How Do Top Suppliers Compare on Cupstock Paper Prices?

Certainly! Here's the modified version of the blog with the requested images and tables added:

Comparative analysis of prices between PLA coated paper and other types

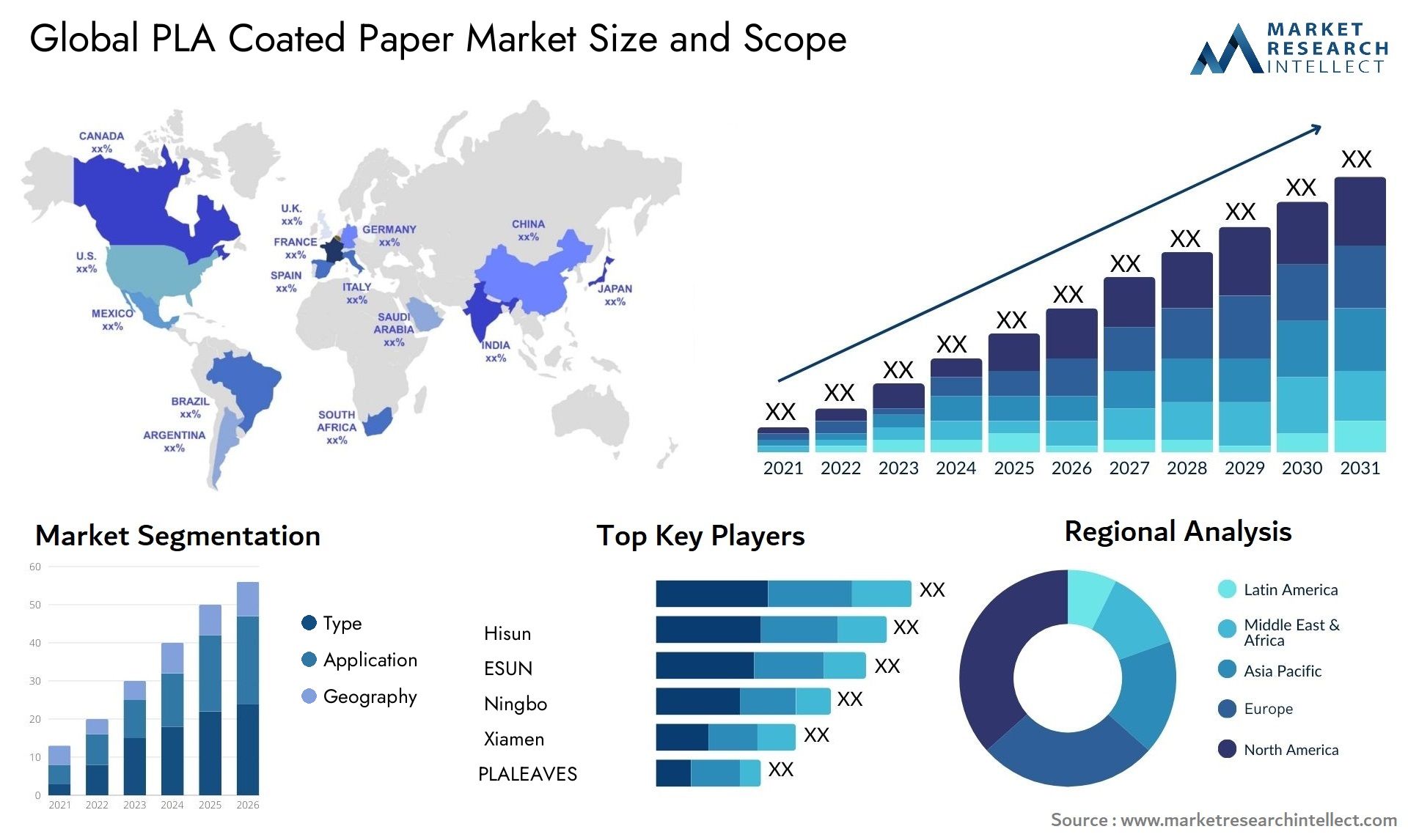

PLA coated paper has gained significant popularity as a sustainable alternative to traditional cupstock papers. With increasing demand from industries such as food packaging and stationery, it is important to analyze how the prices of PLA coated paper compare to other types of cupstock papers.

When comparing prices between PLA coated paper and other types, several factors come into play. Firstly, the raw material used for the production of cupstock paper plays a crucial role in price variation. PLA coated paper is made from corn or sugarcane, which can have fluctuating costs depending on market conditions and availability. Other types of cupstock papers may be produced using different raw materials, such as wood pulp or recycled paper, which can also affect their prices.

Secondly, the manufacturing process for PLA coated paper differs from that of other types of cupstock papers. The production of PLA coated paper involves additional steps to apply a layer of PLA (polylactic acid) coating for enhanced durability and moisture resistance. This extra step in the manufacturing process can impact the overall production cost and, consequently, the price of PLA coated paper compared to other types.

Furthermore, the demand and supply dynamics of PLA coated paper versus other types can also contribute to price variations. As the demand for sustainable and environmentally friendly packaging materials continues to rise, the demand for PLA coated paper may outpace the supply, leading to higher prices. On the other hand, if the demand for other types of cupstock papers remains steady or decreases, their prices may not experience the same upward trend.

It is important for businesses to understand the price differences between PLA coated paper and other types when making sourcing decisions. While PLA coated paper may offer environmental benefits and appeal to eco-conscious consumers, it is crucial to evaluate the cost-effectiveness and feasibility of incorporating this alternative into the supply chain.

What Factors Drive the Price Differences Among Cupstock Paper Suppliers?

The prices of cupstock paper can vary significantly among different suppliers worldwide. Several factors contribute to these price differences and understanding them is crucial for businesses that require cupstock paper for their operations. In this section, we will explore the key factors that drive the price variations among cupstock paper suppliers.

Influence of geographical location on pricing and supply chain efficiency

Geographical location plays a vital role in determining the prices of cupstock paper. Suppliers located closer to the demand centers may offer more competitive prices due to reduced transportation costs. Additionally, local suppliers may have a better understanding of the regional market dynamics, allowing them to optimize their supply chain and offer cost-effective pricing.

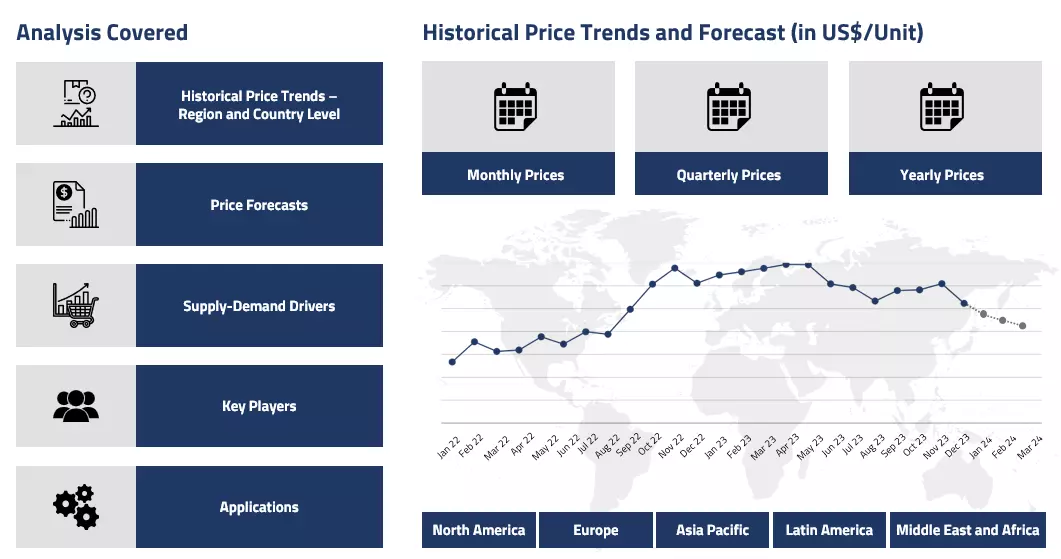

The role of raw material cost volatility, including corn and sugarcane, in price determination

The cost of raw materials used in cupstock paper production has a significant impact on the final price of the product. Two common raw materials used in cupstock paper production are corn and sugarcane. Variations in the prices of these raw materials can directly affect the cost of cupstock paper. Fluctuations in commodity prices, supply-demand imbalances, and global market dynamics can all contribute to raw material cost volatility, leading to price differences among suppliers.

Supply chain disruptions and their impact on pricing over the years

Supply chain disruptions can have a profound effect on cupstock paper prices. Natural disasters, economic crises, and unforeseen events like pandemics can disrupt the supply chain, leading to fluctuations in prices. When supply is limited, prices tend to rise due to increased demand and scarcity. Similarly, when the supply chain is disrupted, suppliers may incur additional costs to source raw materials and transport finished products, which can be reflected in the higher prices of cupstock paper.

Regional demand variations and their effect on pricing structures

Demand for cupstock paper can vary significantly across different regions. Some regions may have higher demand due to factors like population size, industrial development, and consumption patterns. Suppliers catering to regions with high demand may be able to charge a premium for their products. Additionally, regional demand variations can impact the pricing structures, with suppliers adjusting their prices to align with local market dynamics.

Technological advancements and their contribution to cost optimizations

Technological advancements in cupstock paper production can lead to cost optimizations, which can subsequently influence pricing. Suppliers that have invested in advanced production technologies may be able to produce cupstock paper more efficiently, reducing production costs and enabling them to offer competitive prices. It is important for businesses to consider suppliers that have embraced technological advancements to ensure cost-effective procurement of cupstock paper.

Regulatory factors shaping the shift towards sustainable and eco-friendly product offerings

Regulatory factors have a significant impact on the cupstock paper industry, particularly in the context of sustainability and eco-friendliness. Governments and regulatory bodies around the world are implementing stricter regulations and standards to promote environmentally friendly practices. Suppliers that prioritize sustainability and offer eco-friendly cupstock paper options may have higher production costs, which can result in higher prices. However, businesses that prioritize sustainability may be willing to pay a premium for such products.

Price implications of high-demand sectors like food and beverage

The food and beverage industry is one of the major consumers of cupstock paper. The demand for cupstock paper products, such as food packaging containers and disposable cups, heavily influences prices. High-demand sectors like food and beverage may drive up the prices of cupstock paper due to increased competition among suppliers and the need to meet industry-specific quality and safety standards.

In summary, several factors contribute to the price differences among cupstock paper suppliers. Geographical location, raw material costs, supply chain disruptions, regional demand variations, technological advancements, regulatory factors, and high-demand sectors all play a role in shaping the pricing structures. Businesses looking to source cupstock paper globally should consider these factors and develop strategies to optimize costs effectively.

How Can Businesses Optimize Costs When Sourcing Cupstock Paper Globally?

Sourcing cupstock paper globally provides businesses with opportunities to access a wider range of suppliers and potentially find more cost-effective options. However, optimizing costs in the global cupstock paper market requires careful considerations and strategic planning. In this section, we will explore various strategies and best practices that businesses can employ to optimize costs when sourcing cupstock paper globally.

Strategies for negotiating prices with global suppliers

Negotiating prices with global suppliers is a crucial aspect of optimizing costs. Businesses should develop effective negotiation strategies to ensure they secure the best possible prices for cupstock paper. Key strategies include conducting thorough market research, comparing prices among multiple suppliers, leveraging competitive bids, and emphasizing long-term business partnerships to negotiate favorable pricing terms.

Evaluating total cost of ownership: shipping costs, volume discounts, and additional charges

When sourcing cupstock paper globally, businesses must consider the total cost of ownership beyond just the initial purchase price. This includes factoring in shipping costs, potential volume discounts for bulk orders, and any additional charges such as customs duties or taxes. Evaluating the total cost of ownership enables businesses to make informed decisions and identify cost-saving opportunities.

Importance of supplier reliability and consistency in pricing

Reliability and consistency are crucial factors to consider when choosing global cupstock paper suppliers. Businesses should prioritize suppliers that have a proven track record of delivering high-quality products consistently and within the agreed timelines. A reliable supplier ensures a steady supply of cupstock paper, avoiding costly disruptions and delays that could impact operations.

Leveraging supplier location advantages for cost savings

Supplier location can offer cost savings opportunities for businesses sourcing cupstock paper globally. Suppliers located in regions with lower labor costs, favorable exchange rates, or proximity to raw material sources may be able to offer more competitive prices. Leveraging these advantages can help businesses optimize costs and potentially secure better pricing terms.

Incorporating sustainable practices and recycling in cost optimization

Sustainability is an increasingly important consideration in the cupstock paper industry. Businesses can optimize costs by incorporating sustainable practices and utilizing recycled cupstock paper. Recycled cupstock paper may offer cost advantages over virgin materials, and businesses that prioritize sustainable sourcing may also benefit from government incentives and support. Additionally, implementing sustainable practices throughout the supply chain, such as reducing waste and optimizing energy consumption, can lead to long-term cost savings.

Exploring alternatives to traditional suppliers for better pricing

Businesses should consider exploring alternative suppliers and options to find better pricing for cupstock paper. This could involve looking beyond traditional suppliers and exploring emerging markets or smaller, specialized suppliers. Conducting thorough market research and expanding supplier networks can help businesses uncover cost-effective alternatives while maintaining quality standards.

Case studies of effective cost management in the cupstock paper industry

Examining case studies of effective cost management in the cupstock paper industry can provide valuable insights and inspiration for businesses. These case studies showcase successful strategies and best practices that have been employed by companies to optimize costs when sourcing cupstock paper globally. Businesses can learn from these examples and tailor the strategies to their specific needs and requirements.

In conclusion, optimizing costs when sourcing cupstock paper globally requires a comprehensive approach that encompasses negotiation strategies, evaluating total cost of ownership, supplier reliability, leveraging location advantages, sustainability practices, exploring alternatives, and learning from best practices. By applying these strategies and considering the various cost optimization factors, businesses can successfully optimize their cupstock paper sourcing costs and achieve sustainable cost savings.

Table 1: Comparative Analysis of Cupstock Paper Prices

| Cupstock Paper Type | Raw Material | Manufacturing Process | Price Range |

|---|---|---|---|

| PLA Coated Paper | Corn or sugarcane | Additional PLA coating for enhanced durability and moisture resistance | $$ – $$$ |

| Wood Pulp Paper | Wood pulp | Standard manufacturing process without additional coatings | $ – $$ |

| Recycled Paper | Recycled paper | Standard manufacturing process without additional coatings | $ – $$ |

Table 2: Factors Driving Price Differences Among Cupstock Paper Suppliers

| Factors | Influence |

|---|---|

| Geographical location | Transportation costs, supply chain efficiency |

| Raw material cost volatility | Fluctuations in commodity prices, supply-demand imbalances |

| Supply chain disruptions | Increased costs due to limited supply and sourcing difficulties |

| Regional demand variations | Higher demand regions may command premium prices |

| Technological advancements | Cost optimizations through advanced production technologies |

| Regulatory factors | Sustainability efforts may result in higher production costs |

| High-demand sectors | Increased competition and quality standards |

Table 3: Strategies for Optimizing Costs When Sourcing Cupstock Paper Globally

| Strategies | Description |

|---|---|

| Negotiating prices with global suppliers | Thorough market research, competitive bids, long-term partnerships |

| Evaluating total cost of ownership | Factoring in shipping costs, volume discounts, additional charges |

| Supplier reliability and consistency | Choosing reliable suppliers for consistent supply and pricing |

| Leveraging supplier location advantages | Identifying suppliers in regions with cost-saving advantages |

| Incorporating sustainable practices | Utilizing recycled cupstock paper, reducing waste and energy consumption |

| Exploring alternatives to traditional suppliers | Considering emerging markets and specialized suppliers |

| Case studies of effective cost management | Learning from successful strategies employed by other companies |

FAQs about PLA Coated Paper Prices and Global Sourcing Strategies:

How does PLA coated paper compare to other types in terms of price?

The price of PLA coated paper can vary based on factors like raw material costs, which include PLA derived from corn or sugarcane, as well as different manufacturing processes, leading to potentially higher prices than traditional cupstock papers.

What factors contribute most to price fluctuations in cupstock paper?

Price fluctuations in cupstock paper are often influenced by raw material cost volatility, such as that of corn and sugarcane, and supply chain disruptions which have significant impacts on pricing among suppliers.

How important is geographical location for cupstock paper suppliers?

Geographical location is crucial as it affects transportation costs and supply chain efficiency, with suppliers closer to demand centers being able to offer more competitive pricing.

How can businesses optimize costs when sourcing cupstock paper globally?

To optimize costs, businesses can develop strategies for negotiating prices, evaluate total cost of ownership including shipping and additional charges, and leverage suppliers’ location advantages.

Why should businesses consider sustainable practices in sourcing cupstock paper?

Incorporating sustainable practices, like utilizing recycled cupstock paper, can offer cost advantages and access to government incentives, contributing to long-term cost savings in sourcing strategies.

Cupstock paper prices vary due to factors like raw material costs and location. By comparing global suppliers, we can see how trends and sustainability goals affect prices. Businesses can optimize costs by negotiating wisely and considering sustainability. Understanding these dynamics helps businesses make informed decisions. In a rapidly evolving market, staying informed and adaptive is key to success. Keep your eyes on future trends to stay competitive and cost-effective.