Is Paper Cup Production Sustainable?

Paper Cup Production: A Comprehensive Guide

Understanding the Paper Cup Production Process

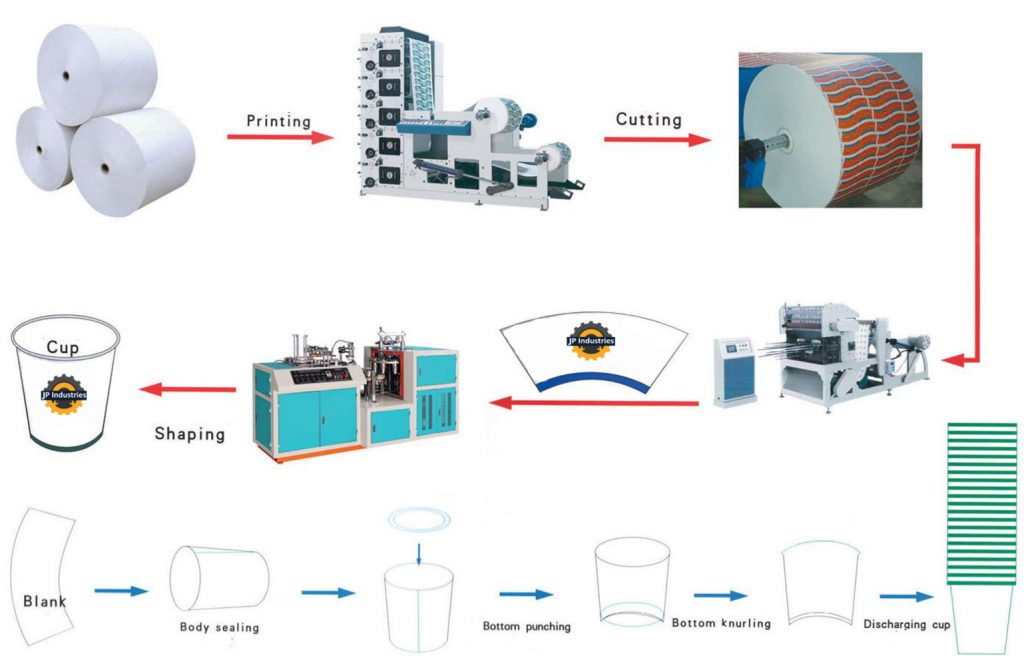

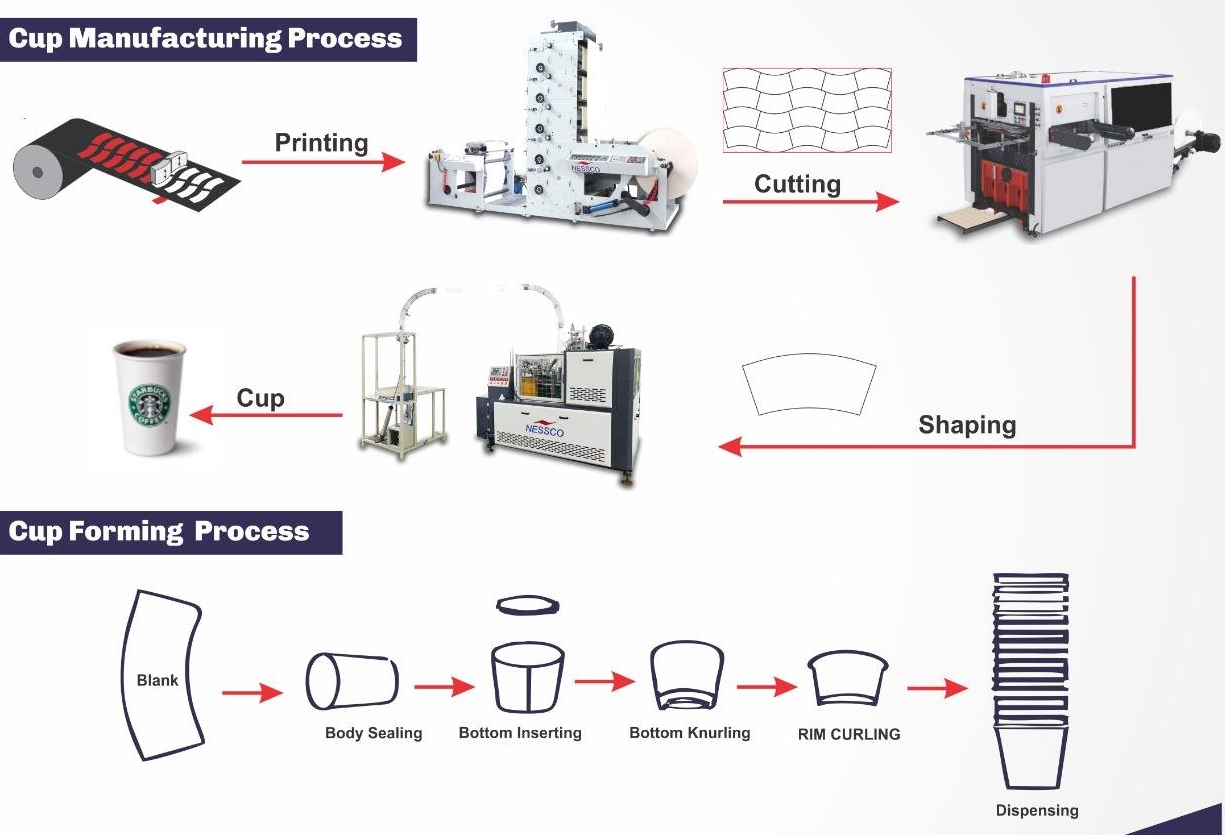

In this section, we will delve into the intricate process of paper cup production. From the selection of raw materials to the transformation of these materials into paper cup blanks, we will explore each step involved in detail.

Steps Involved in Paper Cup Production

The production of paper cups involves several sequential steps to ensure the creation of high-quality and functional cups. Let's take a closer look at these steps:

- Raw Material Selection: Paper cups are typically made from food-grade paperboard sourced from forests managed for responsible paper production. The paperboard undergoes cleaning, pulping, and bleaching to achieve the desired whiteness or color.

- Creation of Cup Blanks: Cup blanks are created by feeding the prepared paperboard into a cup-forming machine. This machine shapes the paperboard into cup blanks through intricate folding and sealing processes. To ensure leak-proof cups, the blanks are coated with a thin layer of PE (polyethylene).

- Printing and Design: Once the cup blanks are formed, they undergo printing with attractive designs, logos, or branding elements. This is done using flexographic or offset printing techniques, which allow for customization and personalization of the cups.

- Cutting and Shaping: After printing, the cups undergo cutting and rim rolling for their final shape and size. This process ensures a comfortable drinking experience for the consumers.

- Quality Control: Before packaging the cups for distribution, they undergo rigorous quality control inspections. These inspections ensure that the cups meet the required standards for leakage resistance, structural integrity, and overall quality.

By understanding the intricacies of each step in the paper cup production process, we can appreciate the craftsmanship and attention to detail that goes into creating these everyday items.

Selection of Raw Materials for Paper Cup Production

The selection of raw materials is a crucial aspect of paper cup production. Here are some key considerations in this process:

- Paperboard: Paper cups consist of a paper layer, a base paper (or middle layer), and a coating layer. The paper layer is typically made from SBS (Solid Bleached Sulfate) pulp, which provides structural strength and contributes to the sustainability of the cups.

- Base Paper: The middle layer, known as the base paper, provides insulation to the cups. It is made using a mix of wood chips and other additives that enhance the thermal properties of the cups, keeping beverages hot or cold for longer periods.

- Coating: The coating layer is responsible for preventing liquid seepage and enhancing the cups' durability. It is commonly made of plastic or PLA (Polylactic Acid). PLA is a plant-based material derived from renewable resources like sugarcane and cornstarch, making it a more eco-friendly option.

- Eco-Friendly Materials: In line with sustainability efforts, paper cup manufacturers are increasingly focusing on using high-grade recycled materials for their cups. These materials not only reduce the environmental impact of the production process but also contribute to the overall sustainability of the cups.

With the selection of the right raw materials, paper cup manufacturers can ensure that their cups meet the necessary quality standards while also aligning with their sustainability goals.

Transformation of Raw Materials into Paper Cup Blanks

The transformation of raw materials into paper cup blanks involves various processes and technologies. Here is a breakdown of this transformation:

- Sheet Formation: The process starts by transforming paperboard sheets into cup blanks. This is done by gluing paper circles together and using heat and pressure to mold them into the desired cup shape.

- Printing and Coating: Once the cup blanks are formed, they undergo printing to incorporate customized designs and branding elements. This is achieved using techniques such as offset, silkscreen, and flexographic printing.

- Coating Application: After printing, the cups are coated with a layer of plastic to provide a barrier against liquid seepage. The plastic coating enhances the cups' leak-proof properties and ensures the cups can safely contain hot or cold beverages.

- Quality Control: Throughout the transformation process, strict quality control measures are implemented to ensure the cups meet the required standards. Leakage tests, particularly with hot liquids, are conducted to ensure the cups' integrity.

- Eco-Friendly Innovations: In recent years, there has been a growing focus on eco-friendly innovations in paper cup production. These include the use of plant-based PLA linings, processes that are CO2 neutral, and the development of recyclable or degradable cups. These innovations aim to reduce the environmental impact of paper cup production and address the challenges associated with recycling.

By investing in efficient machinery and embracing sustainable practices, paper cup manufacturers can continue to evolve and meet the changing demands of the market.

In summary, the paper cup production process involves multiple steps, including raw material selection, blank formation, printing, coating, and quality control. Paper cup manufacturers are also exploring eco-friendly options and innovations to reduce their environmental impact and promote sustainability. With a comprehensive understanding of the production process, we can appreciate the craftsmanship and attention to detail that goes into creating these everyday items.

Machinery and Equipment Used in Paper Cup Production

In the world of paper cup production, the right machinery and equipment play a crucial role in ensuring efficient manufacturing processes and high-quality end products. In this section, we will delve into the various machines and equipment used in paper cup production, highlighting their importance and providing tips for maintenance.

Overview of Machinery Used in Paper Cup Production

Paper cup production involves a series of intricate steps, each requiring specialized machinery and equipment. Let's take a closer look at the key machines used in this process:

- Paper Cup Forming Machine: This is the backbone of paper cup production. The forming machine transforms cup blanks, which are essentially flat sheets of prepared paperboard, into the familiar shape of a cup. The machine uses a combination of heat and pressure to fold and seal the cup blanks, ensuring a tight and leak-proof seal.

- Printing Machine: Once the cups are formed, they can be printed with attractive designs, logos, or branding elements. Printing machines, such as flexographic or offset printers, are used to create these customized designs on the cups. This adds aesthetic appeal and enhances brand visibility.

- Cutting Machine: After printing, the cups go through a cutting process to remove any excess paper and give them their final shape and size. Cutting machines ensure precise and consistent cup dimensions, providing a comfortable drinking experience for consumers.

- Rim Rolling Machine: To finish off the cups, a rim rolling machine is used to create a smooth and rounded rim. This not only adds to the overall appearance of the cup but also makes it easier and more comfortable to drink from.

Importance of Specific Equipment in the Manufacturing Process

Each piece of equipment used in paper cup production serves a specific purpose and contributes to the overall success of the manufacturing process. Here is a closer look at the importance of some key equipment:

- Paper Cup Forming Machine: This machine is the heart of the production process, as it shapes the cup blanks into cups. It ensures precision and consistency in cup formation, resulting in sturdy and well-sealed cups that meet industry standards.

- Printing Machine: Customization is essential for many businesses, and the printing machine allows for unique designs to be applied to paper cups, helping to enhance brand recognition and attract customers.

- Cutting Machine: Consistency in cup dimensions is crucial for both aesthetic reasons and a comfortable drinking experience. A reliable cutting machine ensures that cups are uniform in size and shape, minimizing any potential issues during use.

- Rim Rolling Machine: The rim of a paper cup needs to be smooth and rounded to provide a pleasant drinking experience without any sharp edges. The rim rolling machine achieves this, ensuring that cups are safe and comfortable for consumers to use.

Maintenance Tips for Paper Cup Production Machinery

Proper maintenance of the machinery used in paper cup production is essential to ensure smooth operations and minimize downtime. Here are some maintenance tips to keep in mind:

- Regular Cleaning: Regularly clean and remove any accumulated paper dust or debris from the machinery. This helps prevent malfunctions and improves overall performance.

- Lubrication: Lubricate moving parts as per the manufacturer's recommendations. This reduces friction, extends the lifespan of the equipment, and ensures smooth operation.

- Inspections: Conduct routine inspections to identify any signs of wear and tear, loose parts, or potential issues. Addressing these early on can prevent major breakdowns and costly repairs.

- Staff Training: Properly train staff on the operation and maintenance of the machinery. This empowers them to identify and address minor issues before they escalate, ensuring the equipment is used correctly and efficiently.

- Scheduled Maintenance: Create a maintenance schedule to regularly check critical components, such as motors, belts, and bearings. This proactive approach helps identify and resolve any potential problems before they impact production.

By following these maintenance tips, paper cup production machinery can remain in optimal condition, ensuring uninterrupted production and consistent quality.

In conclusion, the machinery and equipment used in paper cup production are essential for efficient manufacturing processes and high-quality end products. The paper cup forming machine, printing machine, cutting machine, and rim rolling machine all serve crucial roles in different stages of the production process. Proper maintenance of this equipment is vital to ensure smooth operations, minimize downtime, and deliver exceptional paper cups to consumers.

Cost Analysis and Environmental Impact of Paper Cup Production

Paper cup production involves several costs and considerations, ranging from raw materials to manufacturing processes. In this section, we will delve into the breakdown of costs in paper cup production, the environmental considerations associated with manufacturing, and sustainable practices that can be adopted in the paper cup production industry.

Breakdown of Costs in Paper Cup Production

- Raw Materials: The primary raw material used in paper cup production is food-grade paperboard. This paperboard is sourced from forests managed for responsible paper production. The cost of paperboard can vary based on factors such as quality, sustainability certifications (e.g., FSC certified or 100% recycled), and supplier location.

- Coating Materials: Paper cups typically have a coating layer to prevent liquid seepage. This coating layer is commonly made of plastic or PLA (polylactic acid) – a plant-based biopolymer. The cost of coating materials depends on the type and quantity of coating used in the production process.

- Printing: Printing attractive designs, logos, or branding elements on paper cups is an essential aspect of production. The cost of printing can vary depending on the printing technique used (flexographic or offset), the complexity of the design, and the number of colors involved.

- Labor: Labor costs are incurred for operating the paper cup forming machines, conducting quality control inspections, and packaging cups for distribution. The labor cost can vary based on factors such as location, skill level, and production volume.

- Machinery and Equipment: Investing in paper cup forming machines, printing equipment, and other machinery is a significant cost in the paper cup production process. Maintenance and repair costs should also be considered to ensure smooth production operations.

- Packaging and Distribution: Packaging materials used for shipping and distribution of paper cups contribute to the overall production costs. Additionally, transportation costs for delivering the cups to their intended destinations need to be factored in.

Environmental Considerations in Paper Cup Manufacturing

While paper cups are biodegradable and can be easily recycled, there are some environmental considerations associated with their manufacturing process. It's important to be aware of these considerations and work towards minimizing their impact. Some key environmental factors to consider include:

- Sustainable Materials: Opt for paperboard sourced from sustainably managed forests or use high-grade recycled materials for paper cup production. This ensures responsible material sourcing and reduces the impact on forests.

- Eco-friendly Coatings: Explore alternatives to traditional plastic coatings, such as PLA bioplastic coatings made from plant-based materials. These coatings provide the necessary liquid barrier while being more environmentally friendly.

- Recyclability: Paper cups with plastic coatings can be challenging to recycle. Innovations focused on improving the recyclability of paper cups, such as developing plastic-free or easily recyclable coatings, should be encouraged.

- Carbon Footprint: The transportation of paper cups, especially via airplanes, can contribute to carbon emissions. Choosing ground transportation options like trucks, trains, or ships can help reduce the carbon footprint associated with distribution.

- Energy Efficiency: Invest in energy-efficient machinery and equipment to minimize energy consumption in the manufacturing process. Implementing energy-saving measures, like optimizing production schedules and using renewable energy sources, can also help reduce environmental impact.

Sustainable Practices in the Paper Cup Production Industry

To promote sustainability in the paper cup production industry, several practices can be adopted:

- Recycled Materials: Embrace the use of high-grade recycled materials for paper cup production. Reusing paper fibers reduces the demand for virgin materials and supports the circular economy.

- Eco-friendly Coatings: Choose environmentally friendly coating options, such as PLA bioplastic coatings, which are derived from renewable resources and can be composted or recycled.

- Efficient Machinery: Utilize efficient machinery that minimizes waste, reduces energy consumption, and enhances overall production efficiency. Regular maintenance and monitoring of equipment performance can help optimize operations.

- Waste Management: Implement effective waste management practices within the production facility, such as recycling paper waste, properly disposing of used coatings, and minimizing water consumption.

- Lifecycle Analysis: Conduct a lifecycle analysis of paper cup production to identify areas where improvements can be made. This analysis can help assess the environmental impact of the entire production process and guide decision-making towards more sustainable practices.

By considering the breakdown of costs, environmental impact, and adopting sustainable practices, the paper cup production industry can work towards reducing its carbon footprint and promoting more eco-friendly solutions.

–800 words

FAQs about Paper Cup Production:

How does the selection of raw materials impact paper cup production?

To understand the impact of raw materials on paper cup production, we must consider the specific components and their properties that contribute to the final product's quality and sustainability.

What are the key steps involved in transforming raw materials into paper cup blanks?

To transform raw materials into paper cup blanks, several sequential steps such as sheet formation, printing, coating application, and quality control measures must be executed efficiently to ensure the creation of high-quality and functional cups.

Why is maintenance crucial for machinery used in paper cup production?

Proper maintenance of machinery used in paper cup production is essential to ensure the equipment's optimal performance, minimize downtime, and uphold consistent quality standards throughout the manufacturing process.

How can the environmental impact of paper cup production be reduced?

To mitigate the environmental impact of paper cup production, sustainable practices such as the use of recycled materials, eco-friendly coatings, efficient machinery, waste management initiatives, and lifecycle analysis can be implemented to promote eco-friendly solutions and reduce the industry's carbon footprint.

In this comprehensive guide, we covered the paper cup production process in detail. From understanding the steps and materials to the machinery involved, all aspects were explained. The cost analysis and environmental impact shed light on the sustainability and eco-friendly options in this industry. By taking a closer look at the ins and outs of paper cup production, we can make more informed choices. Remember, sustainable practices are key for a greener future.