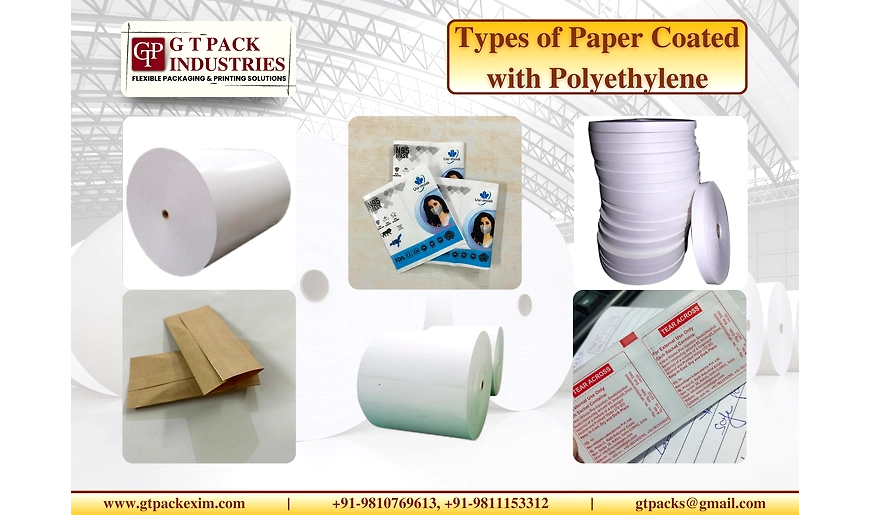

Explores Various Classifications of PE Coated Paper?

What Are the Different Types of PE Coated Paper?

PE coated paper is a versatile material that finds use across various industries. Understanding the different types can help in selecting the right PE coated paper for a specific need. Below, you will learn about multiple classifications of PE coated paper, their properties, and applications.

Overview of Single-side PE-coated Paper: Properties, Uses, and Industry Applications

Single-side PE-coated paper has a protective layer of polyethylene on one side. This type of paper is water-resistant, which is essential for preventing moisture intrusion. Its typical applications include packaging for snacks, baked goods, and fast food. For example, it is often used for burger wraps and sandwich wraps.

This paper works excellently in environments where moisture could damage the product. It also has a good printability feature, allowing for branding and attractive graphics. Look for single-side PE-coated paper in retail settings where customers enjoy eating on-the-go.

In terms of specifications:

- Nedvességállóság: Effective for snacks and baked goods

- Strength: Suitable for wrapping products without tearing

- Nyomtathatóság: Supports high-quality images and logos

Double-side PE-coated Paper: Its Utility in Food Packaging for Frozen Foods, Meat, and Seafood

Double-side PE-coated paper is coated with polyethylene on both sides. This greatly increases its moisture and grease resistance. It is especially useful in the food packaging industry for items like frozen foods, meat, and seafood. The double layer protects food against moisture and keeps it safe during transit and storage.

Double-side PE-coated paper can stand a variety of temperatures. It can handle the freezing temperatures often needed for frozen food packaging while also providing a barrier to grease—ideal for fatty foods.

Here are some features:

- Tartósság: Designed to withstand various storage conditions

- Grease Barrier: Protects fatty foods like meat and fried products

- Sokoldalúság: Works well for trays, wrappers, or food containers

Characteristics and Applications of Sandwich PE-coated Paper in Moisture-sensitive Packaging

Sandwich PE-coated paper features a layer of polyethylene sandwiched between two layers of paper. This construction gives it additional strength and insulation against moisture. The unique design makes it especially effective in packaging for items like sandwiches and burgers.

The moisture barrier property is vital when it comes to maintaining food freshness. This type of packaging prevents sogginess, keeping the food appealing to customers.

Characteristics include:

- Moisture Protection: Keeps contents fresh and dry

- Insulating Properties: Ideal for hot and cold food items

- User Friendly: Easy to handle and transport

Understanding Release Liner PE-coated Paper for Adhesive Applications Like Labels and Tapes

Release liner PE-coated paper is designed specifically for adhesive applications. Often found in the production of labels and tapes, it has a unique coating that allows for easy peeling without tearing. This type of paper serves as a protective backing, ensuring that adhesives maintain their quality until use.

Various industries benefit from using release liner PE-coated paper. For example, the shipping and logistics industry often relies on it for stickers and labels. Its ease of processing means faster production times and higher efficiency.

Key features are:

- Easy Release: Facilitates fast application without mess

- Adhesive Compatibility: Works well with many types of adhesives

- Versatile Use: Suitable for a range of applications in different industries

Distinguishing Between Matte and Glossy PE-coated Paper: Surface Finishes and Industry Uses

Matte and glossy PE-coated papers serve different aesthetic and functional purposes. Matte PE-coated paper has a non-reflective surface that suits muted, high-quality graphics. This type works well for branding and marketing material where a subtle look is preferred.

On the other hand, glossy PE-coated paper offers enhanced contrast and bright colors. It is ideal for product labels where bold visuals are necessary. Many industries use glossy paper for promotional items, as the shiny finish can attract customers.

Both finishes have their distinct advantages:

- Matt kivitel:

- Non-Reflective Surface: Better for text-heavy designs

- Ideal for Premium Products: Appeals to a more upscale market

- Fényes kivitel:

- Enhanced Color Vibrancy: Captivates attention through brightness

- Suitable for Labels: Increases visibility on shelves

Understanding the varied classifications of PE coated paper can significantly improve your packaging choices. As industries evolve, so does the demand for effective, versatile packaging solutions. Each type of PE coated paper brings unique benefits suited for specific requirements, catering to needs from food safety to brand marketing. For instance, if you're interested in the innovative applications of PLA coated paper, check out this insightful article on innovative PLA coated paper applications. Likewise, consider exploring the a PE laminált papír előnyei to understand how it can enhance your product offerings. Finally, if you are looking to grasp the market trends surrounding this material, don't miss the details in exploring PLA coated paper market trends.

What Are the Key Advantages and Disadvantages of Using PE Coated Paper?

PE coated paper is a widely used material in various industries, especially in food packaging. It has several benefits and drawbacks, making it essential to understand its characteristics fully. Let’s explore the advantages and disadvantages of using PE coated paper.

Water Resistance and Grease Barrier Properties

One of the standout benefits of PE coated paper is its vízállóság. This property is critical for food packaging, especially for items like snack foods and baked goods. For example, when you have a burger wrap or a snack bag, the PE coating protects the paper from moisture, keeping the food dry and fresh.

Additionally, the grease barrier property of PE coated paper provides excellent protection for oily or fried foods. As a case study, think about french fries packaged in PE lined bags. The coating prevents oil from leaking out and keeps the packaging clean and effective. In essence, this combination of properties makes PE coated paper a go-to choice for the food industry.

Impact on Food Freshness

Another essential factor regarding PE coated paper is its contribution to food freshness through heat sealing. The heat sealable property enables manufacturers to secure packages tightly, stopping air from entering. This feature ensures a longer shelf life for products.

A chemical inertness of PE coated paper is another vital benefit when packaging food. It does not react with food contents, which avoids altering flavors or introducing unwanted chemicals. For instance, if you package a sandwich in PE coated paper, the sandwich stays fresh without losing its taste or experiencing any flavor changes.

Limitations in Recycling and Environmental Impact

| Előnyök | Hátrányok |

|---|---|

| Víz- és zsírállóság | Recycling difficulty |

| Enhanced shelf life via heat sealing | Non-biodegradable |

| Versatile applications | Higher cost compared to standard paper |

While PE coated paper has many benefits, it also comes with drawbacks. A significant limitation is its recycling difficulty. Standard recycling processes can’t handle PE coatings easily. This means that while the paper itself is recyclable, the PE layer complicates the recycling process. Hydro pulping is one method used, but it can introduce further environmental challenges.

Moreover, PE coated paper is generally non-biodegradable. The long decomposition time raises concerns about landfills and the overall impact on the environment. With growing awareness of sustainability, businesses face scrutiny regarding using products that harm the environment.

Cost Considerations and Thermal Limitations

Cost is another area where PE coated paper can be a disadvantage. Generally, it is more expensive than standard paper options. This higher price can deter some businesses from using it, especially if they operate on tight budgets. Also, the thermal limitations of PE coated paper mean it cannot withstand extremely high temperatures. Heat might compromise the integrity of the coating, which could lead to leaks, especially in hot food applications like takeaway boxes.

Flexibility, Durability, and Printability

| Jellemzők | Előnyök |

|---|---|

| Rugalmasság | Holds shape well for various formats |

| Tartósság | Suitable for heavy items in packaging |

| Nyomtathatóság | Vibrant colors for effective branding |

When it comes to branding, PE coated paper is hard to beat because of its flexibility és durability. It holds its shape well, making it suitable for various sizes and formats. For example, many manufacturers use it in fast-food wrappers and disposable trays, where flexibility is crucial.

Moreover, its printability allows for vibrant colors and quality graphics. This is vital for companies wanting to create appealing branding. A glossy finish accentuates printed graphics, making packaging catch the eye of consumers.

In summary, the balance between its many advantages and a few drawbacks makes PE coated paper a favored choice in food packaging and beyond. While its water and grease resistance are beneficial, its challenges in recycling and cost must also be considered. As companies strive for both quality and environmental responsibility, understanding these factors helps guide the decisions they make.

How Can PE Coated Paper Be Used Across Industries?

PE coated paper is a versatile material with a wide range of applications across different industries. Let's dive into how this material finds its place in food and beverages, pharmaceuticals, and beyond.

Élelmiszer- és italcsomagolás

In the food and beverage industry, PE coated paper shines brightly. It is widely used for making disposable cups, bowls, and wraps. This type of paper helps keep food fresh and maintains safety during transportation. Here’s a closer look at its benefits:

| Előnyök | Leírás |

|---|---|

| Vízállóság | Prevents moisture from seeping into food items |

| Grease Barrier | Effective for oily and greasy food packaging |

| Testreszabás | Allows for vivid branding and logos |

- Vízállóság: The coating acts as a barrier, preventing moisture from seeping in. This is crucial for food items that are prone to sogginess.

- Grease Barrier: PE coated paper stands up against oily and greasy foods. When you think of fast food burgers or fried food packaging, this material is often behind the scenes, doing its job.

PE coated paper is also excellent for customized packaging. Many brands choose this paper to showcase their logos and designs vividly. This not only enhances brand identity but also appeals to consumers who seek convenience.

Pharmaceutical and Health Industry

The pharmaceutical industry greatly relies on PE coated paper for various applications, particularly in packaging and sterilization wraps. Its role here cannot be underestimated:

| Alkalmazások | Felhasználások |

|---|---|

| Csomagolás | Keeps medical supplies sterile |

| Sterilization Wraps | Maintains sterility for surgical instruments |

- Csomagolás: It is essential for keeping medical supplies sterile. The moisture barrier ensures that nothing contaminates the contents inside.

- Sterilization Wraps: These wraps help maintain sterility for surgical instruments and other medical gear during storage and transport.

The use of PE coated paper in healthcare not only ensures protection but also complies with strict regulations around hygiene and safety.

Környezeti megfontolások

When discussing PE coated paper, environmental impact is a significant aspect to consider. Traditional polyethylene (PE) coatings raise questions about sustainability. However, alternative options are available:

- PLA bevonatok: Made from renewable sources like cornstarch, these are biodegradable and compostable under industrial conditions. They are suitable for hot and cold beverages but need special facilities to break down.

- Water-Based Coatings: These coatings do not contain plastic and are fully recyclable. However, while they offer eco-friendliness, they may provide less moisture resistance than PE.

The choice of coatings must align with both business goals and increasing consumer demand for eco-friendly options. Each alternative has its pros and cons.

Industry Case Studies

PE coated paper finds uses in a variety of industries beyond food and pharmaceuticals. Let’s take a look at some case studies to illustrate its broad applications:

-

Kiskereskedelem: Many retailers use PE coated paper for shopping bags, taking advantage of its durability. The bags can carry more weight while keeping contents safe from moisture.

-

Agriculture: PE coated paper plays a role in packaging seeds to protect them from the elements. It ensures farmers get high-quality seeds without damaging their viability.

-

Elektronika: For sensitive electronic products, PE coated paper is used in packaging to prevent moisture and dust from harming the items inside.

Each of these use-cases showcases how adaptable PE coated paper is, meeting specific needs across industries.

Testreszabási és márkaépítési lehetőségek

Customization is vital in ensuring that products stand out in the market. PE coated paper offers unique opportunities for branding:

- Nyomtatási minőség: This paper allows for vibrant prints, making it suitable for logos and marketing messages.

- Various Finishes: Brands can choose from glossy or matte finishes depending on their image. Glossy finishes tend to attract more attention, while matte finishes may suggest elegance.

Some companies produce unique packaging shapes using PE coated paper to enhance customer experience, making products more eye-catching on store shelves.

In conclusion, PE coated paper is much more than just a packaging material. It covers a wide range of uses across industries, offering essential benefits such as water resistance, grease barriers, and customization options. As the market evolves, the focus on sustainability will continue to reshape how industries utilize this essential material.

FAQs about Various Classifications of PE Coated Paper

What are the different types of PE coated paper?

PE coated paper is a versatile material used across various industries, and understanding the different types can help in selecting the right one for specific needs.

What are the properties and uses of single-side PE-coated paper?

Single-side PE-coated paper has a protective layer of polyethylene on one side, making it water-resistant and suitable for packaging items like snacks and fast food.

How does double-side PE-coated paper benefit the food packaging industry?

Double-side PE-coated paper offers increased moisture and grease resistance, and is ideal for packaging frozen foods, meat, and seafood by providing durability and a grease barrier.

What advantages does release liner PE-coated paper offer for adhesive applications?

Release liner PE-coated paper is specially designed for adhesive applications, facilitating easy release for labels and tapes, ensuring high-quality performance without tearing.

How do matte and glossy PE-coated papers differ in their applications?

Matte PE-coated paper features a non-reflective surface suitable for premium products and branding, while glossy PE-coated paper enhances color vibrancy, making it ideal for labels and promotional items.

PE-coated paper is versatile, useful, and found everywhere. We've explored single-side, double-side, and sandwich variations and their roles in packaging. Release liner paper works for labels, while matte and glossy finishes suit different needs. However, consider its environmental impact. While offering water resistance and durability, recycling PE-coated paper remains a challenge. Across industries like food and pharmaceuticals, PE-coated paper meets varied demands. Though not perfect, it bridges function and convenience across sectors. Choose it wisely, balancing its benefits and drawbacks for your specific needs.