What Are the Uses of SBS High Bulk Paper?

Technical Specifications and Purchasing Guidance for SBS High Bulk Paper

SBS High Bulk Paper is available in a range of sizes and weights to suit various packaging needs. Common standard sizes include 7871092MM, 7001000MM, 600900MM, and 640900MM. These sizes offer flexibility and compatibility with different printing and packaging processes.

When it comes to weights, SBS High Bulk Paper typically ranges from 195 to 350 GSM (Grams per Square Meter). The weight of the paper determines its thickness and can vary depending on the specific application. It is important to consider the weight of the paper when selecting the right option for your packaging needs.

Caliper and GSM are two important technical specifications to consider when purchasing SBS High Bulk Paper. Caliper refers to the thickness of the paper, typically measured in inches. SBS High Bulk Paper has a range of calipers, usually between 0.024 to 0.028 inches. The caliper of the paper is closely related to its stiffness, durability, and overall quality.

GSM, on the other hand, stands for Grams per Square Meter. It is a metric unit that measures the weight of the paper, indicating its density. The GSM of SBS High Bulk Paper usually falls within the range of 195 to 350, with higher GSM indicating a denser and heavier paper.

Understanding these technical specifications will help you choose the right SBS High Bulk Paper for your specific packaging requirements.

How is SBS Paper Manufactured? Key Processes and Quality Control

SBS High Bulk Paper is typically made from 100% virgin bleached wood pulp. The manufacturing process involves several key steps to ensure the highest quality of the paperboard. These processes include:

- Pulping: Wood chips from sustainable forestry sources are chemically treated to pulp the wood fibers. The pulp is then typically bleached to achieve a bright, clean appearance.

- Papermaking: The pulp is mixed with water to create a slurry, which is then spread onto a wire mesh to form a continuous sheet of paper. This sheet is then pressed and dried to remove excess moisture.

- Coating: SBS High Bulk Paper is often coated on one or both sides to enhance its printability and surface smoothness. This coating is typically made of clay or other materials that provide a smooth, receptive surface for high-quality printing.

Quality control is an essential part of the manufacturing process for SBS High Bulk Paper. Stringent measures are taken to ensure consistent product quality, including monitoring the pulp quality, maintaining proper temperature and moisture levels during the production process, and conducting thorough inspections to detect any defects or imperfections.

Where to Purchase SBS High Bulk Paper: Top Suppliers and Distributors

When it comes to purchasing SBS High Bulk Paper, it is important to source from reliable suppliers and distributors. Here are some top suppliers and distributors that offer high-quality SBS paper:

- Providing a wide range of SBS paper options, [Supplier 1] is known for its excellent product quality and reliable service. They offer various sizes, weights, and customization options to cater to different customer needs.

- With a strong reputation in the industry, [Supplier 2] is a trusted supplier of SBS High Bulk Paper. They offer competitive pricing, quick delivery, and a wide selection of sizes and weights.

- Specializing in packaging materials, [Supplier 3] offers premium SBS High Bulk Paper. They have a dedicated customer service team and provide customized solutions to meet specific requirements.

It is important to consider factors such as pricing, delivery options, and customer support when selecting a supplier for SBS High Bulk Paper. Researching and comparing different suppliers can help you make an informed decision and ensure a smooth purchasing experience.

Custom Orders: Tailoring SBS Paper to Your Needs

In addition to standard sizes and weights, many suppliers and distributors offer custom order options for SBS High Bulk Paper. This allows you to tailor the paper to your specific requirements, whether it’s a unique size, weight, or coating.

Custom orders provide flexibility and enable you to create packaging solutions that align with your brand image and product specifications. By working closely with your supplier, you can discuss your needs and explore the possibilities for customization.

When placing a custom order, it is important to communicate your requirements clearly and provide any necessary artwork or design files. This will ensure that the supplier can meet your expectations and deliver the desired result.

Cost Considerations: Price Points and Ordering in Bulk

The price of SBS High Bulk Paper can vary depending on factors such as size, weight, coating, and customization options. It is important to consider your budget and the scalability of your packaging needs when evaluating the cost.

Ordering in bulk can often lead to cost savings, as suppliers may offer discounts for larger quantities. If your business has consistent packaging requirements, it may be beneficial to order in larger volumes to take advantage of these savings.

However, it is important to strike a balance between cost and inventory management. Ordering excessive quantities of SBS High Bulk Paper can result in storage challenges and potential waste if product demand fluctuates.

Market Trends: Future Demand and Innovations in SBS Paper

The market for SBS High Bulk Paper is dynamic and influenced by various factors. Understanding market trends and innovations can help you stay ahead of the curve and make informed decisions. Here are some key trends to consider:

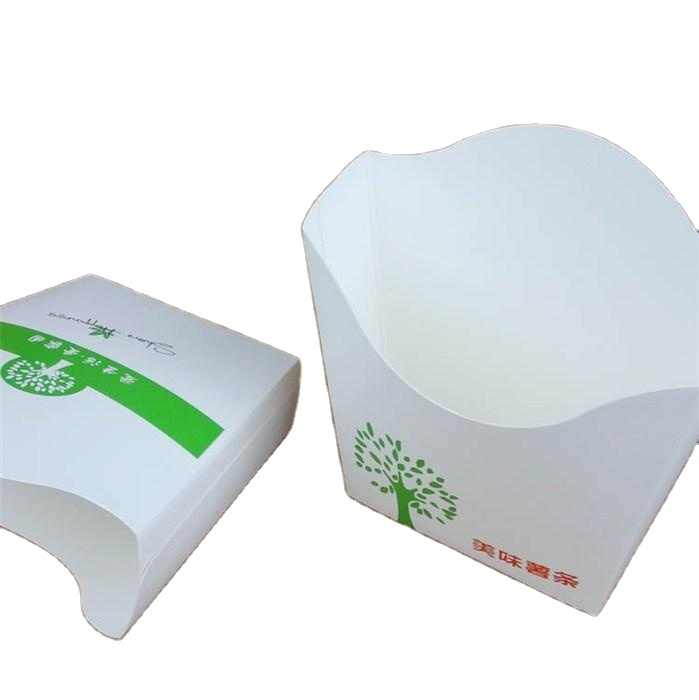

- Increased demand in e-commerce packaging: As online shopping continues to grow, the demand for quality packaging materials, including SBS High Bulk Paper, is on the rise. E-commerce businesses are looking for packaging solutions that offer durability, printability, and a positive unboxing experience.

- Growth in luxury goods packaging: SBS High Bulk Paper is favored for its premium appearance and print quality, making it a popular choice for luxury goods packaging. As the demand for luxury goods continues to grow, so does the demand for high-quality packaging materials.

- Environmental considerations: Sustainability is becoming increasingly important in the packaging industry. SBS High Bulk Paper is often certified by organizations such as the Forest Stewardship Council (FSC), indicating that it comes from responsibly managed forests. Choosing environmentally friendly packaging materials can help enhance your brand’s reputation and appeal to environmentally conscious consumers.

- Innovations in printing techniques: Advancements in printing technology are expanding the possibilities for SBS High Bulk Paper. From embossing and foil stamping to UV coatings and custom prints, these techniques allow you to create unique and visually appealing packaging designs.

By staying informed about market trends and innovations, you can make strategic decisions that align with your business goals and customer preferences.

In conclusion, SBS High Bulk Paper offers numerous advantages and possibilities for packaging applications. Understanding its technical specifications, purchasing guidance, and market trends will help you make informed decisions when selecting and sourcing this premium paperboard. Whether you’re packaging pharmaceuticals, cosmetics, or high-end consumer goods, SBS High Bulk Paper provides the durability, printability, and visual appeal required for exceptional packaging solutions.

FAQs about SBS High Bulk Paper:

What is SBS High Bulk Paper?

SBS High Bulk Paper, also known as Solid Bleached Sulfate Paperboard, is a premium paperboard made from 100% virgin bleached wood pulp, known for its bright appearance and exceptional printability.

How is SBS High Bulk Paper Different from Standard SBS Paper?

SBS High Bulk Paper differs from standard SBS (Solid Bleached Sulfate) Paperboard by offering superior thickness and rigidity, making it more suitable for applications requiring durability and structural integrity.

Why is Moisture Resistance Important in SBS Paper?

Moisture resistance in SBS High Bulk Paper ensures that the packaging and its contents remain intact and undamaged even in humid conditions, making it ideal for packaging food, pharmaceuticals, and cosmetics.

What are the Benefits of High-Quality Printability on SBS Paper?

The exceptional printability of SBS High Bulk Paper allows for vibrant colors, sharp images, and intricate designs, making it ideal for industries that prioritize visual appeal and branding.

Why Choose SBS High Bulk Paper for Food Packaging?

SBS High Bulk Paper is FDA and SGS approved for food contact, providing moisture and grease resistance to maintain the freshness and quality of packaged food items, especially for frozen and refrigerated products.

SBS High Bulk Paper offers excellent printability, durability, and eco-friendliness. It stands out for its bright surface and thick feel, making it ideal for packaging and premium designs. We discussed its uses, from food packaging to cosmetics, and its compliance with industry standards. Choosing this paper ensures strength and quality for various applications. As the market evolves, SBS High Bulk Paper remains a reliable, sustainable choice. Consider its many advantages when making your next packaging decision.