Why Does Offset Paper Weight Matter?

Offset Paper weight : A Comprehensive Guide

In the world of printing and paper, the weight of offset paper plays a crucial role in determining the quality and suitability of the material for different projects. Understanding the offset paper weight is essential for achieving the desired printing results and ensuring the durability of printed materials. In this comprehensive guide, we will delve into the concept of offset paper weight, the measurement standards used, and how to calculate the weight of offset paper accurately.

What is Offset Paper Weight and Why is it Important?

Offset paper weight refers to the measure of a paper’s density or thickness. It determines the stability and durability of the paper, as well as its ability to withstand printing processes and frequent handling. The weight of offset paper is a vital consideration when selecting paper for various printing projects, such as business cards, brochures, and postcards.

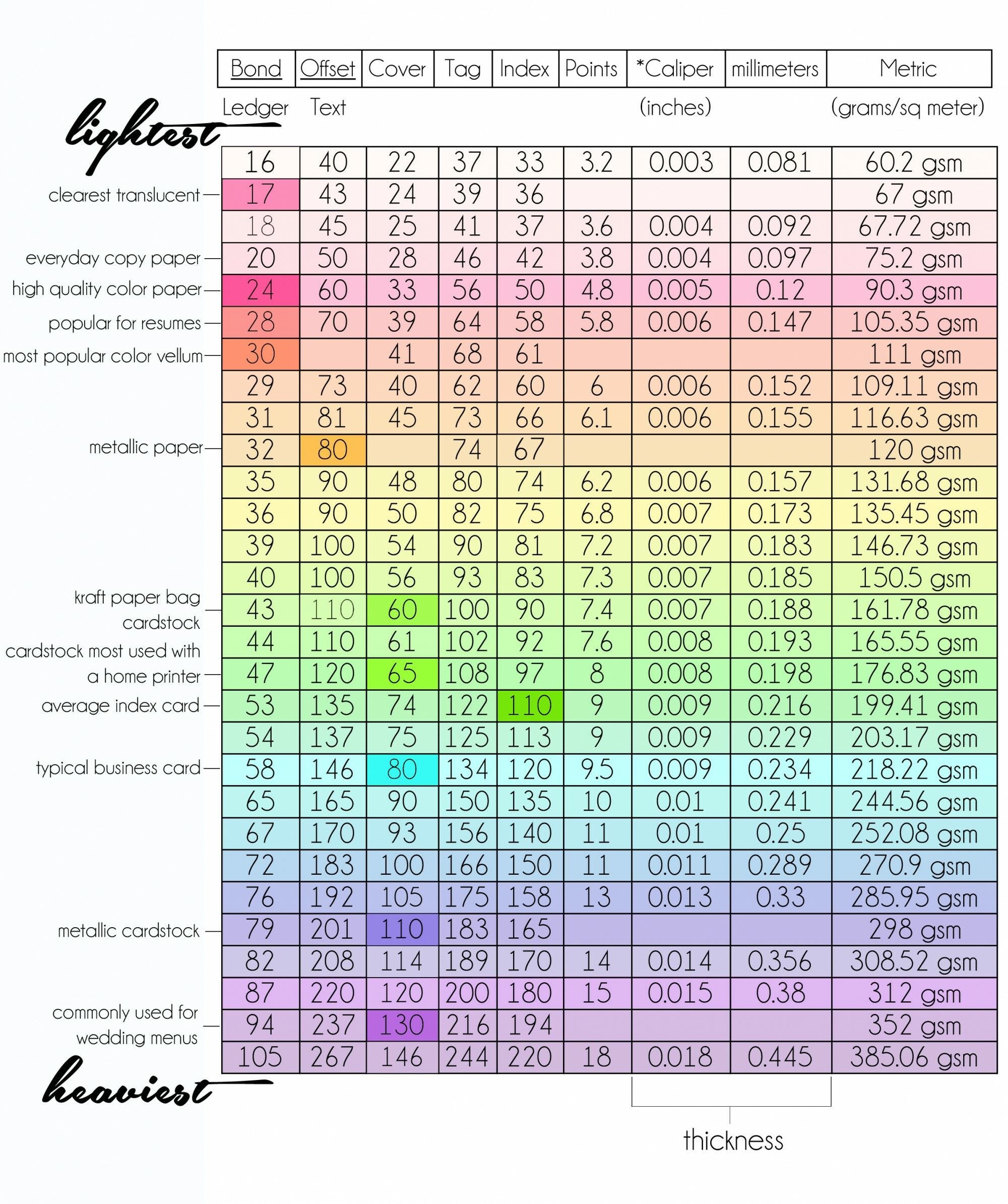

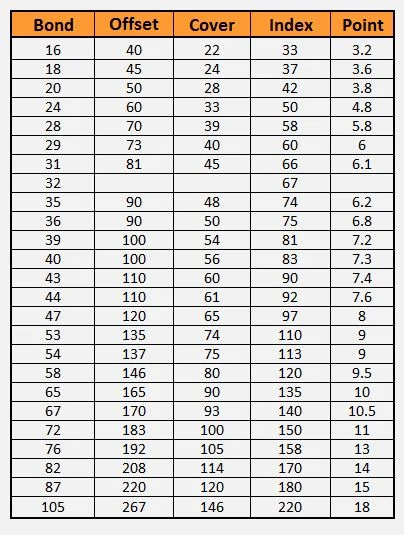

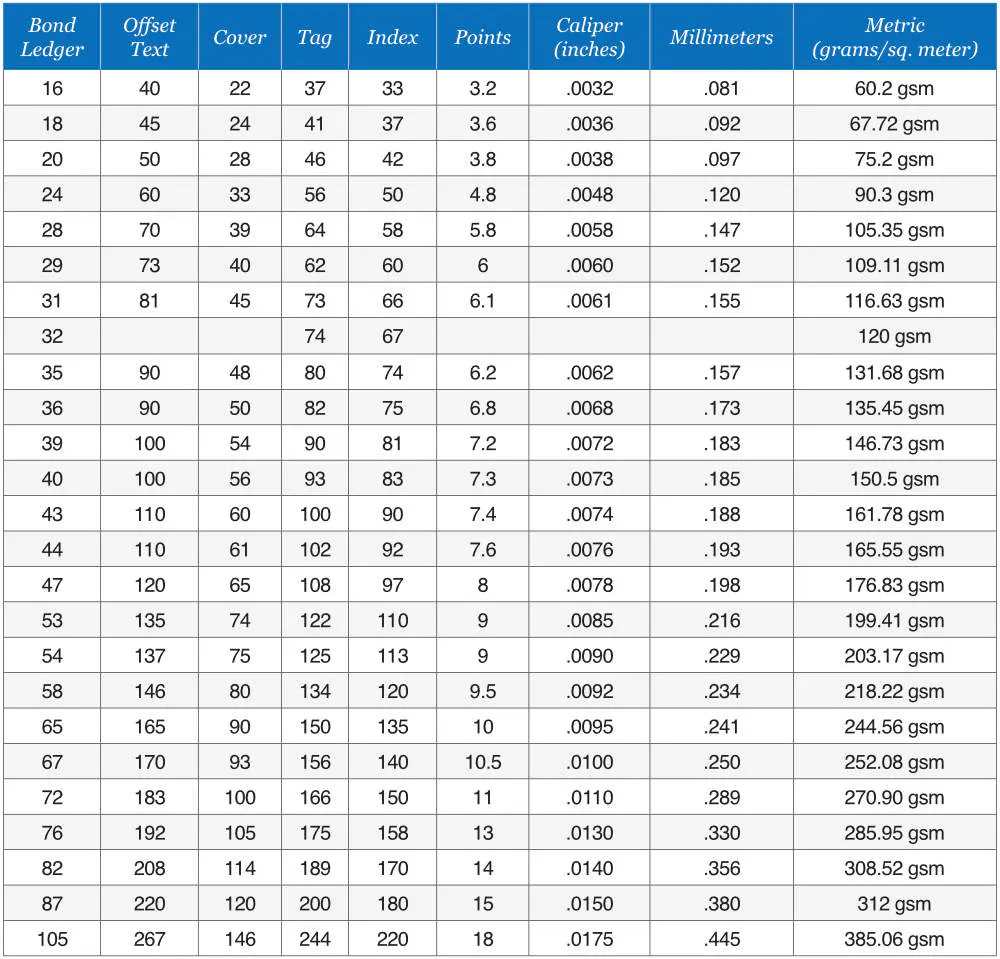

The weight of offset paper is expressed in pounds (lbs) and points (pt). Pound weight measures the weight of 500 sheets of paper in its basic size, while points refer to the thickness of a single sheet of paper. These measurements are used to categorize different types of paper, ensuring consistency and allowing users to make informed choices based on their specific needs.

Understanding the Measurement Standards for Offset Paper Weight

To fully comprehend offset paper weight, it’s essential to be familiar with the various measurement standards used in the printing industry. The most common measurement standards for offset paper weight are pounds (lbs), grams per square meter (gsm), and points (pt).

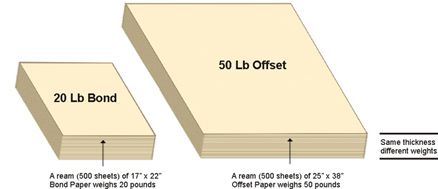

- Pound Weight (lbs): Pound weight is widely used in the United States and measures the weight of 500 sheets of paper in its basic size. It varies depending on the paper category, with different sizes for Bond, Text, Cover, and Index papers. For example, a 20 lb Bond paper will be thinner than a 24 lb Bond paper.

- Grams per Square Meter (gsm): GSM is a global measurement standard that indicates the weight of one square meter of paper. It provides a more accurate and consistent measurement across different paper types and regions. For instance, both a 20 lb Bond paper and a 50 lb Offset paper can have the same weight in gsm, which is 75 gsm.

- Points (pt): Points refer to the thickness of a single sheet of paper and are commonly used for heavier stocks. Each point represents one-thousandth of an inch. For example, 10pt paper has a thickness of 0.010 inches.

Understanding the different measurement standards is crucial for choosing the appropriate paper weight for specific printing projects and ensuring the desired results.

Calculating the Weight of Offset Paper

Calculating the weight of offset paper requires knowing the measurement standard being used, whether it’s pounds (lbs), grams per square meter (gsm), or points (pt).

To calculate the weight of offset paper in pounds (lbs), follow these steps:

- Determine the basis size of the paper category.

- Identify the weight (w) of the paper in pounds (lbs) for 500 sheets in the basic size.

- Calculate the weight of the desired quantity of paper using the formula: Weight (lbs) = (w ÷ 500) × Quantity

To calculate the weight of offset paper in grams per square meter (gsm), use the following formula:

Weight (gsm) = Weight (lbs) × 454 (conversion factor) × area of one sheet in square meters

To calculate the weight of offset paper in points (pt), follow this formula:

Weight (pt) = Weight (lbs) × 1000

By accurately calculating the weight of offset paper, you can make informed decisions when selecting paper for your printing projects and ensure the desired outcome.

In conclusion, understanding the weight of offset paper is crucial for achieving high-quality printing results and determining the durability of printed materials. By comprehending the measurement standards, including pounds (lbs), grams per square meter (gsm), and points (pt), you can make informed decisions and select the appropriate paper weight for your specific needs. Calculate the weight of offset paper accurately to ensure the success of your printing projects.

Different Types of Offset Paper Weights

When it comes to choosing the right paper for your printing needs, one important factor to consider is the weight of the paper. The weight of offset paper refers to the thickness and density of the paper, which can vary depending on the specific needs of your project. In this section, we will explore the different weight categories of offset paper, compare offset paper weight with other paper types, and discuss the practical applications of varying offset paper weights.

Exploring Different Weight Categories of Offset Paper

Offset paper comes in a range of weight categories, each offering unique characteristics and benefits. The weight of paper is typically measured in pounds (lb) or grams per square meter (GSM). Let’s take a closer look at the different weight categories of offset paper:

- Lightweight Paper: Lightweight offset paper typically falls in the range of 50-90 GSM or 20-36 lb. This type of paper is thin and lightweight, making it ideal for projects that require a delicate and smooth finish. It is commonly used for projects like booklets, flyers, and promotional materials.

- Medium Weight Paper: Medium weight offset paper usually ranges from 90-120 GSM or 36-48 lb. This weight category offers a good balance between durability and flexibility, making it suitable for a wide range of applications. It is commonly used for brochures, catalogs, and mailers.

- Heavyweight Paper: Heavyweight offset paper falls in the range of 120-300 GSM or 48-80 lb. This category of paper is thick and sturdy, providing excellent durability and a high-quality feel. It is commonly used for business cards, postcards, and premium printed materials.

By understanding the different weight categories of offset paper, you can make an informed decision about the type of paper that best suits your project’s needs.

Comparing Offset Paper Weight with Other Paper Types

When choosing the weight of your paper, it’s essential to consider how it compares to other paper types. Different types of paper have varying weight standards, and understanding these comparisons can help you find the right paper for your specific needs. Here are some common paper types and their weight standards:

- Bond Paper: Bond paper is commonly used for letterheads, copies, and laser/inkjet printing. It comes in weights ranging from 16 lb to 36 lb or 60-135 GSM.

- Text Paper: Text paper, also known as book paper or offset paper, is commonly used for printed materials like brochures and catalogs. It is slightly heavier than bond paper, with weights ranging from 60 lb to 100 lb or 70-135 GSM.

- Cover Paper: Cover paper, often called cardstock, is used for postcards, business cards, and greeting cards. It comes in weights ranging from 65 lb to 150 lb or 170-409 GSM.

By comparing the weight standards of different paper types, you can determine which type of paper will best meet your project’s requirements. It’s important to note that the same weight of paper may have different thicknesses depending on the paper type.

Practical Applications of Varying Offset Paper Weights

The weight of offset paper plays a crucial role in determining its practical applications. Here are some examples of how varying offset paper weights are used in different printing projects:

- Business Cards: When it comes to business cards, durability and professionalism are key. Recommended paper weights for business cards range from 14-16 pt, ensuring that they withstand frequent handling while maintaining a premium quality appearance.

- Brochures: Brochures are often used for marketing and promotional purposes. The standard weight for brochures is 80 lb, but higher quality brochures may require a heavier weight of 100 lb to create a more substantial and premium feel.

- Postcards: Postcards need to be sturdy and durable, especially during mailing. For this reason, postcards are typically printed on 100 lb paper to ensure they can withstand the rigors of the postal system.

It’s important to keep in mind that while heavier weights of paper offer added durability and a premium feel, they may also increase the production cost due to their sturdier quality. Therefore, when choosing the weight of offset paper for your project, it’s essential to consider both the practical application and your budget constraints.

In summary, understanding the different weight categories of offset paper, comparing offset paper weight with other paper types, and considering the practical applications of varying offset paper weights are crucial factors in choosing the right paper for your printing projects. By selecting the appropriate weight of offset paper, you can ensure that your printed materials meet your desired quality standards and effectively communicate your message.

Factors Affecting Paper Weight in the Printing Industry

The weight of offset paper is an important consideration in the printing industry. It not only impacts the cost of printing but also affects the texture and finish of printed materials. In this section, we will explore the various factors that contribute to paper weight and how they influence the printing process and final product.

Effects of paper weight on printing cost

One of the key considerations when choosing the right paper weight for a printing project is its impact on cost. Generally, heavier paper weights cost more due to their sturdier quality. The cost of paper is calculated based on the weight of a ream, which refers to a specific quantity of paper. Heavier weights require more raw materials, resulting in a higher production cost. Therefore, it’s essential to carefully consider the budget constraints of a project when selecting the paper weight.

Adjustments required for printing with heavier paper weights

Printing with heavier paper weights often requires adjustments in the printing process. The thickness and stiffness of the paper may necessitate changes in the settings of the printing equipment, such as the pressure and ink application. Printers need to ensure that the ink adheres well to the surface of the paper and that the printing is consistent throughout the job. Additionally, the drying process may take longer with heavier paper weights. Therefore, printers need to account for these adjustments when planning and executing a print job.

How paper weight affects the texture and finish of printed materials

The weight of offset paper also affects the texture and finish of printed materials. Heavier weights generally result in a more substantial and high-quality feel. They provide a sense of durability and professionalism, making them ideal for business cards. On the other hand, lighter weights tend to have a more delicate and lightweight feel, making them suitable for items like flyers or brochures. The choice of paper weight can significantly impact the overall perception and impression of the final printed piece.

When considering the texture and finish of printed materials, it’s essential to understand the different options available for various paper weights. Different paper types can have varying thicknesses despite having the same weight. For example, text weight paper is slightly heavier than letterhead paper, while cover weight paper is used for mass mailing postcards and business cards. It’s crucial not to confuse text weight with cardstock, as they have different thicknesses despite potentially having the same weight.

The paper industry also measures paper weight using different units, such as GSM (grams per square meter), which provides a more precise measurement of the weight per area. Standard paper thickness ranges from 60 to 200 GSM, with higher GSM paper being more durable and suitable for projects requiring frequent handling. Understanding the relationship between paper weight and thickness is crucial for choosing the right paper for specific printing projects.

In conclusion, paper weight plays a significant role in the printing industry. It affects the cost of printing, requires adjustments in the printing process, and has a direct impact on the texture and finish of printed materials. By considering these factors and understanding the various options available, printers can choose the right paper weight to meet the specific needs of their projects and deliver high-quality printed materials.

Tables

Table 1: Comparison of Offset Paper Weight Categories

| Weight Category | GSM Range | lb Range |

|---|---|---|

| Lightweight Paper | 50-90 GSM | 20-36 lb |

| Medium Weight Paper | 90-120 GSM | 36-48 lb |

| Heavyweight Paper | 120-300 GSM | 48-80 lb |

Table 2: Comparison of Common Paper Types and Weight Standards

| Paper Type | Weight Range |

|---|---|

| Bond Paper | 16-36 lb or 60-135 GSM |

| Text Paper | 60-100 lb or 70-135 GSM |

| Cover Paper | 65-150 lb or 170-409 GSM |

FAQs about Offset Paper Weight

What is Offset Paper Weight and Why is it Important?

A: The weight of offset paper refers to its density and thickness, influencing its stability, durability, and printing suitability based on the project requirements.

Understanding the Measurement Standards for Offset Paper Weight

A: Offset paper weight is measured in pounds (lbs), grams per square meter (gsm), and points (pt), allowing users to categorize and select paper types accurately.

Calculating the Weight of Offset Paper

A: To calculate the weight of offset paper, use formulas based on the chosen measurement standard – pounds (lbs), grams per square meter (gsm), or points (pt).

Different Types of Offset Paper Weights

A: Offset paper comes in varying weight categories – lightweight, medium weight, and heavyweight – each serving different purposes in printing projects based on their durability and thickness.

Factors Affecting Paper Weight in the Printing Industry

A: Paper weight impacts printing costs, requires adjustments in the printing process for heavier weights, and influences the texture and finish of printed materials.

In conclusion, offset paper weight plays a crucial role in the printing industry. Understanding measurement standards and different weight categories is essential for quality prints. Consider how paper weight impacts printing costs, textures, and finishes. Choose the right paper weight for your needs to achieve optimal results. Offset paper weight is not just a number; it significantly influences the overall printing process and final products.