Are Linerless Labels Eco-Friendly Solutions?

Understanding Linerless Labels

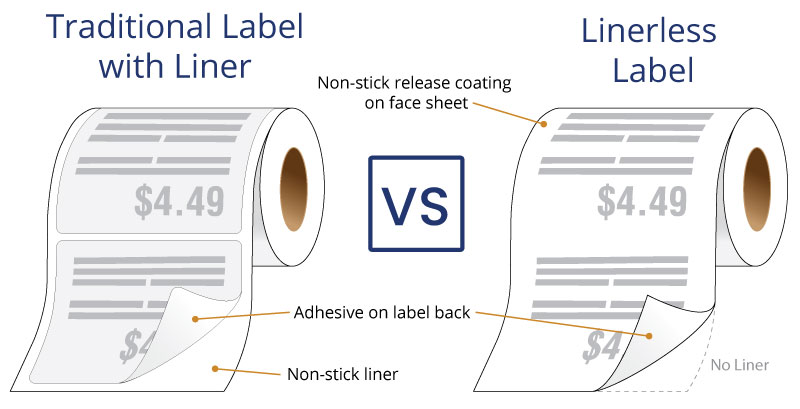

Linerless labels have revolutionized the labeling industry, offering a more sustainable and space-efficient alternative to traditional adhesive labels. Unlike traditional labels, which require a liner backing for support, linerless labels adhere to themselves, eliminating the need for a liner altogether. In this section, we will explore what linerless labels are, how they differ from traditional labels, and their customization options for different applications.

What are linerless labels and how do they differ from traditional labels?

Linerless labels are self-adhesive labels that do not require a separate liner for support. They are designed to stick to surfaces without the need for an additional backing, making them more environmentally friendly and cost-effective.

Traditional labels, on the other hand, consist of three layers: the facestock, the adhesive, and the liner. The liner acts as a support for the label during printing and application. However, once the label is applied, the liner is discarded, leading to unnecessary waste.

Linerless labels offer several advantages over traditional labels. Firstly, they are more sustainable as they eliminate the need for a liner, reducing waste generation. By switching to linerless labels, businesses can save on waste disposal costs and minimize their environmental impact.

Secondly, linerless labels are more space-efficient. Since they do not require a liner, more labels can be accommodated on a roll. This reduces the frequency of roll changes, resulting in increased productivity and decreased downtime.

How do linerless labels adhere to surfaces without a liner?

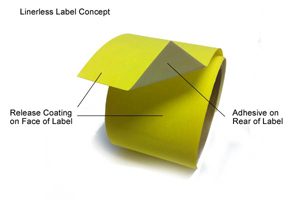

Linerless labels utilize a unique adhesive system that allows them to adhere to surfaces without the aid of a liner. These labels are coated with a release coating that protects against UV, moisture, and chemicals, ensuring their durability.

The adhesive used in linerless labels is designed to stick to itself upon application. This self-bonding characteristic enables the label to securely adhere to surfaces without the need for a separate liner. The adhesive remains strong, providing a reliable bond even in challenging environments.

Can linerless labels be customized for different applications?

Yes, linerless labels can be customized to meet the specific requirements of different applications. Flexible label sizing allows for printing detailed shipping labels and smaller barcode labels from the same roll, providing businesses with versatility and flexibility.

Customization options for linerless labels include variable lengths, widths, and materials. This enables businesses to create labels that cater to their unique labeling needs. By tailoring the labels to fit their specific requirements, businesses can achieve optimal efficiency and cost-effectiveness.

In summary, linerless labels offer a sustainable, cost-efficient, and adaptable solution for businesses. By eliminating the need for a liner and optimizing label usage, linerless labels contribute to waste reduction, lower production costs, and increased productivity. These labels are an excellent choice for businesses looking to enhance their labeling processes while minimizing their environmental impact.

Benefits and Applications of Linerless Labels

Sustainability: Reducing Waste and Environmental Impact

Linerless labels offer several environmental benefits compared to traditional adhesive labels. By eliminating the need for a liner backing, these labels significantly reduce waste generation. Traditional labels with liner backings contribute to the accumulation of non-recyclable waste in landfills. In contrast, linerless labels adhere to themselves, resulting in zero liner waste.

Additionally, linerless labels are more space-efficient. Without the liner, more labels can fit on a single roll, increasing the label capacity by up to 100%. This efficiency saves storage space and reduces the frequency of roll changes, resulting in less wasted material.

Not only do linerless labels reduce waste, but they also contribute to the overall sustainability goals of companies. By choosing linerless labels, businesses demonstrate their commitment to environmental stewardship and reducing their carbon footprint. These labels are often made from eco-friendly materials and are recyclable, further minimizing the impact on the environment.

Cost Efficiency: Savings in Production and Shipping

In addition to their environmental benefits, linerless labels also offer cost-saving advantages for businesses. The removal of the liner backing enables companies to optimize their production and shipping processes, resulting in significant cost savings.

| Cost Savings Areas | Benefits |

|---|---|

| Production Cost Savings | Reduced frequency of roll replacements, minimizing downtime and decreasing labor and material costs |

| Shipping Cost Reduction | Lighter label weight results in up to 50% savings in shipping expenses |

| Space Optimization | Less storage space required, improving warehouse efficiency and reducing storage costs |

Versatile Applications: Industries Benefiting from Linerless Labels

Linerless labels have versatile applications and can benefit a wide range of industries. Some of the sectors that can reap the most rewards from implementing linerless labels include:

- Food Packaging: Linerless labels are particularly suitable for food packaging as they offer excellent adhesion to different surfaces, including rough cardboard. These labels can withstand cold temperatures, moisture, and contact with food products, making them ideal for the food industry’s stringent requirements.

- Retail: Retail businesses can enhance their operations by using linerless labels for pricing, product information, and barcode labels. The customization options and durability of linerless labels make them an efficient solution for the retail industry.

- Logistics and Shipping: Linerless labels are indispensable in the logistics and shipping industry. These labels provide detailed shipping information, clear barcode scanning, and improved traceability. The durability and ease of application make linerless labels a reliable solution for efficiently managing shipping operations.

- Pharmaceuticals: Linerless labels are well-suited for pharmaceutical applications, ensuring accurate product labeling and tracking. They meet regulatory requirements and enhance product safety through tamper-evident features.

- Manufacturing: Manufacturing businesses can benefit from the cost savings associated with linerless labels. By streamlining production processes and reducing downtime due to roll changes, companies can optimize their manufacturing operations and achieve higher productivity.

Remember to follow SEO best practices while creating your content. Use the keyword “linerless labels” and its variations naturally throughout the section, paying attention to the H1, H2, and H3 headings. Incorporate related keywords and semantic keywords to enhance the article’s relevance and readability.

In the next section, we will delve into the process of implementing linerless labels in your business, discussing the necessary equipment and showcasing real-life industry case studies. Stay tuned!

Implementing Linerless Labels in Your Business

Linerless labels are gaining popularity in various industries due to their sustainability benefits, cost-efficiency, and waste reduction advantages. If you’re considering implementing linerless labels in your business, it’s important to understand the equipment needed, explore industry case studies, and learn how to make a seamless transition from traditional labels. In this section, we will dive into these topics to provide you with a comprehensive guide.

What equipment is needed to print and apply linerless labels?

To effectively print and apply linerless labels, you will need specific equipment tailored for this purpose. Here are the key pieces of equipment required:

- Linerless Label Printer: Investing in a linerless label printer is essential. These printers have special mechanisms that can handle linerless labels without the need for a separate liner. They also ensure precise label printing and application.

- Dispenser or Applicator: A dispenser or applicator is used to apply the linerless labels onto products or packaging. This equipment ensures accurate and efficient label placement, saving time and effort.

- Cutter/Trimmer: Depending on your specific needs, you may require a cutter or trimmer to customize the size and shape of linerless labels. This allows you to tailor the labels for different applications or products.

- Label Design Software: Utilizing label design software will enable you to create customized designs and layouts for your linerless labels. This software should be compatible with your linerless label printer to ensure seamless integration.

By investing in the right equipment, you can streamline your linerless label printing and application processes, optimizing efficiency and productivity.

Are there any industry case studies showcasing successful implementation of linerless labels?

Several industries have successfully implemented linerless labels, reaping the benefits they offer. Let’s explore a few industry case studies to understand how linerless labels have made a positive impact:

- Food Packaging Industry: A prominent food packaging company switched from traditional labels to linerless labels, resulting in significant cost savings. By eliminating the liner, they were able to fit more labels on a roll, reducing label roll replacements by half. This not only reduced production downtime but also decreased storage space requirements.

- Logistics and Shipping Industry: A shipping company implemented linerless labels in their operations, leading to substantial cost reductions in shipping. The lighter weight of linerless labels decreased shipping costs by 50%, and the increased label quantity per roll resulted in fewer roll changes, further improving operational efficiency.

- Retail Industry: A major retail chain embraced linerless labels for their product packaging. The linerless labels allowed them to create customized printing, including detailed shipping labels and smaller barcode labels, all from the same roll. This flexibility streamlined their labeling process and improved inventory management.

These case studies highlight the versatility and benefits of linerless labels across various industries. By studying successful implementations, you can gain insights into how linerless labels can positively impact your own business.

How can businesses switch from traditional labels to linerless labels seamlessly?

Making the switch from traditional labels to linerless labels may seem daunting, but with the right approach, it can be a seamless transition. Here are some steps to help you implement linerless labels effectively:

- Assess your Labeling Needs: Evaluate your current labeling requirements and identify areas where linerless labels can offer advantages. Determine the label sizes, shapes, and quantities needed for your products or packaging.

- Choose the Right Equipment: Select the appropriate linerless label printer, dispenser or applicator, and any additional equipment based on your labeling needs. Ensure compatibility between the label design software and the printer to ensure smooth operations.

- Train your Staff: Provide comprehensive training to your staff on how to operate the linerless label equipment, including printer maintenance, label loading, and troubleshooting. Familiarize them with best practices and safety protocols to maximize efficiency and minimize errors.

- Pilot Test and Evaluate: Before fully transitioning to linerless labels, conduct a pilot test. Use a small batch of products or packaging to evaluate the performance and compatibility of the linerless labels. Assess their durability, adhesion quality, and any other specific requirements for your business.

- Communicate with Suppliers and Partners: Inform your suppliers, partners, and other stakeholders about the switch to linerless labels. Ensure they are aware of any changes in label specifications, sizes, or application processes to maintain smooth collaboration.

- Monitor and Optimize: Once you have fully transitioned to linerless labels, closely monitor their performance and continuously optimize your labeling processes. Regularly assess the benefits and identify areas for improvement to ensure long-term success.

By following these steps, your business can seamlessly switch from traditional labels to linerless labels, unlocking the numerous benefits they offer.

Implementing linerless labels in your business requires careful consideration of the equipment needed, learning from successful industry case studies, and a well-executed transition plan. By embracing linerless labels, you can enhance sustainability efforts, reduce costs, and improve overall labeling efficiency. Take the first step towards a more efficient and sustainable labeling solution by implementing linerless labels in your business.

Examples of Industries Benefiting from Linerless Labels

| Industry | Benefits |

|---|---|

| Food Packaging | Excellent adhesion, withstands cold temperatures and moisture, ideal for food industry requirements |

| Retail | Pricing, product information, and barcode labels, customization options for inventory management |

| Logistics and Shipping | Detailed shipping information, clear barcode scanning, improved traceability |

| Pharmaceuticals | Accurate product labeling and tracking, regulatory compliance, tamper-evident features |

| Manufacturing | Cost savings from streamlining production processes, optimized manufacturing operations |

FAQ about Linerless lables

Q: What are linerless labels and how do they differ from traditional labels?

A: Linerless labels are self-adhesive labels that eliminate the need for a separate liner for support, making them more sustainable and cost-effective.

Q: How do linerless labels adhere to surfaces without a liner?

A: Linerless labels use a unique adhesive system that allows them to self-bond and securely adhere to surfaces without the aid of a liner.

Q: Can linerless labels be customized for different applications?

A: Yes, linerless labels can be tailored with variable lengths, widths, and materials to meet the specific requirements of different applications.

Q: What equipment is needed to print and apply linerless labels?

A: To print and apply linerless labels, you will need a linerless label printer, dispenser or applicator, cutter/trimmer, and label design software.

In conclusion, linerless labels offer eco-friendly benefits, cost savings, and versatile applications. Switching to linerless labels can streamline processes and reduce environmental impact. Businesses across various industries can find value in implementing linerless labels with the right equipment and strategies. Embracing this label innovation is a step towards sustainability and efficiency in packaging solutions.