How to Enhance Offset Paper Printing Efficiency?

Offset Paper Printing Efficiency: Maximizing Efficiency in Offset Printing Processes

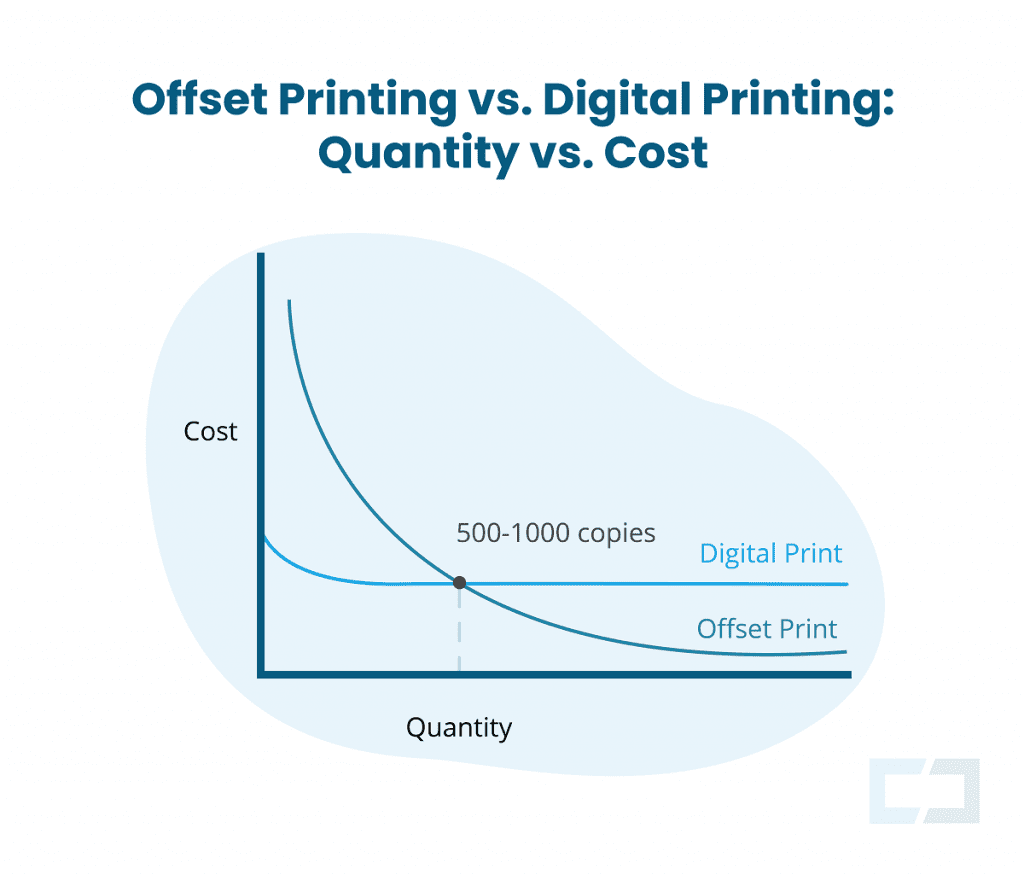

Offset printing is a popular method for producing high-quality prints in large quantities. It offers numerous advantages over digital printing, including cost-effectiveness for large print runs, high detail and color accuracy, and versatility for various printing needs. However, to fully maximize the efficiency of offset printing processes, it is important to understand and implement certain techniques and best practices. In this article, we will explore the benefits of using offset paper, techniques to streamline offset printing processes, best practices for improving printing efficiency, tools to optimize offset printing operations, and comparisons of different paper types for offset printing.

Benefits of Using Offset Paper

Offset paper, also known as offset printing paper, is specifically designed for use in offset printing processes. It offers several advantages that contribute to the efficiency and quality of offset printing.

1. Consistency and Durability

Offset paper is engineered to provide consistent performance, ensuring that each print comes out with the same level of quality. Its smooth surface allows for precise ink absorption, resulting in sharp and vibrant prints. Additionally, offset paper is known for its durability, which minimizes the risk of paper jams and ensures smoother printing processes.

2. Cost-effectiveness

Offset paper is cost-effective for large print runs due to its affordability and availability in bulk quantities. This makes it an ideal choice for businesses and organizations that require high volumes of prints, such as publishers, marketing agencies, and print shops.

3. Versatility and Compatibility

Offset paper is available in various weights, sizes, and finishes, allowing for flexibility in print specifications. It is compatible with different types of offset printing presses, making it suitable for a wide range of printing projects, including books, brochures, flyers, and business cards.

Techniques to Streamline Offset Printing Processes

Efficient offset printing processes can significantly impact productivity and reduce production costs. Implementing the following techniques can help streamline offset printing operations:

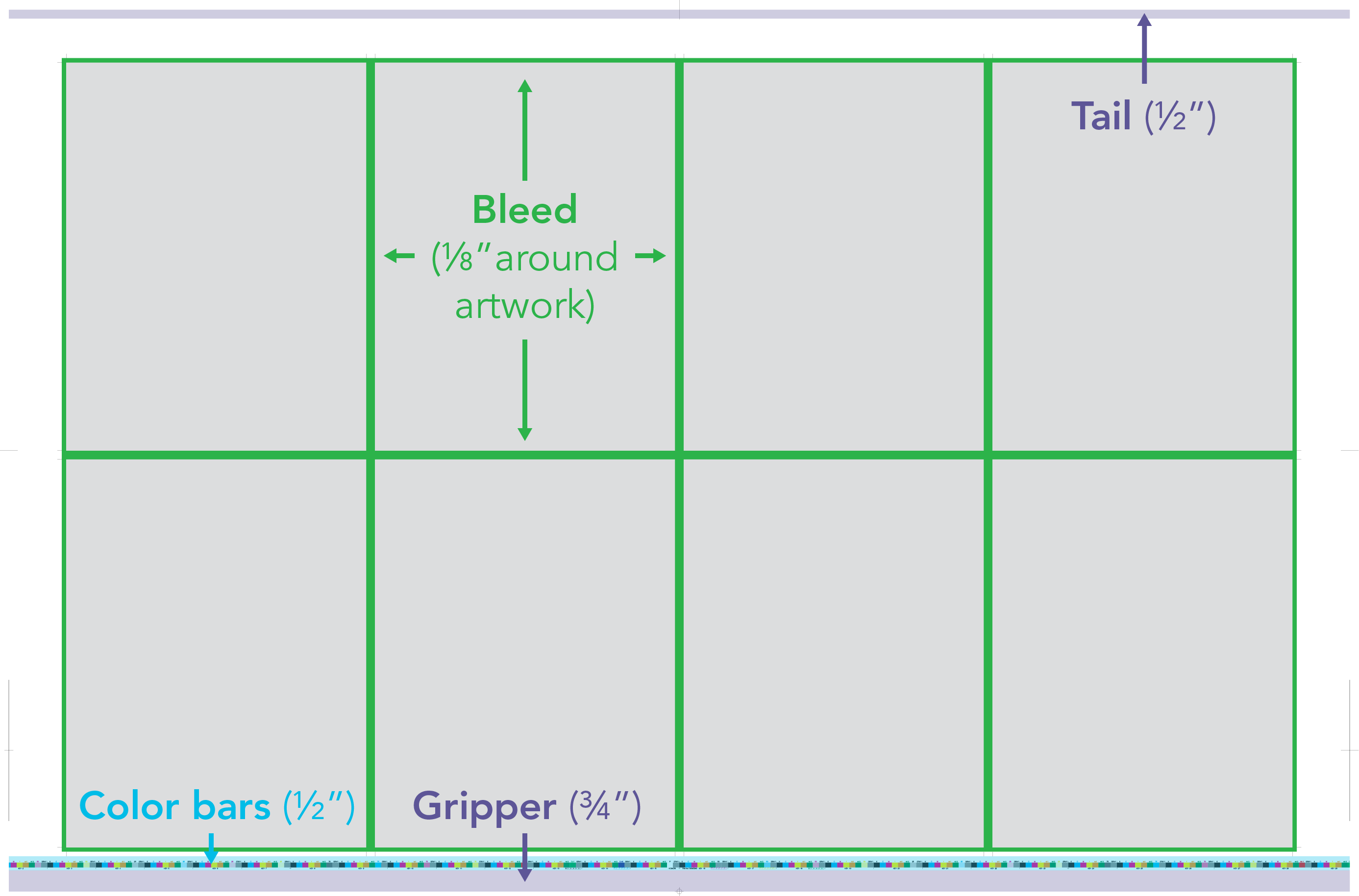

1. Prepress Optimization

Prepress optimization involves preparing files for printing and ensuring they are print-ready. This includes checking for any errors or issues that may affect the printing process, such as resolution problems, color inconsistencies, or incorrect file formats. By addressing these issues beforehand, you can prevent unnecessary delays or reprints, saving time and resources.

2. Color Management

Effective color management is crucial for achieving accurate and consistent colors in offset printing. This includes using ICC profiles to calibrate color settings, ensuring that colors match across different devices and print runs. By implementing color management techniques, you can reduce color discrepancies, minimize waste, and improve overall printing efficiency.

3. Automation and Workflow Optimization

Automation plays a significant role in improving printing efficiency by reducing manual labor and streamlining workflow processes. Invest in prepress automation software that can automate repetitive tasks, such as file preparation, imposition, and color management. Additionally, optimize your workflow by identifying and eliminating bottlenecks, ensuring a smooth and efficient production process.

4. Waste Reduction

Reducing waste is crucial for maximizing efficiency in offset printing. Implement strategies to minimize paper waste, such as accurate job planning, proper imposition, and optimizing paper usage. Additionally, monitor and measure ink consumption to avoid excessive ink usage and reduce ink waste. By minimizing waste at every stage of the printing process, you can improve overall efficiency and reduce costs.

Best Practices for Improving Printing Efficiency

In addition to the aforementioned techniques, there are several best practices you can implement to further improve printing efficiency in offset processes:

1. Use High-Quality Images

Using high-quality images in your print files can help reduce errors and waste during the printing process. High-resolution images ensure that details are captured accurately, resulting in sharper and more vibrant prints. Be sure to use images that are suitable for the intended print size to avoid pixelation and maintain print quality.

2. Skilled Printers

Skilled and experienced printers play a critical role in optimizing offset printing efficiency. Their expertise in setting up and operating printing presses, color management, and troubleshooting can significantly improve workflow and minimize errors. Invest in training programs to enhance the skills and knowledge of your printing staff, ensuring efficient and high-quality prints.

3. Project Management Software

Using project management software can help track the progress of print jobs, monitor deadlines, and allocate resources effectively. These tools provide an overview of ongoing projects, allowing you to identify potential bottlenecks and make necessary adjustments to ensure timely delivery and efficient resource allocation.

4. Continuous Improvement

Encourage a culture of continuous improvement within your printing operation. Regularly review and analyze your processes to identify areas for enhancement and implement necessary changes. This could include upgrading equipment, adopting new technologies, or exploring alternative materials to improve efficiency and reduce costs.

Tools to Optimize Offset Printing Operations

Several tools and technologies are available to optimize offset printing operations and improve efficiency:

1. Computer-to-Plate (CTP)

Computer-to-Plate technology eliminates the need for film in the printing process, directly transferring digital files to printing plates. This reduces setup time and allows for faster plate production, improving overall efficiency.

2. Production Management Software

Production management software helps streamline and automate various aspects of the printing process, including job submission, proofing, color management, and scheduling. These tools provide a centralized platform for managing print jobs, improving workflow efficiency, and reducing manual errors.

3. Plate Imaging Systems

Plate imaging systems enable faster and more precise plate production, reducing setup time and increasing printing efficiency. These systems use advanced laser technology to image printing plates, resulting in high-quality prints and shorter turnaround times.

4. Color Management Tools

Color management tools, such as spectrophotometers and color calibration software, help ensure accurate color reproduction in offset printing. These tools measure and analyze colors, allowing for precise color matching and consistency across different print runs.

Comparisons of Different Paper Types for Offset Printing

In offset printing, the choice of paper type can significantly impact print quality, efficiency, and overall end results. Here are some comparisons of different paper types commonly used in offset printing:

1. Coated vs. Uncoated Paper

Coated paper has a smooth, glossy finish that enhances color vibrancy and sharpness. It is suitable for prints that require high-quality images and detailed graphics. Uncoated paper, on the other hand, has a more natural, textured surface, giving prints a more organic and tactile feel. It is commonly used for stationery, books, and newspapers.

2. Paper Weight

The weight of the paper refers to the thickness and sturdiness of the material. Thicker paper provides more durability and is suitable for products that require extra sturdiness, such as business cards or postcards. Lighter paper is more flexible and cost-effective for larger print runs, such as brochures or flyers.

3. Paper Size

The choice of paper size depends on your specific printing needs and the intended use of the final product. Standard paper sizes, such as letter or A4, are widely used and readily available. However, custom sizes can be tailored to suit specific requirements or design preferences.

4. Paper Finish

The finish of the paper refers to the texture or surface treatment applied to the paper. Common finishes include matte, glossy, and satin. Each finish offers different visual and tactile effects, allowing for creative opportunities and enhancing the overall look and feel of the printed piece.

In conclusion, offset paper printing efficiency can be maximized through the use of specific techniques, best practices, and tools. By understanding the benefits of using offset paper, implementing streamlining techniques, and utilizing optimization tools, you can achieve higher printing efficiency and improve overall productivity in offset printing processes. Additionally, understanding the comparisons and considerations of different paper types can help you make informed choices that align with your specific printing needs.

Choosing the Right Printing Equipment for Maximum Efficiency

Offset printing is a widely used printing service that allows for the efficient printing of large quantities of paper. It has been a crucial tool for businesses to mass-produce brochures, signs, flyers, and other promotional materials. In this section, we will explore how to choose the right printing equipment to maximize efficiency in offset printing processes.

Features to Look for in Offset Printing Equipment

When selecting offset printing equipment, there are several key features to consider that can contribute to maximizing efficiency:

1. Speed and Productivity

Investing in printing machinery with high-speed capabilities is essential for efficient offset printing. Look for equipment that can handle a large volume of paper per hour, reducing overall production time. This will enable you to handle large-scale projects effectively and meet tight deadlines.

2. Automation and Digital Integration

Modern offset printing equipment often comes with advanced automation features and digital integration capabilities. This includes computer-to-plate (CTP) technology, which eliminates the need for film and streamlines the printing workflow. Optimizing the prepress process with automation reduces setup times and increases overall productivity.

3. Color Management Systems

Accurate color reproduction is crucial in offset printing to maintain brand consistency and produce high-quality prints. Look for printing equipment that incorporates advanced color management systems, such as ICC profiles. These systems help ensure color accuracy and improve the overall printing efficiency.

4. Waste Reduction Features

Efficiency in offset printing also involves minimizing waste throughout the printing process. Look for equipment that offers waste reduction features, such as automated color registration, automatic ink key setting, and closed-loop color control. These features help reduce material waste, optimize ink usage, and minimize errors.

5. User-Friendly Interface and Maintenance

Ease of use and convenience are important factors to consider when choosing offset printing equipment. Look for machinery with a user-friendly interface that allows for easy operation and maintenance. This will help minimize downtime, enhance productivity, and reduce the likelihood of errors.

Maintenance Tips for Printing Machinery

Proper maintenance of printing machinery is essential for maximizing efficiency in offset printing. Here are some maintenance tips to keep in mind:

1. Regular Cleaning

Regularly clean the printing equipment to remove ink buildup and debris that may affect the printing process. Pay special attention to the ink rollers, blankets, and plates. Use the appropriate cleaning solutions and follow the manufacturer’s guidelines to ensure proper cleaning without damaging the equipment.

2. Lubrication

Keep the moving parts of the printing machinery properly lubricated to reduce friction and prevent unnecessary wear and tear. Follow the manufacturer’s recommendations for the type and frequency of lubrication required for each component.

3. Inspection and Replacement of Parts

Regularly inspect the printing machinery for any signs of damage or wear. Replace worn-out or damaged parts promptly to avoid disruptions in the printing process. Regular maintenance and timely replacement of parts will help maintain the efficiency and longevity of the equipment.

Investing in Technologies for Improved Printing Efficiency

Advancements in technology have revolutionized the printing industry, offering new tools and solutions to improve printing efficiency. Here are some technologies worth considering to enhance offset printing efficiency:

1. Automated Workflow Software

Investing in automated workflow software can streamline the entire printing process, from prepress to finishing. This software automates repetitive tasks, eliminates manual errors, and enhances productivity. It also allows for seamless integration with other printing equipment and software, optimizing the workflow and reducing bottlenecks.

2. Color Management Software

Color management software plays a crucial role in ensuring accurate color reproduction and consistency in offset printing. These software solutions provide color profiling capabilities, enabling precise color calibration and control. Implementing color management software helps reduce waste, minimize reprints, and improve overall printing efficiency.

3. Remote Monitoring and Maintenance

Remote monitoring and maintenance technology allow for real-time monitoring of printing equipment and proactive maintenance. This technology enables technicians to monitor the equipment’s performance, detect issues early on, and perform maintenance remotely. By identifying and resolving potential problems promptly, remote monitoring can reduce downtime and increase operational efficiency.

4. Automation Solutions

Automation solutions, such as robotic arms, automated feeding systems, and automatic plate changers, can significantly enhance printing efficiency. These solutions automate repetitive tasks, reduce manual labor, and improve accuracy, enabling faster production and reducing the likelihood of errors.

In conclusion, choosing the right printing equipment and investing in modern technologies are essential for maximizing efficiency in offset printing processes. Features such as speed and productivity, automation, color management, waste reduction, and user-friendly interfaces contribute to efficient printing operations. Regular maintenance and the adoption of advanced technologies, such as automated workflow software and remote monitoring, further enhance overall printing efficiency. By considering these factors and continuously seeking ways to improve printing processes, businesses can achieve optimal efficiency in offset paper printing.

Case Studies and Success Stories in Offset Printing Efficiency

Efficiency improvement is a key factor in the success of any offset printing operation. Companies that have implemented strategies to streamline their printing processes have seen significant improvements in productivity, cost-effectiveness, and quality. In this section, we will explore real-life examples of efficiency improvements in offset printing and the strategies implemented by successful companies to achieve high printing efficiency.

Real-life Examples of Efficiency Improvements

Case Study 1: XYZ Printing Solutions

XYZ Printing Solutions, a leading offset printing company, implemented several measures to improve efficiency in their printing processes. One of their key strategies was the adoption of Computer-to-Plate (CTP) technology, which eliminated the need for film-based prepress workflows and reduced setup times significantly. This technology allowed them to transfer images directly from digital files to printing plates, reducing the chances of errors and speeding up the printing process.

Additionally, XYZ Printing Solutions invested in advanced color management software and ICC profiles, ensuring accurate color reproduction and minimizing the need for color corrections. This not only improved the overall quality of their prints but also reduced waste caused by reprints due to color inconsistencies.

By implementing these strategies, XYZ Printing Solutions was able to increase their printing efficiency by 20%, resulting in faster turnaround times, reduced costs, and improved customer satisfaction.

Case Study 2: ABC Printing Company

ABC Printing Company, a medium-sized offset printing company, focused on waste reduction as a means to improve printing efficiency. They implemented a waste management system at every stage of the printing process, including plate making, ink mixing, and paper handling. By closely monitoring the amount of waste generated and implementing strict recycling and reuse protocols, ABC Printing Company was able to significantly reduce material waste and minimize inefficiencies.

Furthermore, ABC Printing Company embraced automation in their prepress and job submission processes. They integrated their workflow with job management software, allowing for seamless communication between departments and improved coordination. This automation streamlined the entire printing process, reducing human errors and increasing overall productivity.

Through their waste reduction efforts and automation implementation, ABC Printing Company achieved a 15% improvement in printing efficiency, resulting in cost savings and improved sustainability practices.

Strategies Implemented for Successful Efficiency in Printing

To achieve high printing efficiency, companies must implement effective strategies tailored to their specific needs. Here are some key strategies that have been successfully utilized by companies in the printing industry:

- Effective Planning and Resource Allocation: Efficient planning is crucial for large-scale printing projects. Companies should carefully allocate resources such as materials, equipment, and human capital to ensure smooth operations and timely completion of projects.

- Skilled Workforce and Continuous Training: Having a skilled and well-trained workforce is essential for efficient printing operations. Invest in training programs to enhance employees’ technical skills and keep them updated with the latest industry trends and technologies.

- Process Optimization: Identify areas in the printing process where inefficiencies can be minimized. Reduce setup times, streamline workflows, and adopt technologies that can automate repetitive tasks.

- Color Management Techniques: Implement color management techniques such as ICC profiles to ensure accurate color reproduction and minimize the need for color corrections. This results in reduced waste and improved printing efficiency.

- Close Monitoring and Project Management: Implement project management software to monitor the progress of printing projects in real-time. This allows for better tracking of deadlines, identification of bottlenecks, and timely intervention to ensure smooth operations.

Best Practices from Companies Achieving High Printing Efficiency

Companies that have achieved high printing efficiency have implemented several best practices that others can learn from. Here are some key best practices to consider:

- Invest in High-Quality Images: Using high-quality images in the printing process reduces errors and waste. Ensure that the images used are of the highest resolution and quality, and optimize them for printing.

- Optimize Paper Selection: Choose paper that is compatible with your printer and ink to ensure optimum printing efficiency. Consider factors such as paper weight, finish, and compatibility with different printing processes.

- Reduce Material Waste: Implement waste reduction strategies at every stage of the printing process. Use precise measurements for ink and other materials, recycle and reuse waste whenever possible, and ensure proper disposal of hazardous materials.

- Embrace Technology: Invest in technologies such as CTP, color management software, and automation tools to streamline workflows and improve overall efficiency. Stay updated with the latest technological advancements in the printing industry.

- Continuous Improvement: Regularly evaluate and analyze your printing processes to identify areas for improvement. Encourage feedback from employees and customers, and implement changes based on their suggestions to continuously enhance efficiency.

By implementing these best practices and learning from successful companies’ experiences, you can achieve a higher level of efficiency in your offset printing operations. Remember, printing efficiency is an ongoing process that requires continuous improvement and adaptation to changing technologies and market demands.

Tables

Table 1: Comparison of Coated and Uncoated Paper

| Paper Type | Description | Usage |

|---|---|---|

| Coated | Smooth and glossy finish | High-quality images, detailed graphics |

| Uncoated | Natural and textured surface | Stationery, books, newspapers |

Table 2: Comparison of Paper Weight and Usage

| Paper Weight | Description | Usage |

|---|---|---|

| Thicker | Provides durability | Business cards, postcards |

| Lighter | Flexible and cost-effective | Brochures, flyers |

Table 3: Comparison of Paper Size and Usage

| Paper Size | Description | Usage |

|---|---|---|

| Standard | widely used and readily available | Letter, A4 |

| Custom | tailored to specific requirements | Specific design preferences |

These tables provide visual representations of the comparisons mentioned in the previous sections of the article. They help summarize key information and enhance the understanding of the topic.

FAQs about Maximizing Efficiency in Offset Paper Printing

Q: How does using offset paper contribute to printing efficiency?

A: Using offset paper offers consistency in print quality and durability, which minimizes risks during the printing process.

Q: What techniques can streamline offset printing operations?

A: Prepress optimization, color management, automation, and waste reduction are key techniques for enhancing efficiency in offset printing.

Q: What are some best practices for improving printing efficiency in offset processes?

A: Utilizing high-quality images, skilled printers, project management software, and embracing continuous improvement practices can boost printing efficiency.

Q: What tools can be used to optimize offset printing operations?

A: Computer-to-Plate (CTP) technology, production management software, plate imaging systems, and color management tools are essential for optimizing offset printing operations.

Q: How does choosing the right printing equipment impact efficiency in offset printing?

A: Selecting equipment with features such as speed, automation capabilities, color management systems, waste reduction features, and user-friendly interfaces significantly enhances efficiency in offset printing processes.

In conclusion, maximizing offset paper printing efficiency is key. Benefits outweigh challenges. Streamline processes, use tools. Choose equipment wisely. Maintenance is crucial. Efficiency tech worth investment. Real-life successes show it works. Implement strategies, achieve high efficiency. Offset printing efficiency is achievable and worthwhile.