What Are the PLA Coated Paper Properties?

What Are the Key Properties of PLA Coated Paper?

PLA coated paper is a versatile and environmentally friendly material widely used in food packaging and other industries. Its key properties contribute to its popularity and make it a preferred choice for businesses looking for sustainable packaging solutions. In this section, we will explore the physical, chemical, mechanical, and thermal properties of PLA coated paper.

Physical Properties of PLA Coated Paper

PLA coated paper exhibits several physical properties that make it suitable for a range of applications.

Thickness and Density

PLA coated paper is available in various thicknesses to cater to different packaging needs. The thickness of the PLA coating can affect the paper’s overall strength and durability. The density of PLA coated paper is typically higher than traditional paper, providing added rigidity and stability.

Surface Smoothness

One of the notable characteristics of PLA coated paper is its smooth surface. The PLA coating creates a glossy and uniform finish, enhancing the overall aesthetic appeal of the packaging. The smooth surface also facilitates the printing process and ensures high-quality graphics and branding.

Optical Clarity and Gloss

PLA coated paper offers excellent optical clarity, allowing consumers to see the products inside the packaging. This property is particularly desirable for food packaging, where product visibility is essential. Additionally, the PLA coating provides a glossy finish, further enhancing the packaging’s visual appeal.

Chemical Properties of PLA Coated Paper

The chemical properties of PLA coated paper play a crucial role in determining its suitability for different applications.

Chemical Composition and Structure of PLA

PLA (polylactic acid) is a biodegradable and compostable polymer derived from renewable resources such as corn starch and sugarcane. The PLA coating on the paper provides water resistance and acts as a protective barrier against oils, greases, and solvents.

Resistance to Oils, Greases, and Solvents

PLA coated paper demonstrates good resistance to oils, greases, and solvents commonly found in food products. It prevents these substances from permeating through the packaging and compromising the quality and safety of the contents. This property ensures that the packaged products remain fresh and intact.

Impact of pH Levels

PLA coated paper is generally resistant to a wide range of pH levels. It can withstand both acidic and alkaline environments without any adverse effects on the paper’s integrity or the packaged contents. This property makes PLA coated paper suitable for packaging a variety of food and beverage products.

Mechanical Properties of PLA Coated Paper

The mechanical properties of PLA coated paper determine its strength, durability, and overall performance in different packaging applications.

Tensile Strength and Elasticity

PLA coated paper exhibits good tensile strength, which refers to its ability to withstand pulling forces without tearing or breaking. It can withstand a certain amount of stretching and deformation without compromising its structural integrity.

Tear Resistance and Durability

The tear resistance of PLA coated paper ensures that the packaging remains intact even under challenging conditions. This property prevents accidental tears and damages, providing reliable protection for the packaged products. PLA coated paper is known for its durability, allowing it to withstand the rigors of handling and transportation.

Folding Endurance

PLA coated paper has excellent folding endurance, enabling it to withstand repeated folding and unfolding without cracking or breaking. This property is particularly important for applications that require frequent opening and closing, such as takeout containers and food wrappers.

Thermal Properties

The thermal properties of PLA coated paper determine its suitability for different temperature conditions.

Temperature Thresholds for Safe Usage

PLA coated paper is suitable for a wide range of temperature conditions. It can withstand cold temperatures as low as -18℃, making it ideal for frozen food packaging and cold storage applications. For short durations, PLA coated paper can also handle temperatures up to 95℃ without compromising its structural integrity.

Thermal Degradation

Like other PLA materials, PLA coated paper undergoes thermal degradation at higher temperatures. It is important to ensure that the packaging remains within the recommended temperature limits to avoid any significant degradation that may affect its performance.

In summary, PLA coated paper exhibits desirable physical, chemical, mechanical, and thermal properties that make it an excellent choice for various packaging applications. Its eco-friendly nature, combined with its exceptional performance, makes it a sustainable and practical solution for businesses looking to reduce their environmental impact while maintaining high-quality packaging.

How Sustainable Is PLA Coated Paper Compared to Other Materials?

With increasing concerns about the environmental impact of plastic products, the demand for sustainable alternatives has been on the rise. One such alternative is PLA coated paper, which offers a promising solution for reducing plastic waste. In this section, we will explore the sustainability of PLA coated paper compared to other materials, taking into consideration its biodegradability and compostability, eco-friendly composition, comparison to other coatings, and recyclability and disposal methods.

Biodegradability and Compostability

One of the key advantages of PLA coated paper is its biodegradability and compostability. PLA, or polylactic acid, is a biodegradable polymer derived from renewable resources like corn starch and sugarcane. When PLA coated paper is disposed of in a composting environment, it undergoes a natural degradation process and breaks down into carbon dioxide, water, and organic matter within 6 to 12 months.

To ensure that PLA products meet certain standards, certification systems such as EN13432 and ASTM D6400 have been established. These standards specify the criteria for compostability, including the required time frame and the absence of any toxic residues after decomposition. Compliance with these standards ensures that PLA coated paper is environmentally friendly and contributes to reducing landfill waste.

Eco-Friendly Composition

The eco-friendly composition of PLA coated paper sets it apart from traditional materials like polyethylene (PE) and polypropylene (PP). PLA is derived from renewable resources, such as corn starch and sugarcane, making it a more sustainable choice compared to petroleum-based plastics.

Additionally, PLA has a lower carbon footprint compared to traditional coatings. The production of PLA requires less energy and emits fewer greenhouse gases, reducing its environmental impact. A lifecycle analysis of PLA coated paper has shown that it performs favorably in terms of sustainability, making it an attractive option for eco-conscious consumers and businesses.

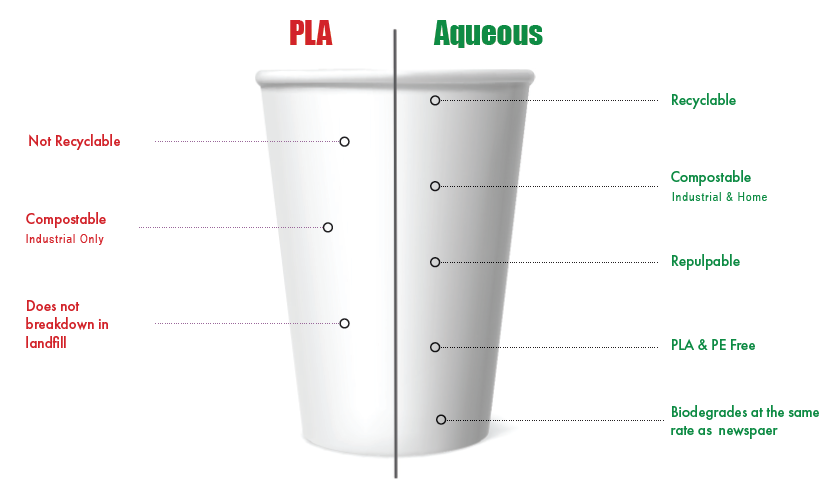

Comparison to Other Coatings

When comparing PLA coated paper to other coatings, it’s important to consider the overall environmental impacts. PE and PP, the most commonly used materials for coatings, have significant drawbacks in terms of sustainability.

PE is a non-biodegradable material that can persist in the environment for hundreds of years. Its production relies on fossil fuels, contributing to carbon emissions and non-renewable resource consumption. On the other hand, PP, while partially recyclable, still has limitations in terms of degradability.

In contrast, PLA coated paper offers a more sustainable alternative. It is biodegradable and compostable, reducing the accumulation of plastic waste in landfills. Additionally, PLA coated paper has a smaller carbon footprint during production, further contributing to its environmental benefits.

Recyclability and Disposal

While PLA coated paper offers significant advantages in terms of biodegradability and compostability, recycling presents some challenges. PLA cannot be recycled in the same way as traditional paper or plastic. When PLA products end up in recycling streams, they can contaminate the recycling process for other materials.

To address this issue, a separate recycling stream for PLA products is required. Some companies and municipalities have implemented specialized recycling facilities that can effectively process PLA products. However, widespread infrastructure for PLA recycling is still limited, making proper disposal through composting the preferred method for achieving environmental benefits.

Industrial composting facilities are equipped to handle PLA products effectively. These facilities provide the necessary conditions for PLA to degrade into harmless substances within a specific time frame. It’s important to note that PLA products should not be composted in home composting systems, as they require higher temperatures and specific conditions not typically found in residential compost piles.

In summary, PLA coated paper offers a sustainable alternative to traditional coatings in terms of biodegradability, compostability, and eco-friendly composition. While recycling PLA products presents challenges, proper disposal through industrial composting facilities ensures the environmental benefits of this material. As awareness of the importance of sustainability grows, PLA coated paper has the potential to play a crucial role in reducing plastic waste and promoting a more environmentally friendly future.

What Are the Applications and Benefits of Using PLA Coated Paper?

Food Packaging Applications

PLA coated paper is widely used in various food packaging applications. It provides excellent water resistance, durability, and safety for direct food contact. Some common food packaging uses of PLA coated paper include:

- Paper cups: PLA coated paper cups are a popular choice for hot and cold beverages. They are sturdy, leak-proof, and can withstand temperatures up to 95℃.

- Takeaway containers: PLA coated paper is ideal for takeaway containers as it provides a moisture barrier and helps keep food fresh. It is also suitable for microwave use.

- Food trays, wrappers, and labels: PLA coated paper can be used for food trays for items like fruits, vegetables, and baked goods. Additionally, it can be used as wrappers and labels on food products, providing both functionality and branding opportunities.

Suitability for Various Temperatures

PLA coated paper has the advantage of being suitable for a wide range of temperatures. It can safely be used in both cold storage and short-duration hot applications. Some temperature-related uses of PLA coated paper include:

- Cold storage uses: PLA coated paper can withstand temperatures as low as -18℃, making it suitable for frozen food packaging and storage.

- Short-duration hot uses: PLA coated paper can be used for packaging hot food items, such as freshly cooked meals, for a short duration of time. It can withstand temperatures up to 95℃ without compromising its integrity.

Benefits of PLA Coated Paper

PLA coated paper offers several benefits that make it a preferred choice in the packaging industry.

- Water resistance and durability: PLA coated paper provides excellent water resistance, ensuring that the packaging remains intact even in moist environments. It also offers durability, preventing leaks and maintaining the freshness of the food.

- Safety for direct food contact: PLA coated paper is approved for direct food contact by regulatory bodies such as the FDA (Food and Drug Administration) and EU (European Union). It does not contain any harmful chemicals, making it safe for use with food.

- Low carbon footprint and emissions during production: PLA coated paper is considered more environmentally friendly compared to traditional petroleum-based coatings. PLA is derived from renewable resources such as corn starch and sugarcane, reducing reliance on non-renewable resources. The production of PLA also emits fewer greenhouse gases, contributing to lower carbon emissions.

Commercial and Industrial Uses

In addition to food packaging, PLA coated paper offers versatility for commercial and industrial uses. Its properties make it adaptable for different shapes and sizes, making it suitable for various products. Some commercial and industrial uses of PLA coated paper include:

- Adaptability for different shapes and sizes: PLA coated paper can be easily molded and shaped to fit different packaging requirements. It is compatible with various forms like cups, boxes, bags, and wrappers, offering design flexibility.

- Branding and customization potential: PLA coated paper can be printed on, allowing for branding and customization. Companies can showcase their logos, designs, and product information on the packaging, enhancing brand visibility and consumer appeal.

In summary, PLA coated paper has a wide range of applications in the food packaging industry and beyond. Its benefits include water resistance, durability, food safety, low environmental impact, adaptability, and branding potential. With its versatility and eco-friendly properties, PLA coated paper is a sustainable choice for many businesses seeking packaging solutions.

FAQs about PLA Coated Paper Properties:

What are the physical properties of PLA coated paper?

A: The physical properties of PLA coated paper include various thicknesses, a smooth surface, and excellent optical clarity and gloss.

How does PLA coated paper provide chemical resistance?

A: PLA coated paper provides chemical resistance through its biodegradable and compostable PLA coating, which protects against oils, greases, and solvents.

What mechanical properties does PLA coated paper exhibit?

A: PLA coated paper exhibits mechanical properties such as high tensile strength, tear resistance, and excellent folding endurance.

How does PLA coated paper perform under different temperatures?

A: PLA coated paper can withstand temperatures ranging from as low as -18℃ to short-duration exposures up to 95℃.

Is PLA coated paper considered environmentally sustainable?

A: PLA coated paper is environmentally sustainable due to its biodegradability, compostability, eco-friendly composition, and lower carbon footprint compared to traditional coatings.

PLA coated paper boasts incredible physical, chemical, and mechanical properties, making it ideal for various applications. Its biodegradability, eco-friendly composition, and recycling options surpass traditional materials. From safe food packaging to durable industrial uses, PLA paper stands out. My final thoughts? PLA coated paper not only offers versatility but also supports environmental sustainability. It’s a smart, responsible choice for today’s needs.