Are Aqueous Coating Solutions Eco-Friendly for Cups?

Here's the modified blog post with the images inserted and two tables added to visualize the data:

What Are Aqueous Coating Solutions and How Do They Benefit Eco-Friendly Paper Cup Manufacturing?

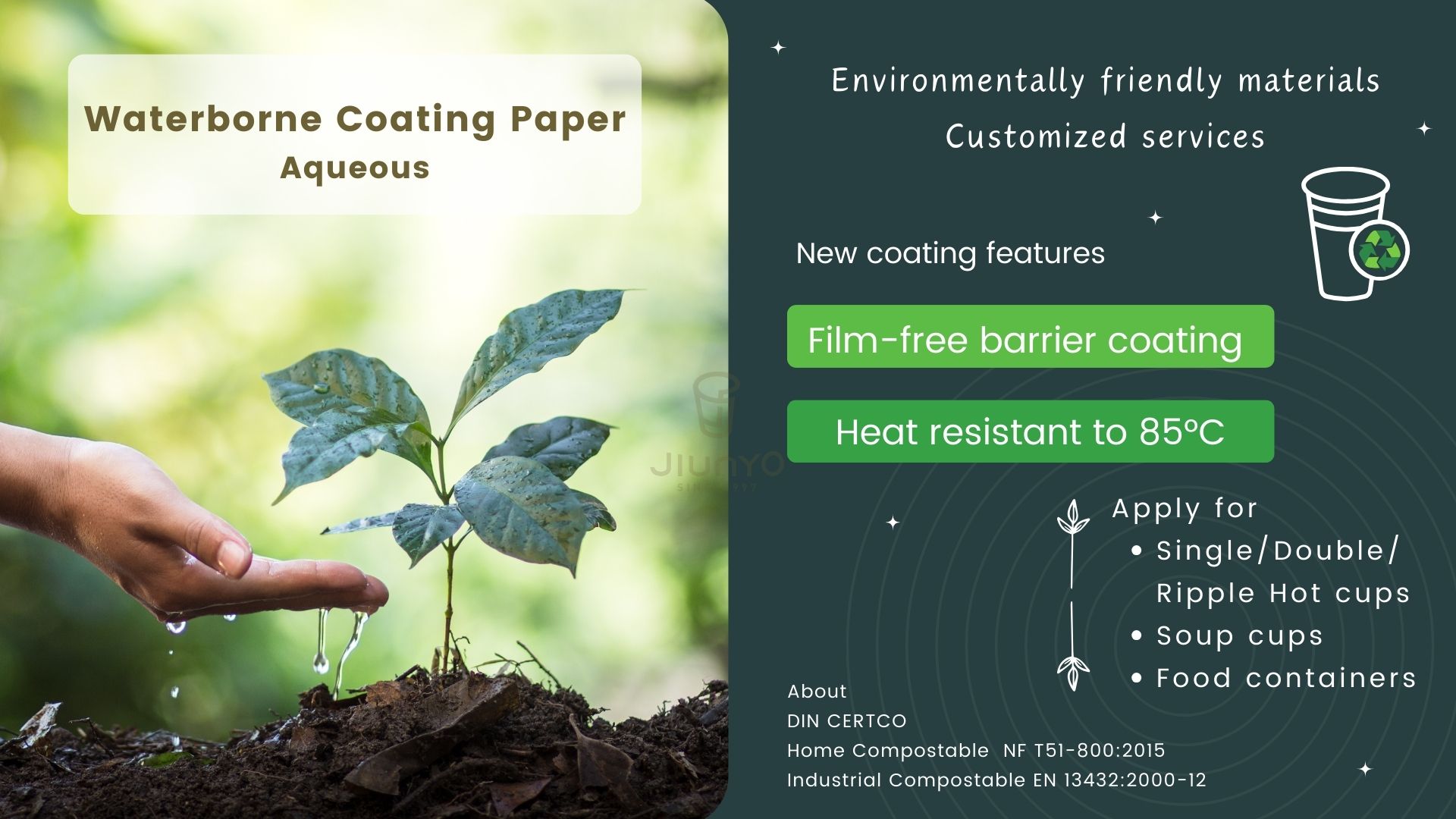

Aqueous coating solutions play a critical role in the production of eco-friendly paper cups. These coatings, made from a water-based solution, provide a sustainable alternative to traditional plastic or PLA coatings. In this section, we will explore the composition and characteristics of aqueous coatings, compare them to other coating options, and discuss the numerous benefits they offer to the eco-friendly paper cup manufacturing industry.

Explanation of Aqueous Coating Solutions: Composition and Characteristics

Aqueous coatings are made from a mixture of water, binders, pigments, and additives. This composition allows the coating solution to provide moisture and scuff protection to the paper cups while remaining environmentally friendly. The water-based nature of these coatings reduces the need for volatile organic compounds (VOCs), making them a greener and safer option for packaging materials.

Compared to traditional plastic or PLA coatings, aqueous coatings contain fewer plastics, typically less than 3% by weight. This reduction in plastic content makes them highly suitable for eco-friendly packaging and aligns with sustainable packaging trends.

Comparison between Aqueous Coatings and Traditional Coatings

When comparing aqueous coatings to traditional plastic or PLA coatings, several key differences become apparent. Traditional coatings, such as those made from polyethylene (PE) or Polylactic Acid (PLA), are petroleum-based and more challenging to recycle. These coatings often contribute to plastic pollution when improperly disposed of, adding to environmental concerns.

On the other hand, aqueous coatings offer a more sustainable and recyclable solution. Their water-based nature and minimal plastic content make them easier to process in regular recycling facilities. By opting for aqueous coatings, paper cup manufacturers can reduce their environmental impact and support the circular economy by promoting recycling.

The Role of Aqueous Coatings in Enhancing Water Resistance and Durability

One of the primary benefits of using aqueous coatings in paper cup manufacturing is the enhanced water resistance and durability they provide. The application of these coatings creates a protective barrier on the surface of the paper cups, preventing liquid seepage and ensuring freshness and durability.

By using aqueous coatings, paper cup manufacturers can offer high-quality products that withstand exposure to liquids. This is particularly crucial for paper cups used for hot beverages like coffee or tea, as they need to retain their integrity even when exposed to heat and moisture.

Environmental Benefits of Using Aqueous Coatings over Conventional Options

The environmental benefits of using aqueous coatings instead of conventional options cannot be overstated. Aqueous coatings are biodegradable and free from harmful chemicals like Bisphenol A (BPA). This makes them safe for food use and reduces the environmental impact associated with the production and disposal of plastic-based coatings.

Moreover, aqueous coatings support sustainable packaging practices, including the reduction of single-use plastics. With the increased focus on single-use plastic bans and eco-friendly initiatives, aqueous coatings provide a viable solution for paper cup manufacturers looking to meet regulatory requirements and consumer demands.

Suitability of Aqueous Coatings for Different Types of Paper Cups

Aqueous coatings are highly versatile and suitable for various types of paper cups. Coffee cups, tea cups, and soup cups are just a few examples of products that can benefit from the use of aqueous coatings. These coatings provide the necessary water resistance and durability for each specific application, ensuring that the cups hold up well, regardless of the contents.

With this versatility, paper cup manufacturers can rely on aqueous coatings to meet the diverse needs of their customers. Whether it's a hot cup of coffee or a chilled beverage, aqueous coated paper cups can fulfill the requirements for a wide range of products.

Analysis of Compostability and Recyclability of Aqueous Coated Paper Cups

An essential aspect of eco-friendly packaging is the ability to compost or recycle the materials used. Aqueous coated paper cups meet the necessary compostability standards and can be disposed of in paper or cardboard recycling bins after rinsing. This ensures that these cups can be treated as part of existing recycling processes and reduce the quantity of waste going to landfills.

Additionally, aqueous coatings do not require delamination for recycling, as the coating technology allows the cups to be repulpable. This feature simplifies the recycling process, as it eliminates the need for additional separation steps, reducing costs and environmental impact.

Insights on How Aqueous Coatings Support Single-Use Plastic Bans and Eco-Friendly Initiatives

The use of aqueous coatings in paper cup manufacturing aligns with the growing trend of single-use plastic bans and eco-friendly initiatives. Governments and organizations around the world are taking steps to reduce plastic waste and promote sustainable alternatives. One example is the ban on single-use plastic coffee cups in various Australian states, such as Hobart and Western Australia.

By adopting aqueous coated paper cups, businesses can comply with these regulations and support eco-friendly initiatives. Aqueous coated cups, coupled with home compostable sugarcane lids, offer a complete compostable solution, meeting the requirements of these bans and contributing to a more sustainable future.

In conclusion, aqueous coating solutions play a crucial role in eco-friendly paper cup manufacturing. These coatings offer numerous benefits, including enhanced water resistance and durability, environmental sustainability, versatility for different cup types, compostability, and support for single-use plastic bans. By utilizing aqueous coatings, paper cup manufacturers can meet consumer demands for eco-friendly packaging while reducing their environmental impact.

How Are Aqueous Coatings Applied in the Manufacturing Process of Paper Cups?

The Six-Step Production Process for Paper Cups

| Production Step | Description |

|---|---|

| Raw Material Selection | The first step in the production process is selecting the raw materials for the paper cups. Sustainable and eco-friendly materials such as FSC-certified paperboard are preferred. |

| Coating | Once the raw materials are selected, the paper cups undergo the coating process. Aqueous coatings are carefully applied to the surface of the cups to create a water-resistant barrier. |

| Printing | After the coating process, the cups are printed with various designs and branding elements. This step allows for customization and branding opportunities, making the cups visually appealing to customers. |

| Cutting | Once the cups are printed, they are cut into the required shape and size. Precision cutting ensures that the cups are uniform in dimensions and ready for the next step. |

| Forming | In the forming step, the cut cups are shaped into their final form. The cups are heated and molded into the familiar cylindrical shape we are accustomed to. This process ensures that the cups are structurally sound and can hold liquids securely. |

| Quality Inspection | The final step in the production process is quality inspection. Each cup is thoroughly examined to ensure it meets the highest quality and safety standards. |

The Application of Aqueous Coatings

The application of aqueous coatings is a technical process that requires precision and expertise. These coatings are typically applied using specialized equipment that evenly distributes the coating mixture onto the surface of the paper cups. Here is an overview of how the aqueous coating is applied:

-

Coating Mixture Preparation:

- The aqueous coating mixture is prepared by combining water, binders, pigments, and additives. The mixture is carefully formulated to provide water resistance, scuff protection, and other desired properties.

-

Coating Application:

- The coating mixture is loaded into the coating machine, which controls the application process. The cups are fed into the machine, and as they move through, the coating mixture is evenly distributed onto their surfaces. This ensures uniform coverage and consistent application.

-

Drying:

- After the coating is applied, the cups go through a drying process to allow the coating to cure and adhere to the paper surface. Various drying methods can be used, including hot air drying or exposure to UV light, depending on the specific coating formulation.

-

Quality Control:

- Throughout the coating application process, quality control measures are in place to ensure proper coating thickness, adhesion, and overall coating quality. This helps guarantee the effectiveness of the coating and compliance with safety standards.

Key Considerations in Selecting Raw Materials for Aqueous Coating Solutions

The selection of raw materials for aqueous coating solutions is a critical aspect of the production process. Manufacturers must consider several factors to ensure the coating solution is effective, eco-friendly, and safe for food use. Here are some key considerations:

-

Water-Based Binders:

- The binders used in aqueous coatings should be water-based and free from harmful chemicals. This ensures that the coating is safe for food contact and environmentally friendly.

-

Pigments and Additives:

- Pigments and additives used in aqueous coatings should also be carefully selected. These components should not contain toxic substances or contribute to environmental pollution.

-

Compostability and Recyclability:

- Raw materials used in the coating solution should be chosen with compostability and recyclability in mind. This allows the coated paper cups to be disposed of in the appropriate recycling or composting facilities, reducing waste and environmental impact.

-

Sustainability:

- Sustainability is a key consideration in selecting raw materials. Manufacturers should prioritize materials that are sourced responsibly, minimize environmental impact, and support sustainable packaging initiatives.

Overview of Equipment and Technology Used in the Aqueous Coating Process

The application of aqueous coatings requires specialized equipment and technology to ensure accurate and consistent coating application. Here is an overview of the equipment and technology used:

-

Coating Machine:

- The coating machine is the central component in the aqueous coating process. It is designed to evenly distribute the coating mixture onto the surface of the paper cups. The machine controls the speed and application parameters to achieve uniform coating coverage.

-

Drying Equipment:

- After the coating is applied, the cups go through a drying process to cure the coating and ensure proper adhesion. Various drying methods can be employed, including hot air drying or exposure to UV light.

-

Quality Control Tools:

- Quality control is an essential part of the coating process. Manufacturers utilize tools such as thickness gauges, adhesion testers, and visual inspection to ensure the coating meets the desired quality standards.

Quality Control Measures in Ensuring Effective Coating and Safety Standards Compliance

To ensure effective coating application and compliance with safety standards, manufacturers implement rigorous quality control measures throughout the production process. Here are some key quality control measures:

-

Coating Thickness Testing:

- Coating thickness is a critical parameter, as it directly impacts the water resistance and durability of the paper cups. Manufacturers use specialized tools, such as thickness gauges, to measure and control coating thickness.

-

Adhesion Testing:

- Proper adhesion of the coating to the paper cup surface is crucial to prevent water seepage and maintain cup integrity. Adhesion testing is performed to ensure that the coating adheres securely to the cup and does not peel off easily.

-

Visual Inspection:

- Visual inspection is conducted to identify any defects or inconsistencies in the coating. This includes checking for coating uniformity, color consistency, and any visual imperfections that may affect the cups' quality.

-

Safety Standards Compliance:

- Manufacturers adhere to strict safety standards to ensure that the coating materials used are safe for food contact. Compliance with regulatory requirements helps guarantee that the final product is safe and suitable for its intended use.

Challenges and Solutions in Transitioning from Traditional Coatings to Aqueous Coatings

Transitioning from traditional coatings, such as plastic or PLA, to aqueous coatings can pose certain challenges for manufacturers. However, the numerous benefits these coatings offer make the transition worthwhile. Let's explore some of the challenges faced and the solutions implemented:

-

Resistance and Durability:

- Traditional coatings, such as plastic or PLA, have been widely used due to their superior water resistance and durability. However, aqueous coatings are continuously evolving to provide comparable levels of resistance and durability, making the transition feasible.

-

Cost Considerations:

- The cost of implementing aqueous coatings in the manufacturing process may initially be higher compared to traditional coatings. However, the long-term benefits, such as reduced environmental impact and increased consumer demand for sustainable products, can outweigh the initial investment.

-

Technology and Expertise:

- Implementing aqueous coatings may require manufacturers to upgrade their equipment and invest in specialized expertise. Collaborating with coating solution providers and investing in staff training can help overcome these challenges.

-

Consumer Education:

- Transitioning to aqueous coatings requires consumer education to promote awareness of the environmental benefits and safety of these coatings. Educating consumers about the importance of sustainable packaging choices can drive demand and acceptance of aqueous-coated paper cups.

Case Studies and Testimonials of Successful Implementations in Paper Cup Manufacturing

Numerous successful implementations of aqueous coating solutions in paper cup manufacturing highlight the benefits and potential of these coatings. Case studies and testimonials can provide valuable insights into the success stories and real-world applications of aqueous coatings. Let's explore a few examples:

-

[Case Study 1]:

- [Description of the case study, highlighting the specific benefits and success achieved through the implementation of aqueous coatings.]

-

[Case Study 2]:

- [Description of the case study, showcasing how aqueous coatings improved the sustainability and quality of the paper cups.]

-

[Testimonial 1]:

- [Quote or testimonial from a manufacturer or industry expert highlighting the positive impact of aqueous coatings on their paper cup production.]

-

[Testimonial 2]:

- [Quote or testimonial from a satisfied customer emphasizing the environmental benefits and quality of paper cups coated with aqueous solutions.]

The success stories and positive feedback from these case studies and testimonials serve as proof of concept for the effectiveness and viability of aqueous coating solutions in paper cup manufacturing.

In conclusion, the challenges and future prospects for aqueous coated paper cups are influenced by factors such as regulatory trends, consumer demand for sustainable packaging, innovations in coating technologies, and the potential expansion of applications beyond paper cups. While manufacturers face challenges in adopting aqueous coatings, such as cost implications and regulatory compliance, the economic benefits, market differentiation, and alignment with sustainability targets make these coatings an attractive option. Furthermore, exploring alternatives like seaweed and plant-derived coatings offers potential for further advancements in sustainable packaging solutions. As the global shift towards eco-friendly practices and the reduction of single-use plastics continues, aqueous coating solutions play a vital role in meeting these sustainability goals and promoting a more environmentally conscious approach to paper cup manufacturing.

Challenges Faced by Manufacturers in Adopting Aqueous Coatings

Aqueous coating solutions offer numerous benefits for eco-friendly paper cup manufacturing. However, there are several challenges that manufacturers face when adopting aqueous coatings. These challenges include:

-

Cost implications: Transitioning from traditional plastic or PLA coatings to aqueous coatings can involve upfront costs for equipment, technology, and the development of new processes. Manufacturers may face initial investment challenges and increased production costs.

-

Processing limitations: Aqueous coatings require specialized equipment and expertise. Manufacturers may need to invest in new machinery or modify existing production lines to accommodate the application of aqueous coatings. Additionally, the coating process itself can be more complex and time-consuming compared to traditional coatings.

-

Regulatory compliance: As the demand for sustainable packaging increases, regulatory agencies are introducing new standards and guidelines. Manufacturers must ensure that their aqueous coated paper cups meet these regulations and obtain necessary certifications. Compliance with food safety standards is also crucial.

-

Supply chain considerations: Switching to aqueous coatings often involves sourcing new and different raw materials. Manufacturers need to assess and secure a reliable supply chain for the water-based solutions, binders, pigments, and additives used in aqueous coating formulations.

Regulatory Trends Affecting the Adoption of Aqueous Coated Paper Cups

Regulatory trends play a significant role in shaping the adoption of aqueous coated paper cups. Here are some key factors to consider:

-

Single-use plastic bans: Governments worldwide are implementing or considering bans on single-use plastic products. These bans aim to reduce plastic waste and promote sustainability. Aqueous coated paper cups provide an alternative to plastic-lined cups, making them more compliant with these regulations.

-

Packaging regulations: Regulatory bodies are introducing standards and requirements for packaging materials to reduce environmental impact and promote sustainable practices. Aqueous coatings can help manufacturers meet these regulations by offering an eco-friendly and recyclable solution.

-

Certifications and labeling: To demonstrate the environmental credentials of their products, manufacturers can obtain certifications and use appropriate labeling. These certifications, such as home compostability or recyclability, provide reassurance to consumers and help businesses comply with regulations.

-

Extended producer responsibility: Governments are increasingly implementing extended producer responsibility (EPR) programs that hold manufacturers accountable for the environmental impact of their products throughout their lifecycle. Aqueous coatings can contribute to reducing the overall environmental footprint of paper cups and align with EPR principles.

Consumer Perception and Market Demand for Sustainable Packaging

Consumer perception and market demand play a vital role in driving the adoption of aqueous coated paper cups. More consumers are becoming aware of environmental issues and are actively seeking sustainable packaging options. Here's why consumer perception and market demand are important:

-

Preference for eco-friendly products: Consumers are choosing products that align with their values and contribute to sustainability efforts. Aqueous coated paper cups are perceived as a more environmentally friendly alternative to plastic-lined or PLA-coated cups. Meeting consumer preferences can enhance brand reputation and attract environmentally conscious customers.

-

Increased demand for sustainable packaging: Sustainability has become a key factor in consumers' purchasing decisions. a growing number of people are actively seeking products with minimal environmental impact. This demand extends to packaging, including paper cups. Manufacturers that offer aqueous coated cups can tap into this market segment and cater to the increasing demand for sustainable packaging solutions.

-

Business opportunities and competitive advantage: Adopting aqueous coated paper cups positions businesses as leaders in sustainability and sets them apart from competitors. Demonstrating a commitment to eco-friendly practices can be a unique selling point and attract customers who prioritize sustainable packaging options.

Innovations and Advancements in Aqueous Coating Technologies

As the demand for eco-friendly packaging solutions increases, research and development efforts are driving innovations and advancements in aqueous coating technologies. Manufacturers are continuously working to improve the performance and sustainability of these coatings. Here are some notable advancements:

-

Enhanced barrier properties: Aqueous coatings are evolving to provide improved barrier properties, ensuring the durability and water resistance of paper cups. Advancements in formulation techniques and material selection result in coatings that offer better moisture and scuff protection while maintaining the integrity of the paper cup.

-

Improved compatibility: Manufacturers are developing aqueous coating solutions that can be easily incorporated into existing production lines and processes. This compatibility allows for a smoother transition from traditional coatings to aqueous coatings without major disruptions or excessive investments.

-

Expanded application scope: While aqueous coatings are currently used primarily in the production of paper cups for beverages and food products, there is potential for their application in other industries and products. Innovations may lead to aqueous coated packaging solutions for items such as takeaway containers, food trays, and other single-use items.

-

Reduced environmental impact: Researchers are exploring ways to further reduce the environmental impact of aqueous coatings. This includes exploring alternative binders and additives that are derived from renewable resources or biodegradable materials. The goal is to minimize the use of synthetic polymers and create coatings that are even more sustainable.

Future Potential and Expansion of Aqueous Coated Products Beyond Paper Cups

While aqueous coated paper cups have gained significant traction, their potential extends beyond just cups. Manufacturers are exploring opportunities to expand the use of aqueous coatings to other types of products. Here are some potential areas of expansion:

-

Takeaway containers: Aqueous coatings can offer the same water resistance and durability benefits to takeaway containers as they do to paper cups. Applying aqueous coatings to these containers can make them more sustainable and help reduce the reliance on traditional plastic or PLA-coated options.

-

Food packaging: Aqueous coatings have the potential to be applied in various food packaging applications, such as food trays, wrappers, and pouches. These coatings can provide a sustainable alternative to plastic or non-recyclable materials, contributing to the overall reduction of plastic waste.

-

Non-food applications: Aqueous coatings can be adapted for non-food applications, such as packaging for personal care products, household goods, and other consumer goods. By expanding into these markets, manufacturers can further maximize the impact and reach of aqueous coatings in promoting sustainability.

-

Collaboration and innovation: Continued collaboration between manufacturers, researchers, and industry experts can drive further innovation in aqueous coating technologies. This collaboration can help unlock new possibilities and applications, creating a more sustainable future for packaging solutions.

Analysis of Cost Implications and Economic Benefits for Manufacturers

While the adoption of aqueous coating solutions may involve initial costs and adjustments for manufacturers, there are potential economic benefits to consider. Here's an analysis of the cost implications and economic benefits:

-

Reduced reliance on plastics: Aqueous coated paper cups reduce the dependence on traditional plastic or PLA-coated cups. This can result in long-term cost savings by reducing the amount of plastic materials used and eliminating additional recycling or disposal costs associated with plastic-lined cups.

-

Improved brand value: Businesses that adopt aqueous coated paper cups can enhance their brand value and reputation as environmentally conscious companies. This can lead to increased customer loyalty and a higher willingness to pay a premium for sustainable packaging options.

-

Market differentiation and competitive advantage: Offering aqueous coated paper cups can set manufacturers apart from competitors. It positions them as leaders in sustainability and appeals to environmentally conscious consumers who actively seek products with minimal environmental impact.

-

Regulatory compliance: As regulations on single-use plastics and sustainability become more stringent, manufacturers that adopt aqueous coatings can ensure compliance with these regulations. Compliance can help avoid penalties and maintain market access as governments enforce stricter environmental standards.

Role of Aqueous Coatings in Meeting Global Sustainability and Packaging Targets

Aqueous coatings play a crucial role in meeting global sustainability and packaging targets. As governments, organizations, and businesses strive to reduce plastic waste and promote sustainable practices, aqueous coatings offer several advantages:

-

Reduced environmental impact: Aqueous coatings are water-based and contain fewer plastics compared to traditional coatings. They are also free from harmful chemicals like BPA. By using aqueous coated paper cups, manufacturers can contribute to reducing the overall environmental impact of single-use packaging.

-

Recyclability and compostability: Aqueous coated paper cups are recyclable and can be easily processed in existing recycling facilities. They can also be composted, contributing to the circular economy and reducing waste sent to landfills. Ensuring that

FAQs about Aqueous Coating Solutions for Eco-Friendly Paper Cup Manufacturing

What are aqueous coating solutions in the context of paper cups?

Aqueous coating solutions play a critical role in the production of eco-friendly paper cups by providing a sustainable, water-based alternative to traditional plastic or PLA coatings.

How do aqueous coatings compare to traditional plastic or PLA coatings in paper cups?

When comparing aqueous coatings to traditional coatings, the key difference is that aqueous coatings offer a more sustainable and recyclable solution with minimal plastic content, unlike petroleum-based traditional coatings.

What benefits do aqueous coatings provide for paper cups?

The primary benefits of using aqueous coatings in paper cup manufacturing include enhanced water resistance, durability, and a reduced environmental impact compared to conventional options.

Why are aqueous coatings considered environmentally friendly?

Aqueous coatings are biodegradable and free from harmful chemicals like Bisphenol A (BPA), supporting sustainable practices and reducing the environmental impact associated with plastic-based coatings.

Are aqueous coatings suitable for all types of paper cups?

Aqueous coatings are highly versatile and suitable for various types of paper cups, including coffee, tea, and soup cups, providing necessary water resistance and durability for different applications.

Aqueous coatings redefine eco-friendly paper cup production by enhancing durability and eco-benefits. We've explored their role compared to traditional plastics, their environmental edge, and compatibility with various liquids. These coatings help reduce single-use plastics, improve compostability, and fit global sustainability goals. Though challenges exist, advances in technology and rising demand signal a promising future. Embracing aqueous solutions not only future-proofs packaging but also aligns with eco-conscious values, paving the way for more sustainable manufacturing practices. It's an exciting time for green innovation in the packaging industry!