How are Paper Cup Production Manufactured?

Understanding the Basics of Paper Cup Production

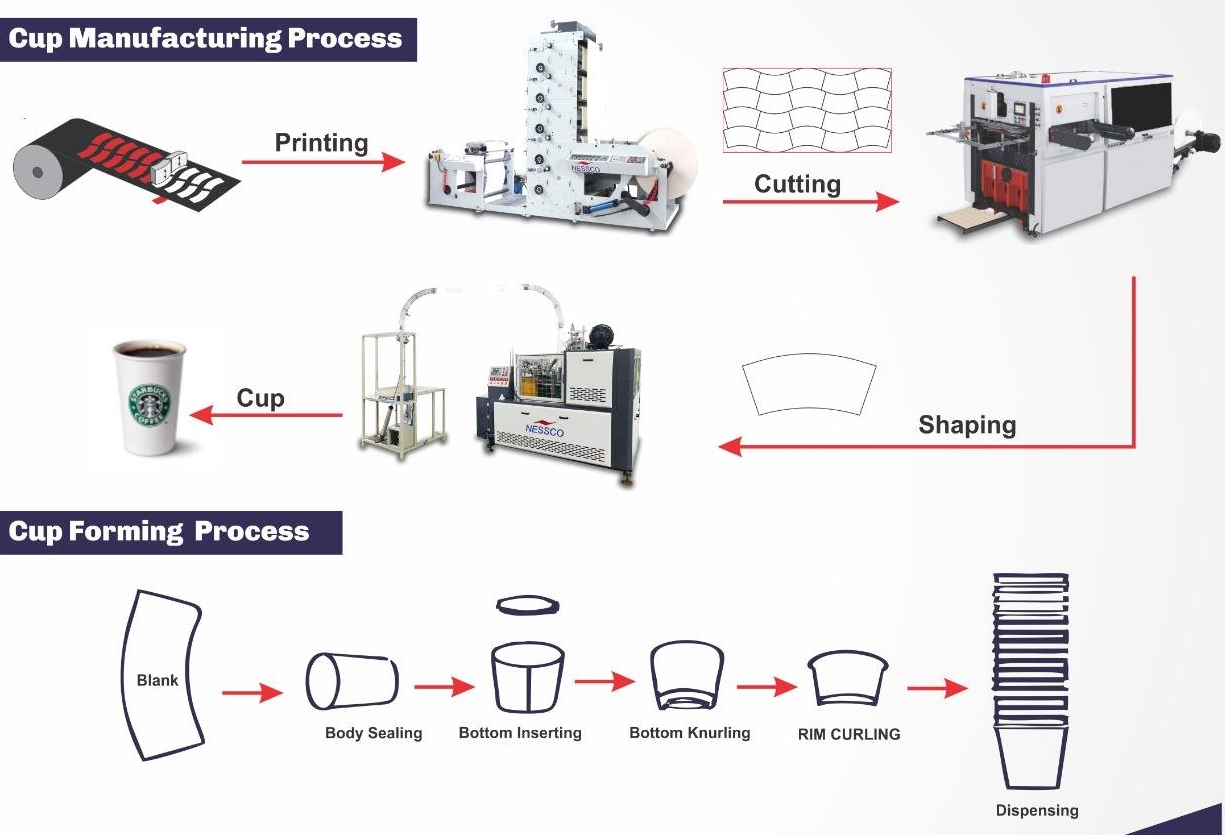

The manufacturing process of paper cups involves several steps that transform raw materials into the final product. In this section, we will explore the key elements of paper cup production, including the manufacturing process and the raw materials used.

How are paper cups manufactured?

The production of paper cups starts with the selection of high-quality and food-grade paperboard. This paperboard can be sourced from sustainably managed forests or made from recycled materials. Once the paperboard is obtained, it undergoes a series of cleaning, pulping, and bleaching processes to ensure its safety and quality.

After the raw material is prepared, cup blanks are created by cutting the paperboard into circles of the desired size. These cup blanks are then shaped into cups through a process of folding and sealing. In some cases, a polyethylene (PE) lining is applied to the interior surface of the cup to make it leak-proof. This PE coating ensures that the cup retains its structural integrity even when filled with hot liquids.

Finally, the cups can be customized with various designs and prints using techniques like flexographic or offset printing. This customization allows businesses to create branded and eye-catching cups that stand out in the market.

What raw materials are used in paper cup production?

The main raw material used in paper cup production is paperboard. Paperboard is a sturdy and food-grade material that provides the necessary strength and durability to the cups. It is typically sourced from sustainably managed forests, ensuring responsible and environmentally friendly production practices.

In addition to paperboard, other materials like polyethylene (PE) are used for the lining of the cup. This PE lining provides a barrier against liquids, making the cups leak-proof. The PE coating is applied to the cup’s interior surface during the manufacturing process.

It is important for manufacturers to ensure that the raw materials used in paper cup production meet the required quality standards and food safety regulations. This ensures that the cups are safe for use with food and beverages.

What are the key steps involved in the manufacturing process?

The manufacturing process of paper cups involves several key steps that ensure the production of high-quality and functional cups. These steps include:

- Raw material preparation: The raw material, typically paperboard, is cleaned, pulped, and bleached to ensure its safety and quality.

- Cup blank creation: The paperboard is cut into circles of the desired size to create the cup blanks. These blanks serve as the starting point for cup formation.

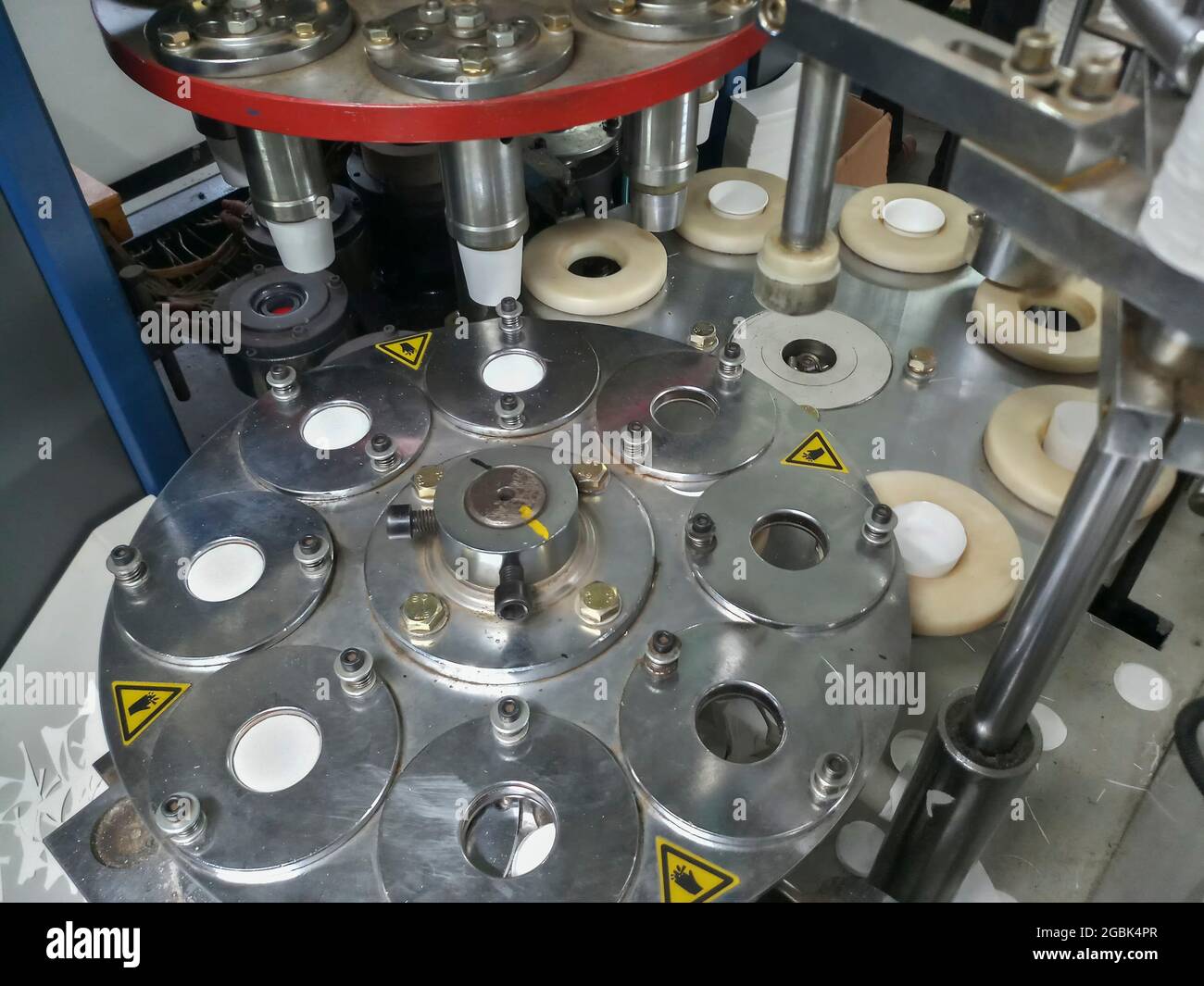

- Cup shaping: The cup blanks are shaped into cups through a process of folding and sealing. This gives the cups their final shape and structure.

- PE lining application: In some cases, a polyethylene (PE) lining is applied to the interior surface of the cup to make it leak-proof. This lining ensures that the cups can hold hot liquids without any leakage.

- Customization: The cups can be customized with various designs and prints using techniques like flexographic or offset printing. This allows businesses to create branded and visually appealing cups.

- Quality control: Before packaging the cups for shipping, manufacturers conduct rigorous quality control checks to ensure that the cups meet the required standards. These checks include tests for leakage with hot liquids and inspections to ensure proper printing and coating.

By following these key steps, paper cup manufacturers can produce high-quality cups that meet the needs and expectations of their customers.

Section 2: Machinery and Equipment Used in Paper Cup Production

[Continued from Section 1]

Now that we have covered the basics of paper cup production, let’s move on to the next section, where we will explore the machinery and equipment used in the process.

Table 1: Raw Materials Used in Paper Cup Production

| Raw Material | Description |

|---|---|

| Paperboard | Sturdy and food-grade material sourced from sustainably managed forests. Provides strength and durability to the cups. |

| Polyethylene (PE) | Material used for the lining of the cup to make it leak-proof. Provides a barrier against liquids. |

Table 2: Key Steps in Paper Cup Manufacturing Process

| Step | Description |

|---|---|

| Raw Material Preparation | The raw material, typically paperboard, is cleaned, pulped, and bleached to ensure its safety and quality. |

| Cup Blank Creation | The paperboard is cut into circles of the desired size to create the cup blanks. These blanks serve as the starting point for cup formation. |

| Cup Shaping | The cup blanks are shaped into cups through a process of folding and sealing. This gives the cups their final shape and structure. |

| PE Lining Application | In some cases, a polyethylene (PE) lining is applied to the interior surface of the cup to make it leak-proof. This lining ensures that the cups can hold hot liquids without any leakage. |

| Customization | The cups can be customized with various designs and prints using techniques like flexographic or offset printing. This allows businesses to create branded and visually appealing cups. |

| Quality Control | Before packaging the cups for shipping, manufacturers conduct rigorous quality control checks to ensure that the cups meet the required standards. These checks include tests for leakage with hot liquids and inspections to ensure proper printing and coating. |

By including these tables, we can visualize the raw materials used in paper cup production as well as the key steps involved in the manufacturing process. This provides a comprehensive understanding of the topic discussed in this article.

FAQs about Paper Cup Production

How are paper cups manufactured?

To manufacture paper cups, high-quality and food-grade paperboard is selected, cleaned, pulped, and bleached to ensure safety and quality. The paperboard is then cut into circles, shaped into cups through folding and sealing, and may have a polyethylene (PE) lining for leak-proofing.

What raw materials are used in paper cup production?

Paperboard is the main raw material used in paper cup production, sourced from sustainably managed forests. Additional materials like polyethylene (PE) are used for cup linings to provide a barrier against liquids and make the cups leak-proof.

What are the key steps involved in the manufacturing process?

The manufacturing process includes raw material preparation (cleaning, pulping, and bleaching), cup blank creation (cutting paperboard into circles), cup shaping (folding and sealing), PE lining application (for leak-proofing), customization through printing, and quality control checks before packaging.

How is customization done in paper cup production?

Customization of paper cups is achieved through techniques like flexographic or offset printing, allowing businesses to create branded and visually appealing designs on the cups.

Why is it important for manufacturers to meet quality standards in paper cup production?

Meeting quality standards ensures that the raw materials used are safe and of high quality, the cups are leak-proof and suitable for use with food and beverages, and that the manufacturing process follows responsible and environmentally friendly practices.

In this guide, I covered the basics, machinery, and innovations in paper cup production. Understanding the manufacturing process and the equipment used is vital. Trends like eco-friendly practices and technological innovations are shaping the industry. Embracing these changes can lead to more sustainable and efficient production. It’s crucial to stay updated with the latest advancements in paper cup manufacturing.