PLA Coated Paper Benefits: What Are They?

How does PLA coated paper compare to traditional plastics?

What are the advantages of using biodegradable paper packaging?

- Paper cups for hot and cold beverages.

- Food boxes and take-out containers.

- Bags and wrappers for food packaging.

- Other potential applications (straws, plates, utensils).

Question Cluster:

- What are the common uses of PLA coated paper?

- What types of food packaging can be made with PLA coated paper?

H2: Production Process and Environmental Benefits of PLA

[Keyword Cluster]= PLA production process, environmental benefits of PLA, sustainable packaging solutions

- Definition of PLA and its composition.

- Process of producing PLA from renewable resources.

- Energy efficiency and reduction of greenhouse gas emissions.

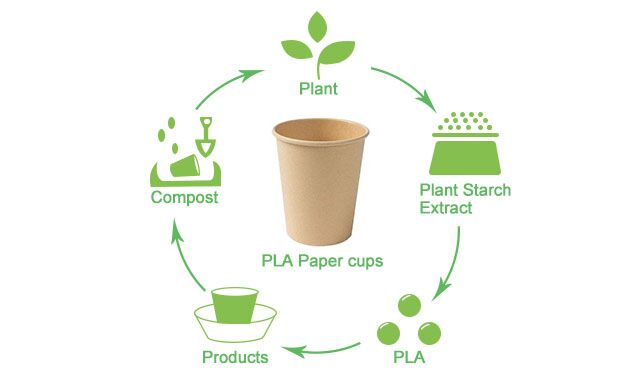

- Environmental benefits of PLA: biodegradability and compostability.

- Proper disposal guidelines for PLA products.

Question Cluster:

- How is PLA produced from renewable resources?

- What are the environmental benefits of using PLA?

- How should PLA products be disposed of properly?

H2: Limitations and Challenges of PLA Coated Paper

[Keyword Cluster]= Limitations of PLA coated paper, challenges of using biodegradable packaging

- Shelf life limitations and potential impact on food preservation.

- Composting requirements and availability of commercial composting infrastructure.

- Cost considerations and competitiveness compared to traditional plastics.

- Barrier limitations for certain packaging applications.

- Disposal challenges and impact on waste management.

Question Cluster:

- What are the limitations of PLA coated paper?

- What challenges are associated with using biodegradable packaging?

- How does PLA coated paper compare to traditional packaging materials in terms of cost and performance?

H2: Conclusion

- PLA coated paper offers a sustainable packaging solution with its biodegradability and compostability features.

- It is derived from renewable resources and complies with bio-standards and food safety regulations.

- While there are limitations and challenges, PLA coated paper has various applications and benefits for reducing environmental impact.

Review Summary:

- PLA coated paper is a sustainable packaging solution made from renewable resources like corn starch.

- It offers several benefits, including being biodegradable, compostable, and safe for food contact.

- PLA coated paper has various applications in food packaging and offers water resistance and durability.

- The production process of PLA involves converting carbohydrates into lactic acid, which is then polymerized.

- PLA has lower energy consumption and greenhouse gas emissions compared to traditional plastics.

- Proper disposal and composting facilities are required for PLA to biodegrade effectively.

- Despite limitations and challenges, PLA coated paper is a viable option for reducing environmental impact and promoting sustainable packaging solutions.

H2: How is PLA Coated Paper Made?

PLA coated paper is a sustainable packaging solution that offers numerous benefits. To understand its advantages, it’s important to first know how it is made. The process of manufacturing PLA coated paper involves several steps.

Base Paper Types Used

The production of PLA coated paper starts with selecting a suitable base paper. Different types of base paper can be used, including kraft paper, white paper, and bamboo paper. These papers serve as the foundation for the PLA coating to be applied.

Melting and Applying the PLA Film Layer

Once the base paper is chosen, the next step is to melt the PLA material into a film layer. PLA, or polylactic acid, is a biodegradable and compostable polymer derived from renewable sources like corn starch. The PLA pellets are heated until they reach a molten state.

The molten PLA is then applied to the base paper using a variety of techniques, such as extrusion coating or hot-melt coating. The thickness of the PLA film layer may vary depending on the desired application and requirements.

Laminating Process for Water Resistance

To enhance the water resistance of the PLA coated paper, a laminating process is often employed. This process typically involves applying a thin layer of a water-resistant material, such as a polyethylene barrier, to the PLA film layer. Lamination helps to create a barrier that prevents the transfer of liquids, ensuring the paper remains durable and water-resistant.

Cooling and Setting to Form Durable, Water-Resistant Paper

After the PLA and lamination processes, the coated paper goes through a cooling and setting phase. This allows the PLA and laminating materials to solidify, forming a durable and water-resistant layer on the base paper.

The cooling and setting process ensures that the PLA coated paper maintains its structural integrity and water resistance. It also allows the paper to be easily handled and converted into various packaging products, such as cups, takeaway containers, boxes, and more.

In conclusion, PLA coated paper is made by selecting a base paper, melting and applying a PLA film layer to the paper, laminating it for water resistance, and then cooling and setting the coated paper to achieve durability and water resistance. This manufacturing process ensures that the final product is an environmentally friendly, biodegradable, and compostable alternative to traditional plastic-coated paper.

H2: Benefits of PLA Coated Paper

PLA coated paper offers numerous benefits that make it a sustainable packaging solution for various industries. From its environmental friendliness to its performance advantages, here are some of the key benefits of using PLA coated paper:

- Environmental friendliness: One of the most significant benefits of PLA coated paper is its environmental friendliness. PLA is derived from renewable resources such as corn starch and sugarcane, making it a more sustainable alternative to petroleum-based plastics. PLA coated paper is also biodegradable and compostable, reducing landfill waste and minimizing its impact on the environment.

- Food safety: PLA coated paper is compliant with FDA regulations and bio-standards, ensuring that it is safe for food contact. It is free of harmful chemicals and does not leach any toxic substances into the food, making it a reliable choice for food packaging applications.

- Performance benefits: PLA coated paper offers excellent performance benefits compared to traditional paper and plastic packaging materials. It provides water resistance, preventing moisture from seeping through and compromising the integrity of the packaging. The PLA coating also enhances the durability of the paper, ensuring that it can withstand the rigors of handling and transportation.

- Lower carbon footprint: PLA coated paper has a lower carbon footprint compared to traditional plastics. The production of PLA requires less energy and generates fewer greenhouse gas emissions, contributing to a more sustainable and eco-friendly packaging solution.

- Versatility for different applications: PLA coated paper is versatile and can be used for various packaging applications. It is commonly used for items such as cups, containers, and wrappers, where a moisture barrier is necessary to keep the food fresh and prevent spoilage. Its adaptability makes it a suitable choice for a wide range of industries, including food service, hospitality, and retail.

Table 1: Applications of PLA Coated Paper

| Application | Description |

|---|---|

| Paper cups for hot and cold beverages | PLA coated paper cups are commonly used for serving hot and cold beverages. They provide a sustainable alternative to traditional plastic or foam cups. |

| Food boxes and take-out containers | PLA coated paper is used for making food boxes and take-out containers. It offers water resistance and helps to keep the food fresh during transportation. |

| Bags and wrappers for food packaging | PLA coated paper can be used for making bags and wrappers for food packaging. It provides a moisture barrier and helps to prevent food spoilage. |

| Other potential applications (straws, plates, utensils) | PLA coated paper can also be used for making other food service items such as straws, plates, and utensils. It offers a sustainable alternative to single-use plastic items. |

Table 2: Environmental Benefits of PLA Coated Paper

| Benefit | Description |

|---|---|

| Renewable resources | PLA coated paper is made from renewable resources such as corn starch and sugarcane. It reduces the dependency on fossil fuels. |

| Biodegradability and compostability | PLA coated paper is biodegradable and compostable, meaning it can break down into natural elements in composting facilities. This reduces landfill waste and environmental impact. |

| Reduced carbon footprint | The production of PLA coated paper requires less energy and generates fewer greenhouse gas emissions compared to traditional plastics. It helps to mitigate climate change. |

| Sustainable packaging solution | PLA coated paper offers a sustainable alternative to petroleum-based plastics. It helps to reduce the overall environmental impact of packaging materials. |

Please note that Markdown formatting may not be directly compatible with WordPress blogs. You may need to adjust the formatting or use a WordPress plugin to ensure the images display correctly. Additionally, for the tables, you can copy and paste the Markdown code into a Markdown table generator to generate the final HTML code that can be used in WordPress.

FAQs about PLA Coated Paper Benefits

Q: What are the common uses of PLA coated paper?

A: Common uses of PLA coated paper include paper cups for hot and cold beverages, food boxes, take-out containers, and bags and wrappers for food packaging.

Q: What types of food packaging can be made with PLA coated paper?

A: Types of food packaging that can be made with PLA coated paper include cups, containers, boxes, and wrappers that require a moisture barrier to keep food fresh and prevent spoilage.

Q: How is PLA produced from renewable resources?

A: PLA is produced from renewable resources by converting carbohydrates, typically from corn starch or sugarcane, into lactic acid, which is then polymerized to form PLA.

Q: What are the environmental benefits of using PLA?

A: The environmental benefits of using PLA include its biodegradability, compostability, lower carbon footprint, and reduced greenhouse gas emissions during production compared to traditional plastics.

Q: What are the limitations of PLA coated paper?

A: Limitations of PLA coated paper include a shorter shelf life, specific composting requirements, higher costs compared to traditional plastics, and certain barrier limitations for specific packaging applications.

PLA coated paper is a biodegradable, eco-friendly packaging option that balances sustainability and functionality. By understanding its origins, production process, and benefits, we realize its potential to replace traditional plastics. PLA coated paper stands out with its water resistance, durability, and lower carbon footprint. It is also safe for food use, meeting various bio-standards. Choose PLA coated paper for a better, greener future. It’s a small change with a big impact.