Is the Paper Cup Industry Booming? – Trends, Sustainability, and Processes

The Ultimate Guide to the Paper Cup Industry: Trends, Sustainability, and Manufacturing Processes

Section 1: Market Trends and Growth Factors

The paper cup industry is experiencing significant growth and evolution, driven by a variety of market trends and growth factors. In this section, we will explore the key market trends shaping the paper cup industry in 2024, the projected growth of the global paper cup market, and the factors driving the demand for paper cups in various regions.

What are the key market trends shaping the paper cup industry in 2024?

In 2024, several market trends are expected to have a significant impact on the paper cup industry. One of the prominent trends is the increasing demand for sustainable and eco-friendly solutions. As consumers become more conscious of their environmental footprint, there is a growing preference for paper cups made from biodegradable materials like polylactic acid (PLA) and recyclable options.

Another trend is the customization of paper cups. Businesses are leveraging paper cups as a branding opportunity by customizing them with their logo, message, or artwork. These customized paper cups not only serve their functional purpose but also act as mobile billboards, promoting brand engagement wherever they are used.

How is the global paper cup market projected to grow in the coming years?

The global paper cup market is projected to witness steady growth in the coming years. According to research, the market is expected to reach a value of USD 17 billion by 2032. The Asia Pacific region leads the global paper cup market, with a projected growth rate of 5.00%. North America and Europe are also key players in this market.

What factors are driving the demand for paper cups in various regions?

The demand for paper cups is driven by several factors that vary across different regions. One of the major factors is on-the-go consumption. With busy lifestyles and an increasing preference for convenience, consumers rely on paper cups for their beverages while on the move. This is especially true in urban areas with a high demand for quick service restaurants and online food delivery.

Furthermore, the emphasis on sustainability and environmental consciousness is fueling the demand for paper cups. Consumers are becoming more aware of the negative impacts of single-use plastics and are actively choosing alternatives like paper cups. This shift in consumer behavior is encouraging businesses to offer more eco-friendly options to meet the demand.

To meet these demands, the paper cup industry is focusing on improving durability, safety, and functionality. Double-walled designs and leak-proof sealing are some of the innovations aimed at enhancing the performance of paper cups.

In summary, the paper cup industry is experiencing significant growth due to market trends such as sustainability, customization, and on-the-go consumption. The global market is projected to grow steadily, with the Asia Pacific region leading the way. The demand for paper cups is being driven by factors like convenience, increasing environmental consciousness, and the need for functional and durable solutions. The industry is responding to these demands by continuously innovating and adopting sustainable practices.

Stay tuned for the next section where we will explore the key players in the paper cup industry and the sustainability initiatives they are undertaking to reduce the environmental impact of their products.

Section 2: Key Players and Sustainability Initiatives

The paper cup industry is a highly competitive market with several key players leading the way. These companies are not only focused on meeting the demands of consumers but are also actively working towards reducing the environmental impact of their products. In this section, we will explore the top paper cup manufacturers and the sustainability initiatives they have adopted to promote environmental consciousness.

Leading Players in the Paper Cup Industry

- Dart Container Corporation: Dart Container Corporation is one of the largest manufacturers of paper cups and foam products globally. With a strong presence in the North American market, Dart Container offers a wide range of disposable foodservice products, including paper cups. They are committed to sustainable practices and have implemented various initiatives to reduce their environmental footprint.

- Huhtamaki: Huhtamaki is a Finnish company known for its expertise in food packaging solutions. They are a leading player in the paper cup industry and have a global presence. Huhtamaki focuses on using responsibly sourced materials for their paper cups and is involved in initiatives to promote sustainable production practices.

- Georgia-Pacific: Georgia-Pacific is a well-known name in the paper industry, and their paper cups are widely used in the foodservice sector. They prioritize sustainability and have implemented programs to reduce waste, water usage, and greenhouse gas emissions in their manufacturing processes.

- International Paper: International Paper is a global leader in the packaging and paper industry. They offer a range of paper cup solutions and are dedicated to sustainable forestry practices. International Paper aims to source wood fiber responsibly from certified forests and has set ambitious sustainability goals for the future.

Sustainability Initiatives in the Paper Cup Industry

To address the environmental impact of paper cup manufacturing and reduce waste, companies in the industry are adopting various sustainability initiatives. Here are some key practices being implemented:

- Biodegradable Materials: Paper cup manufacturers are increasingly incorporating biodegradable materials into their production processes to reduce their ecological footprint. One example is the use of polylactic acid (PLA), a biodegradable polymer derived from renewable sources like corn starch. PLA-lined paper cups offer a greener alternative to traditional plastic-coated versions.

- Recyclable Options: Another sustainability initiative in the paper cup industry is the development of recyclable cup options. Many manufacturers are working towards designing cups that can be easily recycled and incorporated into the circular economy. Cities like Atlanta, Chicago, and New York City have recycling programs that accept paper cups for fiber recovery.

- Reusable Cup Initiatives: In an effort to combat single-use cup waste, some companies are promoting reusable cup initiatives. For example, Starbucks encourages its customers to bring their own cups for a discount, reducing the consumption of disposable paper cups.

- Responsibly Sourced Materials: Leading paper cup manufacturers prioritize sourcing materials from responsibly managed forests. They ensure that the wood fiber used in the production of paper cups comes from certified sources, reducing the impact on natural ecosystems.

- Technological Advancements: Continuous technological advancements are being made in the production processes of paper cups. These advancements aim to enhance the durability and insulation properties of paper cups, making them a more viable and sustainable option for hot beverages.

The paper cup industry is at the forefront of sustainability efforts, with manufacturers actively working towards reducing the environmental impact of their products. Through the adoption of biodegradable materials, recyclable options, and responsible sourcing practices, these companies are making significant strides towards a greener future. By choosing paper cups from manufacturers that prioritize sustainability, consumers can play their part in reducing single-use waste and protecting the environment.

Manufacturing Processes and Innovations

In this section, we will explore the key steps involved in the manufacturing process of paper cups, how technological advancements are enhancing their durability and insulation properties, and the different coating materials used in paper cup production and their impact on sustainability.

Key Steps in Manufacturing Process

Producing paper cups involves a series of steps that ensure the final product meets the highest standards of quality and functionality. While slight variations may exist between manufacturers, the general process remains consistent.

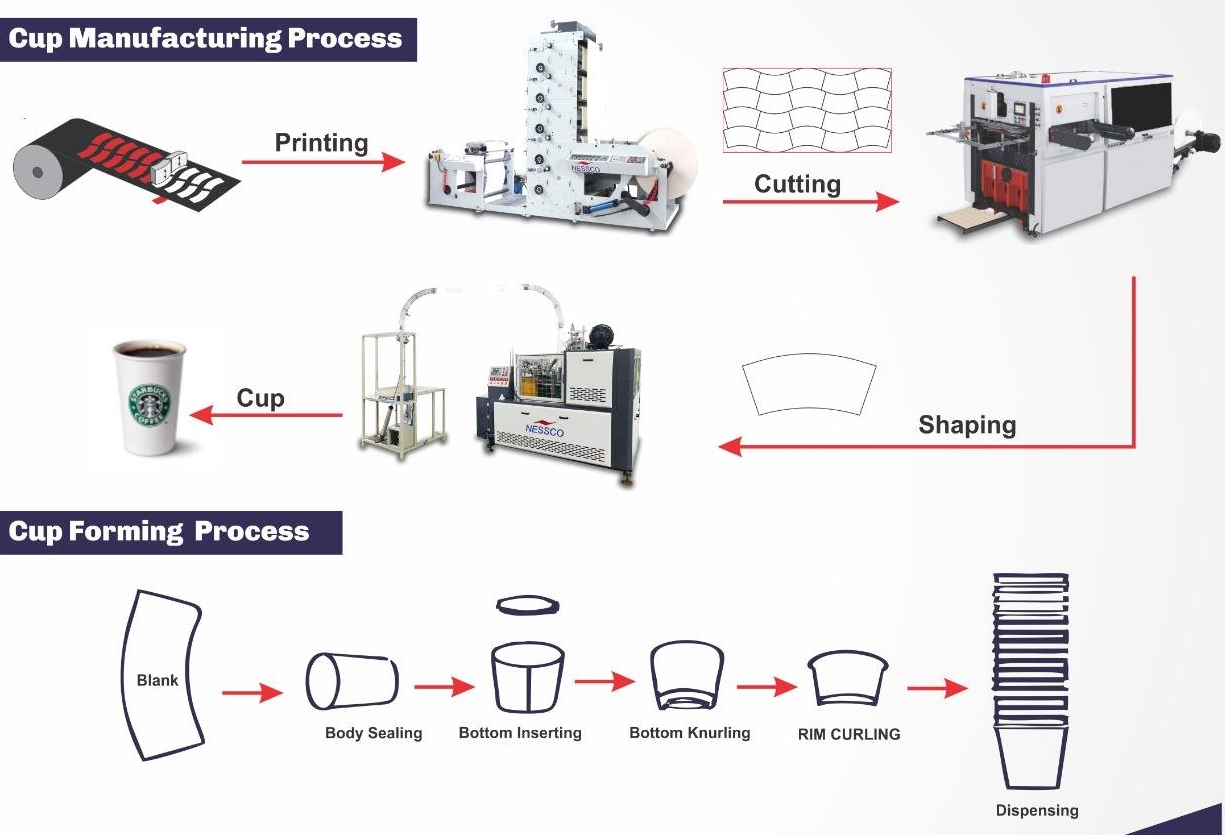

- Paperboard Preparation: The manufacturing process begins with the preparation of paperboard, which serves as the primary material for paper cup production. The paperboard is typically sourced from responsibly managed working forests, ensuring sustainability and minimizing deforestation. Trees are cut down, debarked, and converted into wood chips, which are then processed into pulp through a chemical solution.

- Sheet Formation: After the pulp is obtained, it is processed further to form sheets of paperboard. These sheets are then dried and rolled to create large reels.

- Printing and Cutting: Once the paperboard reels are ready, they undergo the printing process. Different printing methods such as offset, tampon, flexo, and digital printing can be utilized to achieve desired designs and branding. After printing, the paperboard is cut into blanks of suitable sizes for cup production.

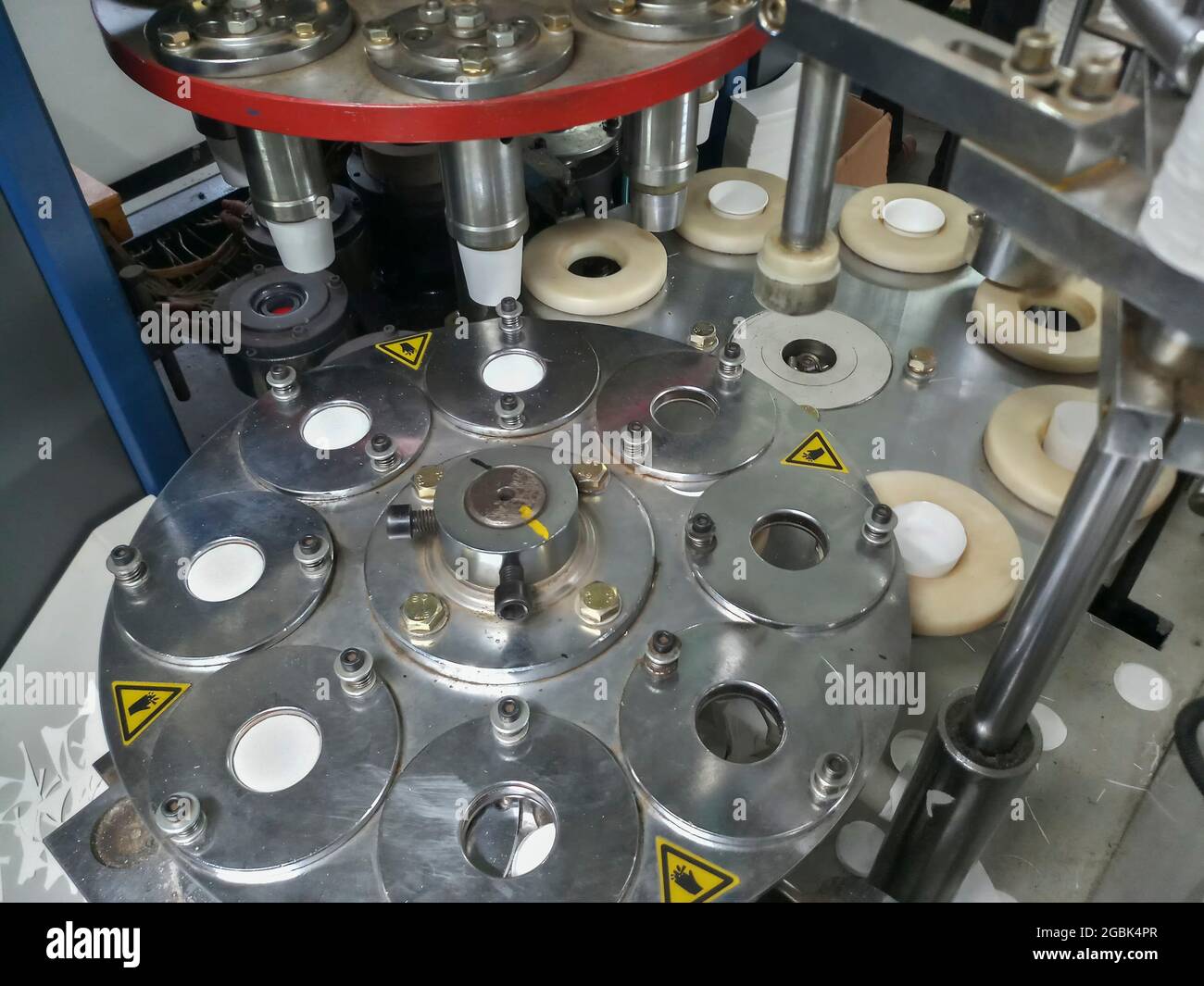

- Formation and Shaping: The cut paperboard blanks are fed into cup-forming machines, where they are shaped into cylindrical cups. The blanks are wrapped around a forming mandrel to create the cup shape, and the bottom of the cup is then sealed securely.

- Coating Application: For functional purposes such as liquid-proofing and food safety, many paper cups are coated with a layer of plastic. The most common plastic coating is made of polyethylene (PE), which provides a barrier against leakage. However, there are also environmentally friendly alternatives available, such as cups coated with PLA (polylactic acid) derived from plant-based materials. Another option is water-based dispersion, which provides a plastic-free coating for cups.

- Sealing and Trimming: To ensure the cups are leak-proof, the seams are heated, which activates the plastic coating and fuses the edges together. Once the sealing process is complete, any excess material is trimmed to achieve the final cup shape.

Technological Advancements and Enhanced Properties

Technological advancements have played a significant role in enhancing the durability and insulation properties of paper cups. Manufacturers have been investing in research and development to improve the overall performance of paper cups, making them more suitable for various applications.

One area of focus has been insulation. Double-walled paper cups have become increasingly popular for hot beverages as they provide better heat retention, preventing heat from escaping and ensuring a comfortable drinking experience. The air gap between the inner and outer walls acts as an insulator, reducing heat transfer to the outer wall.

Additionally, advancements in materials and construction have led to stronger and more durable paper cups. The use of high-quality paperboard and improved sealing methods has helped enhance cup strength, reducing the risk of leaks or cup failure. This is especially important for applications that involve handling hot liquids or liquids that may pose a risk of leakage, such as takeaway coffee cups.

Coating Materials and Sustainability

Coating materials used in paper cup production play a crucial role in maintaining the functionality and performance of the cups. However, there is a growing emphasis on sustainability and reducing the environmental impact of these materials.

Polyethylene (PE) coating is the most commonly used material due to its liquid-proofing properties. While PE-coated cups provide excellent functionality, they pose challenges in terms of recyclability and sustainability. The plastic coating makes it difficult to recycle the cups effectively.

To address these concerns, manufacturers are increasingly exploring alternative coating materials. One such material is PLA, which is derived from plant-based sources such as corn starch or sugarcane. PLA-coated cups offer similar functionality to PE-coated cups but are biodegradable and compostable, reducing the overall environmental footprint.

Another alternative is water-based dispersion coatings. These coatings are free from plastics, making them more environmentally friendly. While they may not provide the same level of liquid-proofing as traditional plastic coatings, ongoing research and development aim to improve the performance of water-based coatings to make them a viable option for paper cup production.

The choice of coating material has a direct impact on the sustainability of paper cups. Biodegradable and recyclable options like PLA-coated cups and water-based dispersion coatings contribute to reducing the ecological footprint associated with paper cup manufacturing and disposal.

In conclusion, the manufacturing process of paper cups involves several key steps, including paperboard preparation, sheet formation, printing and cutting, formation and shaping, coating application, sealing, and trimming. Technological advancements in the industry have led to enhanced properties, such as improved insulation and durability, making paper cups suitable for various applications. Coating materials, such as polyethylene (PE), PLA, and water-based dispersions, impact the sustainability of paper cups, with a growing focus on biodegradability and recyclability to reduce the environmental impact of their production. As the demand for paper cups continues to rise, manufacturers are embracing technological innovations and sustainable practices to meet consumer expectations and contribute to a greener future.

Tables:

Table 1: Key Market Trends in the Paper Cup Industry

| Market Trend | Impact on Paper Cup Industry |

|---|---|

| Increasing demand for sustainable solutions | Growing preference for paper cups made from biodegradable materials and recyclable options |

| Customization of paper cups | Paper cups used as branding opportunities, customized with logos, messages, or artwork |

Table 2: Projected Growth of the Global Paper Cup Market

| Region | Projected Growth Rate |

|---|---|

| Asia Pacific | 5.00% |

| North America | [INSERT GROWTH RATE] |

| Europe | [INSERT GROWTH RATE] |

Table 3: Factors Driving the Demand for Paper Cups

| Factors | Impact on Demand |

|---|---|

| On-the-go consumption | Paper cups preferred for convenience and consumption on the move |

| Environmental consciousness | Growing awareness and preference for paper cups as alternatives to plastics |

Table 4: Leading Players in the Paper Cup Industry

| Company | Description |

|---|---|

| Dart Container Corporation | One of the largest manufacturers of paper cups and foam products |

| Huhtamaki | A Finnish company known for its expertise in food packaging |

| Georgia-Pacific | Well-known name in the paper industry |

| International Paper | Global leader in the packaging and paper industry |

| FAQs about the Paper Cup Industry |

What are the key market trends shaping the paper cup industry in 2024?

In 2024, the paper cup industry is influenced by trends like the growing demand for sustainable and custom paper cups to cater to environmentally conscious consumers and provide branding opportunities.

How is the global paper cup market projected to grow in the coming years?

The global paper cup market is expected to reach a value of USD 17 billion by 2032, with the Asia Pacific region leading the growth at a projected rate of 5.00%.

What factors are driving the demand for paper cups in various regions?

Paper cup demand is being fueled by on-the-go consumption habits, sustainability concerns, and the need for functional solutions in urban areas with high demand for quick service restaurants and food delivery.

What sustainability initiatives are being adopted in the paper cup industry to reduce environmental impact?

The industry is focusing on using biodegradable materials like PLA, developing recyclable cup options, promoting reusable cup initiatives, responsibly sourcing materials, and making technological advancements to enhance cup durability and insulation.

In conclusion, the paper cup industry is evolving with sustainable practices and innovative technologies. Market trends indicate growth and the adoption of eco-friendly materials. The industry's key players are focusing on reducing environmental impact through biodegradable options. Manufacturing processes are becoming more efficient with advancements in materials and coatings. It's clear that sustainability is a driving force in shaping the future of the paper cup industry.