Is Duplex Board Environmentally Friendly and Sustainable?

Duplex Board: Everything You Need to Know

Understanding Duplex Board Properties and Manufacturing Process

When it comes to packaging materials, duplex board is a popular choice due to its sturdy nature and versatility. In this section, we will delve into the properties of duplex board and understand its manufacturing process, giving you a comprehensive overview of this important material.

What are the key properties of duplex board?

Duplex board possesses several key properties that make it an ideal choice for various applications. One of its notable properties is that it is moisture resistant, ensuring that the contents of the packaging remain protected. Additionally, duplex board is anti-curl, meaning it retains its shape and does not become warped or bent easily. This rigidity and resistance to folding make it suitable for packaging delicate items that require extra protection. Moreover, duplex board has a smooth finish, giving it a professional and visually appealing appearance.

How is duplex board manufactured?

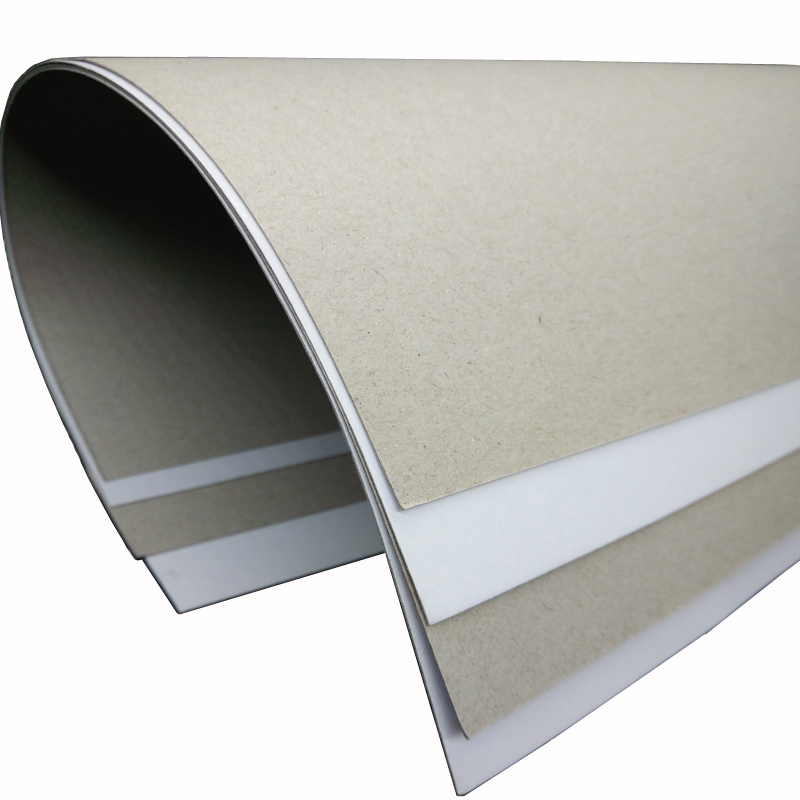

The manufacturing process of duplex board involves multiple steps to ensure its high quality and strength. It begins with pulping wood chips, which are then refined into fibers. These fibers are then formed into a sheet through machines, dried, shaped, and finally cut into the desired dimensions. The composition of duplex board typically consists of a top layer made from bleached chemical pulp and a bottom layer made from unbleached mechanical pulp. The two layers are then bonded together using an adhesive.

What materials are used in the composition of duplex board?

Duplex board is usually made from 100% wood pulp, with a bleached lining on one side, also known as the grey back or white back. This composition provides the necessary strength and durability to the material. The use of wood pulp ensures that the duplex board can withstand the rigors of packaging and transportation.

How is the moisture resistance of duplex board ensured?

To ensure the moisture resistance of duplex board, a coating is applied to the surface. This coating acts as a barrier, preventing water or any other liquid from seeping through and damaging the contents of the packaging. Additionally, the coating enhances the overall strength and rigidity of the duplex board, making it suitable for a wide range of applications.

What makes duplex board rigid and resistant to folding?

The rigidity and resistance to folding of duplex board can be attributed to its composition and manufacturing process. The bonding of the two layers, along with the application of the coating, provides the necessary strength and stability. This makes duplex board a reliable choice for packaging items that need to maintain their shape and structure during transportation and handling.

How is the coating applied to duplex board?

The coating is applied to duplex board through a process known as coating or calendering. During this process, the duplex board is passed through a series of rollers that evenly distribute the coating onto the surface. This ensures a uniform coating, which is crucial for the quality and appearance of the final product.

Why is uniform coating important in duplex board production?

Uniform coating is important in duplex board production for several reasons. Firstly, it ensures that the moisture resistance of the board is consistent throughout, preventing any weak spots or areas that may compromise the integrity of the packaging. Secondly, a uniform coating provides a smooth and even surface, allowing for high-quality printing and a visually appealing finish. Lastly, it contributes to the overall strength and rigidity of the duplex board, making it suitable for various packaging applications.

What gives duplex board a smooth finish?

The smooth finish of duplex board can be attributed to the coating applied during the manufacturing process. The coating evens out the surface of the board, providing a smooth and glossy appearance. This not only enhances the visual appeal of the packaging but also contributes to a professional and high-quality presentation.

In this section, we explored the properties of duplex board and gained insights into its manufacturing process. Understanding these aspects is crucial in determining the suitability of duplex board for different packaging needs. In the next section, we will explore the applications and uses of duplex board in various industries.

Applications and Uses of Duplex Board in Various Industries

Duplex board is a versatile packaging material that finds applications in a wide range of industries. Its unique properties, such as moisture resistance, rigidity, and resistance to folding, make it a preferred choice for various packaging needs. In this section, we will explore the different uses of duplex board in various industries.

How is duplex board commonly used in the packaging industry?

The packaging industry extensively utilizes duplex board for its excellent printability and structural integrity. Duplex board is commonly used for making folding cartons, corrugated boxes, labels, and promotional materials. Its smooth finish and uniform coating make it ideal for high-quality printing and vibrant designs. Duplex board’s ability to be die-cut, folded, and creased makes it a versatile option for packaging needs.

What are the specific applications of duplex board in the beverage industry?

In the beverage industry, duplex board is widely used for packaging disposable cups. Its sturdiness and coated surface make it suitable for holding hot and cold beverages. The moisture resistance properties of duplex board ensure that the cups do not get soggy or lose their shape. Additionally, the smooth finish of duplex board allows for attractive branding and labeling on the cups.

Why is duplex board preferred for corrugated boxes in shipping?

When it comes to shipping, corrugated boxes made from duplex board are a popular choice. The strength and rigidity of duplex board provide the necessary structural integrity to protect the contents during transportation. Moreover, the moisture resistance properties prevent the boxes from getting damaged in humid conditions. The ability to print directly on the surface of duplex board allows for easy identification and branding of the boxes.

How is duplex board utilized in the toy and game industry?

In the toy and game industry, duplex board is commonly used for packaging and display materials. Its strength and rigidity make it suitable for packaging toys and games that require structural integrity. Additionally, duplex board’s excellent printability allows for vibrant and eye-catching designs on packaging boxes and display materials, enhancing the overall appeal of the products.

What role does duplex board play in environmental packaging solutions?

Duplex board is an eco-friendly packaging solution that aligns with sustainability goals. It is made from recycled fibers and is recyclable, contributing to resource conservation and waste reduction. By choosing duplex board for packaging needs, companies can reduce their environmental impact and support a more sustainable future. The visually appealing presentation of products packaged with duplex board also enhances their market appeal.

Why is duplex board accredited for food and medication packaging?

Duplex board is accredited for food and medication packaging due to its safety and hygiene properties. It meets specific regulatory requirements for contact with food and pharmaceuticals, ensuring that the packaged products remain safe and uncontaminated. Moreover, duplex board’s moisture resistance properties protect the integrity of food and medication, preventing any spoilage or damage during storage and transportation.

What makes duplex board ideal for shipping delicate items?

Duplex board is an excellent choice for shipping delicate items, such as dishes or glassware, due to its increased load-bearing capabilities compared to traditional cardboard. Its strength-to-weight ratio allows it to provide better shock absorption and protection for fragile items. The lightweight nature of duplex board also helps in reducing shipping costs without compromising on the safety of the packaged items.

How does duplex board compare to traditional cardboard for shipping purposes?

While duplex board may not be as durable as corrugated cardboard, it provides a more secure barrier for shipping purposes. It is suitable for items shipped via FedEx or UPS, offering a reliable packaging solution. The thickness of duplex board varies based on the product being packaged, with options ranging from 5mm for stable items to 10mm for items needing extra protection. Overall, duplex board offers a balance of strength and functionality, making it an ideal choice for shipping needs.

In summary, duplex board finds extensive applications in various industries, including the packaging, beverage, toy and game, and food and medication industries. Its unique properties, such as moisture resistance and rigidity, make it a preferred choice for packaging needs. Moreover, its eco-friendly nature aligns with sustainability goals, making it a responsible choice for businesses. Whether it’s for packaging delicate items or ensuring the safety and hygiene of food and medication, duplex board provides a reliable and versatile solution.

Environmental Impact and Sustainability of Duplex Board

Duplex board, with its unique properties and composition, offers several environmental advantages, making it a sustainable choice for packaging materials. In this section, we will explore how the use of duplex board contributes to enhanced sustainability and supports resource conservation and waste reduction. We will also delve into the environmental advantages of duplex board and why it is considered an eco-friendly alternative to traditional packaging materials.

How does using duplex board contribute to enhanced sustainability?

Using duplex board in packaging materials contributes to enhanced sustainability in multiple ways. First and foremost, duplex board is made from 100% wood pulp, which is a renewable resource. The use of renewable materials in the production of duplex board ensures that the demand for trees is balanced with responsible reforestation practices, minimizing the impact on forests. This makes duplex board an environmentally responsible choice for businesses looking to reduce their carbon footprint.

Furthermore, duplex board is often manufactured using recycled fibers or waste paper for the bottom layer, known as the grey back or white back. By incorporating recycled materials into the production process, duplex board helps reduce the amount of waste that would otherwise end up in landfills. This not only conserves valuable resources but also reduces the overall environmental impact of the packaging industry.

What are the environmental advantages of duplex board?

Duplex board offers several environmental advantages that make it a preferred choice for sustainable packaging solutions. One of the key advantages is its recyclability. Duplex board can be easily recycled after use, allowing it to be reused in the production of new packaging materials. The recyclability of duplex board helps reduce the demand for virgin materials and minimizes the amount of waste generated.

Another environmental advantage of duplex board is its contribution to resource conservation. By using duplex board in packaging materials, businesses can reduce their reliance on non-renewable resources such as plastics. The use of duplex board as an alternative to traditional packaging materials helps conserve valuable resources and promotes a more sustainable approach to packaging.

Furthermore, duplex board has a lower carbon footprint compared to other packaging materials. Its manufacturing process requires less energy and generates fewer greenhouse gas emissions compared to alternatives such as plastic packaging. By choosing duplex board, businesses can actively reduce their environmental impact and contribute to a greener, more sustainable future.

How does duplex board support resource conservation and waste reduction?

Duplex board supports resource conservation and waste reduction through its composition and recyclability. As mentioned earlier, duplex board is made from renewable wood pulp, which ensures that resources are responsibly managed and replenished. This helps conserve valuable natural resources and promotes sustainable forestry practices.

Moreover, the use of recycled fibers or waste paper in the production of duplex board helps reduce the amount of waste that would otherwise end up in landfills. By incorporating recycled materials, duplex board minimizes the environmental impact of the packaging industry and promotes a circular economy. This approach reduces the need for extracting virgin resources and minimizes the overall carbon footprint of the packaging materials.

Additionally, duplex board’s recyclability plays a crucial role in waste reduction. After use, duplex board can be easily recycled and used in the production of new packaging materials. This recycling process helps divert waste from landfills and reduces the demand for virgin materials. By actively promoting the recycling of duplex board, businesses can contribute to waste reduction efforts and support a more sustainable approach to packaging.

Why is duplex board considered an eco-friendly alternative to traditional packaging materials?

Duplex board is considered an eco-friendly alternative to traditional packaging materials due to its unique properties and sustainability benefits. Unlike materials like plastic or Styrofoam, duplex board is made from renewable resources and is recyclable. This makes it a more environmentally responsible choice for businesses looking to reduce their environmental impact.

Furthermore, duplex board offers excellent printability, allowing businesses to customize and brand their packaging without compromising on sustainability. Its smooth finish and uniform coating make it visually appealing, providing a high-quality presentation for products. By choosing duplex board, businesses can align their sustainability goals with their packaging requirements, creating a visually appealing and eco-friendly packaging solution.

Duplex board’s strength, rigidity, and moisture resistance also make it a reliable alternative to traditional packaging materials. It can withstand the rigors of shipping and storage while providing a secure barrier for products. This durability ensures that the packaging remains intact throughout the supply chain, reducing the need for additional protective measures and promoting sustainability.

What makes duplex board a visually appealing and sustainable choice for packaging?

Duplex board’s visual appeal is a key factor that makes it a sustainable choice for packaging. Its smooth finish and uniform coating provide an excellent surface for printing, allowing businesses to create eye-catching designs and branding on their packaging. This visual appeal enhances the overall presentation of products and creates a positive customer experience.

Furthermore, duplex board’s sustainability features make it an attractive choice for businesses looking to align their packaging with their eco-friendly values. Its renewable composition and recyclability ensure that the packaging materials have a minimal environmental impact. This sustainable aspect resonates with conscious consumers who prioritize eco-friendly products and packaging.

Moreover, the use of duplex board supports the growing demand for sustainable and visually appealing packaging solutions. As more businesses recognize the importance of environmental responsibility, duplex board provides a versatile alternative that meets both sustainability and branding requirements. It offers an aesthetically pleasing packaging solution without compromising on its environmental impact.

How is duplex board’s recyclability beneficial for the global economy?

Duplex board’s recyclability has several benefits for the global economy. Firstly, the recycling of duplex board helps conserve valuable resources and reduces the demand for virgin materials. This reduction in resource extraction leads to cost savings and promotes sustainable practices within the packaging industry.

Additionally, the recycling process of duplex board creates employment opportunities in the recycling and manufacturing sectors. The collection, sorting, and processing of duplex board for recycling require a skilled workforce, contributing to job creation and economic growth. By actively promoting the recyclability of duplex board, businesses can support local economies and contribute to the global circular economy.

Moreover, the widespread adoption of duplex board recycling contributes to waste reduction efforts. It helps divert waste from landfills, minimizing the environmental impact of the packaging industry. This waste reduction not only benefits the environment but also reduces the costs associated with waste management and disposal. By promoting the recyclability of duplex board, businesses can actively contribute to a more sustainable and economically viable future.

In what ways can duplex board be used to align with sustainability goals?

Duplex board can be used in various ways to align with sustainability goals. One of the key areas where duplex board can make a significant impact is in the packaging industry. By choosing duplex board as a packaging material, businesses can reduce their reliance on non-renewable resources and promote a more sustainable approach to packaging.

Moreover, businesses can use duplex board to support their commitment to waste reduction. Duplex board’s recyclability ensures that the packaging materials have a second life after use, minimizing waste and promoting a circular economy. By actively promoting and practicing duplex board recycling, businesses can align with their waste reduction goals and contribute to a more sustainable future.

Furthermore, duplex board can be used in the development of eco-friendly packaging solutions. Its moisture resistance, strength, and rigidity make it suitable for various applications, including food and medication packaging. By incorporating duplex board into their packaging solutions, businesses can provide a visually appealing and sustainable alternative to traditional packaging materials.

Why is sustainable duplex board vital for various applications in today’s market?

Sustainable duplex board is vital for various applications in today’s market due to the increasing focus on environmental responsibility. Consumers are becoming more conscious of the environmental impact of their purchasing decisions, and businesses are striving to meet their expectations by adopting sustainable practices.

In the packaging industry, sustainable duplex board offers a reliable and visually appealing solution that aligns with the growing demand for eco-friendly packaging. It allows businesses to differentiate themselves in the market by providing packaging materials that are both environmentally responsible and visually appealing.

Moreover, sustainability has become a key consideration for businesses across industries. By choosing sustainable duplex board for applications such as printing, stationery, and display materials, businesses can demonstrate their commitment to environmental responsibility. This aligns with the growing trend of sustainability-driven decision-making and helps build trust and loyalty among customers.

In summary, duplex board offers several environmental advantages and contributes to enhanced sustainability. Its recyclability, resource conservation benefits, and visual appeal make it an eco-friendly alternative to traditional packaging materials. By using duplex board, businesses can align with their sustainability goals, support waste reduction and resource conservation efforts, and contribute to a greener and more sustainable future.

Duplex Board Properties

| Property | Description |

|---|---|

| Moisture Resistance | Duplex board is resistant to moisture, ensuring the protection of packaged contents. |

| Anti-Curl | Duplex board retains its shape and does not become warped or bent easily. |

| Smooth Finish | Duplex board has a smooth and visually appealing finish. |

| Strength and Rigidity | Duplex board provides strength and rigidity, making it suitable for packaging needs. |

Applications of Duplex Board

| Industry | Applications |

|---|---|

| Packaging | Folding cartons, corrugated boxes, labels, promotional materials |

| Beverage | Disposable cups |

| Shipping | Corrugated boxes for shipping purposes |

| Toy and Game | Packaging and display materials for toys and games |

| Environmental Packaging | Packaging solutions that are eco-friendly and made from recycled materials |

| Food and Medication Packaging | Packaging for food and medication, meeting safety and hygiene requirements |

| Shipping Delicate Items | Shipping fragile items such as glassware or dishes, providing increased load-bearing capabilities and protection |

Environmental Advantages of Duplex Board

| Environmental Advantage | Description |

|---|---|

| Recyclability | Duplex board can be easily recycled after use, reducing the demand for virgin materials and minimizing waste. |

| Resource Conservation | By using duplex board, businesses can reduce their reliance on non-renewable resources, promoting sustainable practices. |

| Lower Carbon Footprint | The manufacturing process of duplex board requires less energy and generates fewer greenhouse gas emissions compared to alternatives. |

FAQs about Duplex Board:

What are the key properties of duplex board?

To understand the key properties of duplex board, we look at its moisture resistance, anti-curl feature, and smooth finish, which ensure protection, shape retention, and a visually appealing appearance.

How is duplex board manufactured?

In the manufacturing process of duplex board, wood chips are pulped, refined into fibers, formed into a sheet, dried, shaped, and cut into desired dimensions, with a top layer from bleached chemical pulp and a bottom layer from unbleached mechanical pulp bonded together using an adhesive.

What materials are used in the composition of duplex board?

Duplex board is typically made from 100% wood pulp with a bleached lining on one side, providing the necessary strength and durability for various packaging needs.

How is the moisture resistance of duplex board ensured?

To ensure moisture resistance, duplex board undergoes a coating process that acts as a barrier against water seepage, enhancing overall strength and rigidity for diverse applications.

What makes duplex board ideal for shipping delicate items?

The strength, rigidity, and weight-bearing capabilities of duplex board make it an excellent choice for shipping delicate items, offering better shock absorption and protection compared to traditional cardboard options.

In conclusion, we’ve delved into the world of duplex board. Understanding its properties and manufacturing process is vital. Duplex board finds extensive use in many industries due to its versatility. Its environmental impact speaks volumes, promoting sustainability effortlessly throughout different sectors. This material is undoubtedly a game-changer in packaging solutions, offering reliability and eco-friendliness.