Is Cupstock Production Cost Analysis Essential?

Cost Analysis of Cupstock Production: Strategies for Efficiency and Profitability

Section 1: Understanding Cupstick Production Costs

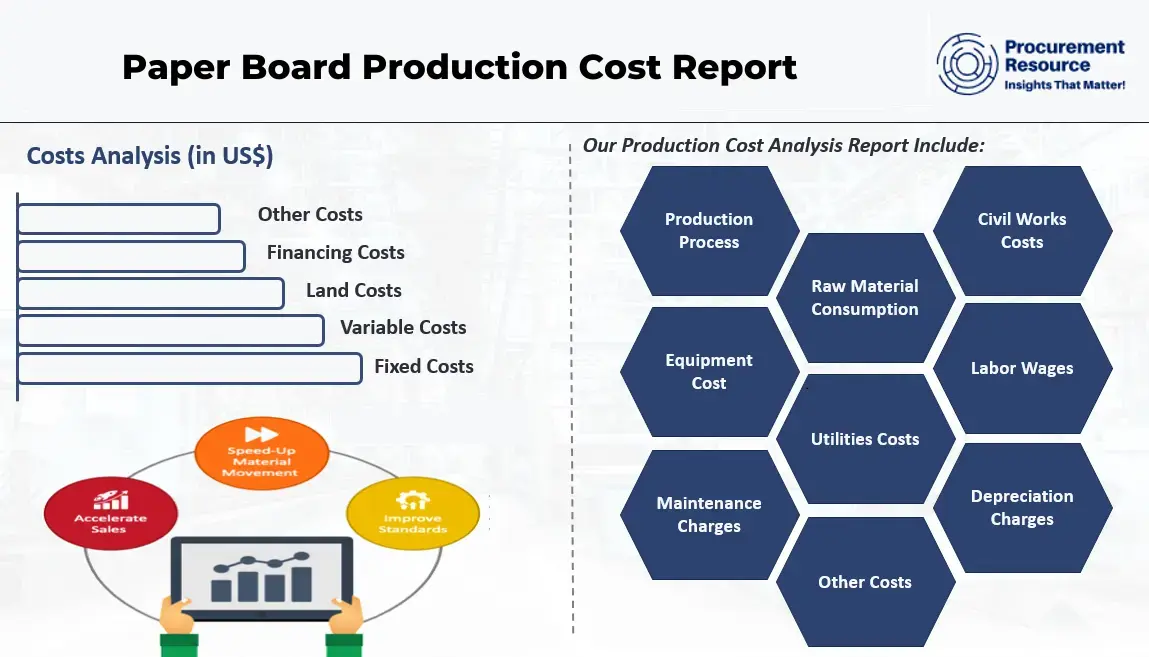

Cupstock production involves several cost elements that contribute to the overall expenses of manufacturing paper cups. It is crucial for businesses in this industry to have a clear understanding of these costs and how they impact profitability. In this section, we will explore the major cost elements involved in cupstock production, including raw materials, labor, equipment, and overhead costs.

1. What are the major cost elements involved in cupstock production?

Cupstock production costs can be divided into several major components. The first and most significant cost element is the raw material used to manufacture cupstock. Paperboard and polyethylene are the key components in cupstock production, and their prices can vary depending on the quality and sourcing.

Apart from raw materials, labor costs also play a significant role in cupstock production. Skilled operators are required to operate the machinery and ensure the quality of the final product. Labor costs can vary based on the region and the skill level of the workers.

Equipment costs are another important aspect to consider. Cupstock production requires specialized machinery, including cup forming machines, printing machines, and cutting machines. The cost of acquiring and maintaining this equipment can be significant, especially for smaller manufacturers.

Overhead costs, such as rent, utilities, and administrative expenses, also contribute to the overall production costs. These costs are necessary for running the production facility and are typically allocated to each unit produced.

2. How do raw materials, labor, equipment, and overhead costs contribute to overall production costs?

Raw materials, including paperboard and polyethylene, account for a substantial portion of cupstock production costs. The quality and price of these materials directly influence the overall cost of producing cupstock. It is essential for manufacturers to strike a balance between cost and quality to ensure profitability.

Labor costs are another significant contributor to production expenses. A skilled and efficient workforce is necessary to ensure smooth production processes and maintain product quality. Managing labor costs efficiently through effective training and optimization of production processes can help reduce overall expenses.

Equipment costs also play a crucial role in cupstock production. Acquiring and maintaining specialized machinery can be expensive, especially for small businesses. However, investing in modern and efficient equipment can lead to increased productivity and lower production costs in the long run.

Overhead costs, such as rent, utilities, and administrative expenses, are necessary for running the production facility. These costs are typically allocated to each unit produced, making them an integral part of the overall production costs.

3. What are the factors influencing the cost of cupstock production?

Several factors can influence the cost of cupstock production. The prices of raw materials, such as paperboard and polyethylene, are subject to market fluctuations and availability. Manufacturers need to closely monitor these price changes to adjust their production costs accordingly.

Labor costs can vary depending on factors such as location and skill level. Regions with higher labor costs can significantly impact the overall production expenses. Optimal workforce management, including efficient scheduling and training programs, can help mitigate these costs.

Equipment costs are influenced by factors such as the type of machinery, its quality, and technological advancements. Investing in advanced and efficient equipment can improve productivity and reduce long-term production costs.

Overhead costs are influenced by factors such as rent, utilities, and administrative expenses. Businesses need to find ways to optimize these costs without compromising on the quality of the production process.

In summary, understanding the major cost elements involved in cupstock production, including raw materials, labor, equipment, and overhead costs, is essential for businesses to optimize their production processes and enhance profitability. Monitoring market trends, managing expenses efficiently, and investing in modern technology can help manufacturers reduce costs and maintain a competitive edge in the cupstock industry.

Next Section: Optimizing Production Costs in Cupstock Manufacturing.

Section 2: Optimizing Production Costs in Cupstock Manufacturing

The production costs in cupstock manufacturing can have a significant impact on the overall profitability of the business. By implementing strategies to reduce costs and optimize efficiency, companies can enhance their bottom line and stay competitive in the market. In this section, we will explore various strategies to optimize production costs in cupstock manufacturing and the role of technology in minimizing costs and improving productivity.

1. Strategies to Reduce Production Costs

There are several strategies that can be implemented to reduce production costs in cupstock manufacturing:

- Streamline the supply chain: Analyze the entire supply chain, from raw material procurement to finished product delivery, to identify any inefficiencies. Look for opportunities to consolidate suppliers, negotiate better prices, and improve logistics to reduce costs.

- Minimize waste: Implement waste reduction initiatives such as lean manufacturing techniques and process optimization. By reducing waste, companies can save on raw material costs and improve overall operational efficiency.

- Invest in automation: Automating certain processes in cupstock manufacturing can lead to significant cost savings. Automated machines can perform tasks more efficiently and accurately than manual labor, reducing labor costs and improving production speed.

- Improve energy efficiency: Explore energy-saving technologies and practices to reduce energy consumption in the manufacturing process. This can result in lower utility bills and environmental benefits.

- Optimize inventory management: Efficient inventory management is crucial to minimize holding costs and prevent overstock or stock shortages. Utilize inventory management software to track inventory levels and optimize ordering to avoid excess inventory and associated costs.

2. Enhancing Efficiency in Cupstock Production

Optimizing efficiency in cupstock production is essential to maximize productivity and reduce costs. Here are a few ways companies can enhance efficiency:

- Standardize processes: Implement standard operating procedures (SOPs) to ensure consistency and efficiency in cupstock production. SOPs help employees understand their roles and responsibilities, leading to improved productivity.

- Invest in training: Provide comprehensive training programs for employees to enhance their skills and knowledge. Well-trained employees are more efficient and less prone to errors, resulting in improved productivity and cost savings.

- Implement continuous improvement practices: Embrace the philosophy of continuous improvement by encouraging employees to identify and suggest process improvements. Regularly review and optimize production processes to eliminate bottlenecks and increase efficiency.

- Optimize equipment utilization: Ensure that equipment is properly maintained and operated at optimal efficiency levels. Regular maintenance and calibration can prevent breakdowns and reduce downtime, resulting in increased production output.

3. Role of Technology in Minimizing Costs and Improving Productivity

Technology plays a crucial role in minimizing costs and improving productivity in cupstock manufacturing. Here are a few examples of how technology can be leveraged:

- Automated forming machines: Technological advancements have led to the development of automated forming machines for cupstock production. These machines can significantly increase production speed and efficiency while reducing labor costs.

- Data analytics: Utilize data analytics to identify inefficiencies and optimize production processes. Analyzing production data can provide insights into areas for improvement, helping businesses make informed decisions to reduce costs and improve productivity.

- Inventory management software: Implement inventory management software to track inventory levels, optimize ordering, and prevent stockouts or excess inventory. This can lead to cost savings by minimizing holding costs and improving supply chain efficiency.

- Quality control systems: Deploy automated quality control systems to ensure consistent product quality and minimize waste. These systems can detect defects in real-time, reducing scrap materials and rework costs.

By implementing these strategies and leveraging technology, cupstock manufacturers can optimize production costs, enhance efficiency, and improve profitability. It is crucial for businesses in the industry to continually evaluate and analyze their production processes, explore new technologies, and stay updated on market trends to maintain a competitive edge in the cupstock manufacturing market.

Market Trends and Profitability Analysis in Cupstock Industry

The cupstock industry is experiencing significant growth and is expected to continue on this trajectory in the coming years. Factors such as increasing environmental concerns and the ban on single-use plastics are driving the demand for paper cups, making the market a profitable one for businesses operating in this sector.

Cupstock Market Projection

According to market research, the global paper cup market is projected to reach a value of $8.2 billion by 2024. This growth can be attributed to the rising adoption of paper cups as a sustainable alternative to single-use plastics. Developing countries, particularly India and China, are playing a crucial role in driving the growth of the paper cup industry.

Key Factors Influencing Profitability

Several key factors contribute to the profitability of businesses in the cupstock industry. Understanding and effectively managing these factors can help companies maintain a competitive edge and maximize their profits.

1. Raw Material Costs: Raw materials, such as paperboard and polyethylene, are major components in cupstock production. The cost of these materials can fluctuate due to factors like availability and market demand. Companies need to carefully analyze and forecast raw material costs to ensure profitability.

2. Labor Costs: The cost of labor is another significant factor influencing profitability. Efficient workforce management and productivity enhancement measures can help control labor costs. Companies can invest in training and automation to optimize labor efficiency and reduce costs.

3. Overhead Expenses: Overhead expenses, such as utilities, maintenance, and administrative costs, also impact profitability. Implementing cost-saving measures, such as energy-efficient technologies and process optimization, can help reduce overhead expenses and increase profitability.

4. Market Competition: The cupstock industry is highly competitive, with several players vying for market share. Analyzing competitor strategies and staying updated on industry trends is essential for maintaining a competitive edge. Companies can differentiate themselves by offering customizable designs, sustainable packaging options, and innovative solutions.

Analyzing Industry Trends and Competitor Strategies

To maintain a competitive edge in cupstock production, companies need to analyze industry trends and competitor strategies. Here are some effective approaches to stay ahead in the market:

1. Research and Market Analysis: Stay updated on the latest market trends, consumer preferences, and regulatory changes affecting the cupstock industry. Engage in continuous market research to identify emerging opportunities and potential threats.

2. Benchmarking Competitor Strategies: Analyze the strategies adopted by key competitors in the cupstock industry. Focus on their pricing models, product offerings, marketing campaigns, and customer engagement strategies. Benchmarking can provide insights into areas for improvement and help refine your own business strategy.

3. Collaborate with Industry Associations: Joining industry associations and participating in industry events can provide access to valuable networking opportunities. Engaging with industry peers enables knowledge sharing and collaboration, fostering innovation and competitiveness.

4. Customer Feedback and Innovation: Gather feedback from customers to understand their evolving needs and preferences. Use this feedback to drive product innovation and development, ensuring that your offerings remain relevant and appealing in the market.

5. Continuous Improvement and Cost Optimization: Embrace a culture of continuous improvement throughout the organization. Encourage employees to contribute ideas for process optimization, cost reduction, and efficiency improvement. Regularly evaluate and optimize production processes to minimize wastage and maximize cost-effectiveness.

By implementing these strategies and staying proactive in analyzing industry trends, cupstock manufacturers can position themselves for long-term success in this flourishing market.

Stay tuned for the next section of this series, where we explore the major cost elements involved in cupstock production and strategies to optimize production costs for better profitability.

Tables

Table 1: Major Cost Elements in Cupstock Production

| Cost Element | Description |

|---|---|

| Raw Materials | Key components include paperboard and polyethylene. |

| Labor Costs | Skilled operators required for machinery operation and quality control. |

| Equipment Costs | Specialized cup forming, printing, and cutting machines. |

| Overhead Costs | Rent, utilities, and administrative expenses. |

Table 2: Strategies to Reduce Production Costs

| Strategy | Description |

|---|---|

| Streamline Supply Chain | Analyze procurement and logistics for cost-saving opportunities. |

| Minimize Waste | Implement lean manufacturing and process optimization. |

| Invest in Automation | Automate tasks to reduce labor costs. |

| Improve Energy Efficiency | Adopt energy-saving technologies and practices. |

| Optimize Inventory Management | Use inventory management software to minimize holding costs and optimize ordering. |

Table 3: Factors Influencing Profitability

| Factor | Description |

|---|---|

| Raw Material Costs | Fluctuations in prices due to availability and market demand. |

| Labor Costs | The cost of labor and workforce management. |

| Overhead Expenses | Utilities, maintenance, and administrative costs. |

| Market Competition | Competitor strategies and differentiation. |

These tables provide a visual representation of the data discussed in the blog, helping readers easily understand and analyze the information.

FAQs about Cupstock Production Cost Analysis

What are the major cost elements involved in cupstock production?

To understand cupstock production costs, one must consider raw materials, labor expenses, equipment costs, and overhead expenses.

How do raw materials, labor, equipment, and overhead costs contribute to overall production costs?

Raw materials, labor, equipment, and overhead costs each play a pivotal role in determining the total expenses associated with cupstock production.

What are the factors influencing the cost of cupstock production?

The prices of raw materials, labor costs, equipment expenses, and overhead costs all influence the overall cost of cupstock production.

What strategies can be implemented to reduce production costs in cupstock manufacturing?

Strategies such as streamlining the supply chain, minimizing waste, investing in automation, improving energy efficiency, and optimizing inventory management can help reduce production costs in cupstock manufacturing.

How can technology help minimize costs and improve productivity in cupstock manufacturing?

Technology can minimize costs and improve productivity by automating forming machines, utilizing data analytics, implementing inventory management software, and deploying quality control systems in cupstock manufacturing.

In this blog post, we delved into the cost analysis of cupstock production, exploring major cost factors like raw materials, labor, and more. Implementing strategies to optimize production costs and embracing technology can lead to enhanced profitability. Understanding market trends and analyzing industry competition are vital for staying ahead in the cupstock industry. By focusing on efficiency and strategic decision-making, companies can thrive in this dynamic market.