Can PLA Coated Paper Be Recycled Efficiently?

How Does PLA Coated Paper Recycling Work?

Introduction

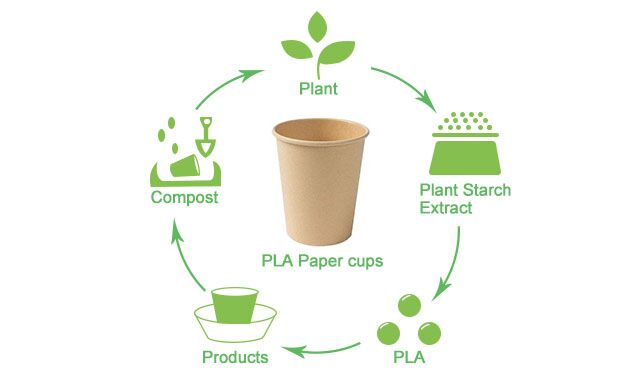

PLA (polylactic acid) coated paper is an eco-friendly alternative to traditional plastic-coated paper. PLA is a biodegradable and compostable polymer derived from renewable resources like corn starch. The PLA coating adds moisture resistance and durability to paper products such as cups, trays, and food packaging. While PLA coated paper offers several environmental benefits, including the reduction of landfill waste and lower greenhouse gas emissions, it requires proper recycling to maximize its sustainability potential.

What is PLA coated paper and how is it produced?

PLA coated paper is made by applying a thin layer of PLA to paper or board surfaces. The PLA coating enhances the strength, water resistance, and grease resistance of the paper, making it suitable for various packaging applications. The process of producing PLA involves fermenting starches into sugars, converting them into lactic acid, and polymerizing them into PLA pellets. These pellets can be derived from crops such as corn or sugarcane. The PLA coating is then applied to the paper or board using a suitable technique, such as extrusion coating or lamination.

How does the PLA coating affect the recyclability of paper?

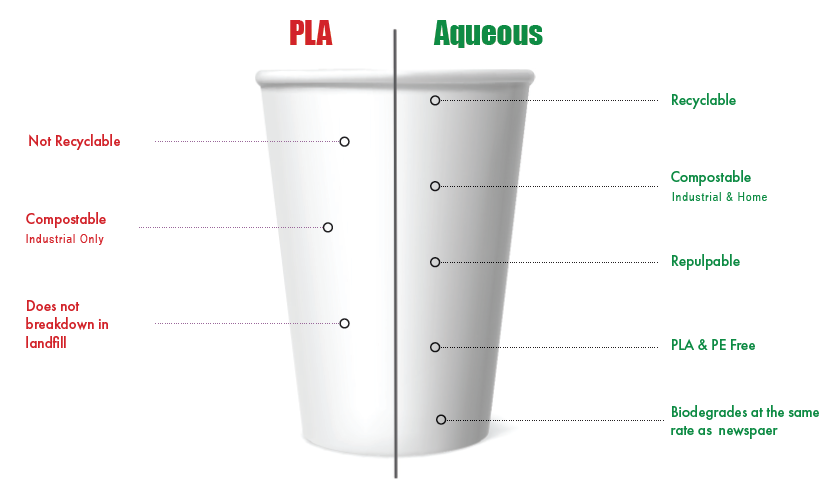

While PLA coated paper is biodegradable and compostable, its recyclability poses certain challenges. The PLA coating can contaminate recycling streams if not properly separated from other paper products during the recycling process. Most recycling facilities are not equipped to handle the separation and processing of PLA coated paper due to the specialized equipment and processes required. As a result, PLA coated paper is often diverted from recycling streams and sent to landfill or composting facilities.

What are the necessary steps to recycle PLA coated paper?

- Collection and Sorting: PLA coated paper products should be separated from regular paper products during collection to prevent contamination. Special recycling bins or separate collection systems may be implemented to ensure proper separation.

- Depolymerization: The PLA coating is depolymerized through a chemical or enzymatic process to break it down into its component monomers, namely lactic acid. This allows for easier separation from the paper fibers.

- Deinking: The paper is deinked using traditional methods or specific chemicals to remove ink and other coatings present on the paper.

- Fiber Recovery: The paper fibers are mechanically or chemically processed to separate them from the PLA coating and any remaining contaminants. The recovered paper fibers can then be used to produce new paper products.

Which recycling facilities accept PLA coated paper?

Not all recycling facilities accept PLA coated paper due to the specialized processes required for its recycling. However, there are specific facilities that can process PLA coated paper and separate the PLA coating from the paper fibers. These facilities are often equipped with the necessary equipment, such as depolymerization reactors and specialized sorting systems, to handle PLA coated paper recycling. It is important to check with local recycling facilities or waste management agencies to determine if they accept PLA coated paper.

What common issues arise during the recycling process of PLA coated paper?

The recycling process for PLA coated paper presents several challenges and considerations:

- Separation and sorting: Proper separation of PLA coated paper from regular paper products is crucial to prevent contamination. If not separated correctly, the PLA coating can contaminate the recycled paper fibers, affecting the quality of the final recycled product.

- Lack of infrastructure: The limited availability of recycling facilities that can process PLA coated paper poses challenges for its recycling. This can result in limited recycling options and increased reliance on landfill or composting facilities.

- Cost considerations: The specialized equipment and processes required for PLA coated paper recycling may increase the cost of the recycling process compared to traditional paper recycling. This can impact the feasibility and scalability of PLA coated paper recycling initiatives.

Detailed comparison between the recycling process of PLA coated paper and traditional paper

| Traditional Paper Recycling | PLA Coated Paper Recycling |

|---|---|

| Collection and Sorting | Collection and Sorting |

| Repulping | Depolymerization |

| Screening and Cleaning | Deinking |

| Deinking | Fiber Recovery |

| Refining and Papermaking |

How to prepare and sort PLA coated paper for recycling

To prepare PLA coated paper for recycling, it is important to separate it from other paper products to prevent contamination. This can be done through proper sorting and collection methods. Here are some guidelines for preparing and sorting PLA coated paper for recycling:

- Separate PLA coated paper: Keep PLA coated paper separate from regular paper products during collection. This can be achieved through separate collection bins or designated recycling streams.

- Avoid contamination: Ensure that PLA coated paper is not contaminated with food waste, liquids, or other non-recyclable materials. Contamination can affect the recyclability of the paper and the quality of the recycled product.

- Follow local recycling guidelines: Check with local recycling facilities or waste management agencies for specific guidelines on recycling PLA coated paper. They may provide instructions on how to prepare and sort PLA coated paper for recycling in your area.

By following these guidelines, you can help maximize the recyclability of PLA coated paper and contribute to a more sustainable waste management system.

Review Summary

- PLA coated paper is produced by applying a thin layer of PLA to paper or board surfaces.

- The PLA coating enhances the strength, water resistance, and grease resistance of the paper.

- PLA coated paper is biodegradable and compostable, reducing landfill waste and greenhouse gas emissions.

- However, the recycling of PLA coated paper poses challenges due to the specialized equipment and processes required for its separation and processing.

- Special recycling facilities are needed to recycle PLA coated paper and separate the PLA coating from the paper fibers.

- Proper sorting and preparation of PLA coated paper for recycling are essential to prevent contamination and ensure its recyclability.

What Are the Environmental Benefits and Challenges of PLA Coated Paper?

Overview of the Environmental Benefits of Using PLA Coated Paper

PLA coated paper offers several environmental benefits compared to traditional petroleum-based materials. One of the key advantages is that PLA is derived from renewable resources, such as corn starch, making it a sustainable and eco-friendly choice. By using PLA coated paper, companies can reduce their reliance on fossil fuels and contribute to a more sustainable future.

Moreover, PLA production has a lower carbon footprint and requires less energy compared to the production of traditional plastics. According to studies, PLA production uses 65% less energy and generates 68% fewer greenhouse gas emissions. This reduction in energy consumption and greenhouse gas emissions helps mitigate climate change impacts and supports the transition to a low-carbon economy.

Additionally, PLA coated paper can play a significant role in reducing landfill waste. PLA is biodegradable and compostable, meaning it can break down naturally over time. This characteristic enables PLA coated paper to be diverted from landfills and processed in commercial composting facilities, where it can decompose within 90 to 180 days. By using PLA coated paper, businesses can contribute to the reduction of waste and promote circular economy principles.

How Does PLA Production Compare to Traditional Plastics in Terms of Carbon Footprint and Energy Efficiency?

The production of PLA has a substantially lower carbon footprint compared to traditional petroleum-based plastics. Traditional plastics are derived from non-renewable resources, namely fossil fuels, which release significant amounts of carbon dioxide and other greenhouse gases during their production. PLA, on the other hand, is made from renewable resources, such as corn starch, which helps reduce carbon emissions.

Moreover, the energy efficiency of PLA production is superior to that of traditional plastics. Producing PLA requires 65% less energy compared to the production of petroleum-based plastics. This energy reduction is attributed to the fact that PLA is derived from renewable resources and undergoes a different manufacturing process.

By choosing to use PLA, companies can significantly reduce their carbon footprint and energy consumption, thereby contributing to a more sustainable and environmentally friendly industry.

The Role of Biodegradable and Compostable Materials in Reducing Landfill Waste

Biodegradable and compostable materials, such as PLA coated paper, play a crucial role in reducing landfill waste. In traditional waste management systems, non-biodegradable materials, including petroleum-based plastics, accumulate in landfills and contribute to environmental degradation. These materials take hundreds of years to decompose, leading to increased landfill space utilization and potential groundwater contamination.

In contrast, biodegradable and compostable materials like PLA coated paper can break down naturally over time without leaving harmful residues. This characteristic enables them to be diverted from landfills and processed in dedicated composting facilities. In these facilities, the materials can decompose within 90 to 180 days, ultimately turning into nutrient-rich compost that can be used to enrich soil and support plant growth.

By promoting the use of biodegradable and compostable materials like PLA coated paper, businesses can contribute to waste reduction, soil enrichment, and a more sustainable waste management system.

Can PLA Coated Paper Biodegrade in Home Compost Conditions?

PLA coated paper has been specifically designed to biodegrade in industrial composting facilities, where specific temperature and humidity conditions are maintained to facilitate decomposition. However, in home composting conditions, PLA coated paper may take a longer time to break down due to the lower temperatures and varied composting conditions.

The complete biodegradation of PLA coated paper in home composting conditions can take up to 90 days or more, depending on various factors such as temperature, moisture content, and the presence of microorganisms. It’s important to note that home composting is less regulated than industrial composting, which can lead to slower decomposition rates.

While PLA coated paper can eventually biodegrade in home compost conditions, it is recommended to dispose of it in dedicated composting facilities whenever possible to ensure more efficient and timely decomposition.

What Are the Limitations and Challenges of PLA Biodegradability?

While PLA offers various environmental benefits, there are limitations and challenges associated with its biodegradability. One of the primary challenges is that the biodegradation of PLA requires specific conditions that are often not present in natural environments. Industrial composting facilities provide the ideal environment for the decomposition of PLA, with controlled temperature, moisture, and microbial activity. However, these facilities are not as widely available as standard waste management systems.

Another limitation is that PLA requires a certain level of heat and moisture for effective biodegradation. In home composting conditions, where temperatures may not reach the level required for rapid decomposition, PLA may take a longer time to break down. Additionally, improper disposal practices, such as mixing PLA coated paper with non-compostable waste, can hinder the biodegradation process.

To overcome these challenges, it is important to educate consumers and businesses about proper disposal methods for PLA coated paper and promote the use of dedicated composting facilities. Furthermore, ongoing research and development efforts are focused on improving the biodegradability of PLA and exploring alternative biodegradable materials that are better suited for natural environments.

Analysis of PLA’s Impact on Natural Ecosystems

While PLA coated paper is generally considered environmentally friendly, it is essential to analyze its impact on natural ecosystems comprehensively. One potential concern is the increased demand for feedstock, such as corn starch, used in PLA production. This increased demand can lead to deforestation, habitat loss, and changes in land use practices, potentially affecting biodiversity and ecosystems.

Additionally, the disposal of PLA coated paper in natural environments, where specific composting conditions are not present, can lead to littering and impact wildlife habitats. Improper disposal practices can result in the accumulation of PLA in ecosystems, potentially disrupting natural processes and causing harm to wildlife.

To mitigate these potential impacts, it is crucial to promote responsible sourcing of feedstock for PLA production and develop comprehensive waste management systems that ensure proper disposal and processing of PLA coated paper. Additionally, continued research and innovation in the field of biodegradable materials can help address these concerns and develop more sustainable alternatives.

In conclusion, PLA coated paper offers various environmental benefits, including reduced carbon footprint, energy efficiency, and waste reduction. However, challenges related to biodegradability and potential impacts on natural ecosystems must be carefully considered and addressed. By promoting responsible use, disposal, and further innovation, PLA coated paper can continue to be a viable and sustainable option in the quest for eco-friendly packaging materials.

Exploring Alternative Biodegradable and Compostable Coatings to PLA

Alternative Coatings

PHB (Polyhydroxybutyrate)

PHA (polyhydroxyalkanoates) is a biopolymer that can be derived from renewable sources, including plant oils and sugarcane. PHA coatings provide similar moisture resistance and durability as PLA but with additional benefits. For instance, PHA is more easily compostable in home compost systems, reducing the need for specialized composting facilities. Additionally, PHA has been found to have a lower carbon footprint than PLA during production, making it a more sustainable choice.

Cellulose-based coatings

Another alternative to consider is cellulose-based coatings. These coatings are derived from plant fibers and offer similar benefits to PLA in terms of moisture resistance and durability. Cellulose-based coatings are biodegradable and compostable, and they can be easily broken down by microorganisms in natural environments. Additionally, cellulose-based coatings can be made from recycled or waste materials, further reducing their environmental impact.

Future Trends in Sustainable Paper Coatings

In terms of future trends, there are ongoing innovations in eco-friendly paper coating technologies. Researchers are exploring various materials, including bio-based polymers and nanomaterials, to develop coatings that are even more sustainable and have improved performance characteristics. These technologies aim to provide enhanced water and oil resistance, thereby increasing the functionality of sustainable paper products.

One notable example of innovation in eco-friendly paper coating technology is the development of nanoparticles derived from natural sources, such as chitosan or cellulose. These nanoparticles can be used to create coatings that improve the barrier properties of paper, making it more resistant to moisture, oils, and grease. This enables the use of sustainable paper in a wider range of applications, including food packaging.

Case studies of successful implementation of alternative coatings can provide valuable insights into their practical use and benefits. For example, some companies have successfully implemented PHA or cellulose-based coatings in packaging solutions, demonstrating their effectiveness as alternatives to PLA. These case studies can serve as inspiration for other businesses looking to adopt more sustainable paper coatings.

It is also important to assess the market demand and consumer trends towards sustainable paper products. As consumers become more environmentally conscious, there is a growing demand for products that offer eco-friendly alternatives to traditional materials. This includes paper products with sustainable coatings that are biodegradable, compostable, and made from renewable resources. By understanding consumer preferences and market trends, businesses can align their product offerings with sustainability goals and meet the growing demand for eco-friendly options.

Governmental regulations and policies also play a crucial role in influencing the use of biodegradable materials in paper coatings. As governments around the world prioritize sustainability and environmental protection, there may be regulations and incentives in place to encourage the adoption of alternative coatings. These regulations can promote the use of sustainable materials and create a more favorable environment for the development and implementation of eco-friendly paper coating technologies.

In summary, alternative solutions and future trends in sustainable paper coatings offer promising options for reducing environmental impact. Exploring alternative biodegradable and compostable coatings such as PHA and cellulose-based coatings can provide comparable performance to PLA while offering additional benefits. Ongoing innovations in eco-friendly paper coating technologies and successful case studies can inspire the adoption of alternative coatings. By considering market demand, consumer trends, and governmental regulations, businesses can make informed decisions to drive the adoption of sustainable paper products.

Tables

Comparison of Environmental Benefits and Challenges

| Environmental Benefit | PLA Coated Paper | Traditional Petroleum-Based Materials |

|---|---|---|

| Renewable Resource | Yes | No |

| Carbon Footprint | Lower | Higher |

| Energy Consumption | Lower | Higher |

| Biodegradability | Yes | No |

| Compostability | Yes | No |

| Waste Reduction | Yes | No |

Comparison of PLA Coated Paper and Alternative Coatings

| Coating | Biodegradability | Compostability | Moisture Resistance | Durability |

|---|---|---|---|---|

| PLA Coated Paper | Yes | Yes | High | High |

| PHA Coating | Yes | Yes | High | High |

| Cellulose-based | Yes | Yes | High | High |

FAQs about PLA Coated Paper Recycling

How does PLA coated paper recycling work?

To recycle PLA coated paper, special recycling facilities are required to separate the PLA coating from the paper fibers, involving steps like collection and sorting, depolymerization, deinking, and fiber recovery.

What is PLA coated paper and how is it produced?

PLA coated paper is made by applying a thin layer of PLA to paper or board surfaces, enhancing strength, water resistance, and grease resistance, produced from renewable resources like corn starch through fermentation and polymerization processes.

What are the necessary steps to recycle PLA coated paper?

To recycle PLA coated paper, the key steps include collection and sorting, depolymerizing the PLA coating, deinking the paper, and recovering the paper fibers for reuse.

Which recycling facilities accept PLA coated paper?

Not all recycling facilities accept PLA coated paper due to specialized processing needs, so it is vital to check with local recycling facilities or waste management agencies if they can handle PLA coated paper.

How to prepare and sort PLA coated paper for recycling?

To prepare PLA coated paper for recycling, separate it from other paper products, avoid contamination with non-recyclable materials, and follow local recycling guidelines for proper sorting and disposal.

Recycling PLA coated paper has its challenges but makes a big difference. We’ve explored how PLA coatings affect recyclability, necessary steps, and facility requirements. We also compared it to traditional paper recycling and discussed preparation tips. Plus, we reviewed environmental pros and cons and future eco-friendly coatings. Despite obstacles, PLA coated paper offers clear benefits. By understanding these processes, we can all support better recycling and sustainability. So, let’s do our part and recycle smarter!