Is Offset Paper GSM Essential for Printing Quality?

Offset Paper GSM

Section 1: Understanding Offset Paper GSM

In the world of printing, paper plays a crucial role in the quality and appearance of the final product. One important factor to consider when selecting paper for printing projects is the GSM, which stands for grams per square meter. GSM is a measurement used to determine the weight or thickness of a paper.

What is GSM and how is it related to offset paper?

GSM simply refers to the weight of a paper, specifically how many grams one square meter of the paper weighs. It is a standardized measurement used in the printing industry to ensure consistency and accuracy when comparing different paper types. Offset paper, on the other hand, is a type of paper commonly used for printing, particularly in commercial printing processes.

Offset paper is known for its smooth surface and excellent ink absorption. It is widely used for various types of printed materials, including flyers, brochures, catalogs, and magazines. The GSM of offset paper can range from as low as 60 GSM to as high as 120 GSM, depending on the specific printing requirements.

Why is GSM crucial for selecting paper for printing projects?

The GSM value of a paper is crucial in determining its weight and thickness, which directly impacts its suitability for different printing projects. The higher the GSM, the thicker and heavier the paper will be. Choosing the right GSM is vital to ensure that the paper can withstand the printing process, maintain its structural integrity, and achieve the desired outcome.

For instance, if you’re printing a brochure that needs to be sturdy and durable, opting for a higher GSM paper would be ideal. On the other hand, if you’re printing a flyer that needs to be lightweight and easily distributable, a lower GSM paper would be more suitable. Understanding the GSM helps you make informed decisions and ensures that the paper you choose is appropriate for the printing project at hand.

How does GSM impact the quality and characteristics of offset paper?

The GSM of offset paper directly affects its quality and characteristics. A higher GSM generally indicates a thicker and more durable paper. It can help enhance the overall look and feel of the printed material by providing a more substantial and professional appearance. The higher the GSM, the more resistant the paper will be to tearing, creasing, and other physical damages.

Furthermore, the GSM of offset paper also influences its ink absorption capacity. Papers with a higher GSM typically have a smoother and denser surface, which allows for better ink pigmentation and color vibrancy. This is especially crucial for printing projects where color accuracy and sharpness are essential, such as in marketing materials or product catalogs.

In summary, understanding the GSM of offset paper is key to selecting the right paper weight for your printing needs. The GSM determines the thickness, weight, durability, and ink absorption capacity of the paper, all of which directly impact the final quality and characteristics of the printed material. By considering the specific requirements of your printing project and choosing the appropriate GSM, you can ensure that your printed materials are of the highest quality.

Benefits and Uses of Different GSM Levels

In the world of offset printing, the GSM (grams per square meter) measurement of paper is crucial for achieving the desired results. Different GSM levels offer unique benefits and are suitable for various printing projects. Understanding the advantages of varying GSM levels can help you make informed decisions and choose the right paper for your specific needs. In this section, we will explore the benefits and common uses of different GSM weights in offset printing, as well as how GSM affects the final appearance and feel of printed materials. Let’s dive in!

Benefits of Varying GSM Levels in Offset Paper

- Durability and Strength: One of the primary benefits of higher GSM levels is the increased durability and strength of the paper. Heavier GSM papers are less likely to tear or get damaged, making them ideal for projects that require resilience and longevity.

- Enhanced Opacity: Higher GSM levels provide better opacity, meaning that the paper is less transparent. This is advantageous when printing on both sides of the paper, as it prevents show-through and ensures that the content remains legible.

- Luxurious Look and Feel: Thicker papers with higher GSM values have a more substantial and luxurious appearance. They give printed materials a sense of quality and professionalism, making them suitable for high-end projects like business cards, invitations, or marketing materials.

- Better Color Reproduction: The density and thickness of paper influence the way ink is absorbed and distributed across its surface. Higher GSM levels contribute to better color reproduction, allowing for vibrant and accurate printing results.

Common Uses for Different GSM Weights in Offset Printing

- 80-100 GSM: These lighter weight papers are commonly used for everyday printing needs, such as flyers, brochures, and newsletters. They offer a good balance between cost-effectiveness and quality, making them suitable for large quantity prints without compromising on appearance.

- 120-160 GSM: These medium weight papers are often used for business cards, postcards, and high-quality promotional materials. They provide a more substantial feel and enhanced durability while still being cost-effective for smaller print runs.

- 200+ GSM: These heavyweight papers are perfect for projects that require a luxurious and professional touch, like premium business cards, presentation folders, or product packaging. The heavier weight adds durability and gives a premium feel to the printed materials.

How GSM Affects the Final Appearance and Feel of Printed Materials

GSM plays a significant role in determining the final appearance and feel of printed materials. The weight of the paper influences aspects such as thickness, rigidity, texture, and even color vibrancy. Here are some specific ways in which GSM affects the end result:

- Thickness and Rigidity: Higher GSM levels result in thicker and more rigid paper, which gives printed materials a sense of substance and durability. On the other hand, lower GSM levels offer a lighter and more flexible feel.

- Texture and Finish: Both the GSM level and the type of coating or finish applied to the paper impact the texture and overall feel of the printed materials. For example, a higher GSM paper with a glossy finish will have a smooth and shiny surface, while a lower GSM paper with an uncoated finish will have a more natural and textured feel.

- Color Intensity: The thickness and density of the paper affect how ink is absorbed and reflected, influencing the color intensity of the printed materials. Heavier GSM papers tend to produce richer and more vibrant colors, while lighter GSM papers may result in a softer and more subtle color palette.

Choosing the Right GSM for Specific Printing Needs

Selecting the appropriate GSM for your specific printing needs requires careful consideration. Factors to keep in mind include:

- Printing Project: Consider the nature of your printing project, whether it’s a brochure, business card, or packaging. Different projects have varying requirements in terms of durability, flexibility, and overall presentation.

- Budget Considerations: Heavier GSM papers can be more expensive than lighter ones. Take into account your budget constraints and balance the desired quality with cost-effectiveness.

- Paper Usage: Consider how the printed materials will be used. For instance, if you’re printing materials that will be frequently handled or require extra durability, opting for a higher GSM paper might be desirable.

- Brand Image: Consider the image you want to portray with your printed materials and whether a heavier or lighter GSM paper aligns with your brand identity. A luxurious brand might benefit from using higher GSM papers, while an eco-friendly or minimalist brand might prefer lighter options.

In conclusion, understanding the benefits and uses of different GSM levels in offset paper is vital for achieving desired printing results. Whether you’re looking for durability, enhanced appearance, or better color reproduction, selecting the right GSM paper can make a significant difference. By considering your specific printing needs and the characteristics of different GSM weights, you can ensure that your printed materials leave a lasting impression.

Comparing Offset Paper GSM to Other Paper Weights

When it comes to selecting the right paper for your printing projects, understanding the differences between paper weights is crucial. One commonly used measurement for paper weight is GSM, which stands for grams per square meter. In the printing industry, GSM is used to indicate the thickness and weight of the paper. In this section, we will explore how offset paper GSM compares to other types of paper weights, the characteristics that set it apart, and the considerations to keep in mind when choosing offset paper GSM over other weights.

How does offset paper GSM compare to other types of paper weights?

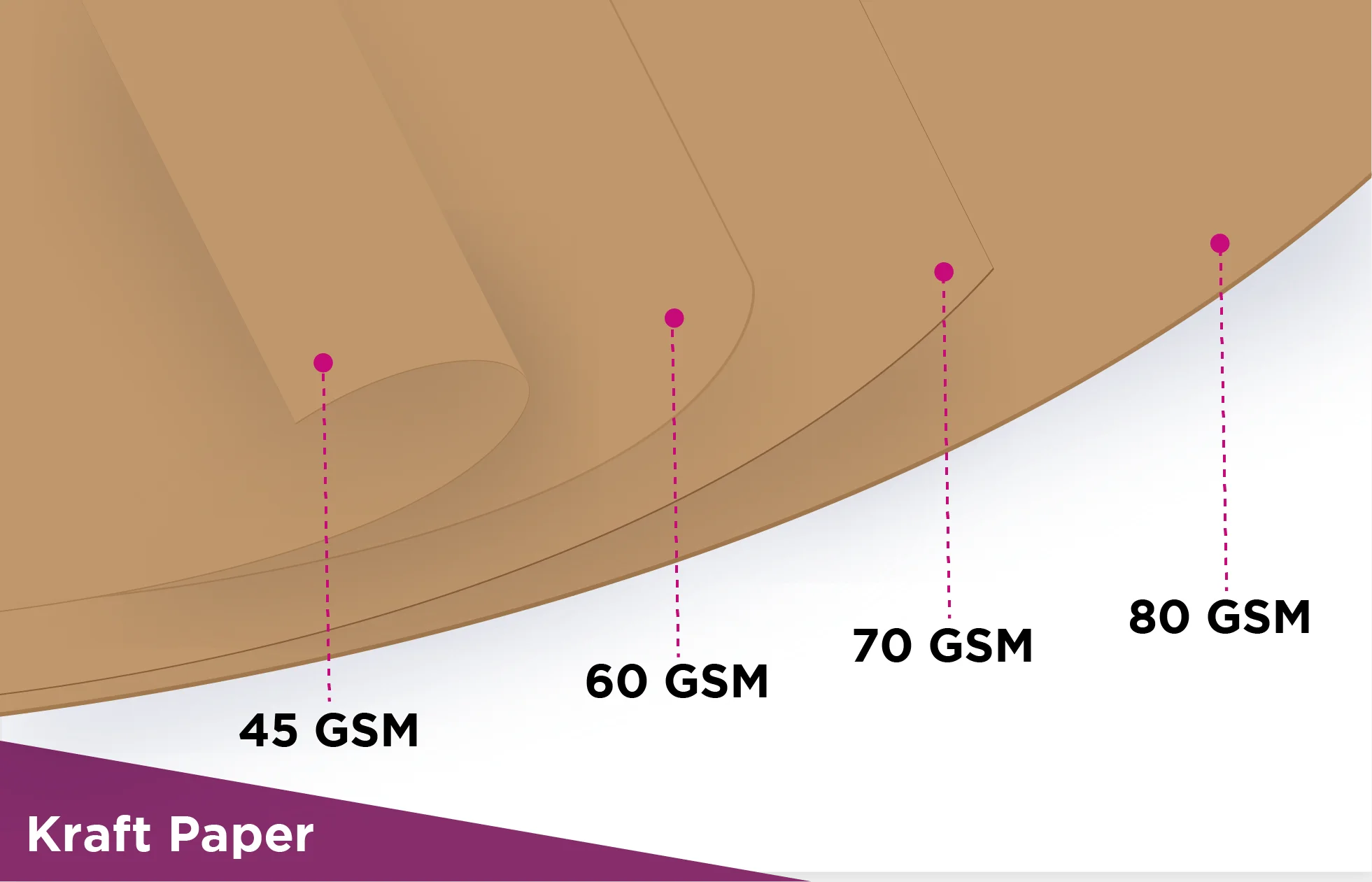

Offset paper GSM offers a versatile range of options for printing needs. It typically falls into the lightweight to mid-weight category, with a GSM range of 70 to 120. Compared to other types of paper weights, such as bond or cardstock, offset paper GSM offers a balance between thickness and flexibility.

When comparing offset paper GSM to lighter weights, such as 60 GSM or 80 GSM, offset paper provides a more substantial feel and improved durability. This is particularly advantageous for projects that require a higher quality finish, such as brochures, flyers, or business cards. On the other hand, offset paper GSM is lighter than heavier weights, like 150 GSM or 200 GSM cardstock, making it more suitable for projects that require a more flexible and foldable paper, such as booklets or leaflets.

Differences in characteristics between offset paper GSM and standard paper weights

One important consideration when comparing offset paper GSM to other paper weights is the thickness and quality it offers. Offset paper GSM is designed to provide excellent print quality while maintaining a reasonable weight and thickness. It offers a smooth surface that is ideal for printing sharp and vibrant images, text, and graphics. Additionally, offset paper GSM typically offers excellent ink absorption, ensuring that the printed material looks professional and has minimal ink bleed.

Another characteristic that sets offset paper GSM apart is its versatility. It can be easily folded, cut, and manipulated to fit various printing needs. Whether you need to create intricate designs, foldable brochures, or sturdy product packaging, offset paper GSM can deliver the desired results.

Furthermore, offset paper GSM is often preferred for its eco-friendly qualities. Many manufacturers produce offset paper using recycled materials or sustainable practices. This makes it an excellent choice for environmentally conscious individuals and businesses.

Considerations when choosing offset paper GSM over other paper weights

When selecting the right paper weight for your printing projects, there are a few considerations to keep in mind. Firstly, assess the desired finished product and determine the level of durability and flexibility required. If you are printing materials that need to withstand handling or folding, offset paper GSM offers the right balance between weight and malleability.

Secondly, evaluate the printing techniques and equipment that will be used. Offset printing, which is known for its high image quality and precision, works exceptionally well with offset paper GSM. It ensures that the ink is absorbed evenly and results in clean and crisp prints. However, if you are planning to use specialty printing techniques, such as letterpress or foil stamping, you may need to consider heavier paper weights for better results.

Lastly, consider your budget and the quantity of printing required. Depending on your specific needs and budget, offset paper GSM may offer a cost-effective solution while still delivering professional results. It is always recommended to request sample sheets before making bulk purchases to ensure that the quality meets your expectations.

In conclusion, offset paper GSM provides a versatile and reliable option for a wide range of printing projects. Its balance between weight, thickness, and flexibility makes it suitable for various applications. By understanding the differences between offset paper GSM and other paper weights, you can make informed decisions and select the right paper for your specific needs. So, whether you are printing brochures, flyers, or packaging materials, consider offset paper GSM as a reliable choice that offers both quality and functionality.

Tables

Benefits of Varying GSM Levels

| GSM Level | Benefits |

|---|---|

| 80-100 | Cost-effective, suitable for everyday printing needs |

| 120-160 | Enhanced durability, ideal for business cards |

| 200+ | Luxurious appearance, perfect for premium materials |

Comparison of Offset Paper GSM with Other Paper Weights

| Paper Weight | Characteristics |

|---|---|

| Offset Paper GSM | Offers a balance between thickness and flexibility |

| Bond Paper | Heavier and more rigid, suitable for specialty printing |

| Cardstock | Thicker and heavier, often used for premium materials |

| Kraft Paper | Eco-friendly option, ideal for sustainable printing |

FAQs about Offset Paper GSM

What is GSM and how is it related to offset paper?

A: GSM refers to the weight of a paper, measured in grams per square meter, and is crucial for determining the thickness and weight of offset paper used in printing projects.

Why is GSM crucial for selecting paper for printing projects?

A: GSM is essential for choosing the right paper weight to ensure durability, ink absorption, and structural integrity in printed materials, impacting the final outcome of the project.

How does GSM impact the quality and characteristics of offset paper?

A: The GSM of offset paper influences its thickness, durability, ink absorption, and overall appearance, with higher GSM resulting in a more professional look and feel.

What are the benefits and uses of different GSM levels in offset paper?

A: Different GSM levels offer varying benefits such as durability, opacity, luxurious appearance, and better color reproduction, catering to different printing needs and enhancing the final results.

In conclusion, understanding offset paper GSM is vital for successful printing projects. Varying GSM levels offer different benefits and appearances. Comparing offset paper GSM to other weights helps in selecting the right paper. Choose wisely for your needs and achieve optimal results in your printing endeavors.