Offset Paper Weight Comparison: What Should You Know?

What Is Offset Paper Weight and How Is It Measured?

When it comes to choosing the right paper for your printing projects, understanding paper weight is essential. Paper weight refers to the thickness or caliper of a sheet of paper, and it is typically measured in pounds (lb.), grams per square meter (gsm), or points (pt.). In this article, we will explore what offset paper weight is and how it is measured, as well as provide you with some useful comparisons of different paper weights.

What is Offset Paper Weight?

Offset paper weight is a term commonly used in the printing industry to describe the weight or thickness of a specific type of paper known as offset paper. Offset paper is a high-quality, uncoated paper that is commonly used for printing books, brochures, and other promotional materials. It is known for its excellent printability and smooth surface.

How Is Paper Weight Measured?

There are three main ways to measure paper weight: GSM, pounds (lb.), and points (pt.). Let’s take a closer look at each measurement method:

Understanding GSM (Grams per Square Meter)

GSM, or grams per square meter, is a universal measure of paper weight that is used worldwide. It represents the weight of a sheet of paper measuring one square meter. The higher the GSM value, the heavier and thicker the paper. For example, a 120 gsm paper will be thicker and heavier than an 80 gsm paper.

GSM is a reliable measurement method because it allows for easy comparison of different paper types, regardless of their size.

Pounds (lb.): Weight of 500 Parent Sheets

Pound, often abbreviated as lb., is a measurement method commonly used in the United States. It represents the weight of 500 sheets of paper of a specific type and size, known as the parent sheet. For example, if 500 sheets of a specific offset paper weigh 70 pounds, it is referred to as 70 lb. paper.

The pound measurement is often used for text or offset stock, which is the type of paper commonly used for inside pages of books and brochures.

Points (pt.): Thickness Measurement

Points, abbreviated as pt., is a measurement method primarily used for cover, board, and card stock. One point is equal to 1/1000 (.001) inches. For example, a 10 pt. stock is 0.01 inches thick.

Points are used to measure the thickness of thicker and more rigid paper stocks, such as those used for covers and business cards.

How Do Different Paper Weights Compare?

Now that we understand how paper weight is measured, let’s take a look at some common offset paper weights and how they compare:

Common Text (Offset) Stock Weights

| Paper Weight | GSM | LB. |

|---|---|---|

| 70 lb. | 105 | 70 |

| 80 lb. | 118 | 80 |

| 100 lb. | 150 | 100 |

Common Cover Stock Weights

| Paper Weight | PT. | LB. |

|---|---|---|

| 10 pt. | – | 250 |

| 12 pt. | – | 300 |

| 14 pt. | – | 350 |

These are just a few examples of commonly used offset paper weights. It’s important to note that there is no direct conversion between gsm, lb., and pt. measurements, so it’s always a good idea to consult conversion charts or consult with your printer or paper supplier to determine the best option for your specific needs.

In Summary

Understanding offset paper weight and how it is measured can help you make informed decisions when choosing the right paper for your printing projects. Whether you’re looking for lightweight text stock or heavyweight cover stock, considering the weight, thickness, and intended use of the paper can ensure that your prints turn out just the way you envision them.

How Do Different Offset Paper Weights Impact Printing Quality?

When it comes to printing, the paper weight you choose can have a significant impact on the final result. The weight of the paper refers to its thickness and is typically measured in pounds (lb.) or grams per square meter (GSM). In this article, we will explore how different offset paper weights can affect the quality of your prints, the durability and rigidity of the paper, the cost implications of choosing different weights, and compatibility with printing equipment. We will also discuss how heavier weights can enhance professional quality and provide examples of common uses for various offset paper weights.

Effect of Paper Weight on Printing Quality

The weight of the paper plays a crucial role in determining the printing quality of your project. Generally, heavier paper weights tend to produce better results. The additional thickness and rigidity of the paper can prevent ink from bleeding and ensure crisp, sharp printing. On the other hand, lighter weights may result in lower print quality, especially when printing images or using vibrant colors.

Durability and Rigidity by Paper Weight

Another factor to consider when choosing paper weight is the durability and rigidity it offers. Heavier weights are more durable and less likely to tear or crease, making them ideal for projects that require longevity, such as presentations or keepsake items. Lighter weights, while cost-effective and suitable for everyday use or large print runs, may be more susceptible to wear and damage over time.

Cost Implications of Choosing Different Paper Weights

The choice of paper weight can also have cost implications. Generally, heavier paper weights are more expensive than lighter ones due to the additional materials required to manufacture them. If you have a budget constraint, opting for a lighter weight can help reduce costs without compromising too much on quality. However, it is essential to strike a balance between cost and the desired outcome of your project.

Compatibility with Printing Equipment

It is crucial to ensure that the paper weight you choose is compatible with your printing equipment. Different printers have specific paper weight requirements, and exceeding those limits can lead to paper jams, misfeeds, or even damage to the machine. Consult your printer’s specifications or contact the manufacturer for guidance on the recommended paper weight range for optimal printing results.

How Heavier Weights Enhance Professional Quality

If you are looking to achieve a more professional and high-quality finish, opting for heavier paper weights is a wise choice. Heavier weights give a more substantial feel to printed materials and can help create a lasting impression with your audience. They are often used for brochures, business cards, invitations, and other materials where a premium look and feel are desired.

Common Uses for Various Offset Paper Weights

- 70lb. Text for Comic Books:

- Comic books require a paper weight that is lightweight yet durable enough to withstand frequent handling. The 70lb. text weight is ideal for this purpose, providing a balance between flexibility and strength.

- 100lb. Text for High-Quality Prints:

- When it comes to high-quality prints, such as art prints or photography, a heavier paper weight like the 100lb. text weight is recommended. It offers excellent color reproduction and durability to showcase the details and vibrancy of the artwork.

- 12pt. Cover for Business Cards:

- Business cards need to make a strong impression and withstand the wear and tear of being carried around. The 12pt. cover weight is commonly used for business cards, providing the necessary thickness and durability for a professional look.

In conclusion, the choice of offset paper weight can significantly impact your printing quality. Heavier weights offer better durability, rigidity, and professional quality but may come with higher costs. Lighter weights are more cost-effective and suitable for large print runs, but may lack the durability and premium feel of heavier weights. Consider the purpose of your project, the printing equipment compatibility, and your budget when choosing the right paper weight for your next printing endeavor.

Choosing the Right Offset Paper Weight for Your Project

When it comes to printing, choosing the right paper weight is crucial for achieving the desired results. Whether you’re working on a professional project or a large print run, understanding how different paper weights impact the final product is essential. In this guide, we’ll explore the factors to consider when selecting the best offset paper weight for your project.

Determining the Purpose of Your Print Project

Before diving into the world of paper weights, it’s important to first determine the purpose of your print project. Are you creating promotional materials for a business event? Designing a high-quality brochure for a client? Or simply printing a large quantity of handouts for an upcoming conference? The intended use of the printed materials will greatly influence the paper weight you should choose.

Matching Paper Weight to Project Type

Different types of projects require different paper weights to ensure optimal results. Let’s explore the two main categories of projects and the ideal paper weights for each:

Light Weights for Large Print Runs

If you’re printing a large quantity of materials, such as handouts, flyers, or newsletters, using a lighter paper weight is often the most cost-effective option. Lighter weights, such as 20-24 lb (75-90 gsm), are more affordable and easier to handle in bulk. These weights are suitable for everyday office use and provide sufficient quality for mass distribution.

Heavy Weights for Professional and Keepsake Items

For projects that require a higher level of quality and durability, heavy paper weights are the way to go. When you want to make a lasting impression with your printed materials, opting for heavier weights, such as 28-32 lb (105-120 gsm), is recommended. These weights are perfect for professional letterheads, brochures, and presentations that require a premium feel and enhanced durability.

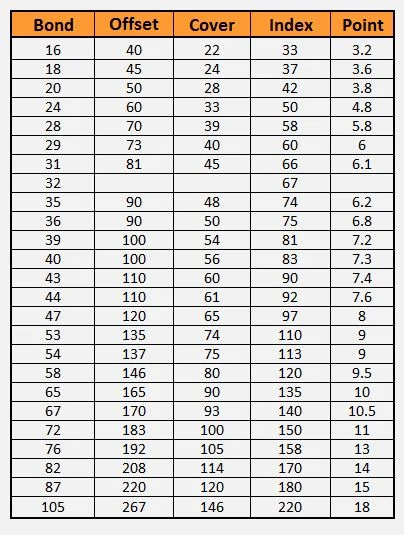

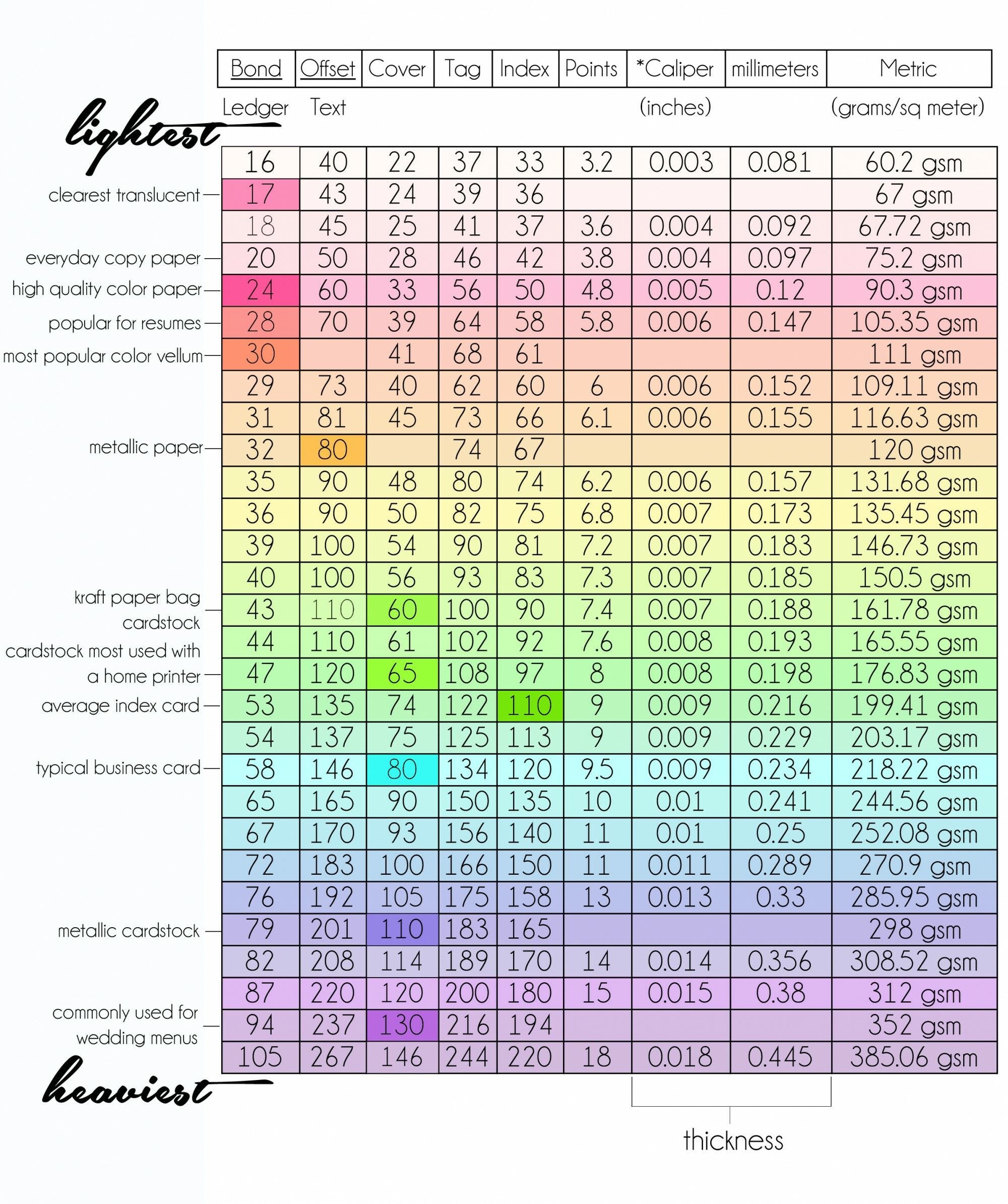

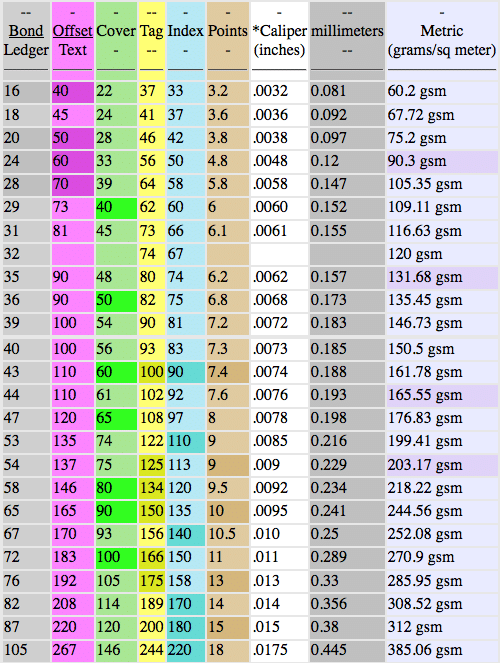

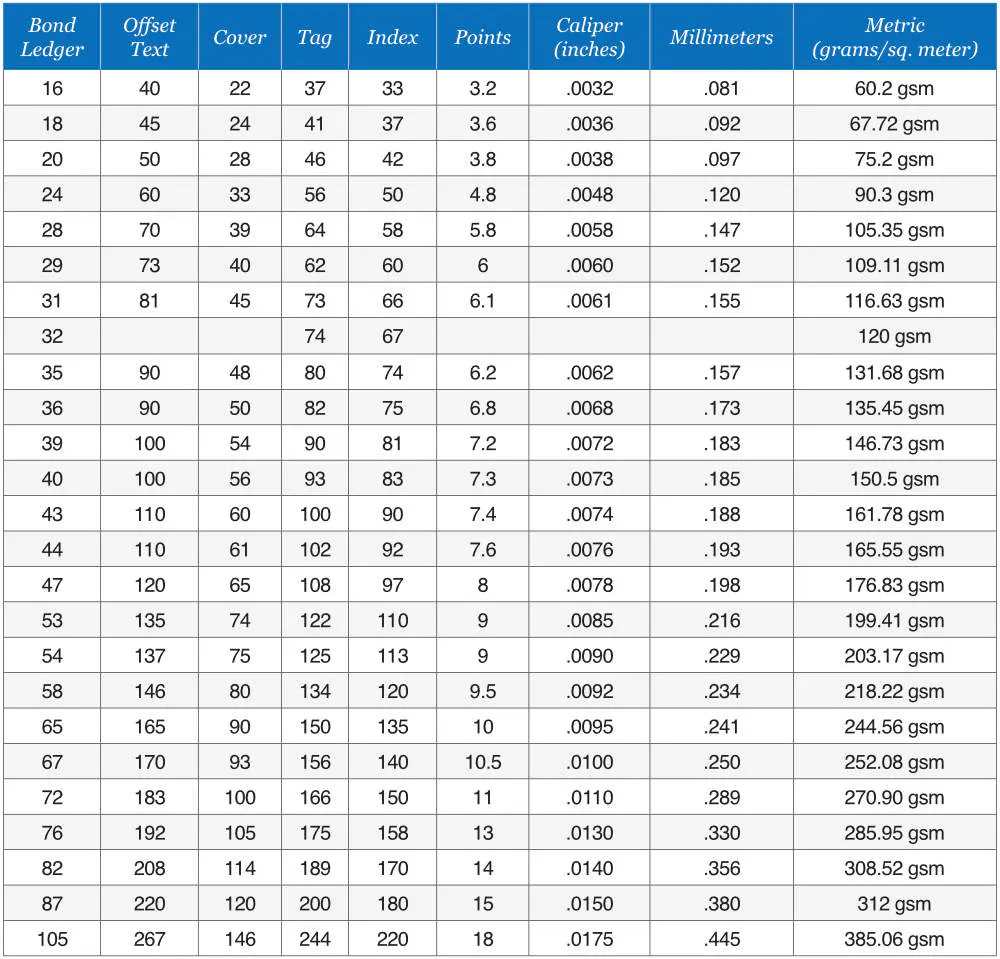

Conversion and Comparison Charts

Navigating the world of paper weights can be confusing, especially when it comes to understanding the different measurements used. To help with this, conversion and comparison charts are available to assist you in determining the thickness and weight equivalencies between different units of measure. Two common conversion charts include:

GSM to Pounds Conversion

GSM (Grams per Square Meter) is the universally used measure of paper weight. However, if you’re more familiar with pounds, a GSM to pounds conversion chart can come in handy. This chart allows you to easily compare the weight of different papers and determine their equivalence in pounds.

Points to Pounds Conversion

Another measurement commonly used for thicker stocks, such as cover stock, is points (pt). Points measure the thickness of paper, with 1 point equaling 1/1000 (.001) inches. If you’re working with different point measurements, a points to pounds conversion chart can help you determine the weight equivalence in pounds.

Practical Tips for Selecting Paper Weight

While conversion charts and comparison tables provide valuable guidance, there are some practical tips to consider when selecting the right paper weight for your project:

- Consider the project’s purpose and budget: Is it a one-time use piece or a keepsake item? Balancing the quality and cost-effectiveness of the paper weight is important.

- Check printer compatibility: Ensure that the chosen paper weight is compatible with your printer. Some printers may have limitations on the maximum weight they can handle.

- Request sample prints: Before committing to a specific paper weight, it’s always a good idea to request sample prints from your printer. This allows you to see how the final product will turn out and make any necessary adjustments.

Visual Aids and Tables for Easy Comparison

To make the selection process even easier, visual aids and comparison tables can provide a quick overview of different paper weights and their applications. These visual aids could include sample prints on different paper weights, allowing you to see and feel the difference between them.

Real World Examples of Successful Paper Weight Choices

Sometimes, the best way to understand the impact of different paper weights is to see real-world examples. Consider researching successful print projects in your industry and take note of the paper weights used. This can provide valuable insights and inspiration for your own projects.

In conclusion, choosing the right offset paper weight for your project is essential for achieving high-quality, professional results. By determining the purpose of your print project, matching the paper weight to the project type, utilizing conversion and comparison charts, and considering practical tips, you’ll be well-equipped to make an informed decision. Remember to always request sample prints and seek inspiration from real-world examples. Happy printing!

FAQs about Offset Paper Weight Comparison

What is offset paper weight?

Offset paper weight refers to the weight or thickness of a specific type of high-quality, uncoated paper known as offset paper, which is commonly used for printing books, brochures, and other promotional materials.

How is paper weight measured?

Paper weight is measured in three main ways: grams per square meter (GSM), pounds (lb.), and points (pt.).

What does GSM stand for in paper weight measurement?

GSM stands for grams per square meter and represents the weight of a sheet of paper measuring one square meter; the higher the GSM value, the thicker and heavier the paper.

How are pounds (lb.) used to measure paper weight?

Pounds (lb.) measure paper weight based on the weight of 500 parent sheets of a specific type and size of paper; for example, 70 lb. paper means 500 sheets weigh 70 pounds.

What does a measurement in points (pt.) indicate for paper weight?

Points (pt.) indicate the thickness of thicker and more rigid paper stocks, such as cover, board, and card stock, where one point equals 1/1000 (.001) inches.

Understanding offset paper weight and its measurement is critical for excellent print results. We’ve covered what offset paper weight is, how to measure it, and the differences between GSM, pounds, and points. Choosing the right paper weight helps your project shine, impacts print quality, and affects cost. Light weights are great for bulk prints; heavy weights offer durability and a professional feel. Use this guide to make informed choices for top-notch outcomes.