Comparing Aqueous Coated Paper and PE Coated Options?

Comparing Aqueous Coated Paper to PE Coated Alternatives for Packaging

When it comes to packaging materials, the choice of coating can greatly impact the functionality, environmental footprint, and cost-effectiveness of the packaging. Two commonly used coatings in the industry are aqueous coated paper and PE (polyethylene) coated alternatives. In this article, we will compare these coatings in terms of their definition, composition, properties, environmental impact, recyclability, cost implications, and market trends.

Definition and Composition of Aqueous Coated Paper

Aqueous coated paper is a water-based coating applied to paper products to enhance their performance and provide various benefits. This coating is typically made from a blend of polymers and is known for its water-resistant properties. It is widely used in packaging applications where moisture resistance is crucial, such as paper cups, containers, and food packaging.

The composition of aqueous coated paper includes a water-based polymer blend. The water-based nature of this coating makes it less harmful to the environment compared to solvent-based coatings. Additionally, this type of coating is often marketed as a plastic-free alternative. However, it is important to note that despite being marketed as environmentally friendly, aqueous coatings may still contain polymers derived from petrochemicals, which are essentially plastics.

Definition and Composition of PE Coated Paper

PE coated paper, on the other hand, involves the application of a polyethylene layer to paper products. Polyethylene is a type of plastic that provides moisture and grease resistance to the paper. This type of coated paper is widely used in food and beverage packaging, especially for items like baked goods, fast food, frozen food, and snacks.

The application process for PE coating involves extrusion coating, in which a layer of polyethylene is applied to the paper through a heated extruder. This coating provides a strong barrier against water and grease, making it ideal for food packaging. PE coated paper can come in different types, such as single-sided, double-sided, sandwich, release liner, matte, and glossy options.

Comparison of Properties

One of the key considerations when comparing aqueous coated paper to PE coated alternatives is their properties. Let's take a closer look at some of the important properties and how they differ between the two coatings.

-

Moisture and grease resistance: Both aqueous coated paper and PE coated alternatives offer moisture and grease resistance. However, PE coatings provide a stronger barrier against water and grease due to the inherent properties of polyethylene. This makes PE coated paper particularly suitable for applications where a high level of protection is required.

-

Durability and flexibility: PE coated paper is known for its durability and flexibility. The polyethylene layer adds a protective barrier, making the paper more resistant to tearing and damage. On the other hand, aqueous coated paper may not offer the same level of durability as PE coated paper.

Considerations for Selecting a Coating

When selecting a coating for packaging, there are several factors to consider. Here are a few key considerations:

-

Application-specific needs: Different applications may have specific requirements in terms of moisture resistance, durability, and barrier properties. It is important to consider the specific needs of your packaging when choosing between aqueous coated paper and PE coated alternatives.

-

Industry trends and preference for eco-friendly materials: Sustainable packaging has become a major trend in the industry. Many companies and consumers are increasingly looking for eco-friendly packaging solutions. Aqueous coated paper, with its water-based nature and potential for reduced plastic content, may align better with these sustainability goals. However, it is important to critically evaluate the environmental impact of aqueous coatings, considering the presence of synthetic polymers and challenges in recycling.

In summary, comparing aqueous coated paper to PE coated alternatives for packaging involves considering factors such as their definition, composition, properties, environmental impact, recyclability, cost implications, and market trends. Both coatings offer moisture resistance, but PE coatings provide a stronger barrier against water and grease. Selecting the appropriate coating depends on application-specific needs and industry trends towards eco-friendly materials.

How do Aqueous and PE Coatings Impact the Environment and Recycling?

Environmental Footprint of Aqueous Coatings

Aqueous coatings have gained popularity in the packaging industry due to their water-based nature and the perception that they are plastic-free. However, there are misconceptions surrounding their environmental impact. While aqueous coatings may reduce the overall plastic content in packaging, they often contain synthetic polymers derived from petrochemicals, which are plastics. These coatings contribute to sustainability efforts by using fewer petrochemicals compared to full plastic linings, but they are not entirely plastic-free.

Environmental Impact of PE Coatings

On the other hand, PE coatings are known for their moisture and grease resistance properties. However, their non-biodegradable nature poses challenges in terms of environmental impact and recycling. PE-coated products are difficult to recycle in traditional facilities, as the presence of the polyethylene layer complicates the recycling process. As a result, these products often end up in landfills, contributing to the growing issue of waste disposal.

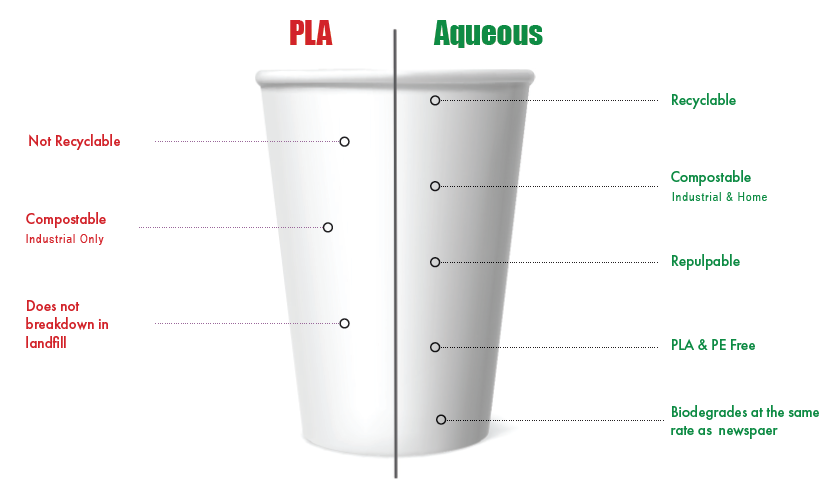

Recyclability and Compostability

The recyclability of products with aqueous coatings varies depending on the polymer blend and the specific recycling facility. Traditional recycling facilities face challenges in processing these products due to the complexity of separating the coating from the paper. However, advances in compostable coatings offer a more sustainable solution. Compostable coatings, made from natural and renewable resources, can decompose in composting environments, minimizing their impact on the environment.

Market Trends and Regulations

There is an increasing demand for sustainable materials in packaging as more consumers become environmentally conscious. Brands are adopting eco-friendly packaging options to meet this demand and improve their brand image. In Europe, there is a legislative push for the use of eco-friendly alternatives in packaging, further driving the adoption of compostable and biodegradable materials. These market trends and regulations are shaping the industry's shift towards more sustainable practices.

In summary, both aqueous and PE coatings have their environmental impacts. Aqueous coatings may reduce the overall plastic content in packaging, but they still contain synthetic polymers derived from petrochemicals. PE coatings, while effective in moisture and grease resistance, are non-biodegradable and pose challenges in recycling. Advances in compostable coatings offer a more sustainable option for packaging. Market trends and regulations are pushing for the adoption of eco-friendly materials, driving brands towards sustainable packaging solutions.

What are the Economic and Functional Considerations in Choosing Between Aqueous and PE Coatings?

When it comes to packaging materials, choosing the right coating is crucial. Both aqueous coated paper and PE coated alternatives have their own advantages and drawbacks. Understanding the economic and functional considerations of each can help businesses make an informed decision.

Cost Implications

Cost is often a significant factor in decision-making for businesses. When comparing aqueous and PE coatings, there are several cost-related considerations:

1. Comparison of manufacturing complexities and material costs: Aqueous coatings are water-based, which can result in higher manufacturing complexities and material costs compared to PE coatings. The process of applying aqueous coatings requires specialized equipment and expertise, which can impact the overall cost.

2. Long-term savings potential with water-based coatings: While the initial cost of aqueous coatings may be higher, they offer long-term savings potential. Aqueous coatings are known for their durability, which can reduce the need for frequent reapplication. Additionally, the use of water-based coatings aligns with the growing demand for sustainable packaging solutions, which can enhance a brand's positioning and potentially lead to increased customer loyalty.

Performance Under Various Conditions

The performance of coatings in different conditions is an essential consideration in packaging. Here's how aqueous and PE coatings stack up:

1. Heat and liquid resistance comparison: Both aqueous and PE coatings offer heat and liquid resistance to varying degrees. PE coatings excel at heat resistance, making them suitable for hot beverages and food items. However, advancements in water-based coatings have improved their thermal properties, making them increasingly viable for heat-sensitive applications.

2. Effectiveness in maintaining product integrity: Both coatings are designed to provide protection and maintain the integrity of packaged products. Aqueous coatings create a barrier against moisture and oil, ensuring the freshness and quality of the contents. PE coatings offer excellent moisture and grease resistance, making them ideal for items such as baked goods, fast food, frozen food, and snacks.

Consumer Trends and Market Influence

Consumer trends and market influences play a significant role in shaping the packaging industry. Here's how they impact the choice between aqueous and PE coatings:

1. Shift towards sustainable packaging solutions: The global movement towards sustainability has influenced consumer preferences and purchasing decisions. As consumers become more environmentally conscious, there is a growing preference for packaging solutions that minimize negative environmental impacts. Aqueous coatings, being water-based and potentially more biodegradable and compostable, align with this trend and can position brands as environmentally responsible.

2. Branding and positioning benefits in adopting eco-friendly coatings: Brands that adopt eco-friendly packaging solutions, such as aqueous coatings, can gain a competitive edge in the market. Consumers are increasingly drawn to brands that demonstrate a commitment to sustainability. By incorporating green practices into their packaging choices, businesses can build a positive brand image and attract environmentally conscious consumers.

Future Prospects and Innovations

The future of packaging coatings is marked by innovation and the development of sustainable alternatives. Here are some notable advancements to consider:

1. Developments in biodegradable coatings: The packaging industry is witnessing advancements in biodegradable coatings, offering promising alternatives to traditional coatings. These coatings, such as those derived from renewable resources like corn starch, present an opportunity for businesses to meet sustainability goals while maintaining packaging integrity and functionality.

2. Industry shifts reducing reliance on traditional plastics: There is a growing movement within the packaging industry to reduce reliance on traditional plastics, including PE coatings. As consumer demand for sustainable materials increases, more businesses are exploring innovative solutions to minimize their environmental footprint. This shift presents opportunities for the adoption of aqueous coatings and other eco-friendly alternatives.

In conclusion, choosing between aqueous coated paper and PE coated alternatives for packaging involves considering economic and functional factors. While aqueous coatings may have higher initial costs, they offer potential long-term savings and align with consumer trends towards sustainability. PE coatings excel in heat resistance and moisture resistance but face challenges in recycling and biodegradability. Understanding these considerations and keeping an eye on future prospects and innovations can help businesses make informed decisions when it comes to coating selection for packaging.

Visualizing Data – Economic Considerations

To further understand the economic considerations when choosing between aqueous coated paper and PE coated alternatives, let's take a look at the following table:

| Consideration | Aqueous Coated Paper | PE Coated Paper |

|---|---|---|

| Manufacturing complexities and costs | Higher | Lower |

| Long-term savings potential | Yes | No |

| Overall cost | Higher | Lower |

Visualizing Data – Functional Considerations

To visualize the functional considerations when choosing between aqueous coated paper and PE coated alternatives, consider the following table:

| Consideration | Aqueous Coated Paper | PE Coated Paper |

|---|---|---|

| Heat resistance | Moderate to High | High |

| Moisture resistance | High | High |

| Barrier against water and oil | Effective | Excellent |

| Durability | Moderate | High |

These tables provide a clear overview of the economic and functional considerations when choosing between aqueous coated paper and PE coated alternatives.

FAQs about Comparing Aqueous Coated Paper to PE Coated Alternatives for Packaging

What is aqueous coated paper?

Aqueous coated paper is a water-based coating applied to paper products to enhance their performance and provide various benefits, including moisture resistance.

How does PE coated paper differ from aqueous coated paper?

PE coated paper involves the application of a polyethylene layer to paper products, providing stronger moisture and grease resistance compared to aqueous coated paper.

What environmental impacts do aqueous and PE coatings have?

The environmental impact of aqueous coatings includes the potential presence of synthetic polymers from petrochemicals, while PE coatings are non-biodegradable and difficult to recycle, often ending up in landfills.

What are some economic considerations in choosing between aqueous and PE coatings?

Economic considerations include the higher initial costs of aqueous coatings due to manufacturing complexities, balanced by their potential for long-term savings and alignment with sustainable packaging trends.

How do consumer trends influence the choice of packaging coatings?

The shift towards sustainable packaging solutions influences the choice between coatings, with growing preference for eco-friendly options like aqueous coatings that align with consumer demand for reduced environmental impact.

Choosing between aqueous and PE coatings involves many factors. We've examined their definitions, compositions, and roles in packaging. Aqueous coatings, being water-based, offer a sustainable edge, while PE coatings provide solid barrier protection. Both have unique qualities in moisture resistance and durability. Consideration should align with specific needs and industry trends favoring eco-friendly options. The environmental and recycling discussion reveals a push for greener solutions, with legislation supporting sustainable materials. Economically, aqueous might save money long-term despite higher initial costs. As innovation continues, industries may lean toward biodegradable alternatives. Embrace change for a cleaner, sustainable future.