What are the Types of Offset Paper Available?

Types of Offset Paper: A Comprehensive Guide

Introduction

When it comes to offset printing, choosing the right type of paper is crucial to achieve desired printing results. Offset printing is a widely used printing technique that involves transferring ink from a plate to paper via a rubber cylinder. Different types of offset paper are available, each with its own unique characteristics and applications. In this comprehensive guide, we will explore the various types of offset paper, their features, and the impact of paper choice on printing results.

Section 1: Coated Offset Paper

Coated offset paper is a popular choice for many printing projects. It is characterized by a smooth, glossy, or matte finish that enhances the appearance of printed images and text. The coating applied to the paper surface affects ink absorption and sharpness of prints. There are two main types of coated offset paper: gloss-coated and matte-coated.

Gloss-coated paper provides a high shine and excellent color vibrancy. It is commonly used in brochures, catalogs, and high-quality prints. On the other hand, matte-coated paper offers a subtle shine and a textured feel. It is often used in applications where reduced glare and writability are important, such as magazines and books.

When choosing coated offset paper, it is important to consider factors such as print project requirements, desired visual appeal, and budget constraints. Gloss-coated paper is ideal for making images and text stand out, while matte-coated paper provides a more subdued and sophisticated look. The choice between gloss and matte coating depends on the desired aesthetic and intended use of the printed material.

Section 2: Uncoated Offset Paper

Uncoated offset paper, as the name suggests, lacks the smooth coating found on coated papers. It has a rougher, more natural texture that is suitable for applications where writability and a tactile feel are important. Uncoated paper is commonly used in publications that require extensive text, such as newspapers and magazines.

Uncoated paper allows for printing and stamping on both sides, making it versatile for various office needs. It is recommended for office stationery such as envelopes, letterheads, notepads, and desk pads. The coarse structure of uncoated paper also makes it suitable for writing with various pens and stamping.

When selecting uncoated offset paper, consider the required paper weight for your printing project. Heavier weights result in sturdier paper, while lighter weights are suitable for easy distribution. Uncoated paper offers a more natural and organic feel compared to coated papers, making it a popular choice for eco-conscious individuals and businesses.

Section 3: Paper Weights and Sizes for Offset Printing

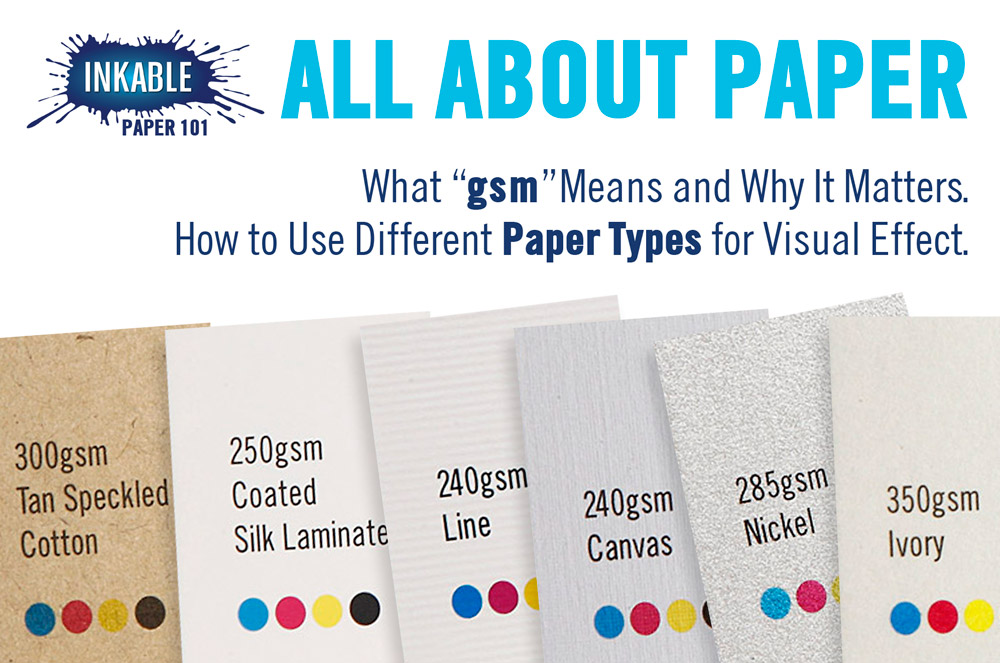

In offset printing, paper weight is an important consideration as it affects durability, printing quality, folding, creasing, and visual appeal. Paper weight is typically measured in grams per square meter (gsm). It is crucial to select the appropriate paper weight based on the specific requirements of the print project.

For brochures and catalogs, paper weights ranging from 60-100 gsm are commonly used. Business cards often require heavier paper weights, ranging from 100-200 gsm, to ensure durability. High-quality prints, such as art prints or posters, may require paper weights of 200 gsm or higher to achieve optimal results.

In addition to paper weight, it is also important to consider the standard paper sizes for offset printing. Common paper sizes include A4 (8.27" x 11.69"), A5 (5.83" x 8.27"), and letter-size (8.5" x 11") for international and North American markets. By selecting the appropriate paper size, you can optimize sheet usage and reduce costs.

To summarize, the choice of offset paper has a significant impact on printing results, color accuracy, and ink absorption. Coated papers offer enhanced color vibrancy, while uncoated papers provide a more natural feel with better writability. Different paper weights and sizes are suitable for various print materials, with heavier weights ensuring durability and lighter weights facilitating easy distribution. By understanding the characteristics of different types of offset paper and selecting the right one for your printing project, you can achieve the desired visual appeal and printing quality.

FAQs about Coated and Uncoated Offset Paper

How does the coating affect the characteristics of offset paper?

In offset paper, the coating affects characteristics like texture, ink absorption, and appearance, impacting the overall print quality.

What are the benefits of using coated offset paper?

Coated offset paper enhances color vibrancy, reduces show-through, and provides protection against moisture and smudging, resulting in high-quality prints.

What are the differences between gloss-coated and matte-coated papers?

Gloss-coated paper offers a high shine and vibrant colors, while matte-coated paper provides a subtle shine and a textured feel, catering to different aesthetic preferences.

What are the advantages of using uncoated offset paper?

Uncoated paper offers benefits such as writability, a natural appearance, enhanced ink absorption, quick drying, and environmental friendliness.

How can designers optimize their designs for printing on uncoated paper?

Designers can optimize their designs for uncoated paper by considering the texture, selecting high-quality inks, allowing for sufficient drying time, choosing the right paper weight, and performing test prints for quality assurance.

In summary, we explored Coated and Uncoated Offset Paper types. Choosing right paper crucial. Coating impacts print quality; Uncoated paper offers different advantages. Consider paper weight for durability. Match paper weight and size to printing needs to enhance results. Understanding paper types key to successful printing projects.