What Are Common PLA Coated Paper Applications?

What is PLA Coated Paper and How is It Made?

Definition and Composition

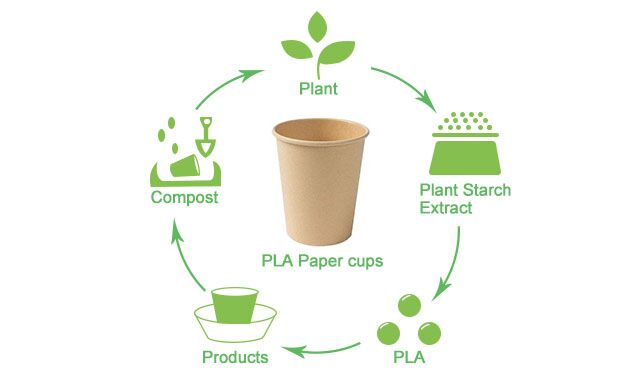

PLA coated paper, also known as polylactic acid coated paper, is a type of biodegradable paper coating that offers water resistance and environmental benefits. It is made by laminating a thin layer of PLA onto various types of base paper, such as kraft, white, or bamboo paper. PLA, or polylactic acid, is a polymer derived from renewable resources like corn starch or sugarcane.

The main advantage of PLA coated paper is its eco-friendliness. It is made from plant-based renewable resources, reducing reliance on non-renewable petroleum-based coatings. PLA is non-toxic and suitable for food contact, meeting bio-standards and FDA regulations for food safety.

Manufacturing Process

The production of PLA coated paper involves several technical steps. First, the base paper is selected based on the specific application requirements. Kraft paper, white paper, and bamboo paper are commonly used as base papers.

Next, the PLA coating is applied to the base paper. The PLA is derived from renewable plant sources and is melted to form a thin film. This film is then laminated onto the base paper using specialized equipment. The lamination process ensures that the PLA coating adheres securely to the base paper, providing water resistance and durability.

Environmental Benefits

PLA coated paper is considered eco-friendly for several reasons. Firstly, it is made from renewable resources, reducing the dependence on fossil fuels and mitigating the environmental impact associated with petroleum-based coatings.

Additionally, PLA coated paper is 100% compostable. Under industrial composting conditions, PLA biodegrades within 6-12 months, converting into carbon dioxide and water. This reduces landfill waste and contributes to a more sustainable waste management system. It is important to note that PLA requires specific composting conditions to biodegrade, and it is not suitable for home composting.

Compared to traditional polyethylene (PE) coatings, PLA has a lower carbon footprint. PLA production requires less energy and emits fewer greenhouse gases, making it a more environmentally friendly option.

In summary, PLA coated paper is a biodegradable and compostable alternative to petroleum-based coatings. It is derived from renewable resources, provides water resistance, and offers environmental benefits through reduced landfill waste and lower carbon emissions.

What Are the Applications of PLA Coated Paper?

PLA coated paper, also known as polylactic acid coated paper, is a versatile material with a wide range of applications. Its unique properties make it suitable for various industries, particularly in the food sector. In this article, we will explore the common uses of PLA coated paper in the food industry, its non-food applications, and showcase some real-world examples of successful implementations.

Common Uses in the Food Industry

1. Paper Cups

PLA coated paper is widely used in the production of paper cups for hot and cold beverages. Its water resistance and durability make it an excellent choice for retaining the temperature of the drinks and preventing leakage.

2. Food Boxes and Containers

Food boxes and containers made from PLA coated paper provide insulation and retain the freshness of the food. They can withstand temperature variations, making them suitable for various types of food, including hot meals, salads, and desserts.

3. Bags and Wrappers

PLA coated paper bags and wrappers offer an eco-friendly alternative to traditional plastic bags and wrappers. They can be used for packaging a variety of food products such as sandwiches, pastries, fruits, and vegetables.

4. Labels and Tags

PLA coated paper is durable and water-resistant, making it ideal for labels and tags in the food industry. It can withstand different handling and storage conditions, ensuring that important information remains intact.

Advantages of PLA Coating for Take-Out and On-the-Go Foods

The use of PLA coated paper in the food industry offers several advantages:

- Biodegradability: PLA is derived from renewable resources, making it biodegradable and compostable. It reduces landfill waste and contributes to a more sustainable future.

- Safety: PLA coated paper is safe for food contact. It complies with bio-standards and FDA regulations, ensuring that it does not contain any harmful chemicals that could potentially contaminate food.

- Reduced Carbon Footprint: PLA has a lower carbon footprint compared to petroleum-based coatings, as it requires less energy and emits fewer greenhouse gases during production.

- Customizable and Aesthetic: PLA coated paper can be produced in various shapes and sizes, allowing for customized packaging solutions. It also has a smooth and glossy surface, enhancing the presentation of the products.

Non-Food Applications

While PLA coated paper is commonly used in the food industry, its applications are not limited to this sector. Here are some examples of non-food applications for PLA coated paper:

1. Labels and Tags

PLA coated paper labels and tags are not only suitable for food products but are also used in other industries such as cosmetics, health and beauty, and home goods. The water resistance and durability make them ideal for labeling various products.

2. Disposable Tableware

PLA coated paper can be used in the production of disposable tableware such as plates, bowls, and cutlery. These eco-friendly alternatives to plastic tableware are perfect for events, parties, and other occasions.

3. Medical Products

The moisture resistance and durability of PLA coated paper make it suitable for medical applications such as sterilization wraps, bandages, and packaging for medical devices. Its biodegradability is an added advantage in healthcare settings.

Case Studies and Real-World Examples

To further illustrate the applications of PLA coated paper, let’s take a look at some real-world examples:

Successful Implementation in Food Packaging

One successful implementation of PLA coated paper in food packaging is the collaboration between a leading fast-food chain and a sustainable packaging supplier. The fast-food chain replaced their traditional plastic-lined packaging with PLA coated paper, reducing their plastic waste significantly. The switch not only aligned with their sustainability goals but also resonated with their environmentally-conscious customers.

Innovative Non-food Applications

Besides food packaging, PLA coated paper has been used innovatively in other applications. One example is the use of PLA coated paper for seedling pots in the horticulture industry. The pots are biodegradable and can be directly planted into the soil, eliminating the need for plastic pots and reducing waste.

Testimonials from Manufacturers and Consumers

Manufacturers and consumers alike have praised the use of PLA coated paper for its eco-friendly nature and superior performance. Manufacturers appreciate the sustainability aspect and the positive brand image associated with using environmentally-friendly materials. Consumers value the convenience and peace of mind that comes with knowing they are using a product that is both safe and sustainable.

In conclusion, the applications of PLA coated paper are vast and diverse. Its eco-friendly nature, coupled with its durability and water resistance, make it a preferred choice for food packaging, as well as in other industries. The examples highlighted in this article demonstrate the successful implementation and growing popularity of PLA coated paper in various real-world scenarios. As more businesses and consumers prioritize sustainability, the demand for PLA coated paper is expected to continue to grow.

Sources:

[1] Ecoflexibles

[2] NatureWorks

How Does PLA Coated Paper Compare to Traditional Coatings?

PLA (polylactic acid) coated paper is a sustainable and environmentally friendly alternative to traditional coatings like polyethylene (PE). In this section, we will explore the key differences and advantages of PLA coated paper compared to traditional coatings.

Biodegradability and Environmental Impact

PLA coated paper stands out for its biodegradability and reduced environmental impact. Unlike traditional petroleum-based coatings that take centuries to decompose, PLA coated paper biodegrades within 6-12 months under industrial composting conditions. This means that it can convert into carbon dioxide and water, leaving behind no harmful residues in the environment.

How fast does PLA coated paper decompose?

PLA coated paper decomposes at a faster rate compared to traditional coatings. In industrial composting facilities, where temperature, humidity, and microbial activity are controlled, PLA coated paper can completely biodegrade within 6-12 months. It is important to note that home composting conditions may not provide the optimal environment for PLA to decompose rapidly.

Industrial vs. home composting: What you need to know

To ensure the proper decomposition of PLA coated paper, it is recommended to dispose of it in industrial composting facilities. These facilities provide the necessary conditions, such as high temperatures and microbial activity, that accelerate the degradation process. Home composting may not reach the required temperatures for efficient PLA decomposition, so it is best to avoid composting PLA coated paper at home.

PLA’s role in reducing plastic waste and pollution

PLA coated paper plays a significant role in reducing plastic waste and pollution. By replacing traditional coatings with PLA, which is derived from renewable resources like corn starch or sugarcane, we can reduce our reliance on non-renewable resources. Additionally, PLA coated paper helps lower the carbon footprint as it requires less energy and emits fewer greenhouse gases during production compared to petroleum-based coatings.

Safety and Regulatory Compliance

PLA coated paper meets various bio-standards and complies with regulations set by the FDA and the EU for food contact materials. These certifications ensure the safety of PLA coated paper for both consumers and the environment.

What bio-standards does PLA coated paper meet?

PLA coated paper meets bio-standards such as EN13432 and ASTM D6400. These standards ensure that the materials used in PLA coating meet specific criteria for biodegradability and compostability. PLA coated paper’s compliance with these bio-standards guarantees its eco-friendly properties and its ability to break down into harmless byproducts.

FDA and EU regulations on PLA coated paper for food contact

PLA coated paper complies with the regulatory requirements of both the FDA in the United States and the EU for food contact materials. This means that PLA coated paper is deemed safe for direct contact with food without any harmful effects. The FDA and EU regulations ensure that PLA coated paper undergoes rigorous testing to ensure it does not introduce any contaminants or toxins into food products.

Consumer and environmental safety of PLA

The safety of PLA coated paper extends to both consumers and the environment. As PLA is derived from natural, renewable resources, it does not contain any harmful chemicals or toxins. This makes PLA coated paper a safe option for food packaging and other applications where direct contact with humans and the environment is involved.

Performance and Cost Considerations

PLA coated paper offers excellent performance in terms of water resistance, strength, and durability. It compares favorably to traditional PE coatings in these aspects. Additionally, the cost implications and market readiness for PLA coated paper are important factors to consider.

Water resistance, strength, and durability of PLA coated paper

PLA coated paper provides a high level of water resistance, ensuring that it can effectively protect food products from moisture and liquid absorption. It also offers sufficient strength and durability to withstand handling and various environmental conditions. The PLA coating creates a protective barrier that maintains the integrity of the paper and prevents it from becoming weak or easily damaged.

Comparison of PLA and conventional PE coating thickness and performance

When comparing PLA coated paper to conventional PE coated paper, PLA coatings are typically thicker, around 30gsm, compared to PE coatings which range from 15-20gsm. The thicker coating of PLA contributes to its enhanced water resistance and durability.

Cost implications and market readiness for PLA coated paper

As with any new technology, the cost of PLA coated paper may currently be higher compared to traditional coatings. However, as the market for PLA coated paper continues to grow, economies of scale and advancements in production techniques are expected to reduce costs. Additionally, the demand for sustainable and eco-friendly alternatives is increasing, driving the market readiness for PLA coated paper.

In Summary

PLA coated paper offers several advantages compared to traditional coatings. Its biodegradability and reduced environmental impact make it a sustainable choice. It meets the necessary safety and regulatory requirements for food contact materials, ensuring consumer and environmental safety. PLA coated paper also performs well in terms of water resistance, strength, and durability. While PLA coated paper may currently have higher costs than traditional coatings, the market is evolving to meet the growing demand, making it a promising option for various applications.

FAQs about PLA Coated Paper Applications

What is PLA coated paper made from?

PLA coated paper, also known as polylactic acid coated paper, is made by laminating a thin layer of PLA onto various types of base paper.

What are the environmental benefits of PLA coated paper?

The environmental benefits of PLA coated paper include being made from renewable resources and being 100% compostable under industrial conditions.

How is PLA coated paper used in the food industry?

PLA coated paper is used in the food industry for producing items like paper cups, food boxes, containers, bags, and wrappers due to its water resistance and durability.

Can PLA coated paper be composted at home?

PLA coated paper requires industrial composting conditions to biodegrade effectively and is not suitable for home composting.

How does PLA coated paper compare to traditional coatings?

PLA coated paper biodegrades within 6-12 months under industrial composting conditions, reducing plastic waste and pollution compared to traditional petroleum-based coatings like polyethylene (PE).

PLA coated paper is an eco-friendly alternative to traditional coatings. We’ve explored its definition, composition, and manufacturing process, showing its benefits for the environment. PLA coated paper stands out for its use in food packaging and various non-food applications. Also, its biodegradability and safety compliance make it a strong competitor against petroleum-based coatings. In summary, PLA coated paper offers a sustainable, reliable solution for multiple industries, reducing plastic waste and meeting global safety standards. Consider this innovative option for your packaging and beyond.