How to Optimize Print Adhesion on Aqueous Coated Paper?

How can you ensure optimal print adhesion on aqueous coated paper for bulk orders?

Print adhesion is a vital aspect of achieving high-quality, long-lasting prints on aqueous coated paper, especially when dealing with bulk orders. Aqueous coating provides a glossy or matte finish to the paper, enhancing its visual appeal and durability. However, the coating can pose challenges in terms of ink adhesion if not properly optimized. In this article, we will discuss various techniques and strategies to ensure optimal print adhesion on aqueous coated paper for bulk orders.

Importance of surface preparation: Understanding wetting and surface tension

Before diving into specific techniques, it is essential to understand the concept of wetting and surface tension. Wetting refers to the ability of a liquid, such as ink or coating, to spread and make contact with a solid surface. Surface tension plays a significant role in this process, influencing how well the liquid spreads and adheres to the coated paper.

Inks and coatings with high surface tension may exhibit poor wetting on aqueous coated paper, leading to weak adhesion and potential print defects. On the other hand, if the surface tension of the liquid is equal to or lower than the surface energy of the paper, optimal wetting and adhesion can be achieved.

To improve wetting and adhesion, it is crucial to elevate the surface energy of the coated paper through surface preparation techniques. This includes methods like corona treatment, flame treatment, or plasma treatment, which increase the surface energy of the paper by creating microscopically roughened surfaces. These techniques enhance ink or coating absorption, leading to better adhesion and print quality.

Selecting the right aqueous coating for specific paper types

Choosing the appropriate aqueous coating for your specific paper type is essential for achieving optimal print adhesion. Different paper types have varying characteristics and surface energies, which can affect the compatibility and adhesion of the coating.

It is crucial to work closely with your coating supplier or manufacturer to ensure compatibility between the paper and the coating. Consider factors such as the porosity, surface energy, and smoothness of the paper when selecting the coating. Conducting compatibility tests and obtaining samples of coated paper can help in assessing adhesion and print quality before committing to bulk orders.

Additionally, consider the desired finish (glossy or matte), the level of durability required, and any specific performance characteristics needed for your print project. Discussing these requirements with your coating supplier can help in selecting the most appropriate coating for optimal print adhesion.

Techniques to elevate surface energy for improved adhesion

In addition to selecting the right coating, there are several techniques you can employ to elevate the surface energy of aqueous coated paper, thereby improving print adhesion:

-

Corona Treatment: Corona treatment involves exposing the paper to a high-frequency electrical discharge. This process creates a temporary increase in surface energy by modifying the chemical bonds on the paper's surface. Corona treatment enhances ink or coating adhesion by improving wetting properties and increasing surface roughness.

-

Flame Treatment: Flame treatment is another surface modification technique that improves surface energy and promotes better adhesion. It involves exposing the paper to a controlled flame, which removes contaminants and chemically alters the surface. Flame treatment creates a more receptive surface for inks and coatings, leading to improved adhesion.

-

Plasma Treatment: Plasma treatment utilizes ionized gas to modify the surface of the coated paper. It effectively removes contaminants and increases surface energy through the formation of free radicals. Plasma treatment can be tailored to specific substrates and provides excellent cleaning and activation capabilities, resulting in enhanced adhesion.

Primer coatings: Functions and selection criteria

Primer coatings play a crucial role in promoting adhesion between aqueous coated paper and inks or coatings. These coatings act as a bridge between the substrate and the ink or coating, enhancing compatibility and improving adhesion.

The primary functions of primer coatings include:

- Surface Preparation: Primer coatings prepare the surface of the coated paper by enhancing its surface energy and roughness, ensuring better ink or coating adhesion.

- Barrier Protection: Primer coatings can provide a barrier between the aqueous coating and the ink, preventing migration and bleed issues.

- Improved Print Quality: By providing a smooth and consistent surface, primer coatings improve print quality by minimizing dot gain and enhancing color vibrancy.

When selecting a primer coating, consider the specific requirements of your print project and the characteristics of the aqueous coated paper. Factors to consider include compatibility with the chosen ink or coating, drying time, and the desired level of enhancement in print adhesion.

Consult with your coating supplier to determine the most suitable primer coating for your specific application. Conducting compatibility tests and analyzing the results can help ensure optimal adhesion and print quality in bulk orders.

Choosing the right inks: Importance of low surface tension solvents

Inks play a critical role in achieving optimal print adhesion on aqueous coated paper. Choosing the right inks with low surface tension solvents is essential for promoting wetting and adhesion on the coated surface.

Low surface tension solvents reduce the surface tension of the ink, enhancing its ability to spread and adhere to the coated paper. This promotes better wetting and improved adhesion, resulting in high-quality prints.

When selecting inks, consider the compatibility with the aqueous coating and the surface energy of the coated paper. Your ink supplier can provide guidance on the appropriate ink formulations for optimal adhesion. Conducting compatibility tests and print trials can help in assessing print quality and adhesion before proceeding with bulk orders.

Managing printing conditions: Temperature, humidity, and drying times

Print adhesion can also be influenced by various printing conditions, such as temperature, humidity, and drying times. It is important to maintain optimal conditions to ensure the best results in bulk order printing.

Temperature and humidity can affect the drying process of inks and coatings. High humidity levels can prolong drying times and lead to issues like ink smudging and poor adhesion. Controlling the printing environment and ensuring optimal temperature and humidity conditions can help mitigate these issues and improve adhesion.

Drying times are equally crucial, as insufficient drying can result in poor adhesion and ink transfer. Ensure that the printed materials have sufficient time to dry before any handling or further processing. Following the recommendations provided by your ink and coating suppliers regarding drying times can help in achieving optimal print adhesion.

Considerations for bulk order printing: Efficiency vs. quality

When dealing with bulk orders, striking a balance between efficiency and print quality is essential. While speed and cost-effectiveness are crucial in large-scale production, maintaining optimal print adhesion and quality cannot be compromised.

Ensure that your printing equipment is properly calibrated and maintained to achieve consistent results throughout the bulk printing process. Regular maintenance, including cleaning and replacing parts as necessary, can help avoid issues that may impact print adhesion.

Performing regular quality checks and conducting adhesion tests at different stages of production can help identify any issues early on and prevent potential problems with print adhesion. This will help you maintain the desired level of print quality while optimizing efficiency in bulk order printing.

Troubleshooting common adhesion issues

Despite taking all the necessary precautions, issues with print adhesion may still arise. Understanding and troubleshooting these common issues can help achieve optimal adhesion in your bulk order printing:

-

Poor Ink Adhesion: If the ink is not adhering properly to the aqueous coated paper, it could be due to inadequate wetting or mismatched surface energies. Review your surface preparation techniques, ink formulation, and coating compatibility to address this issue.

-

Print Defects: Print defects like smudging, bleeding, or poor color vibrancy can indicate adhesion issues. Evaluate the compatibility between the ink, primer coating, and aqueous coating to identify and rectify any potential compatibility issues.

-

Peeling or Flaking: In certain cases, prints may exhibit peeling or flaking, indicating poor adhesion between the ink and the paper. Review the surface preparation techniques, ink formulation, drying times, and coating compatibility to address this issue.

By understanding these common issues and taking appropriate corrective measures, you can troubleshoot adhesion issues in bulk order printing and achieve optimal print quality.

In conclusion, ensuring optimal print adhesion on aqueous coated paper for bulk orders requires attention to surface preparation, coating selection, primer coatings, ink compatibility, printing conditions, and troubleshooting common adhesion issues. By implementing the techniques and strategies discussed in this article, you can improve print adhesion, enhance print quality, and achieve success in bulk order printing on aqueous coated paper.

What equipment and materials adjustments are necessary for successful print adhesion on aqueous coated paper?

Achieving optimal print adhesion on aqueous coated paper for bulk orders requires careful consideration of equipment and materials adjustments. By making the necessary modifications, you can ensure consistent and reliable results. Let's explore the key adjustments you need to make for successful print adhesion.

Equipment upgrades and maintenance for consistent results

Investing in quality printing equipment and ensuring regular maintenance is essential for achieving consistent print adhesion. Outdated or poorly maintained equipment can result in subpar adhesion, leading to print defects and decreased print quality. Consider upgrading your printing equipment to modern models that offer advanced features designed to improve print adhesion. Additionally, follow the manufacturer's maintenance guidelines to keep your equipment in optimal condition.

Importance of corona and plasma treatments

Corona and plasma treatments are effective techniques for enhancing print adhesion. These surface treatment methods modify the surface energy of the substrate, increasing its wettability and improving ink adhesion. Corona treatment involves exposing the substrate to a high-voltage electrical discharge, while plasma treatment uses ionized gas to modify the substrate's surface. Both methods create a more receptive surface for the ink, leading to better adhesion and print quality.

Role of UV curing technology in adhesion

UV curing technology plays a crucial role in print adhesion on aqueous coated paper. UV curing involves using ultraviolet light to dry and cure the ink instantly. This quick curing process helps ensure proper adhesion between the ink and the coated paper. UV curing technology offers several advantages, including improved print quality, enhanced durability, and reduced drying times. Consider incorporating UV curing technology into your printing process to enhance print adhesion on aqueous coated paper.

Testing substrate wettability: Using dyne solutions effectively

Testing the wettability of the substrate is vital for optimizing print adhesion. Dyne solutions are commonly used to assess substrate wettability. These solutions have known surface tensions, and by applying them to the substrate and observing how they spread, you can determine the substrate's surface energy. A wetted surface indicates a lower dyne level solution than the substrate, indicating inadequate wetting and potential adhesion issues. By conducting regular dyne solution tests, you can ensure that the substrate's surface energy is suitable for proper print adhesion.

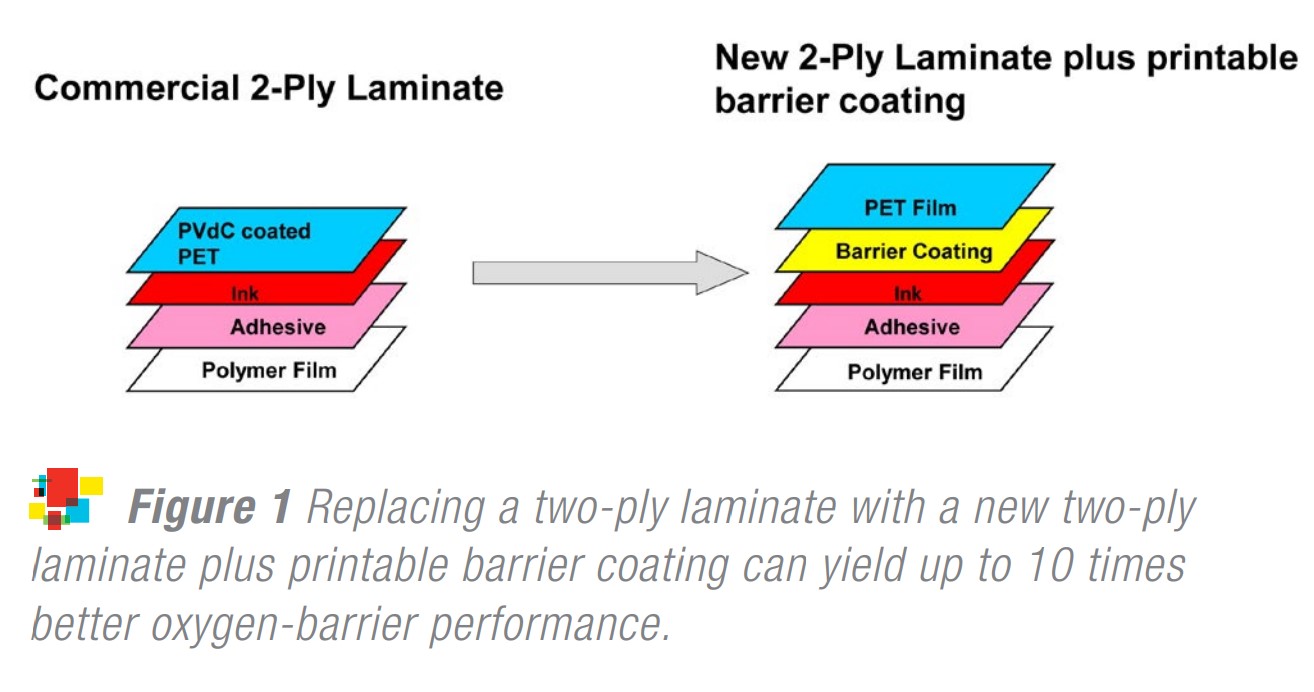

Raw material selection: Enhancing adhesion through material blends

The selection of raw materials significantly impacts print adhesion on aqueous coated paper. Certain material blends and modifications can enhance adhesion properties. For example, blending polyolefin with polyacrylic resins or PMMA (polymethyl methacrylate) improves ink adhesion up to seven times. By mixing raw materials with low-additive counterparts, you can reduce film oil formation, leading to improved ink adhesion. It's crucial to select raw materials that are compatible with aqueous coatings and optimize adhesion.

Surfactants and additives: Optimizing ink formulations

Surfactants and additives are essential components of ink formulations that can optimize print adhesion on aqueous coated paper. Surfactants reduce the surface tension of inks and coatings, improving their wetting properties and promoting adhesion to the substrate. Additionally, additives can be used to modify the ink's properties, such as its viscosity and drying time, to enhance adhesion. By carefully formulating your inks with the right surfactants and additives, you can improve print adhesion and overall print quality.

Ensuring ink compatibility with aqueous coatings

Compatibility between the ink and the aqueous coating is crucial for achieving optimal print adhesion. Not all inks are suitable for use with aqueous coatings, and using incompatible inks can result in poor adhesion and print quality. It's important to select ink formulations specifically designed for use with aqueous coatings. These inks are formulated to ensure proper adhesion and compatibility, resulting in excellent print adhesion on aqueous coated paper.

Post-printing processes: Scoring, cutting, and folding considerations

Post-printing processes can also impact print adhesion on aqueous coated paper. When scoring, cutting, or folding the printed materials, it's important to consider the impact on adhesion. Scoring the paper before folding can prevent cracking and ensure proper adhesion in the folded areas. Additionally, avoiding folding over areas with high ink densities or applying excessive pressure during cutting and folding can help maintain adhesion. Taking these considerations into account during post-printing processes can help preserve print quality and adhesion.

By making the necessary equipment and materials adjustments, you can optimize print adhesion on aqueous coated paper for bulk orders. Upgrading and maintaining your equipment, utilizing surface treatments, incorporating UV curing technology, testing substrate wettability, selecting appropriate raw materials and additives, ensuring ink compatibility, and considering post-printing processes all contribute to achieving successful print adhesion.

Tables:

FAQs about How to Optimize Print Adhesion on Aqueous Coated Paper for Bulk Orders

How can you ensure optimal print adhesion on aqueous coated paper?

To ensure optimal print adhesion on aqueous coated paper, it is essential to understand the concept of wetting and surface tension, as well as elevate the surface energy of the coated paper through treatments like corona, flame, or plasma.

What is the importance of selecting the right aqueous coating for specific paper types?

Selecting the right aqueous coating for specific paper types ensures compatibility and optimal adhesion by considering factors such as porosity, surface energy, and smoothness of the paper.

How do primer coatings enhance print adhesion?

Primer coatings enhance print adhesion by preparing the surface through increased surface energy and roughness, offering barrier protection, and improving print quality by minimizing dot gain and increasing color vibrancy.

Why is it essential to choose inks with low surface tension solvents?

Inks with low surface tension solvents are essential because they promote wetting and adhesion on the coated surface, ensuring high-quality prints by reducing surface tension and improving spreading ability.

What are the key printing conditions to manage for optimal print adhesion?

Managing temperature, humidity, and drying times during printing is crucial as these conditions influence drying processes and can affect adhesion, requiring control to prevent issues like ink smudging and poor adhesion.

Ensuring great print adhesion on aqueous coated paper is all about preparation. Start by preparing surfaces properly and picking the right coating for your paper. Use primers and choose inks with low surface tension. Control the printing environment, balancing efficiency with quality for bulk orders. Fine-tune your equipment and consider UV treatments for better results. With these strategies, you can improve print adhesion and handle large projects with confidence.