Is Cup Stock Material Essential in Beverage Packaging?

Understanding Cup Stock Material

What is cup stock material and how is it used in the beverage industry?

Cup stock material is a specially laminated paperboard that is commonly used in the manufacturing of paper cups for the beverage industry. It consists of multiple layers of paper and a plastic coating, which provides strength, durability, and resistance to liquids. The plastic coating acts as a barrier, preventing leakage and ensuring that the cup remains sturdy even when holding hot or cold liquids.

In the beverage industry, cup stock material is used to create a wide range of cups for various drinks, including hot and cold beverages like coffee, tea, soda, juice, and water. These cups are popular in cafes, coffee shops, fast-food restaurants, convenience stores, and other establishments that offer beverages for on-the-go consumption. The use of cup stock material ensures that the cups can withstand the temperature and moisture associated with these drinks without compromising their structural integrity.

What are the characteristics of cup stock material in packaging solutions?

Cup stock material possesses several key characteristics that make it an ideal choice for packaging solutions in the beverage industry.

Firstly, cup stock material is lightweight yet strong, which makes it easy to handle and transport while providing excellent protection for the beverages inside. The laminated layers of paper and the plastic coating create a robust structure that can withstand the rigors of transportation and usage.

Secondly, cup stock material is moisture-resistant due to the plastic coating. This property is essential for preventing leakage and maintaining the intended quality and freshness of the beverages. The plastic coating effectively acts as a barrier, preventing the liquid from seeping through the cup and causing any potential damage.

Thirdly, cup stock material offers excellent printability, allowing for attractive and eye-catching designs to be applied to the cups. Beverage companies can use custom logos, branding elements, and engaging graphics to create a strong visual identity and enhance the overall appeal of their products. This is crucial for attracting customers and promoting brand awareness.

Lastly, cup stock material is recyclable and can contribute to sustainable packaging solutions. While the plastic coating presents a challenge in terms of recyclability, advancements in recycling technology have made it possible to separate the plastic from the paper layers, allowing for the recycling of cup stock material. Additionally, some cup stock materials are now being produced with biodegradable or compostable coatings, further reducing the environmental impact of these cups.

How is the production process of cup stock material different from other packaging materials?

The production process of cup stock material differs from that of other packaging materials due to the specific requirements and characteristics of cup stock.

The production of cup stock material typically involves several stages. Initially, the base paper is manufactured using a process called pulping, where wood chips are converted into pulp and then formed into sheets. These sheets are then dried and passed through several refining and coating processes to ensure the proper thickness, smoothness, and uniformity of the final product.

The coating process is a critical step in the production of cup stock material. It involves applying a thin layer of plastic to the surface of the base paper, which provides the necessary barrier properties and enhances the cup’s durability. The plastic coating can be applied using various methods, such as extrusion coating or lamination, depending on the specific requirements and desired characteristics of the cup stock material.

Compared to other packaging materials, such as plastic or glass, the production process of cup stock material utilizes more environmentally friendly materials, such as paper sourced from sustainably managed forests. Additionally, the plastic coating used in cup stock material can be made from recyclable or biodegradable materials, further reducing its environmental impact.

Overall, the production process of cup stock material prioritizes the creation of a strong, moisture-resistant, and environmentally friendly packaging material that meets the unique demands of the beverage industry.

Benefits and Applications of Cup Stock in Packaging

In the highly competitive beverage industry, packaging plays a crucial role in attracting consumers and enhancing brand image. One material that has gained popularity in the industry is cup stock. Cup stock is a laminated paperboard material used in the manufacturing of paper cups, with a plastic coating to prevent leakage. In this section, we will explore the benefits of using cup stock material in beverage packaging and its various applications beyond beverage products.

Sustainable Aspects of Cup Stock Material in Beverage Packaging

Sustainability is a key factor driving packaging choices in today’s market. Consumers are increasingly concerned about the environmental impact of packaging materials, and beverage companies are actively seeking more sustainable options. Cup stock material offers several sustainable aspects that make it an attractive choice for beverage packaging.

Renewable and Recyclable Material

Cup stock material is predominantly made from renewable resources such as paper or paperboard. Paper cups made from cup stock material can be recycled and turned into new paper products, reducing waste and conserving valuable resources. Additionally, many cup stock materials are produced using recycled content, further reducing the environmental footprint.

Biodegradable and Compostable Options

In recent years, advancements in cup stock technology have paved the way for biodegradable and compostable options. These materials can break down naturally in the environment, eliminating the need for resource-intensive recycling processes. Biodegradable and compostable cup stock materials provide an eco-friendly alternative that aligns with the growing demand for sustainable packaging solutions.

Reduced Carbon Footprint

Compared to alternative packaging materials such as plastic, cup stock material has a lower carbon footprint. The production and disposal of plastic packaging contribute significantly to greenhouse gas emissions and environmental pollution. Cup stock material, on the other hand, requires less energy and resources to produce, resulting in reduced emissions and environmental impact.

In addition to its sustainable aspects, cup stock material offers cost-effective solutions for beverage companies. The cost-effectiveness of cup stock material can be attributed to various factors that make it an economical choice for packaging.

|

Lower Production Costs |

|---|---|

|

Lightweight and Space-Efficient |

|

Customizable Printing and Branding Options |

|

Lower Production Costs

Cup stock material is widely available and can be produced in large quantities at affordable prices. The manufacturing process of cup stock material is well-established, allowing for efficient production and cost savings. This affordability makes cup stock material an attractive option for beverage companies, particularly small and medium-sized businesses.

Lightweight and Space-Efficient

One of the advantages of cup stock material is its lightweight nature. Cup stock-based packaging is lighter than alternatives such as glass or metal, resulting in lower transportation costs. Moreover, the compact and stackable design of cup stock containers allows for efficient use of storage space, reducing warehouse costs.

Customizable Printing and Branding Options

Cup stock material offers beverage companies the opportunity to customize their packaging with vibrant and eye-catching designs. The smooth surface of cup stock material allows for high-quality printing, enabling brand differentiation and creating a memorable experience for consumers. Customizable printing options on cup stock packaging eliminate the need for additional labeling or wrapping, reducing overall packaging costs.

Applications of Cup Stock Material in the Packaging Industry

While cup stock material is primarily associated with paper cup manufacturing, its applications extend beyond beverage products. The versatility of cup stock material makes it suitable for various packaging needs in different industries.

|

Food Packaging |

|---|---|

|

Takeaway and Quick-Service Restaurant Packaging |

|

Specialty Packaging |

|

Food Packaging

Cup stock material is commonly used in the food industry for packaging products such as ice cream, frozen foods, and baked goods. The material’s resistance to grease and moisture makes it ideal for these applications. Cup stock packaging ensures the quality and freshness of food products while providing an appealing display for consumers.

Takeaway and Quick-Service Restaurant Packaging

The demand for takeaway services and quick-service restaurants has been on the rise, especially in urban areas. Cup stock material is extensively used for packaging takeout beverages, soups, sauces, and other grab-and-go food items. Its durability and leak-proof properties make it a reliable choice for transporting food and beverages safely.

Specialty Packaging

Cup stock material can be combined with other materials to create specialized packaging solutions. For example, cup stock laminated with film is commonly used in the production of reclosable bags and stand-up pouches. These packaging options provide convenience, accessibility, and extended shelf life for a variety of products.

In conclusion, cup stock material offers numerous benefits and applications in the packaging industry, particularly in beverage packaging. Its sustainable aspects, cost-effectiveness, and versatility make it an attractive choice for beverage companies aiming to align their packaging choices with consumer preferences. Furthermore, cup stock material’s applications extend beyond beverages, proving its adaptability across various packaging needs in different industries. By leveraging cup stock material, companies can meet their packaging requirements while contributing to a more sustainable future.

Market Trends and Future Outlook for Cup Stock in Beverage Packaging

The beverage industry is constantly evolving, and packaging solutions play a vital role in meeting the changing needs of consumers and businesses. Cup stock, as a popular material in beverage packaging, is impacted by market trends and demands for sustainable and cost-effective solutions. In this section, we will explore the current market trends and future outlook for cup stock in beverage packaging.

1. Impact of Eco-Friendly Packaging Solutions

The demand for eco-friendly packaging solutions has been on the rise in recent years, driven by increasing consumer awareness and concerns about environmental sustainability. This trend has had a significant impact on the cup stock market as businesses seek alternatives to traditional packaging materials.

Cup stock, with its inherent recyclability and biodegradability, has become a preferred choice for eco-conscious beverage companies. The plastic coating used in cup stock ensures leak-proof functionality while maintaining the paper-based sustainability. As a result, there has been a shift away from foam cups and lids towards paper-based options. This transition is driven by both consumer demand for environmentally friendly options and regulatory pressures to reduce plastic waste.

2. Projected Growth Trends for Cup Stock in Beverage Packaging

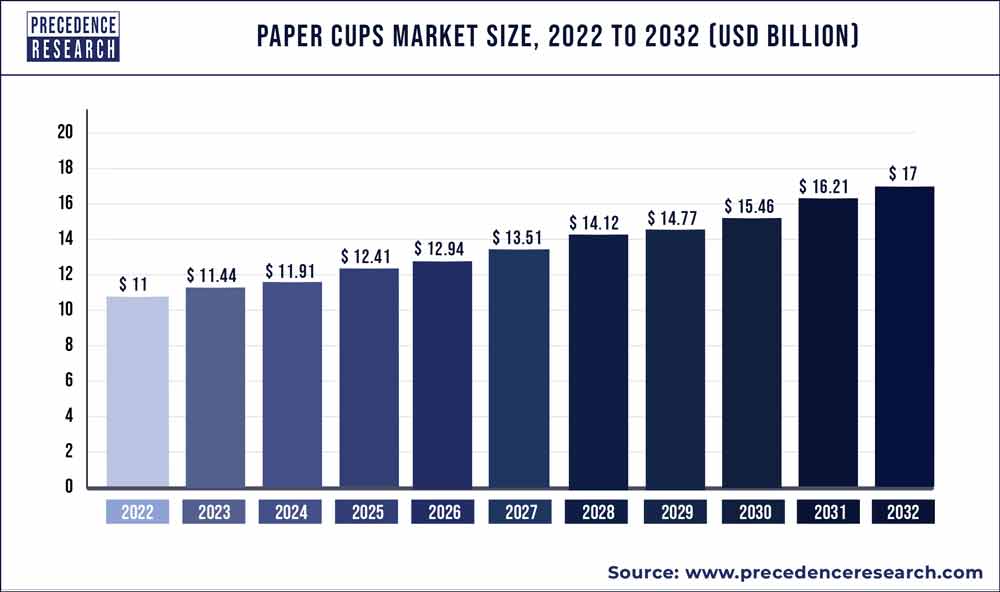

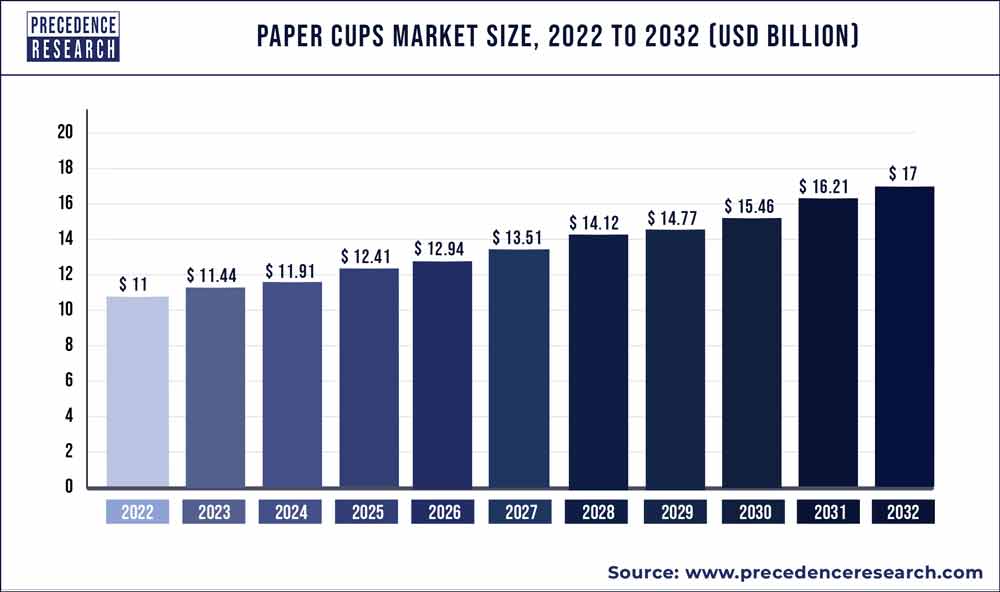

The future looks promising for cup stock in beverage packaging, with projected growth trends showing a positive outlook. The cups and lids market is expected to reach USD 54.25 billion by 2032, with a compound annual growth rate (CAGR) of 11.9% from 2024 to 2032. This growth can be attributed to various factors, including the increasing demand for takeaway services, convenience-driven packaging solutions, and the shift towards eco-friendly materials.

In particular, the food and beverages application segment dominates the cups and lids market, with fast-food and quick-service restaurants driving the demand for packaging solutions. The North American market leads the way in the cups and lids sector, owing to the high demand for convenience and eco-friendly packaging options.

3. Innovation by Major Market Players

To keep up with the evolving needs of the beverage industry, major market players are focusing on innovation in cup stock materials. Companies like Berry Global Inc. and Printpack Inc. are investing in research and development to expand their product lines and global footprint.

Innovation in cup stock materials involves exploring new materials, coatings, and manufacturing processes. For example, specialty paper and film are being used in combination with cup stock for printed laminates, stand-up pouches, and reclosable bags. This allows for greater customization and branding opportunities for beverage companies.

Furthermore, collaboration between cup stock manufacturers and renowned paper mills ensures the use of high-quality materials that meet industry standards. These partnerships also facilitate continuous R&D support, enabling market players to develop new, sustainable cup stock options.

In Summary

The cup stock market in beverage packaging is influenced by market trends such as the demand for eco-friendly solutions. Businesses are transitioning from foam cups to paper-based options due to the sustainability advantages offered by cup stock. The future outlook for cup stock in beverage packaging is positive, with projected growth trends indicating a flourishing market. Major market players are innovating to meet the evolving needs of the beverage industry, exploring new materials, coatings, and manufacturing processes. By embracing sustainability and investing in research and development, cup stock manufacturers are well-positioned to play a pivotal role in the future of beverage packaging.

FAQs about Cup Stock in Beverage Industry:

What is cup stock material and how is it used in the beverage industry?

To understand cup stock material and its role in the beverage industry, it’s essential to know that cup stock material is specially laminated paperboard used in making paper cups and has a plastic coating for strength and resistance to liquids.

What are the characteristics that make cup stock material ideal for packaging solutions?

In terms of packaging, cup stock material is advantageous due to being lightweight yet strong, moisture-resistant, offering excellent printability, and being recyclable or having biodegradable coatings for sustainability.

How does the production process of cup stock material differ from other packaging materials?

The production process of cup stock material involves multiple stages, including pulping, paper coating, and refining processes specific to cup stock requirements, using environmentally friendly materials and methods compared to other packaging materials.

Why is cup stock material a cost-effective packaging solution for beverage companies?

Cup stock material is cost-effective for beverage companies due to lower production costs, lightweight and space-efficient properties for transportation savings, and customizable printing options that eliminate the need for additional labeling or wrapping.

In what other industries can cup stock material find applications beyond beverage packaging?

Cup stock material’s versatility extends beyond beverage packaging to food packaging like ice cream and baked goods, takeaway and quick-service restaurant packaging, and specialty packaging for products like reclosable bags and stand-up pouches, highlighting its adaptability in different industries.

In this comprehensive guide on cup stock in the beverage industry, we explored its material properties and production process. Cup stock offers sustainability and cost-effectiveness, with diverse applications in packaging solutions. The market trends show a rising demand for eco-friendly options, projecting significant growth for cup stock in the next decade. Major players are innovating to meet the industry’s evolving needs with cup stock materials, promising a bright future for this packaging solution.