Is High-Performance Specialty Paper the Right Choice for You?

Characteristics and Types of High-Performance Specialty Paper

High-performance specialty paper is a unique type of paper that stands out from typical office or printing paper. It possesses specific characteristics that make it suitable for a wide range of applications and industries. In this section, we will explore the key characteristics of high-performance specialty paper, the different types available, and how these characteristics impact its uses and applications. We will also discuss the benefits of using high-performance specialty paper for specific projects.

Key Characteristics of High-Performance Specialty Paper

High-performance specialty paper is designed to meet specific performance requirements achieved through manufacturing processes or the addition of specific materials. Some of the key characteristics of high-performance specialty paper include:

- Waterproof: Specialty papers with waterproof properties are commonly used in applications where exposure to moisture or liquids is expected. These papers are resistant to water damage, ensuring durability and reliability.

- Oil-Proof: Certain specialty papers are treated with coatings that make them resistant to oil and grease. These papers are commonly used in the food service industry for applications like packaging and wrappers.

- High-Temperature Resistant: Specialty papers that can withstand high temperatures are utilized in applications where heat resistance is crucial. These papers maintain their structural integrity even under extreme temperature conditions.

- Flame-Retardant: Flame-retardant specialty papers are treated with materials that inhibit the spread of flames. They are commonly used in industries where fire safety is a priority, such as construction and manufacturing.

- High-Strength: Some specialty papers possess exceptional strength and durability. These papers can withstand heavy usage, making them suitable for applications that require robust performance and longevity.

- Translucency: Translucent specialty papers offer superior translucency, allowing light to pass through while providing an elegant and delicate appearance. These papers are commonly used in applications such as brochures, business cards, and invitations.

- Gloss Surface: Specialty papers with a mirror-like gloss surface provide a luxurious and high-quality appearance. These papers are often used in applications where visual appeal is essential, such as folders, packaging, and greeting cards.

These characteristics make high-performance specialty paper suitable for a variety of industries and applications, including consumer goods, industrial products, building materials, commercial printing, and high-tech applications. The wide range of properties ensures that there is a specialty paper available to meet the diverse needs of different projects.

Different Types of Specialty Paper Available

Now that we understand the key characteristics of high-performance specialty paper, let's explore the different types that are available in the market. Each type of specialty paper offers unique properties and characteristics, making them suitable for specific applications. Here are some types of specialty paper commonly used:

- ASPIRE Petallics: This two-sided metallic paper and envelope line is inspired by continent petals and metals. It is ideal for brochures, business cards, invitations, and various graphic design projects. ASPIRE Petallics specialty paper is compatible with printing methods such as offset lithography, thermography, flexographic printing, letterpress, gravure, and more.

- Currency Metallic Specialty Paper: Available in gold and silver, currency metallic specialty paper adds a touch of elegance to brochures, business cards, and graphic design projects. It offers both aesthetic appeal and durability, making it a popular choice for high-end applications.

- Glama Natural: Glama Natural is a natural translucent paper with superior translucency and foldability. It is commonly used in applications such as brochures, business cards, invitations, and graphic design projects. Glama Natural specialty paper is compatible with printing methods like offset lithography, screen printing, foil stamping, and more.

- Glama Kraft: Glama Kraft is a printable Kraft paper made from 100% recycled content. It is ideal for various projects, including brochures, business cards, and packaging. With its sustainable and eco-friendly properties, Glama Kraft is a popular choice for environmentally conscious projects.

- Kromekote®: Kromekote® specialty paper is known for its mirror-like gloss surface. It offers exceptional printability and is suitable for applications that require a high level of visual appeal, such as folders, packaging, greeting cards, and more. Kromekote® specialty paper is compatible with printing methods like offset lithography, foil stamping, screen printing, and more.

- Pixelle Specialty Papers: Pixelle offers a comprehensive portfolio of specialty papers designed to cater to various markets and specific project needs. Their specialty papers undergo a meticulous process, from the lumber yard to the final packaging, ensuring the highest quality and performance. Pixelle also focuses on sustainability and offers innovative barrier coating technologies for sustainable packaging solutions, such as blocking grease, retaining liquids, sealing aromas, and replacing plastic with renewable substrates.

- Release-Treated Candy Cup Paper: Specialty papers like release-treated candy cup paper are designed for niche food service applications. These papers are treated to be fluted and are available in multiple color options. They are commonly used for candy cups and provide the necessary strength and functionality for food packaging.

These are just a few examples of the different types of high-performance specialty papers available in the market. Each type offers distinct characteristics and features that make them suitable for specific applications. When selecting specialty paper for a project, it is essential to consider the desired properties and performance requirements to ensure optimal results.

Impact of Specialty Paper Characteristics on Uses and Applications

The unique characteristics of specialty paper have a significant impact on its uses and applications. The specific properties of specialty paper make it ideal for various industries and projects. Here are some examples of how the characteristics of specialty paper impact its applications:

- Food Packaging: Specialty papers that are waterproof, oil-proof, and heat-resistant are commonly used in food packaging applications. These papers provide a protective barrier against moisture, grease, and high temperatures, ensuring the food's freshness and integrity.

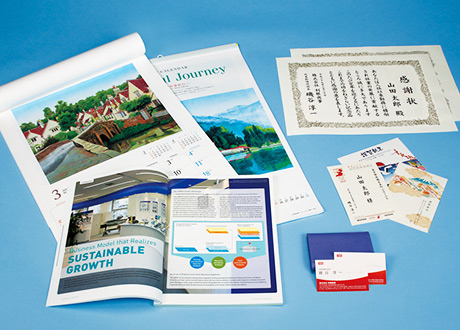

- Graphic Design Projects: Translucent and glossy specialty papers are often used in graphic design projects to create visually appealing brochures, business cards, invitations, and other promotional materials. These papers enhance the overall aesthetic and make a strong impression on the target audience.

- High-Tech Applications: High-performance specialty papers with specialized coatings and properties are used in high-tech applications that require extreme durability, water resistance, and heat resistance. These papers are commonly found in industries such as aerospace, automotive, and electronics.

- Sustainable Packaging: Specialty papers that focus on sustainability and innovativeness are widely used in sustainable packaging solutions. These papers offer eco-friendly alternatives to traditional plastic packaging, contributing to environmental preservation and reducing waste.

The characteristics of high-performance specialty paper play a crucial role in determining its suitability for specific projects and industries. Understanding these characteristics enables users to select the right paper for their needs, ensuring optimal performance and desired outcomes.

Benefits of Using High-Performance Specialty Paper

Using high-performance specialty paper for specific projects offers several benefits. Here are some advantages of utilizing high-performance specialty paper:

- Enhanced Durability: Specialty papers are designed to withstand various environmental conditions and provide superior durability compared to regular office or printing paper. This means that your project will be able to withstand heavy usage, wear and tear, and external factors that could potentially damage the paper.

- Improved Aesthetics: Specialty papers come in a wide range of finishes, colors, and textures, allowing you to create visually appealing and attention-grabbing products. Whether you are designing brochures, business cards, or packaging, specialty paper adds a touch of luxury and sophistication to your project.

- Customization Options: Specialty papers offer customization options, allowing you to choose the specific properties and finishes that best suit your project's requirements. Whether you need a specific level of translucency or a particular color, specialty paper can be tailored to meet your unique needs.

- Environmental Sustainability: Many specialty papers are produced using sustainable practices and renewable resources. By using high-performance specialty paper, you can contribute to environmental preservation and support sustainable packaging solutions.

- Versatility: High-performance specialty paper is suitable for a wide range of applications across various industries. Whether you are in the food industry, graphic design field, or high-tech sector, specialty paper can meet your specific requirements and enhance your project's performance.

By utilizing high-performance specialty paper, you can achieve superior results in your projects, elevate your brand's image, and cater to specific industry requirements.

In conclusion, high-performance specialty paper offers unique properties and characteristics that make it suitable for various applications and industries. Understanding the key characteristics of specialty paper, the different types available, and how these characteristics impact its uses and applications is essential for selecting the right paper for your specific projects. By utilizing high-performance specialty paper, you can enhance durability, improve aesthetics, customize your products, support sustainability, and achieve versatile results. So, next time you embark on a project that requires exceptional performance and distinct visual appeal, consider using high-performance specialty paper.

Throughout this section, we have explored the key characteristics and types of high-performance specialty paper, discussed how these characteristics impact its uses and applications, and highlighted the benefits of using high-performance specialty paper for specific projects. In the next section, we will delve into the applications and best practices for using high-performance specialty paper, providing insights into how to effectively utilize specialty paper in different scenarios.

Applications and Best Practices for High-Performance Specialty Paper

High-performance specialty paper offers unique properties and characteristics that make it a versatile choice for a variety of applications. From graphic design projects to commercial printing and packaging, specialty paper can elevate the quality and aesthetics of any project. In this section, we will explore some common applications of high-performance specialty paper and provide best practices for using it effectively.

Common Applications of High-Performance Specialty Paper

High-performance specialty paper finds its application in various industries, including graphic design, commercial printing, packaging, and more. Here are some common applications:

- Brochures and Flyers: High-performance specialty paper is often used for creating eye-catching brochures and flyers. The unique textures, finishes, and colors of specialty paper can help businesses stand out and make a lasting impression on potential customers.

- Business Cards: Specialty paper can add a touch of elegance and professionalism to business cards. With options like metallic finishes or textured surfaces, specialty paper can make business cards more memorable and visually appealing.

- Invitations: Whether it's for weddings, parties, or corporate events, specialty paper is a popular choice for creating stunning invitations. Its unique textures and finishes can add a touch of sophistication and elegance to any special occasion.

- Packaging: Specialty paper is also widely used in the packaging industry. Its durability, strength, and ability to withstand various printing techniques make it perfect for product packaging, gift boxes, and retail displays.

Best Practices for Using Specialty Paper in Graphic Design Projects

When using specialty paper in graphic design projects, it's important to consider the following best practices:

- Understand the Project Requirements: Before selecting a specialty paper, it's crucial to understand the project requirements. Consider factors like budget, printing method, desired visual effects, and the overall theme or concept of the project.

- Choose the Right Paper Weight: Specialty papers come in various weights, and selecting the right weight is essential to achieve the desired effect. Lighter weights are ideal for projects like brochures or flyers, while heavier weights work well for business cards or packaging.

- Consider the Printing Method: Different types of specialty paper require specific printing methods to ensure the best results. It's important to consult with a printing professional to determine the recommended printing method for the chosen specialty paper.

- Experiment with Textures and Finishes: One of the advantages of specialty paper is the wide range of textures and finishes available. Experimenting with different textures and finishes can help create unique and visually appealing designs. Consider options like metallic, matte, glossy, or embossed textures based on the project requirements.

Recommended Printing Methods for Different Types of Specialty Paper

The choice of printing method can significantly impact the final result when working with specialty paper. Here are some recommended printing methods for different types of specialty paper:

- Offset Lithography: Offset lithography is a commonly used printing method for specialty paper. It provides high image quality and works well with a wide range of specialty papers, including metallic, translucent, or textured finishes.

- Foil Stamping: Foil stamping is an excellent option for adding metallic accents or logos to specialty paper. It creates a luxurious and eye-catching effect, making it ideal for high-end packaging or business cards.

- Screen Printing: Screen printing is suitable for specialty papers that require vibrant and opaque colors. It works well on textured papers and can create unique effects that traditional printing methods cannot achieve.

- Letterpress: Letterpress printing is a traditional method that involves pressing ink into specialty paper using a printing press. It creates an elegant and tactile effect, making it popular for wedding invitations or high-quality stationery.

- Embossing and Debossing: Embossing and debossing are techniques used to create raised or recessed patterns on specialty paper. These techniques add depth and texture to the design, making it visually appealing and engaging.

Selecting the Right Specialty Paper for Specific Projects and Needs

Choosing the right specialty paper for a specific project requires careful consideration of various factors. Here are some key points to keep in mind:

- Project Requirements: Understand the specific requirements of the project, including budget, printing method, durability, and desired visual effects.

- Paper Type: Consider the different types of specialty paper available, such as metallic, translucent, textured, or coated paper. Each type has its own unique properties and characteristics that can enhance the overall design.

- Color and Finish: Select the color and finish of the specialty paper based on the desired aesthetic and brand image. Consider options like vibrant colors, metallic finishes, or matte textures to suit the project.

- Paper Weight: Choose the appropriate paper weight based on the project requirements. Lighter weights are suitable for projects like brochures or flyers, while heavier weights are ideal for business cards or packaging.

- Environmental Considerations: Consider the environmental impact of the specialty paper. Look for papers that are made from sustainable sources and have recognized certifications for environmental stewardship.

By following these best practices and considering the specific requirements of each project, you can effectively utilize high-performance specialty paper to create visually stunning and impactful designs. Whether it's for graphic design, packaging, or promotional materials, specialty paper offers endless possibilities for creating unique and memorable experiences.

Sustainability and Innovation in High-Performance Specialty Paper

Specialty paper is known for its unique properties and high-performance capabilities. In addition to these characteristics, the industry has also made significant strides in sustainability and innovation. In this section, we will explore how high-performance specialty papers contribute to sustainable packaging solutions, the innovative technologies used in their production, the environmental certifications consumers should look for, and how the quality of specialty paper impacts its environmental impact.

How do high-performance specialty papers contribute to sustainable packaging solutions?

Sustainable packaging has become a priority for many businesses and consumers. High-performance specialty papers play a crucial role in providing sustainable packaging solutions. These papers are often made from renewable resources, such as responsibly sourced wood pulp or recycled fibers. They are also produced using eco-friendly manufacturing processes that minimize waste and reduce the use of harmful chemicals. By using high-performance specialty papers for packaging, companies can reduce their carbon footprint and contribute to a more sustainable future.

One example of sustainable packaging made possible by high-performance specialty paper is the use of barrier coatings. These coatings can replace traditional plastic laminates, making the packaging fully recyclable and reducing the amount of non-biodegradable waste. Barrier coatings are used to create grease-resistant, moisture-resistant, and aroma-sealing properties in the paper, making it suitable for food and beverage packaging.

What innovative technologies are being used in the production of specialty paper?

Innovation is key to the development of high-performance specialty papers. Manufacturers are constantly researching and implementing new technologies to enhance the properties and performance of specialty papers. One such innovation is the use of FlexArmor™ technology for oil- and grease-resistant papers. This technology ensures the safety and sustainability of food service applications by providing a barrier against moisture and grease without the need for plastic coatings.

Another innovative technology used in specialty paper production is the development of functional coatings. These coatings enhance the performance and durability of the paper, making it suitable for applications that require specific properties such as water resistance, flame retardancy, or high-temperature resistance. By applying these coatings, manufacturers can customize specialty papers to meet the unique needs of various industries.

What environmental certifications should consumers look for when purchasing specialty paper products?

When purchasing specialty paper products, it is important to look for environmental certifications that ensure sustainable sourcing and responsible manufacturing practices. Some of the certifications to consider include:

- Forest Stewardship Council (FSC): This certification ensures that the paper comes from responsibly managed forests that meet stringent environmental and social standards.

- Programme for the Endorsement of Forest Certification (PEFC): Similar to FSC, PEFC certifies that the paper comes from sustainably managed forests.

- Sustainable Forestry Initiative (SFI): SFI certification promotes responsible forestry practices and ensures that the paper is sourced from legal and responsibly managed forests.

By choosing specialty paper products with these certifications, consumers can support environmentally conscious manufacturers and contribute to the preservation of our forests.

How does the quality of specialty paper contribute to its environmental impact?

The quality of specialty paper plays a significant role in its environmental impact. Higher-quality papers are often more durable and have better performance properties, allowing them to be used for longer periods of time. This reduces the need for frequent replacements and ultimately reduces waste.

Additionally, high-quality specialty papers are often produced using more advanced manufacturing processes that are designed to minimize waste and pollution. These processes may include efficient use of energy and water, as well as the recycling or reuse of production byproducts. By investing in high-quality specialty papers, consumers can contribute to a more sustainable and environmentally friendly paper industry.

In conclusion, sustainability and innovation are key factors in the production and use of high-performance specialty papers. These papers contribute to sustainable packaging solutions, utilize innovative technologies, and adhere to environmental certifications. By choosing high-quality specialty papers, consumers can make a positive impact on the environment while enjoying the unique properties these papers offer.

In the next section, we will explore the characteristics and types of high-performance specialty paper.

FAQs about High-performance specialty paper:

What are some key characteristics of high-performance specialty paper?

A: To identify key characteristics of high-performance specialty paper, we look at factors like waterproof properties, oil-proof coatings, high-temperature resistance, flame retardance, high strength, translucency, and gloss surfaces.

What are some common types of specialty paper available?

A: Various types of specialty paper are available in the market, such as ASPIRE Petallics, Currency Metallic Specialty Paper, Glama Natural, Glama Kraft, Kromekote, Pixelle Specialty Papers, and Release-Treated Candy Cup Paper.

How do the characteristics of specialty paper impact its applications?

A: The characteristics of specialty paper, such as water resistance, flame retardance, gloss surfaces, and high strength, determine its suitability for applications like food packaging, graphic design projects, high-tech applications, and sustainable packaging solutions.

What are the benefits of using high-performance specialty paper?

A: Using high-performance specialty paper offers benefits such as enhanced durability, improved aesthetics, customization options, environmental sustainability, and versatility in various industries and projects.

What are some best practices for using specialty paper in graphic design projects?

A: When using specialty paper in graphic design projects, it's crucial to understand project requirements, choose the right paper weight, consider the printing method, and experiment with textures and finishes to achieve unique and visually appealing designs.

In conclusion, we've covered all aspects of high-performance specialty paper. Understanding its characteristics, types, and applications is essential for effective usage in various projects. The sustainability and innovation in specialty paper highlight its importance in environmentally friendly solutions. By selecting the right paper and printing methods, one can optimize results in graphic design and packaging. Remember, choosing quality specialty paper with eco-certifications can make a significant difference in reducing environmental impact.