Offset Paper Costs: How to Manage Expenses?

Offset Paper Costs

Section 1: Understanding Offset Paper Costs

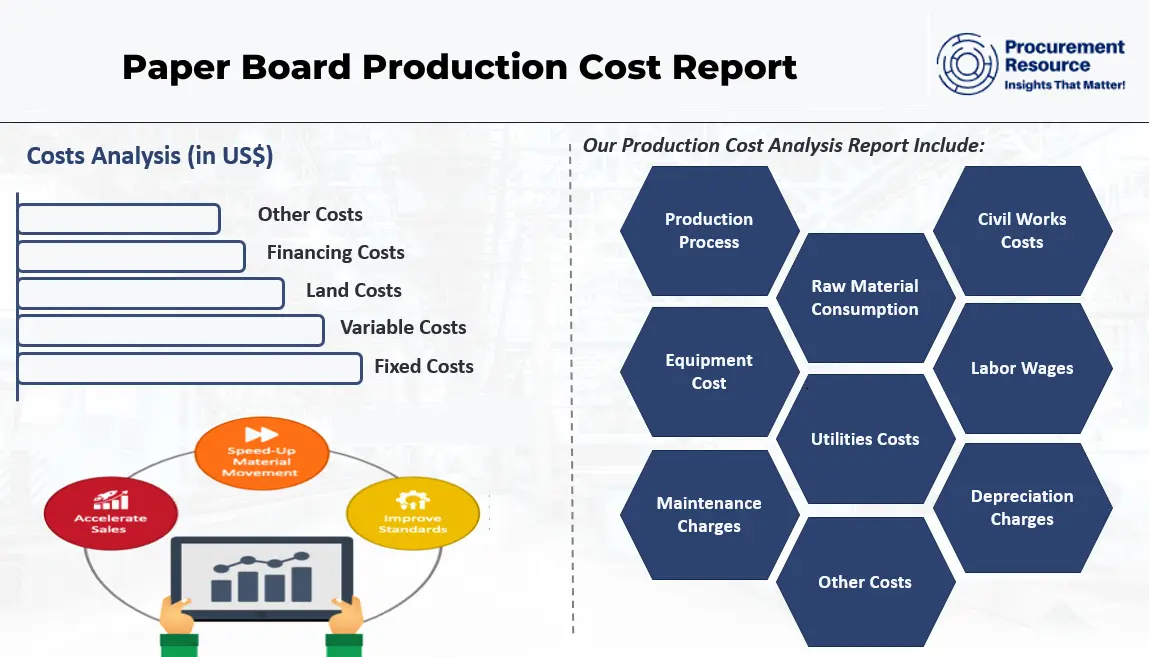

In the world of printing, offset paper production is a crucial process that involves various cost components. To fully comprehend how costs are incurred and managed in offset paper production, it is essential to understand the role of offset printing and how businesses can optimize cost management. In this section, we will explore these key aspects in detail.

What are the key cost components involved in offset paper production?

Offset paper production entails several cost components that contribute to the overall expenses. To give you a comprehensive understanding, let’s delve into each of these components:

- Materials: The type and quality of paper, ink, and finishes used in offset printing directly affect production costs. More embellishments and higher-quality materials tend to increase expenses. It’s essential to consider these factors while planning a print job to avoid unexpected budget surprises.

- Complexity: The complexity of the design, including single-color versus multi-color graphics, significantly impacts the cost. Intricate and detailed graphics require additional effort and resources, thereby increasing the overall production costs.

- Standard Costs: Design, prepress, plate creation, and press setup are fundamental processes that incur certain costs. These costs can range from hundreds to thousands of dollars, depending on the size and complexity of the print run.

- Extra Costs: Apart from standard costs, additional expenses may arise from opting for higher-quality materials or post-press services. It’s crucial to meticulously plan and budget for these extras to ensure cost efficiency.

How does offset printing contribute to overall production costs?

Offset printing, the primary method used in offset paper production, plays a significant role in determining the overall production costs. Understanding its influence is vital for cost optimization. Here are a few key points to consider:

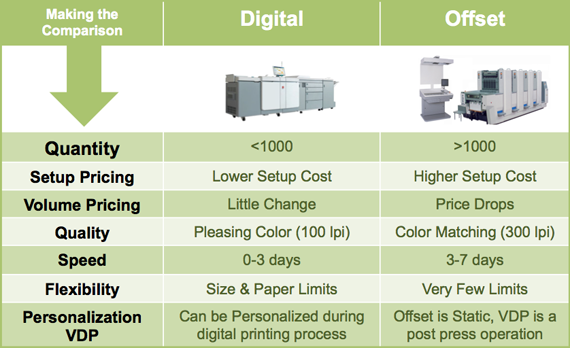

- Print Run Size: The size of the print run has a direct impact on the cost per unit. While offset printing may be expensive for small runs, the cost per unit significantly decreases as the quantity increases. It’s essential to evaluate the print requirements and choose the most cost-effective printing method accordingly.

- Maintenance Costs: Offset printing presses require regular setup and cleaning, which incurs additional expenses. It’s important to consider ongoing maintenance costs when assessing the overall production costs.

- Ink Costs: The cost of ink varies depending on the printing method. Offset ink is generally cheaper per unit, but setup costs can influence the overall expenses. Digital printing, on the other hand, offers quicker setup times, reducing production time.

How can businesses optimize cost management in offset paper production?

Optimizing cost management in offset paper production is crucial for businesses to remain competitive and profitable. Here are a few strategies to consider:

- Planning Ahead: By planning for bulk orders in advance, businesses can take advantage of economies of scale and negotiate better pricing with suppliers. Efficient planning also helps in mitigating rush job expenses.

- Design and Material Choices: Carefully consider design and material choices to optimize costs. Finding the right balance between quality and cost efficiency is essential. Consulting with a reliable printing partner can provide expert advice on cost-effective design and material options.

- Collaborating with Printing Partners: Building a partnership with a reliable printing partner is key to cost optimization. They can offer competitive pricing, expert advice, and insights into the latest trends and technological advancements in offset paper production.

In conclusion, understanding the key cost components involved in offset paper production, the role of offset printing in overall production costs, and implementing effective cost management strategies can help businesses achieve cost optimization and maximize profitability in their printing operations.

Keep Reading: Cost-Saving Strategies in Offset Paper Production

Section 2: Cost-Saving Strategies in Offset Paper Production

Effective Cost-Saving Strategies for Offset Paper Production

- Bulk Ordering: Planning ahead and placing bulk orders for paper and other materials can significantly lower costs. By ordering in larger quantities, businesses can take advantage of volume discounts and reduce per-unit expenses.

- Material Choices: Carefully selecting the type of paper, ink, and finishes can impact production costs. Opting for materials that strike a balance between quality and affordability can help keep expenses in check.

- Reliable Printing Partner: Finding a trusted printing partner who can offer expert advice and competitive pricing is essential. Collaborating with a reliable partner can help businesses identify the most cost-effective solutions for their specific needs.

- Offset Printing Optimization: Negotiating scale with offset printing can lead to a reduction in the cost per unit. As the quantity increases, the cost advantage of offset printing becomes more apparent compared to digital printing.

- Digital Printing for Shorter Runs: For shorter runs, digital printing is often the more cost-effective option. Its quick setup and lower maintenance costs make it a viable choice for smaller print quantities.

- Proper Project Assessment: Carefully evaluating the specific requirements of each project is crucial in choosing between offset and digital printing. Understanding the project’s complexity, desired results, and quantity needs will help determine the most cost-efficient method.

Role of Industry Benchmarks in Optimizing Production Efficiency

Table 1: Productivity Comparison

| Metric | Industry Benchmark | Company A | Company B |

|---|---|---|---|

| Job Setup Time | 20 minutes | 25 minutes | 18 minutes |

| Production Speed | 1000 units/hour | 900 units/hour | 1100 units/hour |

| Waste Reduction | 5% | 4% | 6% |

Table 2: Cost Comparison

| Cost Component | Industry Benchmark | Company A | Company B |

|---|---|---|---|

| Materials | $5000 | $5500 | $4800 |

| Design and Prepress | $2000 | $1800 | $2200 |

| Press Setup | $3000 | $2800 | $3200 |

In conclusion, by analyzing and comparing production metrics against industry benchmarks, businesses can identify areas for improvement and implement measures to increase efficiency. Additionally, implementing cost-saving strategies can help businesses optimize their offset paper production and reduce expenses without compromising quality.

Section 3: Impact of External Factors on Offset Paper Production Costs

The cost of offset paper production is greatly influenced by external factors such as market trends, supply chain issues, and other market influences. In this section, we will explore how these factors impact paper prices and production costs, the current trends in the paper market that affect offset paper production, and strategies businesses can adopt to mitigate rising costs.

How do external factors impact paper prices and production costs?

External factors such as the ongoing pandemic and supply chain issues have had a significant impact on paper prices and production costs. The pandemic has disrupted global supply chains, causing shortages in raw materials and increasing transportation costs. As a result, paper manufacturers have been faced with challenges in sourcing materials and delivering finished products, leading to increased production costs.

Additionally, the increase in demand for tissue products during the pandemic has led to a surge in wood pulp prices, a key component in paper production. Wood pulp prices have risen by 25% in 2021, averaging around $250 per ton. These increased costs are being passed on to papermakers, resulting in higher paper prices.

Furthermore, other market influences such as freight shortages, mill closures, and rising energy and fuel costs have also contributed to the increase in paper prices. Papermakers are passing on these increased costs to consumers, leading to price hikes in the printing industry.

Current trends in the paper market affecting offset paper production costs

Several current trends in the paper market are directly impacting offset paper production costs. Firstly, the increased demand for tissue products, especially in the wake of the pandemic, has created a strain on the paper market. This increased demand has led to higher prices for paper, affecting the overall cost of offset paper production.

Secondly, the closure of mills and supply chain disruptions have resulted in reduced availability of paper, particularly specialty papers used in offset printing. This limited supply has further driven up prices in the market.

Additionally, the shortage of freight and increased transportation costs have added to the overall cost of paper production. These factors have made it challenging for businesses to source paper and deliver printed materials efficiently.

Strategies for businesses to mitigate rising costs in offset paper production

Facing rising costs in offset paper production, businesses can implement strategies to adapt to market influences and mitigate these costs. Here are some recommendations:

- Diversify paper suppliers: Exploring alternative paper suppliers can help businesses secure a stable supply chain. Researching and building relationships with multiple suppliers can provide flexibility and potentially lead to better pricing.

- Optimize print runs: Analyzing print runs and optimizing them for cost-efficiency can help reduce production costs. Consolidating print jobs and printing in larger quantities can help lower the cost per unit.

- Consider digital printing: For shorter print runs or variable data printing needs, digital printing can be a more cost-effective alternative to offset printing. Digital printing allows for quicker setup and reduces production time, making it ideal for shorter runs.

- Negotiate contracts: Businesses can negotiate volume-based contracts with print suppliers to secure better pricing. Establishing long-term partnerships and providing a consistent volume of work can help drive down costs.

- Evaluate alternative production methods: Assessing the true cost breakdown of outsourcing offset printing versus in-house printing can help businesses make informed decisions. Sometimes, running a job in-house with minimal profit margins may be more profitable than outsourcing with significant markups.

- Explore outsourcing options: Considering outsourcing print and mail communications to specialized companies can help businesses reduce operational expenses. Outsourcing can provide fixed paper allocations, cost savings on equipment and energy, and access to expertise that can help manage rising costs.

By implementing these strategies, businesses can adapt to market influences and mitigate the impact of rising costs in offset paper production.

In conclusion, external factors such as the pandemic, supply chain issues, and market influences have significantly impacted paper prices and production costs in offset paper production. Understanding these factors, as well as current trends in the paper market, is crucial for businesses seeking to optimize cost management and mitigate rising costs. By staying informed, diversifying suppliers, optimizing print runs, considering digital printing, negotiating contracts, evaluating alternative production methods, and exploring outsourcing options, businesses can navigate the challenges posed by external factors and maintain cost-effective offset paper production.

FAQs about Offset Paper Production Costs

What are the key cost components involved in offset paper production?

A: Key cost components in offset paper production include materials, complexity of design, standard costs, and extra costs.

How does offset printing contribute to overall production costs?

A: Offset printing influences production costs through factors like print run size, maintenance costs, and ink costs.

How can businesses optimize cost management in offset paper production?

A: Businesses can optimize cost management by planning ahead, making informed design and material choices, and collaborating with printing partners.

How do external factors impact paper prices and production costs?

A: External factors like the pandemic, supply chain issues, and market influences impact paper prices and production costs significantly.

What are some cost-saving strategies for offset paper production?

A: Cost-saving strategies include bulk ordering, material choices, collaboration with reliable printing partners, offset printing optimization, and leveraging digital printing for shorter runs.

In conclusion, understanding offset paper costs is crucial. Offset printing affects overall expenses. Optimizing cost management ensures efficiency. Cost-saving strategies are essential for businesses. Industry benchmarks are vital for efficiency. Implementing strategies to reduce costs is key. External factors impact paper production costs. Adapting to market influences helps mitigate rising costs.