Are Standard Offset Paper Sizes Ideal?

Section Title: Understanding Offset Paper Sizes

In the world of printing, offset paper sizes play a crucial role in determining the final look and feel of printed materials. Whether you’re designing a brochure, poster, or business card, understanding the standard offset paper sizes used in the industry is essential. In this section, we will delve into the various offset paper sizes, their specifications, and how they impact printing projects.

What are the standard offset paper sizes used in the printing industry?

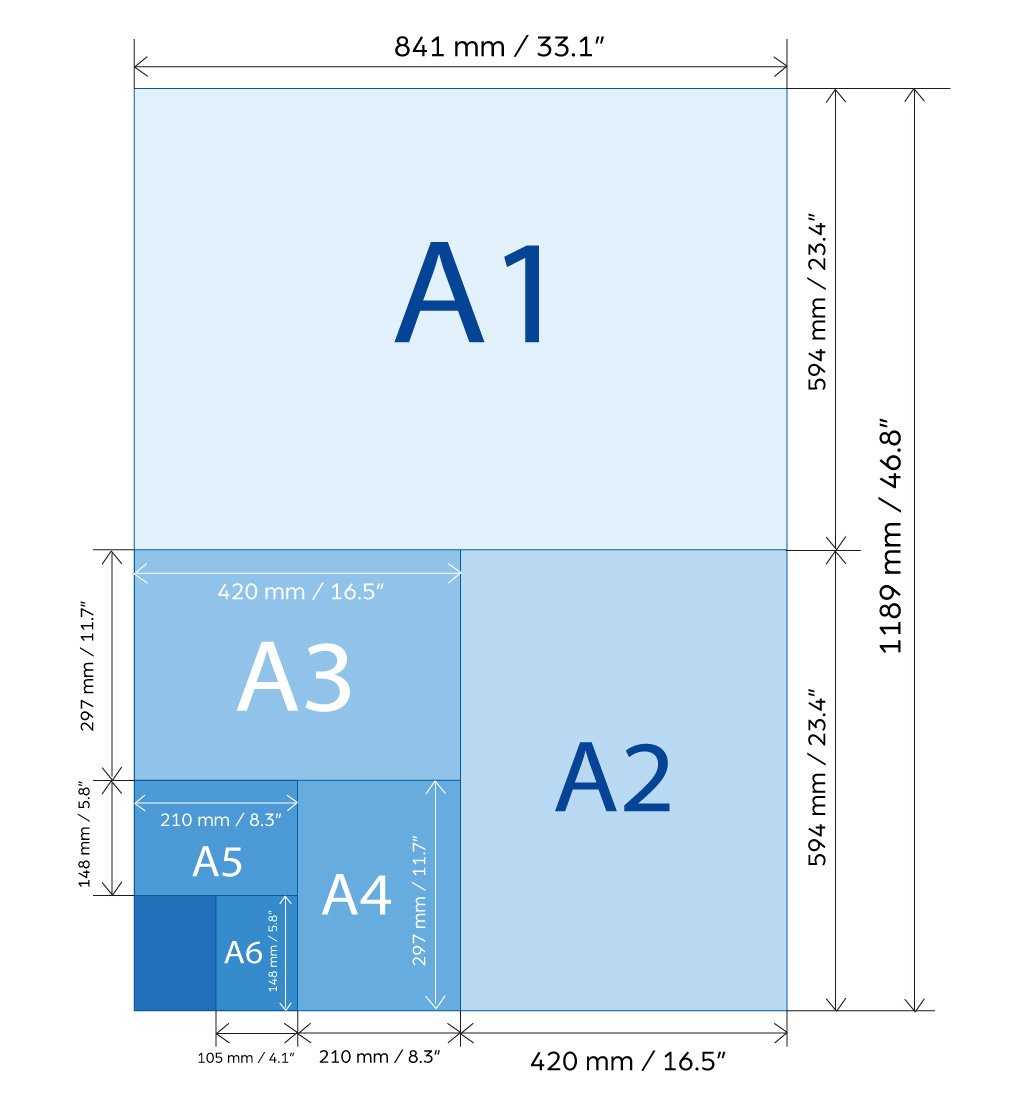

The printing industry relies on a set of standard paper sizes for offset printing. These sizes are globally recognized and widely used. The most commonly used standard offset paper sizes include:

- A4 (210mm x 297mm): This is the most common size for documents like letters, brochures, and flyers.

- A5 (148mm x 210mm): A5 paper is often used for booklets, postcards, and smaller brochures.

- A6 (105mm x 148mm): A6 paper size is commonly used for pocket-sized booklets, notepads, and postcards.

Apart from these sizes, there are other standard offset paper sizes like A3, A2, A1, and A0, which are larger and commonly used for large posters, banners, and architectural prints.

How do variations in paper sizes impact printing projects?

When selecting the right paper size for your offset printing project, it’s important to consider how variations in paper sizes can impact the final outcome. Here are a few factors to keep in mind:

- Layout and Design: Different paper sizes offer different layout options. For instance, a larger paper size allows for more content and design elements, while a smaller size may require a more concise layout.

- Cost and Quantity: The cost of printing can vary depending on the paper size and quantity required. Larger paper sizes generally cost more, especially when printing in large quantities.

- Visual Impact: The choice of paper size can significantly impact the visual impact of your printed materials. Larger paper sizes may create a more striking effect, while smaller sizes can be more compact and portable.

- Intended Use: Consider the purpose and use of the printed materials. For example, if you’re creating a business card or a flyer to be handed out, a smaller paper size like A6 may be more suitable. On the other hand, for a poster or a brochure meant to attract attention, a larger paper size like A3 or A2 may be more effective.

Factors to consider when selecting the right paper size for offset printing

Choosing the right paper size for your offset printing project involves considering several factors. Here are some key points to keep in mind:

- Audience and Target Market: Consider the preferences and expectations of your target audience. If your materials are aimed at professionals or corporate clients, standard sizes like A4 may be more appropriate. On the other hand, if your target audience is more artistic or creative, experimenting with different sizes may be suitable.

- Longevity: Consider how long you want your printed materials to last. Smaller sizes may be more prone to getting lost or misplaced, while larger sizes tend to have a longer lifespan.

- Practicality and Efficiency: Evaluate the practicality and efficiency of using a specific size for your project. Consider factors like ease of distribution, storage, and cost.

- Branding and Personalization: Choosing a unique paper size can help set your brand apart and make your materials stand out. Consider if a non-standard size aligns with your branding strategy and adds to the overall impact of your design.

In conclusion, understanding offset paper sizes is crucial for achieving the desired outcome in your printing projects. From selecting the appropriate standard size to considering the impact of variations, taking these factors into account will help ensure that your printed materials are visually appealing, practical, and aligned with your brand’s objectives.

Section title: Exploring Paper Weight and Coating Options

When it comes to offset printing, choosing the right paper weight and coating can significantly impact the overall quality and appearance of the final printed product. In this section, we will delve into the common paper weights used in offset printing and explore the different paper coatings available.

What are the common paper weights used in offset printing?

Paper weight is an important consideration in offset printing as it affects the durability and feel of the printed material. Commonly used paper weights in offset printing include 70gsm, 80gsm, and 100gsm. The term “gsm” stands for grams per square meter, which is a universal measure for paper weight. These weights are ideal for various printed materials such as brochures, flyers, and business cards.

It’s important to note that paper weight classifications can vary depending on the region and printing practices. Text weight paper is lightweight and commonly used for documents, while cover weight paper is heavier and suitable for covers or inserts. Bond paper is often used for letterheads and business forms. However, it’s always best to consult with your printer to determine the most appropriate paper weight for your specific printing needs.

How do different paper coatings affect the final print outcome?

In offset printing, paper coatings play a crucial role in determining the finish and appearance of the printed material. There are several coating options available, including gloss, matte, and uncoated.

- Gloss coating: Gloss coating provides a shiny and reflective finish to the printed material. It enhances color vibrancy and gives a polished look. Gloss-coated paper is commonly used for brochures, catalogs, and high-quality prints.

- Matte coating: Matte coating offers a more subtle shine compared to gloss coating. It provides a smooth, non-reflective surface that is ideal for designs that require a sophisticated and elegant appearance. Matte-coated paper is commonly used for business cards, postcards, and art prints.

- Uncoated paper: Uncoated paper does not have any coating applied to its surface. It has a rougher texture and a natural feel, making it suitable for designs that require a tactile experience or are intended for writing, such as stationery, letterheads, and notepads.

Each coating option has its unique characteristics and can impact the color saturation, clarity, and overall look of the printed material. When selecting a paper coating, consider the desired aesthetics, the type of design, and the intended use of the printed material.

Table 1: Common Paper Weights

| Weight | Description |

|---|---|

| 70gsm | Lightweight, ideal for documents |

| 80gsm | Standard weight for various prints |

| 100gsm | Slightly heavier, suitable for brochures and business cards |

Table 2: Paper Coating Options

| Coating | Description |

|---|---|

| Gloss | Provides a shiny finish, enhances color vibrancy |

| Matte | Offers a non-reflective surface, suitable for sophisticated designs |

| Uncoated | Has a rough texture, natural feel, ideal for tactile experiences and writing |

Choosing the right paper weight and coating for your offset printing project requires careful consideration. By considering factors like project type, design aesthetics, budget, and printing method, you can make informed decisions that result in visually appealing and high-quality printed materials.

Maximizing Efficiency in Offset Printing

In the world of offset printing, maximizing efficiency is crucial for reducing costs and producing high-quality prints. Efficient practices not only save time and resources but also result in better outcomes for both the printer and the client. In this section, we will explore tips for optimizing press sheets, the importance of efficient design, and strategies for maximizing efficiency in the offset printing process.

Tips for Optimizing Press Sheets

Press sheet optimization is a key aspect of minimizing waste and reducing printing costs in offset printing. By utilizing the space on press sheets effectively, printers can maximize the number of prints produced while minimizing the amount of paper used. Here are some tips for optimizing press sheets:

- Combine Versions: If you have multiple versions or variations of a design, consider combining them onto a single press sheet. By doing this, you can reduce the number of press sheets required and save on paper costs.

- Fill the Press Sheet: Make sure to utilize the entire surface area of the press sheet. Leaving empty spaces on the sheet is wasteful and increases costs. By filling the press sheet to its maximum capacity, you can reduce paper waste and increase the overall efficiency of the printing process.

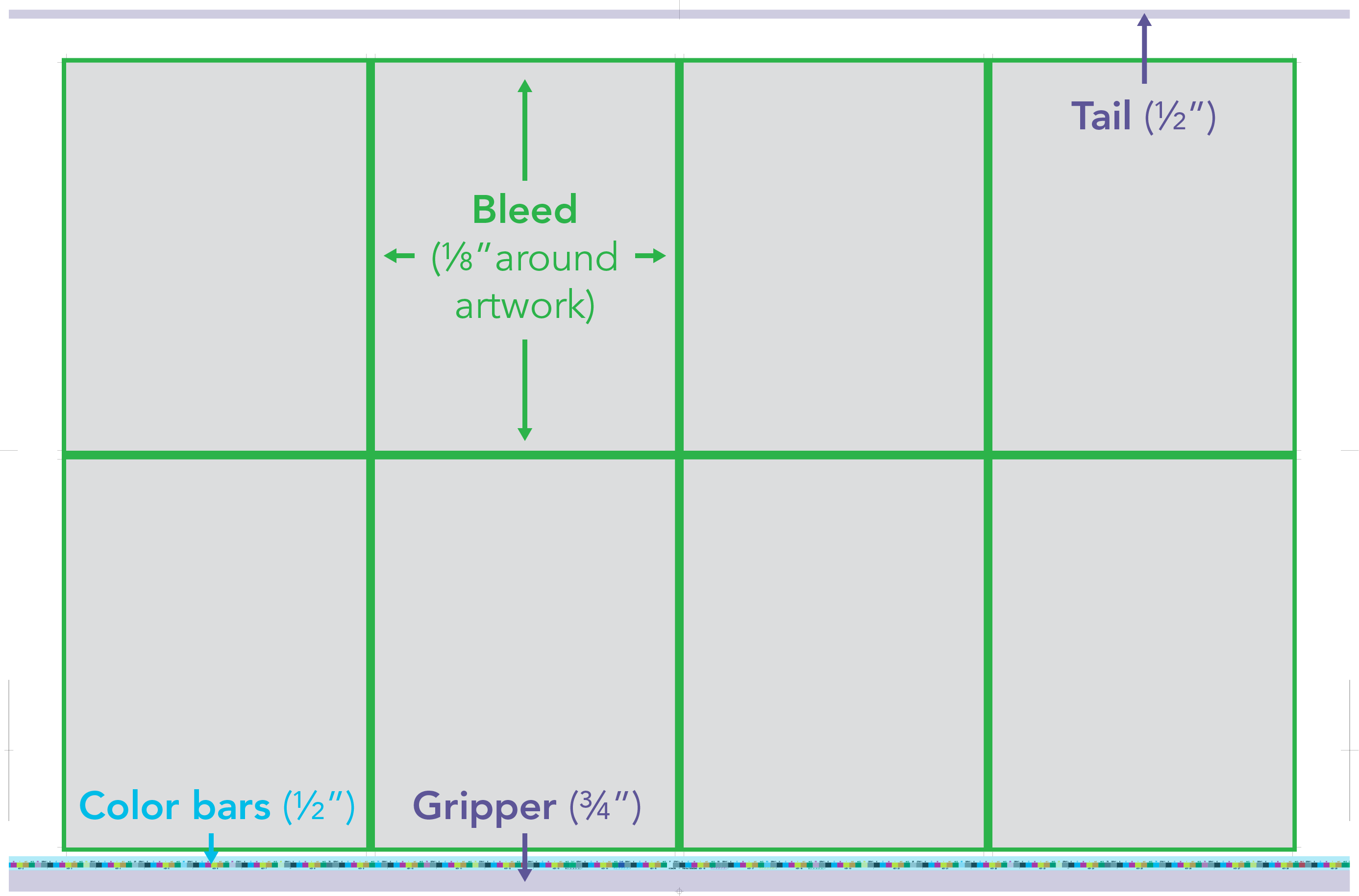

- Leave Space for Gripper and Tail: When designing for offset printing, it is important to leave space on the press sheet for the gripper and tail. The gripper is used to hold the sheet during printing, and the tail allows for proper registration. Leaving sufficient space for these elements ensures smooth and accurate printing.

- Consider Bleed and Color Bars: Incorporating bleed and color bars into your designs is essential for accurate printing. Bleed allows the design to extend beyond the final trim size, ensuring that there are no white edges. Color bars help in maintaining color consistency throughout the printing process.

- Stick to Standard Sizes: Using standard paper sizes can help reduce waste and cost. Standard sizes, such as A4 (210mm x 297mm) or letter-size (8.5″ x 11″), are readily available and cost-effective as they maximize paper usage and minimize trimming.

Understanding the Importance of Efficient Design

Efficient design practices play a significant role in offset printing. A well-designed print file not only enhances the appearance of the final output but also optimizes the printing process. Here’s why efficient design is crucial:

- Reduces Printing Costs: Efficient design reduces printing costs by minimizing material waste. By optimizing the layout and utilizing the press sheet effectively, you can reduce the number of sheets needed for a print run, thus cutting down on expenses.

- Improves Turnaround Time: Efficient design ensures that the print file is ready for the press without any unnecessary delays or complications. By following industry-standard design practices and providing print-ready files, you can help streamline the offset printing process and achieve faster turnaround times.

- Enhances Print Quality: Well-designed files result in better print quality. By properly setting up colors in CMYK format and ensuring that the design elements are aligned correctly, you can achieve accurate color reproduction and avoid any misregistrations or inconsistencies.

- Minimizes Errors: Efficient design reduces the chances of errors during the printing process. By adhering to design guidelines and best practices, you can avoid common issues such as image resolution problems, font compatibility issues, or incorrect file formats. This saves time and resources, allowing for a smoother printing experience.

Strategies for Maximizing Efficiency in Offset Printing Processes

To maximize efficiency in offset printing, it’s important to implement effective strategies throughout the printing process. Here are some strategies to consider:

- Plan Ahead: Proper planning is essential for efficient offset printing. This includes understanding the requirements of the print project, setting realistic timelines, and coordinating with the printer in advance. By planning ahead, you can ensure smooth workflow and timely delivery.

- Clean Mailing Lists for Direct Mail Efficiency: If your print project involves direct mail, it’s crucial to clean your mailing lists. Removing duplicate or incorrect addresses and ensuring accurate data improves efficiency by reducing the chances of undelivered mail and unnecessary printing costs.

- Stick to Standard Sizes: Standard paper sizes, such as A4 or letter-size, are readily available and cost-effective. By sticking to these sizes, you can reduce waste, streamline the printing process, and keep costs in check.

- Optimize Paper Stock Availability: For large quantity orders, it is wise to discuss paper stock availability with the printer beforehand. Ensuring the availability of the desired paper size and type eliminates delays and ensures a seamless printing process.

- Maximize Press Sheets for Cost Savings: By carefully optimizing press sheets, you can reduce paper waste and achieve cost savings. Efficiently arranging designs on the press sheet can significantly impact the number of prints produced, making the overall printing process more efficient.

In summary, maximizing efficiency in offset printing involves optimizing press sheets, utilizing efficient design practices, and implementing smart strategies throughout the printing process. By following these tips and strategies, you can minimize waste, reduce printing costs, and achieve high-quality prints in an efficient manner. Efficient offset printing benefits both the printer and the client, resulting in a successful and streamlined printing experience.

Table 1: Comparison of Standard Offset Paper Sizes

| Size | Dimensions (mm) | Dimensions (inches) |

|---|---|---|

| A4 | 210 x 297 | 8.27 x 11.69 |

| A5 | 148 x 210 | 5.83 x 8.27 |

| A6 | 105 x 148 | 4.13 x 5.83 |

| A3 | 297 x 420 | 11.69 x 16.54 |

| A2 | 420 x 594 | 16.54 x 23.39 |

| A1 | 594 x 841 | 23.39 x 33.11 |

| A0 | 841 x 1189 | 33.11 x 46.81 |

Table 2: Comparison of Common Paper Weights

| Weight (gsm) | Description |

|---|---|

| 70 | Lightweight, ideal for documents |

| 80 | Standard weight for various prints |

| 100 | Slightly heavier, suitable for brochures/cards |

Table 3: Comparison of Paper Coating Options

| Coating | Description |

|---|---|

| Gloss | Provides a shiny finish, enhances color vibrancy |

| Matte | Offers a non-reflective surface, suitable for sophisticated designs |

| Uncoated | Has a rough texture, natural feel, ideal for tactile experiences and writing |

These tables provide a visual comparison of standard offset paper sizes, common paper weights, and paper coating options to help readers better understand the different options available in the offset printing industry.

FAQs about Understanding Offset Paper Sizes

What are the standard offset paper sizes used in the printing industry?

A: To understand the standard offset paper sizes used in the printing industry, consider globally recognized sizes like A4, A5, and A6 for various purposes.

How do variations in paper sizes impact printing projects?

A: Evaluating how variations in paper sizes impact printing projects involves considering layout options, cost implications, visual impact, and the intended use of the materials.

Factors to consider when selecting the right paper size for offset printing

A: When selecting the right paper size for offset printing projects, consider factors like the audience, longevity, practicality, and branding strategy.

FAQs about Exploring Paper Weight and Coating Options

What are the common paper weights used in offset printing?

A: To understand common paper weights used in offset printing, consider weights such as 70gsm, 80gsm, and 100gsm, each with specific applications and characteristics.

How do different paper coatings affect the final print outcome?

A: Exploring how different paper coatings affect the final print outcome involves understanding the attributes of gloss, matte, and uncoated options and their impact on color, finish, and overall appearance.

In conclusion, we covered standard offset paper sizes and their impact on printing. Consider paper weight, coatings, and efficiency for successful offset printing projects. Remember, selecting the right paper size and finish is crucial for quality prints. Efficiency in design and press sheet optimization can reduce costs and waste significantly. Keep these tips in mind for successful offset printing projects.