to printed designs and makes it an excellent choice for projects that require a touch of sophistication. Its versatile nature allows for various applications in the printing industry.

| Paper Type | Characteristics | Uses |

|---|---|---|

| Vellum Bristol Paper | Uncoated and translucent paper | Media kits, promotional materials, catalogs |

Benefits of Using Kraft Paper for Shipping and Packaging Purposes

If you’re looking for a durable and environmentally-friendly option for shipping and packaging, Kraft paper is the way to go. Made from 100% recyclable materials, Kraft paper is known for its strength and resistance to tear. It provides excellent protection for products during transit and is an eco-friendly alternative to traditional packaging materials. Additionally, Kraft paper has a natural and rustic appearance that adds a touch of charm to packaging designs.

| Paper Type | Benefits |

|---|---|

| Kraft Paper | Durable and eco-friendly shipping and packaging solution |

Understanding How Paper Weight Affects Durability, Texture, and Quality

Paper weight plays a crucial role in determining the durability, texture, and quality of printed materials. Thicker paper, such as cardstock, provides a more substantial feel and can enhance the overall quality and perception of printed materials. Lighter paper, such as that used for high-volume printing, offers more flexibility and is suitable for projects that require easy folding and handling, such as brochures and flyers. The choice of paper weight should be based on the intended usage and durability needed for the specific project.

Printer Compatibility Considerations When Choosing Paper Weight

When selecting a paper weight for your printing projects, it’s important to consider printer compatibility. Different printers have specific weight and thickness limitations, and exceeding those limits can result in printing issues and damage to the printer. Consult your printer’s specifications and recommendations to ensure that you choose a paper weight that is compatible with your printer. This will help you achieve optimal printing results and avoid any potential problems.

Impact of Paper Weight on Different Printing Project Outcomes

The paper weight you choose can significantly impact the outcome of your printing projects. Heavier paper weights, such as cardstock, provide a more substantial feel and can enhance the overall quality and perception of printed materials. Lighter paper weights, like 60lbs and 70lbs, offer more flexibility and are suitable for projects that require easy folding and handling, such as brochures and flyers. Understanding the desired outcome of your print project and selecting the appropriate paper weight will ensure that you achieve the desired results.

Incorporating Paper Weight Knowledge in Selecting Papers for Various Projects

Having a good understanding of paper weight allows you to make informed decisions when selecting papers for your different projects. Whether you’re printing business cards, brochures, or packaging materials, considering the appropriate paper weight ensures that you achieve the desired outcome. By matching the paper weight to the specific needs of each project, you can enhance the overall appearance, durability, and quality of your printed materials.

Tips for Achieving Optimal Results by Matching Paper Weight to Printing Needs

To achieve optimal results in your printing projects, it is essential to match the paper weight to your specific printing needs. Here are some tips to help you make the right choice:

- Consider the intended usage and durability requirements of your printed materials.

- Consult the printer’s specifications and recommendations for paper weight compatibility.

- Use thicker paper weights, like cardstock, for projects that require sturdiness and durability.

- Opt for lighter paper weights, such as 60lbs and 70lbs, for projects that require flexibility and easy handling.

- Experiment with different paper weights to determine the best fit for your specific printing projects.

- Take into account the desired perception and quality of the final product when choosing paper weight.

By considering these tips and understanding the impact of paper weight on your printing projects, you can ensure that you achieve the best possible results.

In conclusion, paper weight is a critical factor to consider when selecting paper for your printing projects. Understanding the various applications and considerations of different paper weights allows you to make informed decisions and achieve optimal results. Whether you’re using cardstock for business cards or Kraft paper for packaging, selecting the right paper weight will enhance the overall appearance, durability, and quality of your printed materials.

FAQs about understanding paper weights for offset printing

What is the significance of paper weight in offset printing?

In offset printing, the significance of paper weight can be explained using the formula: Weight = thickness + density, impacting durability, stiffness, and overall feel of print materials.

How are paper weights measured in the printing industry?

Paper weights in the printing industry are measured using systems like pounds (lbs) and grams per square meter (GSM), with conversions aiding in selecting the right paper weight.

Differentiating between 50lbs, 60lbs, 70lbs, and 80lbs paper options

When differentiating between paper options like 50lbs, 60lbs, 70lbs, and 80lbs, understanding the weight of 500 sheets in their respective basis sizes is crucial for selection.

Understanding the impact of paper weight on printing quality

The impact of paper weight on printing quality can be evaluated by considering factors like durability, resistance to tearing, and suitability for specific printing needs.

Benefits of using varying paper weights in different print projects

By using varying paper weights in different print projects, you can achieve a premium feel, flexibility, and enhanced durability based on the requirements of each project.

In conclusion, Offset Paper Weights are vital in print projects. Understanding GSM and basis size is crucial for superior printing. Differentiating between Text Weight and Cover Weight papers is essential. Using various paper weights can enhance printing quality. Consider paper finish and coating’s impact on thickness. Choose the right paper weight to match specific printing needs. Utilize cardstock for business cards and Kraft paper for packaging. Match paper weight to printing needs for optimal results.