How much does a paper cup factory investment cost?

Understanding the Paper Cup Manufacturing Business

Starting a paper cup manufacturing business can be a lucrative venture in today’s market. With the increasing preference for environmentally-friendly and sustainable products, the demand for paper cups has been steadily rising. In this section, we will explore different aspects of the paper cup manufacturing business, including the market trends, production process, and environmental sustainability.

Different sizes and specifications of paper cups

Paper cups come in various sizes and specifications to cater to different needs and preferences. Common sizes include small, medium, and large cups ranging from 50 ml to 200 ml in volume. The weight of the paper cups typically ranges from 4 to 5 grams, and they are made using 180 to 200 GSM paper. The size and weight of the cups can vary based on the market demand and customer requirements.

Materials used in paper cup manufacturing

The materials used in paper cup manufacturing are primarily derived from renewable resources such as wood pulp or other plant-based sources. The paper used for making paper cups is generally coated with a thin layer of polymer, such as polyethylene, to provide moisture resistance. However, there is a growing demand for biodegradable and compostable paper cups, which utilize plant-based materials like polylactic acid (PLA), a renewable and compostable polymer. These eco-friendly options are gaining popularity due to their reduced environmental impact.

Market trends and growth projections for the paper cup industry

The market for paper cups has been experiencing steady growth over the years. According to industry experts, the market is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026. This growth can be attributed to factors such as the increasing demand for convenience food and beverages, the rising popularity of takeout and food delivery services, and the shift towards eco-friendly alternatives to plastic cups. Market research plays a crucial role in understanding the target audience, identifying major competitors, and determining market potential.

Production process of paper cups

The production process of paper cups involves several steps. It starts with the cup forming process, where the paper is fed into a cup-making machine. The machine then cuts the paper into the desired shape and forms it into a cup. The cup is then coated with a thin layer of polymer for moisture resistance. Once the cups are formed, they go through a printing process where branding, designs, or other information can be added. Finally, the cups are packed and prepared for distribution. Automation and the use of advanced paper cup making machines can significantly improve production efficiency and maximize output.

Environmental sustainability in paper cup production

Environmental sustainability is a key consideration in the paper cup manufacturing industry. The increasing awareness about the environmental impact of plastic waste has led to a growing demand for eco-friendly alternatives. To meet this demand, paper cup manufacturers are adopting sustainable practices such as using renewable and biodegradable materials. Additionally, efforts are being made to develop innovative solutions for recycling and proper disposal of paper cups. It is essential for manufacturers to stay updated on environmental regulations and industry standards to ensure their products are in line with sustainability goals.

In conclusion, understanding the paper cup manufacturing business involves exploring different sizes and specifications of paper cups, the materials used in their production, market trends and growth projections, the production process, and environmental sustainability. By gaining comprehensive knowledge of these aspects, entrepreneurs can make informed decisions when starting their own paper cup manufacturing business.

Calculating Investment Costs

Starting a paper cup manufacturing business requires careful consideration of the various costs involved. In this section, we will break down the investment costs into different categories to help you understand the financial aspects of setting up your own paper cup factory.

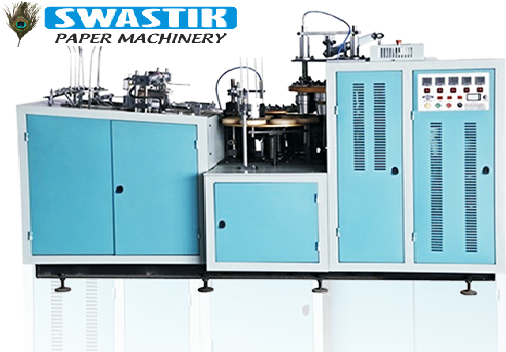

Machinery required for setting up a paper cup manufacturing unit

One of the major expenses in starting a paper cup manufacturing business is investing in the right machinery. The machinery required for paper cup production includes:

- Paper cup forming machine: This machine is used to form paper cups from the selected raw materials. It is important to choose a reliable and efficient machine that can handle the desired cup size and production capacity.

- Printing machine: If you plan to offer customized paper cups with branding or design, a printing machine is required. This machine allows you to add logos, graphics, or text on the cups.

- Packaging machine: Depending on your production volume and requirements, you may also need a packaging machine to efficiently pack the finished paper cups.

The cost of these machines can vary depending on the brand, quality, specifications, and additional features. It is recommended to research and compare different suppliers to find the best machinery that suits your requirements and budget.

Breakdown of costs for raw materials

The raw materials used in paper cup manufacturing include:

- Paper: High-quality food-grade paper is essential for producing durable and hygienic paper cups. The cost of paper depends on factors such as size, weight, and grade of the paper. It is advisable to source paper from reputable suppliers to ensure the quality and consistency of your cups.

- Ink and coating: If you choose to offer customized paper cups, you will need ink and coating materials for printing and adding a protective layer to the cups. The cost of ink and coating materials depends on the quantity and quality required.

- Other consumables: Additional consumables like glue, packaging materials, and cleaning supplies also contribute to the overall cost of raw materials. It is important to consider these expenses when calculating the investment costs.

To optimize cost and ensure a steady supply of raw materials, consider establishing strong relationships with suppliers and exploring bulk purchasing options.

Labor expenses in paper cup production

Labor costs are another significant component of the investment costs in a paper cup manufacturing business. The number of employees required depends on the scale of production and the level of automation in your factory. Some key positions include:

- Machine operators: These individuals are responsible for operating and maintaining the paper cup forming, printing, and packaging machines.

- Quality control inspectors: Quality control is crucial to ensure that the produced paper cups meet the required standards. Inspectors will check the cups for any defects or imperfections.

- Administrative and support staff: Depending on the size of your business, you may need administrative personnel to handle tasks such as purchasing, inventory management, and customer service.

It is important to research and understand local labor laws and regulations to ensure compliance and calculate the associated costs accurately.

Regulatory requirements and permits

Before starting a paper cup manufacturing business, you need to be aware of the regulatory requirements and permits in your jurisdiction. These may include:

- Business registration and licenses: You will need to register your business and obtain the necessary licenses and permits to operate legally.

- Environmental regulations: As the paper cup industry is increasingly focusing on sustainability, you may be required to comply with certain environmental regulations. This may include waste management and recycling programs.

- Health and safety compliance: Ensuring a safe and healthy working environment for your employees is important. Compliance with health and safety regulations may involve implementing safety protocols and providing necessary protective equipment.

It is essential to consult with local authorities or regulatory bodies to understand the specific requirements and costs associated with compliance.

Potential returns on investment in the paper cup business

While the initial investment costs can seem significant, a well-run paper cup manufacturing business can yield attractive returns on investment. The potential returns depend on various factors such as market demand, pricing strategy, production efficiency, and effective marketing.

It is important to conduct market research to identify potential customers and understand their preferences and requirements. Building strong relationships with local coffee shops, fast food chains, and corporate offices can help establish a solid customer base.

Investing in digital marketing strategies, such as social media advertising and SEO, can help promote your paper cups to a wider audience, increasing your chances of attracting more customers.

Furthermore, offering customization options, such as branding and design, can differentiate your paper cups from competitors and potentially justify higher pricing.

By carefully analyzing the market trends, optimizing costs, and ensuring quality and customer satisfaction, your paper cup manufacturing business can become a profitable venture with sustainable returns on investment.

In the next section, we will explore strategies for cost optimization in the paper cup manufacturing business, offering tips and insights on how to maximize profits and minimize expenses.

Stay tuned!

Sources:

- https://www.marketsandmarkets.com/Market-Reports/paper-cup-market-145209717.html

- https://www.grandviewresearch.com/industry-analysis/paper-cup-market

Strategies for Cost Optimization

In a competitive business landscape, cost optimization is essential for the success and profitability of a paper cup manufacturing business. By implementing effective strategies, you can maximize efficiency and minimize expenses. In this section, we will explore various tactics to help you optimize costs in your paper cup factory.

Implementing Cost-Effective Marketing Strategies

Marketing plays a crucial role in promoting your paper cup products and attracting customers. However, it’s important to find cost-effective ways to reach your target audience. Here are some strategies to consider:

- Digital Marketing: Leverage the power of digital platforms to market your paper cups. Utilize social media advertising and search engine optimization (SEO) techniques to increase your online visibility and reach a wider audience without incurring substantial costs.

- Content Marketing: Create high-quality, informative content related to paper cup usage, eco-friendliness, and customization options. This can attract potential customers and establish your brand as an authority in the industry.

- Referral Programs: Encourage satisfied customers to refer your paper cup products to others in exchange for discounts or incentives. This can help generate new leads and expand your customer base at a minimal cost.

- Partnerships and Collaborations: Explore partnerships with local businesses, such as coffee shops or catering companies, that regularly use paper cups. Cross-promotion and collaborative marketing efforts can help you reach a larger audience while sharing marketing costs.

Tips for Optimizing Production Efficiency

Efficient production processes can significantly impact your bottom line. By optimizing production, you can reduce waste, increase output, and lower operational costs. Consider implementing the following tips:

- Invest in Automatic Paper Cup Making Machines: Automatic machines can streamline production, minimize manual labor, and increase productivity. They also help maintain consistent quality while reducing the risk of errors or flaws in the finished products.

- Maintain Regular Equipment Maintenance: Regular maintenance of your paper cup making machines can prevent breakdowns and costly repairs. Schedule routine inspections, cleanings, and servicing to ensure optimal performance and prolong the lifespan of your equipment.

- Train and Engage Your Workforce: Well-trained and motivated employees are crucial for efficient production. Provide comprehensive training on machine operation, product quality standards, and waste reduction techniques. Encourage open communication and feedback to foster a collaborative and efficient work environment.

- Implement Lean Manufacturing Principles: Adopt lean manufacturing principles, such as just-in-time inventory management and waste reduction techniques (e.g., 5S methodology), to eliminate unnecessary costs and streamline your production processes.

Collaborating with Suppliers for Cost Savings

Developing strong relationships with suppliers can lead to cost savings in the long run. Consider the following strategies to collaborate effectively with your suppliers:

- Bulk Raw Material Purchases: Collaborate with suppliers to negotiate favorable pricing and discounts for purchasing raw materials in bulk. By consolidating your orders and establishing long-term relationships with trusted suppliers, you can potentially reduce material costs.

- Continuous Communication: Maintain open lines of communication with your suppliers to stay informed about market fluctuations, upcoming promotions, or new materials and techniques that can help optimize costs in your paper cup production.

- Supplier Performance Evaluation: Regularly evaluate your suppliers based on factors such as timely delivery, quality of materials, and responsiveness to your needs. This evaluation will help you identify reliable and cost-effective suppliers while ensuring a high standard of raw materials for your paper cup production.

Utilizing Digital Marketing for Reaching a Wider Audience

Digital marketing offers cost-effective methods to expand your reach and attract potential customers. Here are some digital marketing strategies to consider:

- Social Media Advertising: Utilize social media platforms like Facebook, Instagram, and LinkedIn to engage with your target audience, run targeted advertisements, and promote your paper cup products. Leverage user analytics to monitor the effectiveness of your campaigns and make data-driven adjustments.

- Search Engine Optimization (SEO): Optimize your website and content with relevant keywords related to paper cups, their benefits, and customization options. This will improve your search engine rankings, increase organic traffic to your website, and attract potential customers who are actively searching for paper cup products.

- Email Marketing: Build an email list of potential customers and existing clients. Regularly send out newsletters, updates, and promotions to keep your audience engaged and informed about your paper cup offerings. Email marketing is a cost-effective way to nurture customer relationships and generate repeat business.

Customization Options to Attract More Clients

Offering customization options for your paper cups can set you apart from competitors and attract more clients. Consider the following customization options:

- Branding and Design: Allow customers to personalize their paper cups with custom logos, colors, and designs. This can help businesses promote their brand identity and create a unique experience for customers.

- Size and Volume Options: Offer a range of sizes and volumes to cater to different customer needs. Whether it’s a small espresso cup or a large takeaway cup, providing various options can help you cater to different industries and customer preferences.

- Eco-Friendly Materials: Highlight your use of eco-friendly materials, such as biodegradable or compostable paper, to appeal to environmentally conscious customers. Sustainable packaging choices can be a significant selling point for businesses that prioritize eco-friendly practices.

By incorporating these cost optimization strategies into your paper cup production business, you can maximize efficiency, reduce unnecessary expenses, and attract more customers. Keeping a keen eye on costs while delivering high-quality products can help ensure a profitable venture in the competitive paper cup industry.

FAQs about paper cup manufacturing business:

What are the common sizes and specifications of paper cups?

To begin, paper cups typically come in sizes such as small, medium, and large, with volumes ranging from 50 ml to 200 ml and weights between 4 to 5 grams, made using paper of 180 to 200 GSM.

What materials are commonly used in paper cup manufacturing?

In paper cup manufacturing, materials are primarily sourced from renewable resources like wood pulp, often coated with polymers like polyethylene for moisture resistance, with increasing demand for biodegradable options like polylactic acid (PLA).

How has the paper cup industry been growing?

Industry experts project a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026, attributing this growth to factors like the popularity of takeout services, the rise in eco-conscious alternatives, and the demand for convenience food and beverages.

What is the production process of paper cups?

The production process involves cup forming using machines, coating for moisture resistance, printing for customization, and packing for distribution, with automation and advanced machines playing a vital role in improving efficiency.

Why is environmental sustainability important in paper cup production?

Environmental sustainability is crucial due to the increasing demand for eco-friendly alternatives, leading manufacturers to adopt renewable and biodegradable materials, while also focusing on developing recycling solutions and meeting environmental regulations.

In conclusion, starting a paper cup making business costs $5,000 to $10,000. Expect a 25% to 40% profit margin. Trends show a 4.3% annual growth. Use eco-friendly materials for production. Explore marketing and customization strategies for success in the industry. By investing in efficient machinery and collaborating with suppliers, you can optimize costs and scale your business effectively. Be mindful of location costs, potential returns, and market trends when venturing into the paper cup manufacturing business.