Is Cupstock Paper Compatible with Flexographic Printing?

How Does Cupstock Paper Perform with Flexographic Printing?

Cupstock paper has unique properties that make it especially suitable for flexographic printing. Flexo printing uses flexible plates to transfer ink onto various substrates, including cupstock. This method is proficient because it allows quick drying and efficient production for high-volume orders.

Characteristics of cupstock paper and its suitability for flexographic printing

Cupstock paper is often coated, giving it a smooth surface ideal for printing. This coating helps the ink adhere properly, enhancing color vibrancy. The paper also has a barrier that protects against moisture, making it perfect for cold or hot beverages.

Flexographic printing requires materials that can handle various inks and quick drying times. Cupstock fits well within these parameters. Its composition allows for excellent ink transfer, minimizing the risk of ink bleeding or smudging. For more insights, check out the benefits of PE laminated paper as it provides a strong foundation for understanding paper compatibility.

Overview of the flexographic printing process and its advantages for cupstock paper

Flexographic printing is advantageous for several reasons. It uses fast-drying inks, allowing for quick production cycles. The process is efficient for printing on uneven surfaces, like those found in cupstock.

Flexography can produce high-quality images while maintaining low operational costs. It is particularly effective for large runs, where setup costs can be spread over a larger print volume. Understanding the dynamics of environmentally friendly biodegradable paper cups can further enhance your knowledge of sustainable printing practices.

Types of inks used in flexographic printing on cupstock and their environmental benefits

Flexographic printing often employs water-based inks, UV inks, or solvent-based inks. Water-based inks are increasingly popular due to their lower environmental impact. They produce fewer VOCs and are safer for food packaging.

On the other hand, UV inks dry quickly under UV light, allowing for vibrant prints. This method prevents smudging and makes the process more efficient.

Common challenges faced when using cupstock paper for flexographic printing

Despite being highly compatible, challenges can still arise when using cupstock paper with flexo printing. One common issue is ink absorption variability. Some cupstock varieties aren’t uniform, leading to inconsistent print quality.

Another challenge is drying time. While flexo inks dry quickly, the moisture content in cupstock can slow this process. This might result in smudging if not adequately managed.

Best practices for ink absorption and drying times with cupstock paper in flexographic setups

To achieve optimal results, here are some best practices to consider:

-

Check Ink Compatibility: Ensure that the ink selection suits the cupstock used. Water-based inks typically offer better adhesion.

-

Control Environment: Maintain consistent temperature and humidity levels during printing. This helps with ink drying and adhesion.

-

Run Test Prints: Perform test prints to monitor drying times and adjust production settings accordingly.

Economic and speed considerations for using flexographic printing on cupstock paper

Flexographic printing is generally cost-effective for larger orders of cupstock paper. Initial setup costs can be high due to the need for new plates but become economical as the print volume increases. The speed of flexographic presses also means that more products can be printed in less time compared to other methods.

For high-volume projects, flexo is often the best choice. It minimizes wastage and enhances productivity, especially for brands that require timely delivery.

Success stories or case studies illustrating effective use of flexographic printing on cupstock

Brands like Starbucks have turned to flexographic printing for their custom paper coffee cups. In one case study, they reduced production time by 30% using this process.

Similarly, local coffee roasters found that flexo printing on cupstock helped them achieve vibrant, detailed designs while adhering to sustainable practices. Feedback from customers emphasized the importance of aesthetics and environmental impact.

Environmental considerations and sustainable practices in flexographic printing on cupstock

Flexographic printing is lauded for its sustainability. The ability to use water-based inks aligns with eco-friendly practices. Many companies are keen on waste reduction—from raw materials to printing methods.

Flexo also employs energy-efficient drying, further reducing its carbon footprint. Sustainable practices are critical in today’s market, and flexographic printing on cupstock aligns with these values through responsible methods.

In summary, cupstock paper's compatibility with flexographic printing makes it a favored choice for various applications. The combination of its characteristics, the flexo printing process, and best practices leads to excellent results, aligning well with economic and environmental considerations. By using the right techniques and inks, one can leverage the benefits of cupstock when utilizing flexographic printing, producing high-quality, vibrant, and environmentally-friendly printed materials.

Is Offset Printing Ideal for Cupstock Paper Applications?

Offset printing is a popular technique that brings high-quality images to life on various materials. When it comes to cupstock paper, this method proves to have several advantages. Let’s delve into how offset printing works and why it's beneficial for cupstock paper.

Overview of offset printing and its benefits for cupstock paper

Offset printing involves transferring ink from a metal plate to a rubber blanket, which then applies the ink to the paper. This process allows for incredibly sharp images, vibrant colors, and excellent consistency over large runs. For your cupstock paper needs, offset printing offers high-resolution images and true color fidelity. It excels in printing complex designs with fine details, making it an optimal choice for coffee cups and other food service applications.

Benefits of offset printing on cupstock include:

-

Stunning Color Accuracy: Offset printing can reproduce colors very accurately. It uses the CMYK color model and can utilize Pantone colors for specific shades. This makes it suitable for eye-catching designs.

-

High Volume Efficiency: Once the setup is completed, offset printing can produce large quantities quickly and uniformly, creating consistent quality across prints.

-

Cost-Effectiveness for Bigger Jobs: While setup costs may be higher, if you are printing in large volumes, offset becomes economically sensible.

Factors that affect the performance of offset printing on cupstock paper

The compatibility of cupstock paper with offset printing can be affected by several factors:

-

Paper Coating: The coating on cupstock can impact ink adhesion and drying times. A smooth, coated surface is preferable for optimal ink transfer.

-

Moisture Content: Cupstock paper should maintain a specific moisture level. Too much or too little moisture can lead to issues with ink adherence and may cause paper curling.

-

Surface Tension: Higher surface tension can hinder ink absorption. You may need to pre-treat papers to improve print quality.

By paying attention to these factors, you can achieve optimal results in your printing.

Types of inks compatible with offset printing on cupstock and benefits

The choice of ink is crucial for successful offset printing on cupstock. Here are the common types:

-

Oil-based Inks: These inks offer rich colors and good durability. They dry through evaporation and are suited for most cupstock applications.

-

UV Inks: These inks cure under ultraviolet light, allowing for fast drying times. They boast high gloss and strong adhesion, perfect for vibrant color outputs.

-

Water-based Inks: Often used for eco-friendly projects, these inks are less harmful but may not be suitable for all types of cupstock.

Each ink type has unique benefits, and your choice should reflect your target market and environmental concerns.

Technical considerations: setup, paper handling, and drying concerns

Proper setup is crucial to achieving high-quality offset prints on cupstock. Here are the key technical aspects to focus on:

-

Plate Preparation: Ensure plates are correctly aligned and calibrated. Misalignment can lead to color inconsistencies.

-

Drying Time: Offset inks can take time to dry, especially on coated papers. Consider using lead drying technology or UV curing if fast turnaround is required.

-

Paper Handling: Ensure your cupstock is properly stacked and fed into the printer. Uneven or warped paper can cause registration issues.

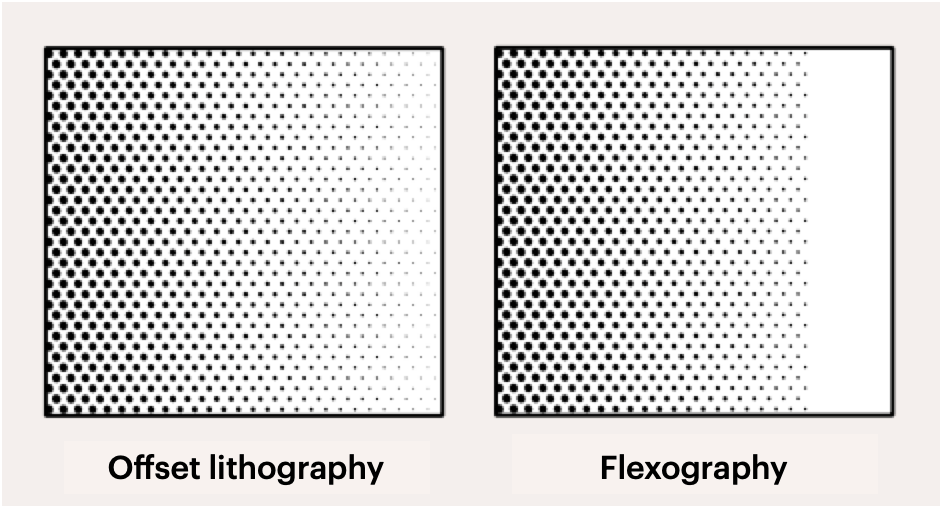

Comparative analysis: Offset vs. Flexo printing for cupstock paper

When comparing offset printing with flexographic printing for cupstock, it's essential to evaluate your project requirements:

| Feature | Flexographic Printing | Offset Printing |

|---|---|---|

| Speed | High speed, ideal for large volumes | Slower setup, better for detailed jobs |

| Quality | Good, but limited detail | Superior quality and color accuracy |

| Initial Costs | Lower setup cost but high plate costs | Higher setup costs; economical for large runs |

| Color Range | Basic color range, more suited for specific designs | Broad color range, supports Pantone and CMYK |

By understanding these differences, you can select the right printing method based on your project's needs.

Common issues and troubleshooting tips for cupstock paper in offset printing

While offset printing can produce great results, it’s not without challenges:

-

Ink Smudging: Ensure adequate drying time between printing. Use quick-drying inks if necessary.

-

Paper Curling: This issue often arises when moisture content varies. Always use properly conditioned paper.

-

Color Variance: Maintain consistent press speed and environment to avoid fluctuations in color quality.

Case studies or examples of successful offset printing projects on cupstock

Consider a project where a coffee shop increased its brand recognition with custom printed cupstock. They utilized offset printing for their design, featuring vibrant colors and intricate graphics. The result was a stunning product that not only looked great but pleasantly stood out in the market.

Practical guidelines for achieving high-quality results with offset printing on cupstock

To ensure success in your offset printing projects on cupstock paper, adopt the following practices:

-

Consistent Environment: Maintain a controlled temperature and humidity to avoid issues and ensure optimal ink behavior.

-

Test Runs: Always print samples to refine your setup before the final production run.

-

Ink Selection: Choose the right ink based on your project needs. Consider factors like drying time, color accuracy, and environmental impact.

Implementing these strategies will help you unlock the full potential of offset printing on cupstock paper.

What Are the Key Considerations for Optimal Cupstock Paper Printing?

When it comes to printing on cupstock paper, several factors play a crucial role in achieving high-quality prints. Both flexographic and offset printing offer unique advantages and challenges. Understanding these differences helps in making informed decisions for optimal cupstock paper print quality.

Key differences between flexographic and offset printing methods for cupstock paper

Flexographic printing uses flexible plates, making it ideal for high-volume orders. It's known for its rapid production and versatility, allowing prints on various substrates, including cupstock paper. Flexo presses run at high speeds, which is great for custom paper coffee cups. However, it may struggle with small texts or intricate details.

On the other hand, offset printing excels in producing high-quality prints with sharp details and vibrant colors. This method is perfect for large runs of complex designs, thanks to its consistent quality. Offset printing is often the choice for magazines, brochures, and materials that demand precision.

| Feature | Flexographic Printing | Offset Printing |

|---|---|---|

| Speed | High speed, ideal for large volumes | Slower setup, better for detailed jobs |

| Quality | Good, but limited detail | Superior quality and color accuracy |

| Initial Costs | Lower setup cost but high plate costs | Higher setup costs; economical for large runs |

| Color Range | Basic color range, more suited for specific designs | Broad color range, supports Pantone and CMYK |

By understanding these differences, you can select the right printing method based on your project's needs.

Importance of material and ink compatibility in cupstock paper printing

Material and ink compatibility are crucial for successful printing on cupstock paper. Flexographic printing allows the use of various versatile inks, including water-based options. This is especially important when dealing with food-related products, where environmental benefits are necessary.

Offset printing typically uses oil-based inks, which can provide vibrant color saturation and detail. It's essential to choose inks that work well with the type of cupstock paper being used. Using the wrong ink could lead to poor adhesion, smudging, or color inaccuracies.

Strategies for ensuring high print quality and handling of cupstock paper

To achieve high print quality on cupstock paper, it's vital to ensure proper handling and printing conditions. The following strategies can help:

- Keep tension low: In flexographic setups, maintaining low tension prevents misregistration, which can ruin prints.

- Temperature control: Ensure temperatures stay below 80°C. This prevents damage to flexible plates during the flexographic process.

- Pre-conditioning sheets: For offset printing, allow cupstock sheets to acclimate to the environment. Engage in a 24-hour preconditioning period to ensure optimal conditions.

- Correct setup: Align plates accurately during the setup phase to achieve high-quality, vibrant prints. Misalignment can lead to color inconsistency.

These practices ensure your printing output remains high quality and consistent.

Cost and volume considerations: Choosing the right method for the project

When deciding between flexographic and offset printing, consider your project's scale and budget. For large orders, both flexographic and offset are cost-effective options. You will find flexo to be more economical due to its faster production speeds and lower operational costs for bulk printing.

However, for smaller orders, digital printing or offset printing may be better suited. Offset printing, while slower to set up, delivers excellent color accuracy and detail. Here’s a quick comparison:

| Volume Size | Recommended Printing Method |

|---|---|

| Large Orders | Flexographic or Offset |

| Small Orders | Digital or Offset |

Environmental impact and sustainability in cupstock paper printing choices

Sustainability is a growing focus in the printing industry. Flexographic printing utilizes water-based and UV inks, which often possess lower environmental impacts. This is ideal for prints that are food safe, particularly in the case of coffee cups and related products.

Offset printing can use eco-friendly options like vegetable-based inks that adhere to sustainability standards. It's essential to consider the environmental impact when selecting materials and inks, ensuring they’re suitable for your project's goals.

Advances in printing technology enhancing cupstock printing efficiency

Technology continues to enhance printing efficiency for both flexographic and offset methods. Innovations such as automated setups and digital interfaces streamline production workflows. Flexographic printing now provides improved plate-making processes that lead to quicker turnaround times.

This is particularly relevant in industries requiring rapid shifts in branding or designs. Current advancements also focus on creating biodegradable products, such as water-washable plates. This attention to sustainability aligns with changing consumer expectations and environmental regulations.

Summary of best practices for both flexographic and offset printing on cupstock

To maximize the quality and efficiency of your printing projects on cupstock paper, consider these best practices:

- Always ensure material and ink compatibility.

- Follow precise setup and calibration procedures.

- Take environmental factors into account when selecting inks.

- Choose the printing method that best suits the job volume and design complexity.

Future trends and innovations in cupstock paper printing techniques and materials

The future of cupstock paper printing looks promising. We anticipate further advancements in digital printing technology, making it possible to produce shorter runs more economically. Innovations in eco-friendly inks and materials will foster sustainability options.

Flexographic techniques can be expected to evolve, with a focus on versatility and speed. New materials may also emerge, offering improved durability and print quality. Staying informed about these trends will help keep your print projects at the forefront of the industry.

FAQs about Cupstock Paper Compatibility with Flexographic and Offset Printing

How does cupstock paper perform with flexographic printing?

Cupstock paper has unique properties that make it especially suitable for flexographic printing due to its smooth and coated surface ideal for ink adhesion and quick drying times.

What are the advantages of using flexographic printing on cupstock paper?

Using flexographic printing on cupstock allows for efficient production with fast-drying inks, suitable for high-volume orders and uneven surfaces.

What types of inks are best for flexographic printing on cupstock?

Flexographic printing on cupstock often uses water-based, UV, or solvent-based inks, with water-based inks being favored for lower environmental impact.

What are common challenges with flexographic printing on cupstock paper?

Common challenges with flexographic printing on cupstock include ink absorption variability and the potential slowing of drying times due to moisture content in the paper.

How does offset printing compare to flexographic printing for cupstock?

Offset printing offers higher image quality and color accuracy for cupstock, while flexographic is faster and more cost-effective for high-volume orders.

Flexographic printing shines with cupstock paper due to its speed and versatility. We explored flexo printing's benefits, ink choices, and green practices. Offset printing offers precision for cupstock, yet faces different hurdles. Key to success? Choose the right method based on your needs. Keep ink compatibility and drying times in check. Future trends promise better techniques and eco-friendly options. With the right strategy, both printing methods can deliver great results. Always align your printing choices with your project goals and sustainability ideals.