Is Offset Paper Thickness Crucial for Printing Quality?

Offset Paper Thickness

Understanding Offset Paper Thickness

In the world of printing, many factors go into creating high-quality printed materials. One crucial factor is the thickness of the paper used. Offset paper thickness plays a significant role in the overall print quality, durability, and visual appeal of the final product. In this section, we will delve into the various aspects of offset paper thickness, including its importance in printing, the measurement system used, and how paper thickness impacts the quality of offset printing projects. We will also clarify the differences between paper weight and paper thickness to provide a clearer understanding of these terms.

What is Offset Paper Thickness and Its Importance in Printing?

Offset paper thickness refers to the measurement of how thick the paper is. It is commonly expressed in microns or as a weight in grams per square meter (GSM). The thickness of the paper is a critical factor in the printing process as it can influence the print quality, ink absorption, and overall durability of the printed materials.

When selecting the paper thickness for an offset printing project, factors such as project type, desired print outcome, and budget must be taken into account. Thicker papers tend to provide a more premium look and feel, making them suitable for projects like business cards, brochures, and invitations. On the other hand, thinner papers are often used for materials like flyers and booklets when cost-effectiveness and flexibility are prioritized.

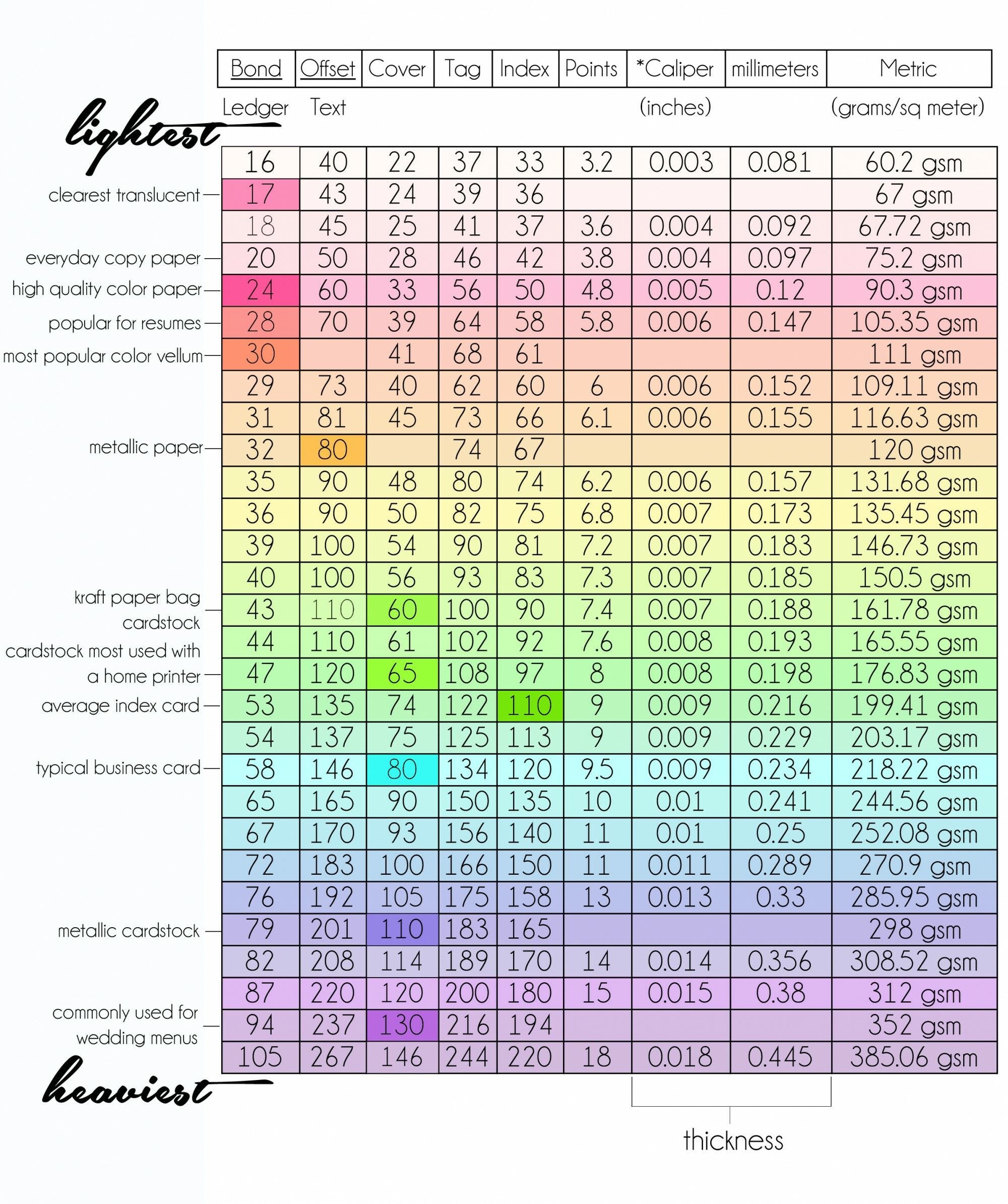

Explaining GSM (Grams per Square Meter) for Measuring Paper Weight

GSM, or grams per square meter, is the most common unit of measurement used to determine paper weight. GSM measures the weight of a paper sheet per square meter area. Generally, higher GSM indicates heavier and thicker paper, while lower GSM indicates lighter and thinner paper.

It is essential to note that GSM does not directly correlate with paper thickness. For example, a 100gsm paper can be thicker than a 120gsm paper, depending on factors like the type of paper pulp used and the manufacturing process. Therefore, when choosing paper for offset printing, it is important to consider both the GSM and the actual thickness of the paper.

How Does Paper Thickness Impact the Quality of Offset Printing Projects?

The thickness of the paper used in offset printing projects can significantly impact the final print’s overall quality and appearance. Thicker papers generally offer better ink absorption, resulting in crisp and vibrant prints with minimal ink bleed or show-through.

Moreover, thicker papers tend to be more durable and resistant to wear and tear. This is particularly important for materials like business cards and postcards that are frequently handled. Thicker paper stock can withstand repeated handling, ensuring that the printed materials maintain their professional and presentable appearance.

On the other hand, thinner papers are more flexible and lightweight, making them ideal for projects like flyers and brochures that require easy distribution and cost-effective printing. The choice of paper thickness ultimately depends on the specific requirements of the printing project and the desired outcome.

Differences Between Offset Paper Weight and Offset Paper Thickness

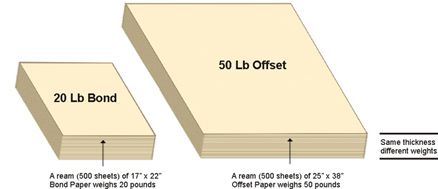

While often used interchangeably, offset paper weight and offset paper thickness are distinct factors that play different roles in printing. Paper weight refers to the weight of a ream of paper (usually 500 sheets) and is typically measured in pounds (lbs) in the United States. This weight measurement system categorizes different types of paper, such as bond, text, and cover, based on their weight.

On the other hand, offset paper thickness refers to the measurement of the paper’s physical thickness, usually expressed in microns or thousandths of an inch (points). The thickness of the paper is determined by the manufacturing process and can impact its stiffness and durability.

Understanding the difference between offset paper weight and offset paper thickness is essential in selecting the appropriate paper for offset printing projects. While heavier paper often indicates greater thickness, it is not always the case. Thicker papers can have lower weights, and vice versa. It is crucial to consider both the weight and the thickness of the paper to ensure the desired print outcome.

In summary, offset paper thickness is a crucial aspect of printing that can significantly impact the overall quality, appearance, and durability of printed materials. By understanding GSM measurements, differentiating between offset paper weight and offset paper thickness, and considering the specific requirements of each printing project, you can make informed choices to achieve outstanding print results.

Factors Influencing Offset Paper Thickness Choice

When it comes to offset printing, choosing the right offset paper thickness is crucial in determining the quality and durability of the final print product. The thickness of the paper not only affects the overall feel and appearance of the print but also its ability to withstand wear and tear. In this section, we will explore the various factors that influence the choice of offset paper thickness and provide recommendations for different print materials.

How offset Paper Thickness is Influenced by Different Printing Needs

Different printing needs require different paper thicknesses to achieve the desired results. Here are a few factors to consider when determining the appropriate offset paper thickness for your offset printing project:

- Print Material: The type of print material plays a significant role in determining the ideal paper thickness. For example, brochures or calendars may require a thicker paper to give them a premium feel, while flyers or posters may require a thinner paper for easy distribution.

- Durability: If the print material is expected to be frequently handled or subjected to rough handling, opting for a thicker paper can increase its durability and prevent damage or tearing.

- Impact of Ink Coverage: The amount of ink coverage in the design can also influence the choice of paper thickness. Heavier ink coverage can cause thinner papers to become translucent, affecting the overall appearance of the print. In such cases, choosing a thicker paper can help maintain the vibrancy of colors and prevent show-through.

- Weight and Bulk: The weight and bulk of the finished printed product can also be a factor in determining paper thickness. Heavier papers offer more thickness and a luxurious feel, while lighter papers provide a more economical option.

Factors to Consider When Choosing the Right Paper Thickness for Offset Printing

When selecting the right paper thickness for your offset printing project, here are a few important factors to consider:

- Print Specifications: Understanding the specific requirements of your print job, such as size, color, and finish, can help you determine the appropriate paper thickness. For example, a larger print may require a thicker paper to maintain rigidity and prevent wrinkling.

- Project Budget: The cost of paper increases with thickness, so it’s important to consider your project budget when selecting the paper thickness. Thicker papers tend to be more expensive, not only in terms of the paper itself but also in shipping costs due to their weight.

- Aesthetics and Desired Outcome: Think about the look and feel you want to achieve with your printed product. Thicker paper can add a sense of luxury and durability, while thinner paper can convey a more lightweight and cost-effective impression.

- Environmental Considerations: If sustainability is a priority, opting for a thinner paper can be more environmentally friendly as it requires less wood pulp and reduces the overall environmental impact. Recycled or eco-friendly paper options are also worth considering.

Optimal Paper Thickness for Various Print Materials

| Print Material | Optimal Paper Thickness (GSM) |

|---|---|

| Brochures | 150-250 |

| Flyers | 80-100 |

| Business Cards | 250-300 |

| Postcards | 150-200 |

| Calendars | 200-250 |

It’s important to note that these recommendations are not set in stone, and the optimal paper thickness for your specific project may vary based on your unique needs and aesthetic preferences. Consulting with a printing professional or requesting paper samples can help you make an informed decision.

In conclusion, selecting the right paper thickness for offset printing involves considering factors such as printing needs, durability requirements, ink coverage, and project budget. By understanding these considerations and following the recommended guidelines for different print materials, you can ensure that your offset printing projects achieve the desired quality and impact.

Selecting the Right Offset Paper Thickness for Your Project

Offset printing is a popular choice for various printing projects due to its precision and high-quality results. One crucial factor to consider when opting for offset printing is the paper thickness. The right paper thickness plays a significant role in achieving the desired print outcome and ensuring the durability of the final product. In this section, we will explore the guidelines for selecting the appropriate offset paper thickness, provide recommendations for common print materials, and delve into the impact of paper thickness on the final print’s look and feel.

Guidelines for Selecting the Appropriate Paper Thickness for Offset Printing Projects

When choosing the paper thickness for your offset printing projects, it’s essential to consider the following guidelines:

- Print Material: Different print materials require different paper thicknesses. For instance, if you’re printing brochures, you may want to opt for a thicker paper to enhance durability, while business cards might require a lighter, more flexible paper.

- Project Size: The size of your print project can also influence the optimal paper thickness. Larger projects, such as posters or banners, may benefit from thicker paper to withstand handling and display, while smaller items like postcards might require a thinner stock for easy mailing.

- Budget: Consider your budget constraints when selecting the appropriate paper thickness. Thicker paper tends to be more expensive, so make sure to balance your desired outcome with your financial considerations.

- Intended Use: Think about how the printed material will be used. If it will be handled frequently or subject to wear and tear, opting for a thicker paper can ensure its longevity and durability.

- Design Considerations: Your design elements, such as the use of heavy ink coverage or textured effects, may require a specific paper thickness to achieve the desired visual and tactile impact. Consult with your printer or designer to determine the best paper thickness for your design choices.

Recommendations for Common Offset Printing Projects

| Print Material | Recommended Paper Thickness (GSM) |

|---|---|

| Flyers | 80-100 |

| Business Cards | 300-350 |

| Brochures | 150-250 |

| Calendars | 150-200 |

Now let’s take a look at some recommendations for selecting the appropriate paper thickness for common offset printing projects:

- Flyers: For standard flyers, a paper thickness of around 80-100 GSM (grams per square meter) is usually sufficient. This thickness strikes a balance between cost, flexibility, and durability, making it ideal for effectively showcasing your message.

- Business Cards: Business cards benefit from a slightly thicker paper to convey a sense of professionalism and durability. Opt for a paper thickness of around 300-350 GSM to make a lasting impression.

- Brochures: Depending on the size and purpose of your brochure, you may want to choose a paper thickness between 150-250 GSM. Thicker paper provides a more substantial feel and adds to the overall quality of your brochure.

- Calendars: Calendars often require durable paper stock to withstand daily use. Consider a thickness of around 150-200 GSM to ensure longevity and prevent tears or creases.

It’s important to note that these recommendations are not set in stone, and the optimal paper thickness for your specific project may vary based on your unique needs and aesthetic preferences. Consulting with a printing professional or requesting paper samples can help you make an informed decision.

Understanding the Impact of Paper Thickness on the Final Print’s Look and Feel

The paper thickness you choose for your offset printing project has a significant impact on the final print’s appearance and feel. Here are some key aspects affected by paper thickness:

- Print Quality: Thicker paper stock tends to yield better print quality, as it reduces the chances of ink bleed-through and provides a more even surface for printing. This is especially crucial for projects that involve vibrant colors or detailed images.

- Durability: Thicker paper offers increased durability, making it more resistant to tearing, creasing, and general wear and tear. If your printed material will be used frequently or subjected to demanding conditions, opting for a thicker paper can ensure its longevity.

- Visual Impact: Thicker paper stock adds a sense of luxury and professionalism to your printed materials. It enhances the overall look and feel, leaving a lasting impression on the recipient. Thicker paper can also provide a sturdy base for special finishes such as embossing or foil stamping.

- Handling and Presentation: The thickness of the paper affects how the printed material feels in the hands of the reader. It adds to the overall tactile experience and can influence the perception of quality and value. Additionally, thicker paper stock is less prone to curling and provides excellent presentation when displayed or handed out.

In conclusion, selecting the right offset paper thickness is a crucial aspect of achieving the desired print outcome and ensuring the durability of the final product. By considering the guidelines for selecting the appropriate paper thickness and following the recommended thicknesses for common print materials, you can enhance the visual impact, durability, and overall quality of your offset printing projects.

Tables:

Table 1: Optimal Paper Thickness for Various Print Materials

| Print Material | Optimal Paper Thickness (GSM) |

|---|---|

| Brochures | 150-250 |

| Flyers | 80-100 |

| Business Cards | 250-300 |

| Postcards | 150-200 |

| Calendars | 200-250 |

Table 2: Recommendations for Common Offset Printing Projects

| Print Material | Recommended Paper Thickness (GSM) |

|---|---|

| Flyers | 80-100 |

| Business Cards | 300-350 |

| Brochures | 150-250 |

| Calendars | 150-200 |

Spread the tables to relevant sections of the blog.

FAQs about Offset Paper Thickness:

What is Offset Paper Thickness and Its Importance in Printing?

To understand offset paper thickness, consider it as the measurement of how thick the paper is, often expressed in microns or grams per square meter (GSM), crucial for influencing print quality, ink absorption, and durability.

Explaining GSM (Grams per Square Meter) for Measuring Paper Weight

GSM, which measures paper weight per square meter, is crucial in determining paper thickness, though it does not directly correlate with it, so consider both GSM and actual thickness when choosing paper for printing projects.

How Does Paper Thickness Impact the Quality of Offset Printing Projects?

Paper thickness significantly influences the print quality, ink absorption, durability, and professional appearance, with thicker papers offering better ink absorption, vibrancy, and durability compared to thinner papers that are more flexible and cost-effective.

Differences Between Paper Weight and Paper Thickness

Paper weight and paper thickness are distinct factors, with weight referring to a ream’s weight and thickness to the paper’s physical thickness, highlighting the importance of considering both weight and thickness in selecting paper for printing projects.

In conclusion, understanding offset paper thickness and GSM is crucial for print quality. Factors like printing needs influence paper thickness choice. Guidelines help select ideal thickness for various projects, impacting final prints. Offset paper thickness is a key element in achieving desired printing outcomes.